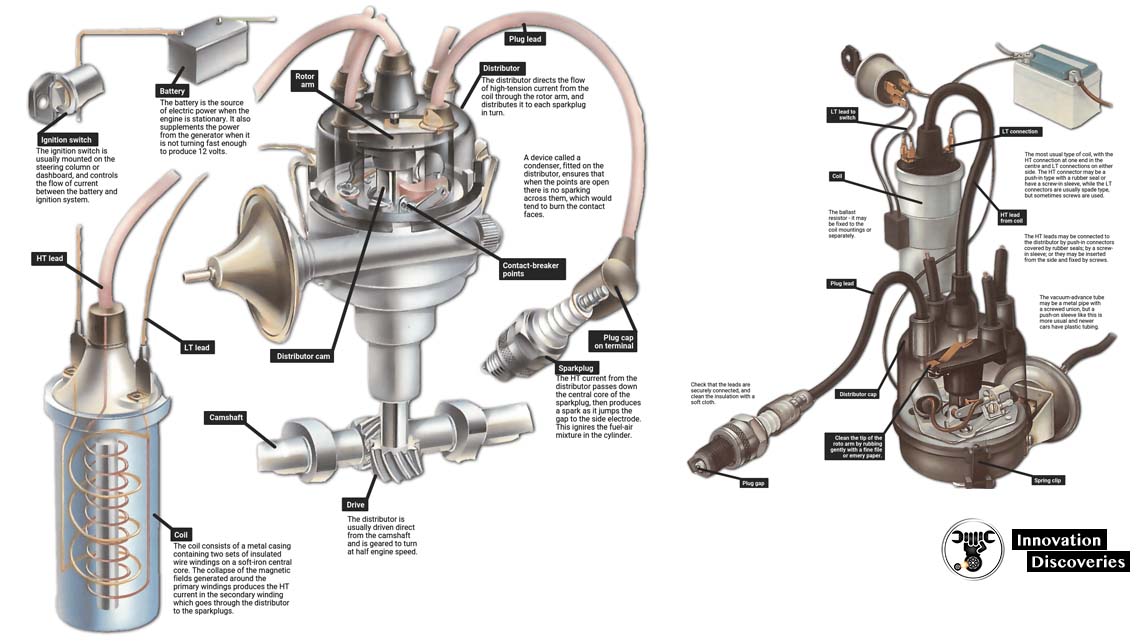

Ignition Distributor is a mechanical device which is used to transfer the High voltage current produced by the secondary coil to the correct spark plugs incorrect firing order and an incorrect amount of time.

It has a mechanically-timed ignition.

It was the year 1910 in which the first reliable Battery operated ignition system was developed by Delco (Dayton Engineering Laboratories Co.). And this ignition was developed by Charles Kettering.

