An environment-friendly EV driving for everyday use, motor-based hybrid driving for long-range travel.

A reliable power supply in case of emergencies.

MITSUBISHI MOTORS has been developing electric vehicles (EVs) from early on to tackle environmental problems such as global warming and air pollution.

They introduced EVs including the i-MiEV and the MINICAB-MiEV, which are mainly used as city commuters.

However, EVs must overcome such challenges as a driving range and charging infrastructure to meet a broader range of expectations.

The solution to these challenges is the plug-in hybrid electric vehicle (PHEV).

With a PHEV, you can enjoy EV driving for everyday activities and hybrid driving for family outings on weekends without worrying about charging.

The electricity stored in the traction battery can be used as a power supply in the outdoors or case of emergencies.

You can also use electricity at home via Vehicle-to-Home (V2H) system.

In a sense, PHEV is a storage battery that runs. It is social-good mobility that not only provides a solution to environmental problems but also serves as part of the infrastructure to supply power even when it is stationary.

With environment-friendly technologies centered on PHEVs, They will continue to contribute to the realization of a sustainable society.

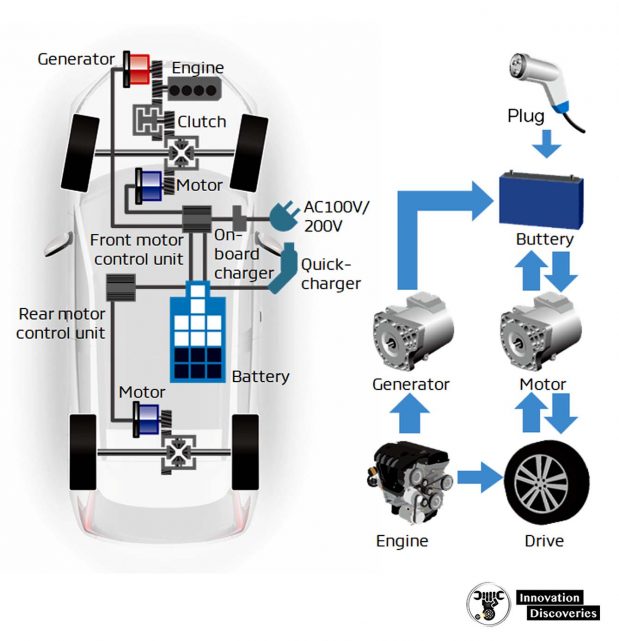

Basic PHEV structure

In order to answer the needs of customers to extend the driving range of EVs, MITSUBISHI MOTORS developed the plug-in hybrid EV (PHEV) system by combining their hybrid technologies with the high-environmental performance EV technologies MITSUBISHI MOTORS had developed over the years.

- Equipped with an engine and a generator to produce power for extending EV cruising range

- Primarily driven by two motors at the front and rear as the system is based on an EV architecture

- Hybrid (HEV) equipped with a charger (plug) = Plug-in HEV

Plug-in hybrid EV based on an EV architecture

By equipping their PHEVs with the right amount of lithium-ion batteries:

- Can be used as EVs for most daily activities, and can run without CO2 emissions as gasoline is not consumed in EV mode.

- Can be driven long distances on vacations in HEV mode, which achieves the same or greater driving range as internal combustion engine vehicles and enables comfortable driving without worrying about battery range despite using the motors as the main drive.

