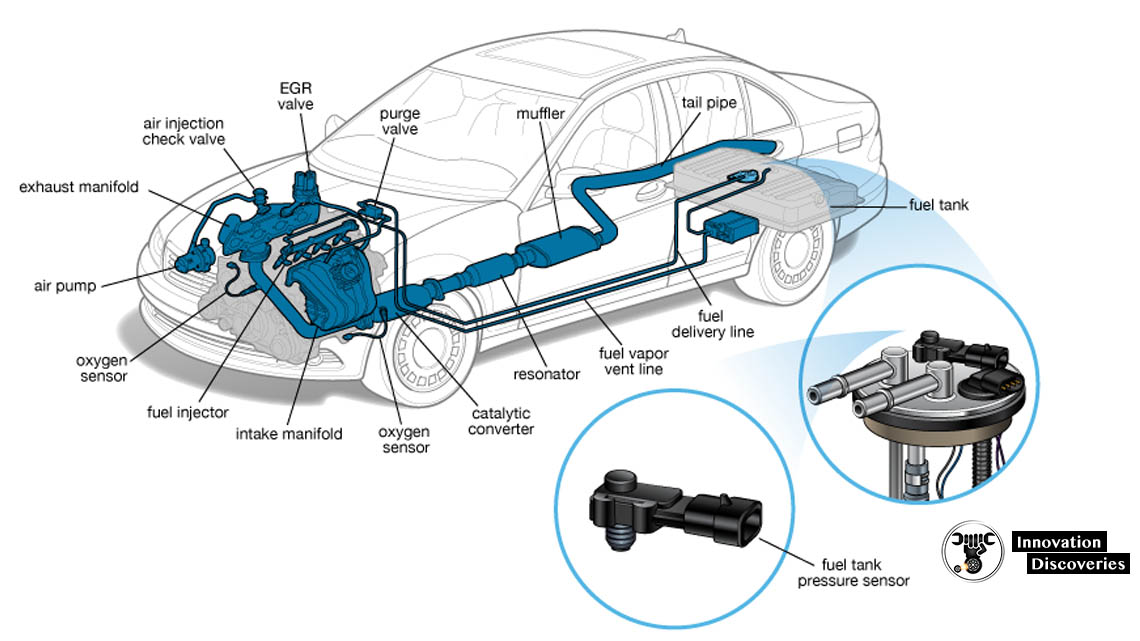

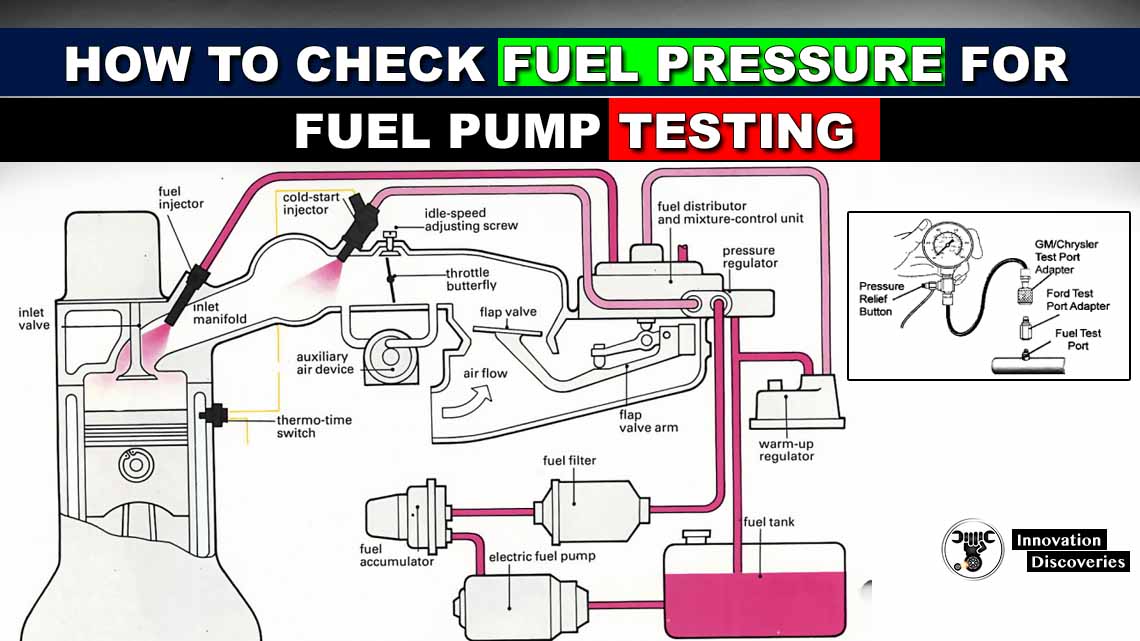

The function of the fuel system is to store and supply fuel to the cylinder chamber where it can be mixed with air, vaporized, and burned to produce energy.

The fuel, which can be either gasoline or diesel is stored in a fuel tank.

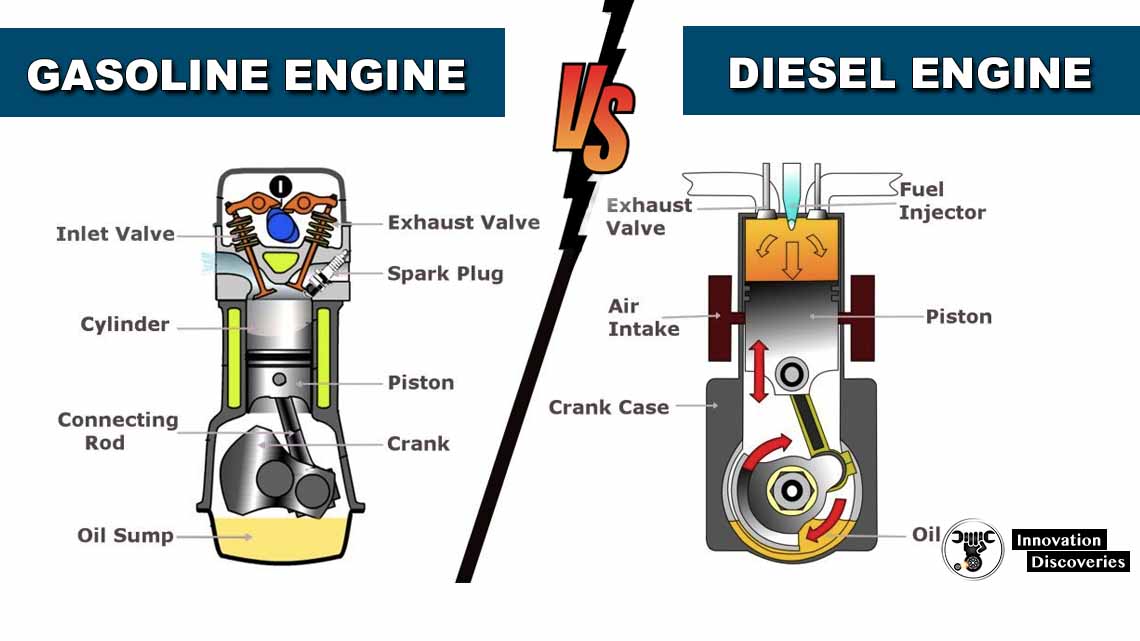

Read: HOW DO GASOLINE ENGINES DIFFER FROM DIESEL ENGINES?

Download: GASOLINE ENGINE MANAGEMENT | PDF

A fuel pump draws the fuel from the tank through fuel lines and delivers it through a fuel filter to either a carburettor or fuel injector, then delivered to the cylinder chamber for combustion.

COMPONENTS

1. Fuel Tank

The fuel tank is the main storage for the fuel that runs the vehicle.

Generally speaking, the gas tank is generally found at, or under, the rear of the vehicle.