Main Parts

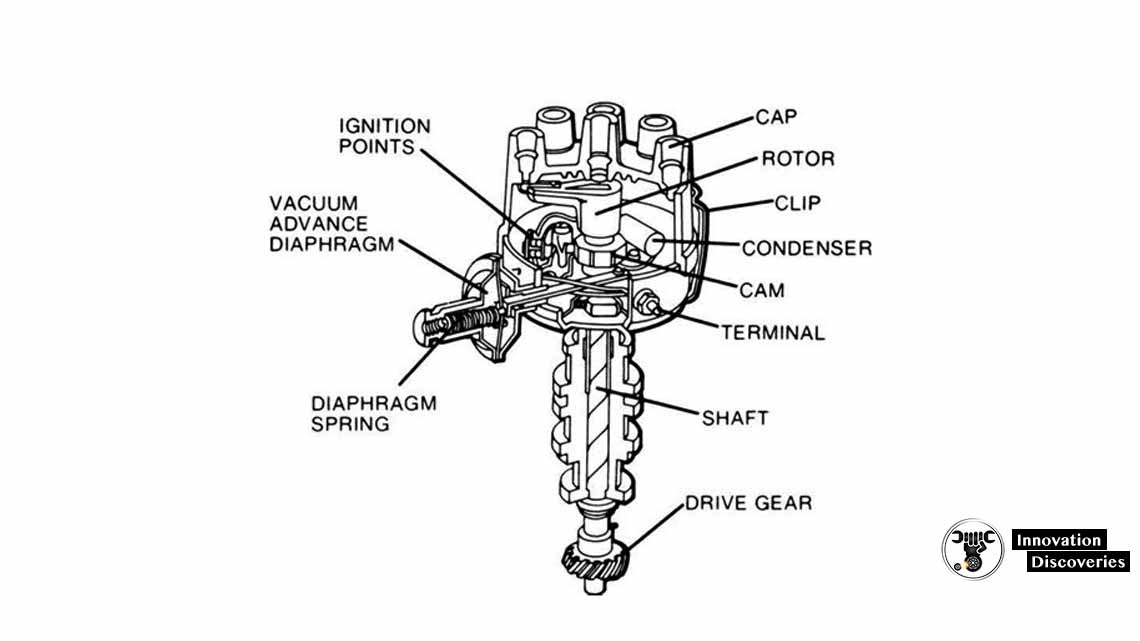

1. Distributor Cap

It is a cover that protects the internal parts of the distributor.

It has one post for each cylinder and in contact points types ignition system it also has one central post which is connected to the ignition coil to receive the current from it.

Some engines have two spark plugs per cylinder in that case, the distributor has two leads per cylinder.

In the wasted spark system, A single contact is used for two leads, but each lead connects one cylinder.

In General, motors where high energy ignition (HEI) system used, there is no central post in the distributor cap.

The ignition coil is placed on the top of the distributor.

Inside the distributor cap, the plug terminals are arranged around the circumference of the cap based on the firing order.

So, the secondary voltage-current must be sent to the correct spark plug at the right time.

The rotor rotates inside the distributor cap.

Also Read: Ignition Coil – Main Parts, Working Principle and Application

2. Rotor

The rotor is present at the top of the distributor shaft. It is driven by the camshaft of the engine and hence synchronized to it.

The rotor is pressed against a carbon bush on the central terminal of the distributor cap.

The central terminal of the distributor is connected to the ignition coil.

The rotor is made in such a way that its central tab is electrically connected to its outer edge so the current that is coming into the central terminal travels through the carbon bush point to the outer edge of the rotor.

As the camshaft rotates, it rotates the distributor shaft.

Due to this the rotor attached to the distributor shaft also starts rotating.

When the outer edge of the rotor passes to each internal plug terminal in the distributor cap it fires each spark plug in the correct sequence.

3. Contact Breaker

It is a mechanically designed breaker point.

Its one end is fixed and another end is movable. It is attached to the breaker assembly. Its main function is to make and breaks the primary circuit current.

When the lobes of the cam pushes the cam follower of the contact breaker, The points of the breaker which were touching each other moves apart and Breaks the primary current to flow through the primary winding of the ignition coil.

4. Distributor Shaft.

It is a shaft which lies in the middle of the ignition distributor.

It is connected directly to the camshaft of the engine through a gear drive.

Consists of a cam which is used to break the point of the contact breaker.

5. Cam

It is attached to the distributor shaft and rotates with it.

It has lobes that are used to open the contact breaker point.

The number of lobes is equal to the number of engine cylinders.

As the cam rotates, it pushes the cam follower and the breaker points move apart leads to breaking of current.

