Introduction:

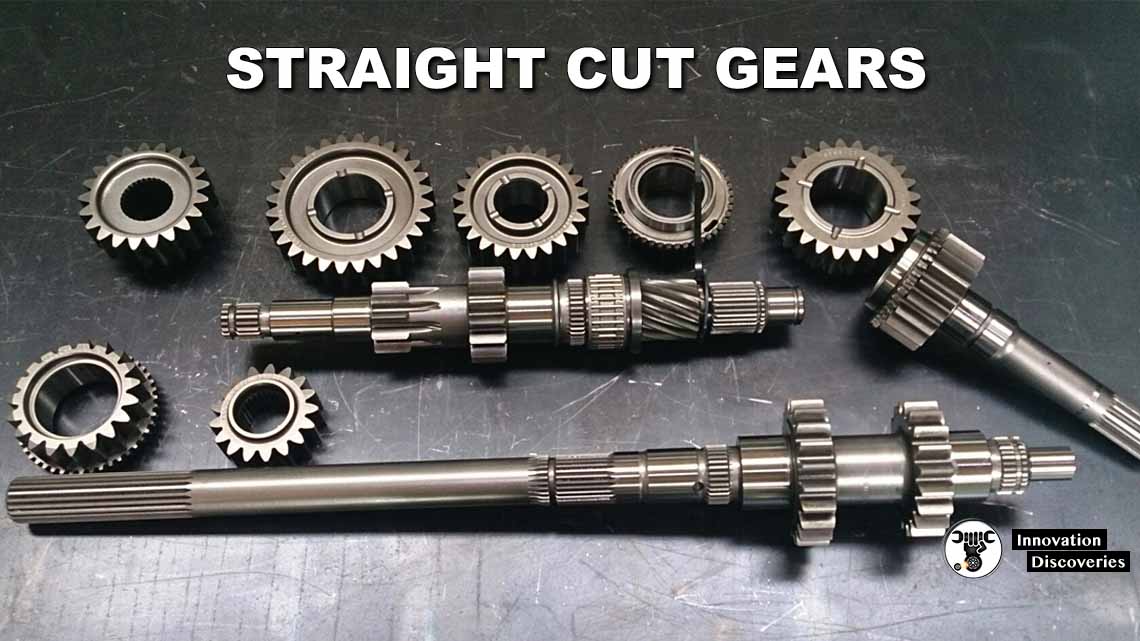

Straight cut gears, also known as spur gears, are a type of gear arrangement commonly used in various applications, including automotive transmissions, racing vehicles, and industrial machinery. Unlike helical gears, which have angled teeth, straight cut gears have teeth that are cut perpendicular to the gear’s axis. This distinctive design offers both advantages and disadvantages.

Advantages of Straight Cut Gears:

Increased Efficiency:

Straight cut gears have less tooth-tooth sliding contact compared to helical gears. This reduced sliding friction results in higher mechanical efficiency, meaning less power loss during transmission. This efficiency improvement can be particularly beneficial in high-performance applications where power transfer is critical.

Enhanced Durability:

The straight-cut tooth profile of these gears distributes the load more evenly across the gear face. This design feature enables them to handle higher torque loads and provides greater strength and durability. Consequently, straight cut gears are often preferred in demanding applications where reliability and longevity are crucial, such as racing or heavy-duty industrial machinery.

Simplicity and Cost-Effectiveness:

Straight cut gears are simpler to manufacture than helical gears due to their straight tooth design. This simplicity can lead to lower production costs, making them more accessible and cost-effective for certain applications. Additionally, their straightforward design facilitates easier maintenance and repair.

Also, read:

SEE MORE:

Advantages in Brief:

- Increased efficiency due to reduced sliding friction.

- Enhanced durability and strength to handle high torque loads.

- Simplicity in manufacturing, maintenance, and repair.

Disadvantages Of Straight-Cut Gears

Noise and Vibration:

One of the primary drawbacks of straight cut gears is the noise they produce. The straight-cut tooth profile results in a characteristic whining sound during operation, which can be more pronounced at higher speeds. Moreover, the lack of helix angle in the teeth can generate additional vibrations, potentially leading to a noisier and less comfortable driving experience.

Increased Stress on Bearings:

Straight cut gears produce axial thrust forces that can place additional stress on the gear bearings. The absence of helical angles to offset these forces means that proper bearing selection and maintenance become critical to ensure longevity and prevent premature wear or failure.

Lower Contact Ratio:

The straight-cut tooth design of spur gears results in a lower contact ratio compared to helical gears. This reduced contact ratio can lead to higher localized stresses on the gear teeth, potentially resulting in accelerated wear over time, especially under heavy loads or high-speed applications.

Disadvantages In Brief:

- Produces noticeable noise and vibrations during operation.

- Places additional stress on gear bearings.

- Lower contact ratio may lead to accelerated wear under heavy loads or high speeds.

Conclusion

Straight cut gears offer advantages such as increased efficiency, enhanced durability, and cost-effectiveness. They are particularly suitable for high-performance applications where power transfer and reliability are paramount.

However, their notable disadvantages include increased noise and vibration, higher stress on bearings, and lower contact ratios, which can impact their suitability for certain applications. When considering the use of straight cut gears, it’s essential to carefully evaluate the specific requirements, trade-offs, and the overall impact on the intended application.

Visit Forum

Visit Our Friendly Website

One Comment