Read More:

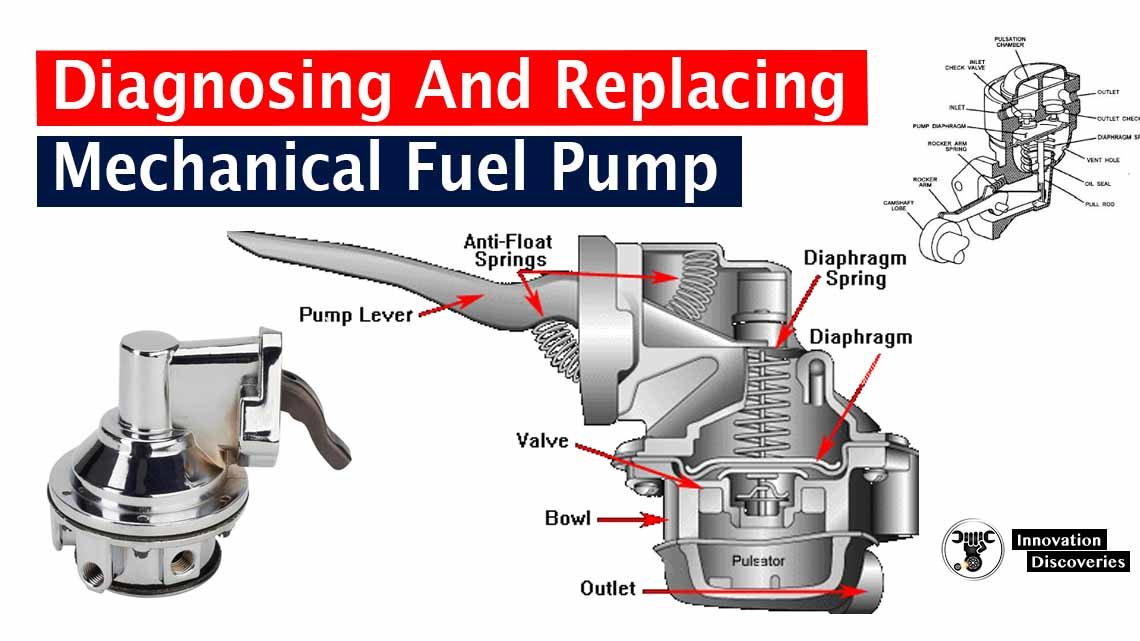

- DIAGNOSING AND REPLACING A MECHANICAL FUEL PUMP

- WHAT HAPPENS WHEN YOU PUT SUGAR IN THE GAS TANK?

- WHICH PARTS ARE MOST DAMAGED WHEN CARS RUN OUT OF FUEL?