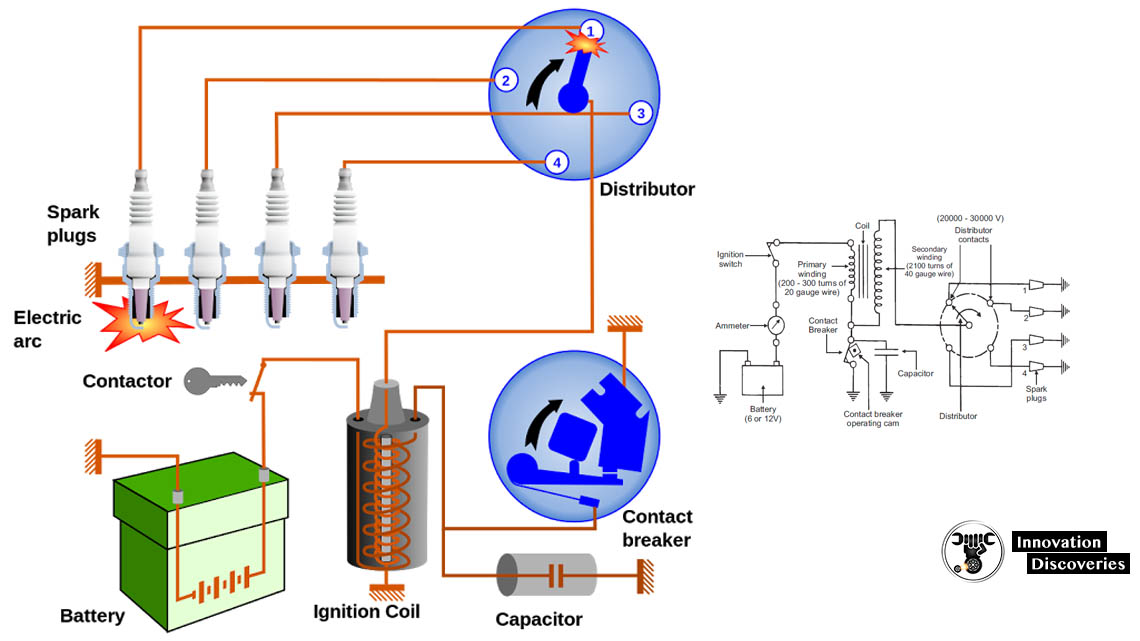

6. Capacitor

It is used to prevent the overheating of the contact point of the contact breaker.

It helps in the production of high voltage current by reversing the current flow through the primary coil.

7. Spark Advance Mechanism:

It is a mechanism that is used to advance the spark in the spark-ignition engine.

We have generally two types spark advance mechanism and i.e. centrifugal advance spark and vacuum spark advance mechanism.

Its main function is to ignite the fuel before the piston reaches the TDC.

This allows the complete burning of the air-fuel mixture within the cylinder and Results in the maximum pressure on the piston.

Working

- As the ignition distributor shaft rotates, it rotates the cam and rotor.

- When the cam pushes the cam follower of the contact breaker, the contact points of the contact breaker open and collapse the primary current through the primary winding.

- This produces a high voltage current in the secondary winding. The high voltage current produced is transferred to the distributor’s central terminal.

- The current from the central terminal reaches the outer edges of the rotor through the carbon bush. As the rotor comes in front of the internal terminal of the spark plug in the distributor cap, the high voltage electrical pulses (or surge) pass to the spark plug and it produces a spark within the cylinder head.

- The distributor produces spark in each of the spark plugs in the correct sequence and incorrect amount of time.

- In this way, the ignition distributor works.

For better explanation Watch the video given below:

Application

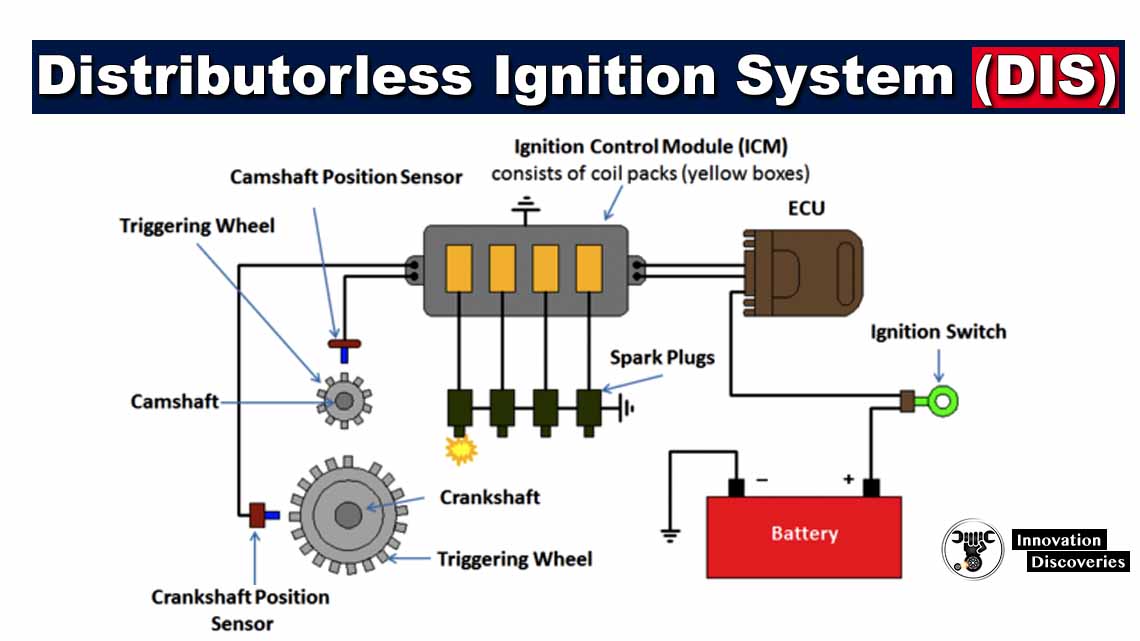

Ignition distributor is used in battery ignition system, Magneto ignition system as well as in an electronic ignition system.

Bhad me jay duniya dari hum to result dekhengw bus