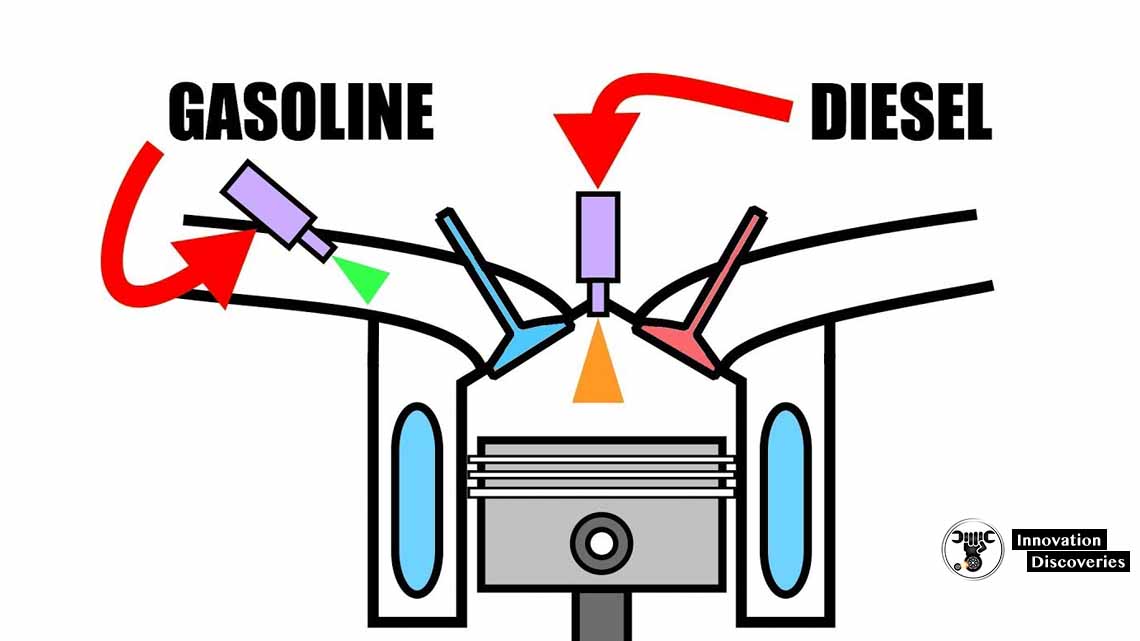

2. Fuel Injectors:

Sprays a fine mist of fuel into the combustion chamber of each cylinder or throttle body, depending on the design.

The fuel injectors are driven by the fuel pump and their job is to spray a fuel and air mixture into the combustion chamber, ready to be ignited to produce power to the driven wheels.

The fuel injectors are a nozzle, with a valve attached, the nozzle creates a spray of fuel and air droplets (atomization).

This can be viewed similar to that of a perfume dispenser or deodorant can in principle, spraying a fine mist.

Read More:

- FUEL INJECTOR CLEANING: IS IT TRULY NECESSARY FOR AN AUTOMOBILE?

- WHAT IS MULTIPLE POINT FUEL INJECTION(MPFI)?

- COMMON PROBLEMS OF THE FUEL DELIVERY SYSTEM

3. Fuel Fill Hose

The Fuel Fill Hose is the main connector from the gas cap to the fuel tank.

This is the point where the Gasoline (or other fuel) is put into the vehicle.

4. Gas Cap

The gas cap seals the fill hose and is used to ensure that

A) Gas does not spill out from the car, and

B) that the fuel system remains pressurized correctly (in vehicles that use pressurized systems).

5. Fuel Pump

The fuel pump is used to pump the fuel from the fuel tank, via the fuel lines into the fuel injectors, which spray the fuel into the combustion chamber- in order to create combustion.

There are two types, mechanical fuel pumps (used in carburettors) and electronic fuel pumps (used in electronic fuel injection).

- Mechanical fuel pumps: these are driven normally by auxiliary belts or chains from the engine.

- Electronic fuel pumps: controlled by the electronic fuel injection system, these are normally more reliable and have fewer reliability issues than their mechanical counterparts.

6. Fuel Filter

The fuel filter is the key to a properly functioning fuel delivery system.

This is more true with fuel injection than with carbureted cars.

Fuel injectors are more susceptible to damage from dirt because of their close tolerances, but also fuel injected cars use electric fuel pumps.

When the filter clogs, the electric fuel pump works so hard to push past the filter, that it burns itself up. Most cars use two filters.

One inside the gas tank and one in a line to the fuel injectors or carburettor.

Unless some severe and unusual conditions occur to cause a large amount of dirt to enter the gas tank, it is only necessary to replace the filter in the line.

7. Fuel Lines

The Fuel Lines connect all of the various Fuel System components.

Steel lines and flexible hoses carry the fuel from the tank to the engine.

When servicing or replacing the steel lines, copper or aluminium must never be used.

Steel lines must be replaced with steel.

When replacing flexible rubber hoses, the proper hose must be used.

Ordinary rubber such as used in vacuum or water hose will soften and deteriorate.

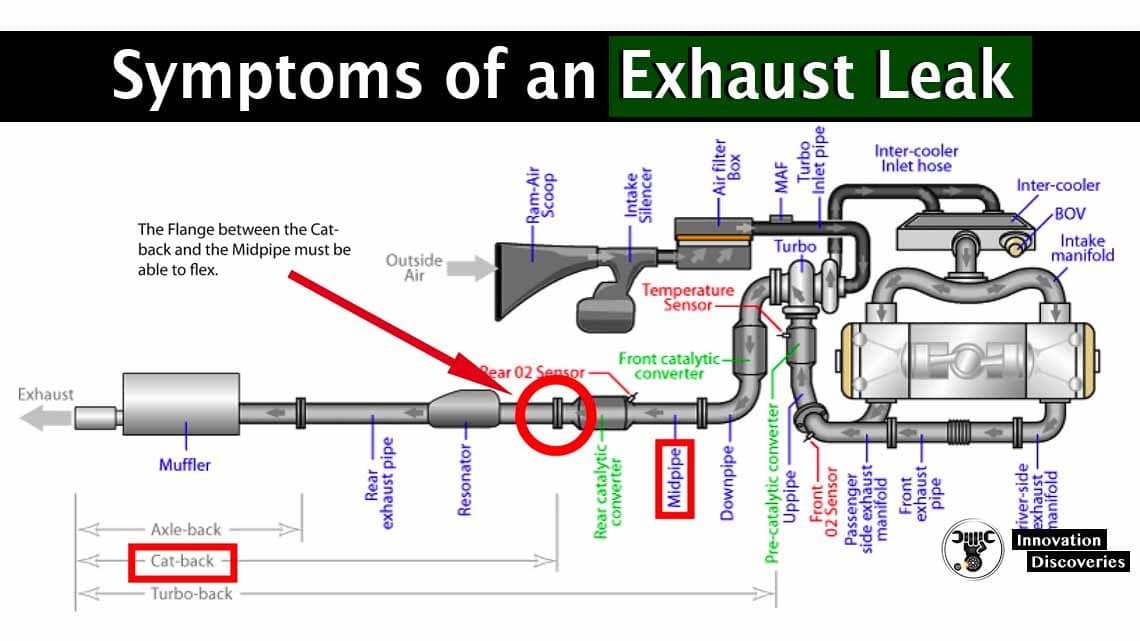

Be careful to route all hoses away from the exhaust system.

8. Fuel Gauge

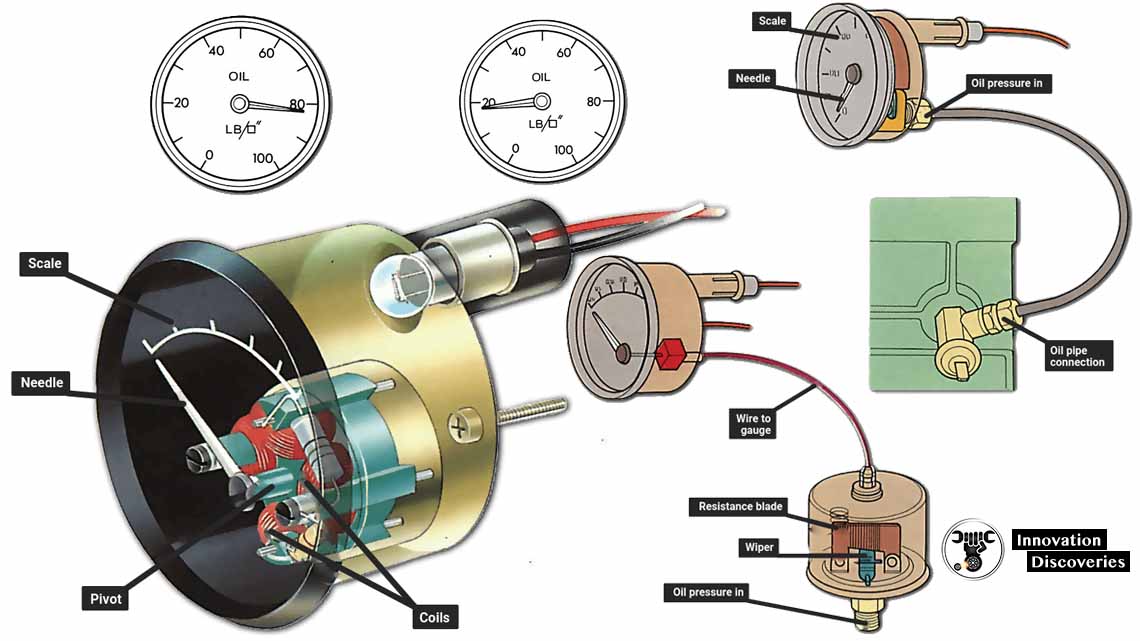

The fuel gauge exists as a display item in the vehicle’s dashboard.

It is intended to show the driver the actual amount of fuel in the fuel tank. On older cars, it’s common for fuel gauges (or their related part, the sending unit) to be inaccurate.

When you first start driving your classic vehicle, take time to learn how accurate the system is.

It’ll save you from a long walk to the gas station if you run out of gas!

For More Knowledge : HOW AN OIL PRESSURE GAUGE WORKS

9. Fuel Gauge Sending Unit.

In terms of the fuel system, this may be your biggest headache.

Sending units, at best, are generally a flawed design.

Usually, the sender is most accurate between 1/4 and 3/4 of a tank of gas.

Outside of this, the gauge becomes progressively more inaccurate as you reach the tank limits (full or empty).

Based on the age of the vehicle, the type of carburetion/fuel injection, and the emissions standards in place at the time it may also have.

10. Fuel return lines.

They are generally the same types of line tubing as the main Fuel Line.

These specific lines are used for a couple of purposes.

Primarily they are used to return excess fuel to the gas tank for recirculation.

Additionally, they capture gasoline Vapor, which, as they are pushed back to the gas tank, cool and condense back into the liquid.

In particular, diesel-powered fuel injected engines often use the fuel as a cooling mechanism for the fuel injector.

They can recirculate significant amounts of fuel.

11. Emission Vapours Controls.

These are often used in combination with fuel return lines.

The goal of this section of the overall system is to ensure that gasoline vapours are not released into the ambient air.

If this occurs, many bad things may happen:

- 1) The earth-shattering boom of gasoline vapours igniting.

- 2) The unpleasant smell of gasoline is routed into the interior of the vehicle,

- 3) It can harm the environment.

12. Fuel Pressure Regulator.

The Fuel Pressure Regulators are primarily found in fuel-injected cars.

Fuel injection, as opposed to carburetion, is a high-pressure system.

The fuel pressure regulator ensures that the system maintains the proper amount of pressurization.

13. Pulsation Damper:

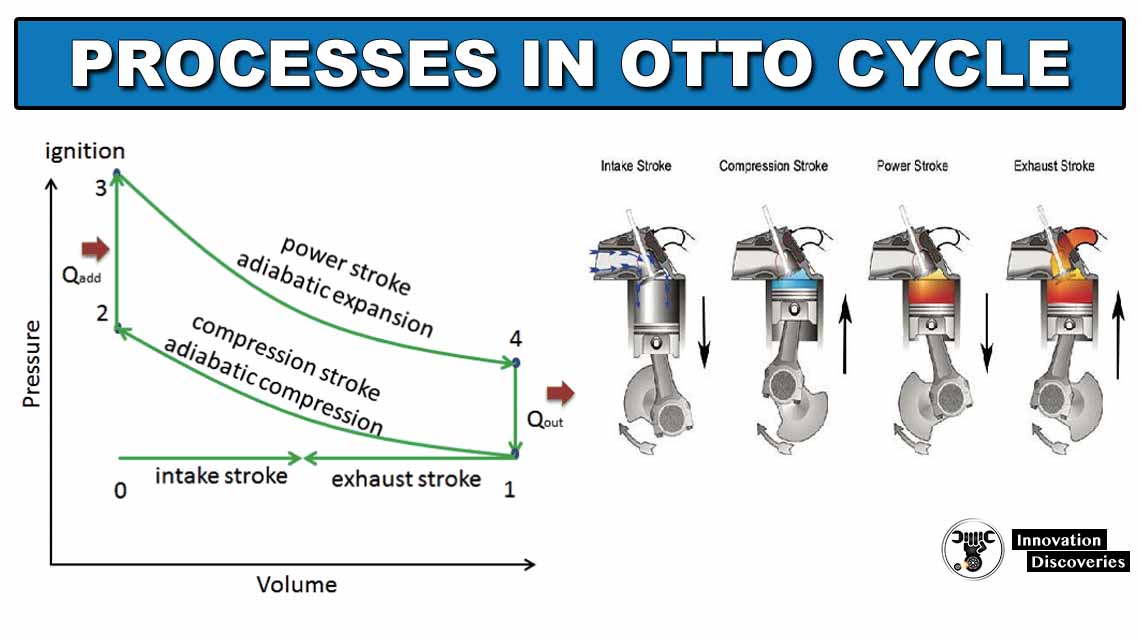

As the fuel Injectors rapidly open and close in time with the engines OTTO cycle, pressure fluctuations appear in the fuel system.

A Pulsation Damper job is to help combat the pressure levels reducing fuel delivery inconsistency.

WORKING PRINCIPLE

Some of this may seem a little silly, as many components are pretty evident to all of us.

Fundamentally, once you fill the tank with gasoline, the system is “ready.”

When you start the car, the fuel pump begins the process of drawing fuel from the fuel tank, through the fuel lines and fuel filter, to the system that controls fuel/air delivery to the engine (a carburettor or fuel injector).

While the car is running, a continuous supply of fuel is delivered in this fashion.

The fuel system in modern cars is a complex and intricate combination of components and electronics.

Generally, Fuel systems work in the following ways:

- • Fuel is delivered from the fuel tank to the fuel injectors via a fuel pump and fuel lines. The pump is typically positioned close to the fuel tank or within the tank itself.

- • Fuel leaving the fuel tank and fuel pump passes through a fuel filter that purifies and gets rid of any containment. This usually is a high capacity inline design to maximize flow rates.

- • Fuel travels along the fuel lines and is delivered to the fuel injectors. Fuel Injector pressures are controlled via a pressure regulator.

- • Any fuel which is not used and exceeds pressure rates is returned via fuel lines back into the fuel tank.

Carbureted Engines

The fuel system for this type of engine is generally a low-pressure system.

If the vehicle is equipped with a mechanical fuel pump, the number of revolutions of the motor (RPMs) controls how quickly fuel is delivered.

The faster the car is going (or revving), the more significant the movement of the fuel pump and the overall volume of fuel being carried.

If the vehicle is equipped with an electric fuel pump, the whole process is the same, but some form of restrictor is necessary to ensure that the appropriate amount of fuel is delivered.

This can be a pressure regulator, an overflow system with return lines, or a vehicle-specific mechanism.

Read: CAR THERMOSTAT FUNCTIONS, FAILURE SYMPTOMS, AND REPLACEMENT COST

Fuel Injected Engines

Once the vehicle is started, providing that the gas cap was installed and sealed correctly, the system becomes pressurized.

Your modern car is probably fuel injected.

Ever notice the release of air when you go to add gasoline?

This is the vehicle releasing the system pressure.

The electric fuel pump continuously pumps gas, ensuring that the system has the correct level of pressure.

In addition to the regular fuel delivery, it also passes through the pressure regulator, which ensures that the fuel pressure at the point of the Injector is correct so that the amount of fuel injected into the engine is appropriate.

Depending on the year and the vehicle in question, the level of the technology that controls the system may be simple wiring type controls or a computer.

SYMPTOMS

The primary symptoms of any vehicle fuel system that is showing signs of wear or deterioration are:

- Difficult Engine Starting

- Slow or Hesitation at Acceleration

- Stalling While Driving

- Intermittent Power Loss

- Check Engine Light or Service Engine Soon Light Illuminated

- Engine Idling Rough

- Excessive Engine Smoke

- Noticeable Fuel Odors

- Decreased Fuel Economy

EMISSION CONTROLS

Emission controls are an add on to the primary fuel system and vary in complexity based on the year, vehicle, and legal controls in place at the time of manufacture.

Fundamentally, they ensure that the appropriate amount of fuel is delivered, excess fuel is returned to the gas tank, and hazardous vapours are not allowed to escape the system.

Because of the variability in this specific segment of the system, you need to review the technical information that specifically relates to your vehicle.

Visit Forum

Visit Our Friendly Website

12 Comments