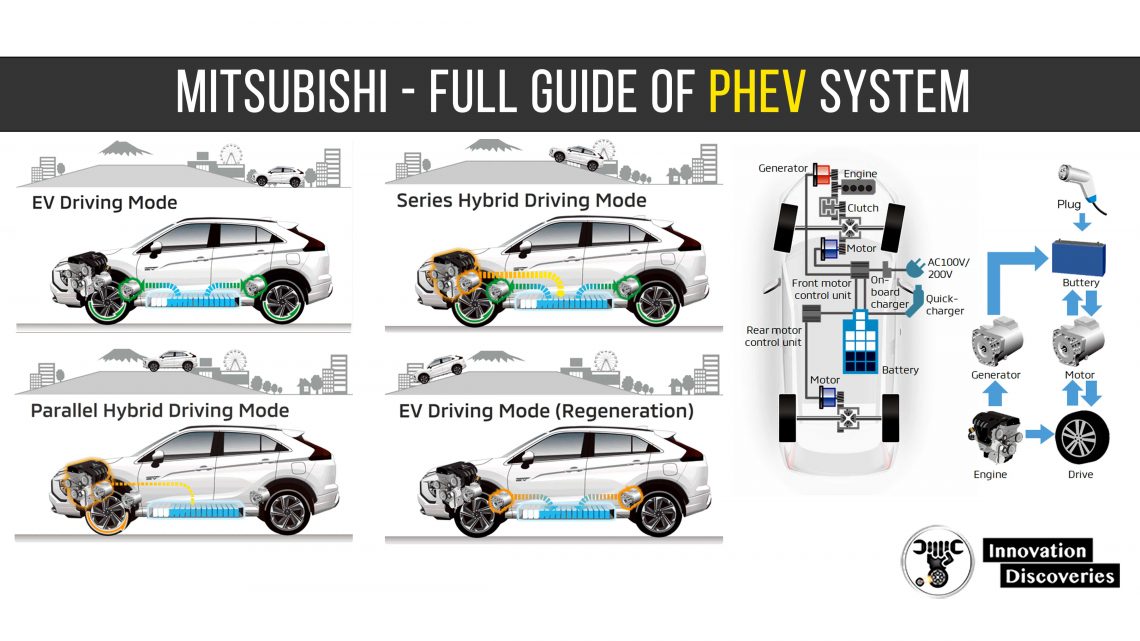

Automatic switching between driving modes depending on the conditions

Their PHEVs automatically switch between EV and hybrid modes depending on the driving conditions and remaining battery power to enable smooth, comfortable driving.

EV Mode

In this mode, PHEVs run on the motors using power stored in the battery, without using gasoline or emitting CO2 while running.

Drivers can enjoy the quiet, clean, and powerful running feel of the motors.

HEV Modes

- Series Hybrid Mode

In this mode, Their PHEVs use the engine as a generator to run the motors in combination with power from the batteries.

- Parallel Hybrid Mode

In this mode, PHEVs primarily run using the high-efficiency engine at high speeds and apply the excess engine output to generate power for charging the battery pack.

The motors assist the engine during acceleration.

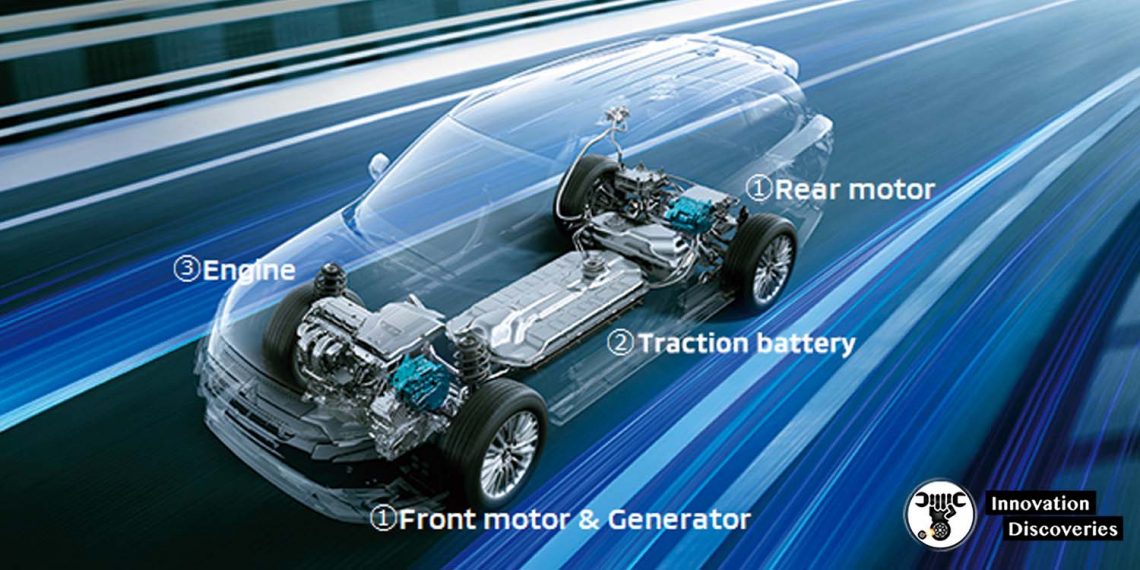

PHEV components

With a generator and two high-output motors installed at the front and rear of the vehicle and a high-capacity traction battery installed under the floor, They designed the layout for the PHEV components in consideration of the vehicle weight balance.

The design also realizes a low center of gravity with superior front-rear weight distribution, while ensuring enough cabin and cargo space even with five occupants.

Given the superb response and powerful acceleration of the front and rear motors, Their PHEVs can run stably in any road condition, including cities and curvy mountain roads.

Front motor & Generator, Rear motor

PHEVs are equipped with a compact, lightweight, high-output motor at the front and rear.

With their good response and powerful acceleration, the two motors serve as a 4WD system that drives all four wheels.

The oil-cooling system used for the front motor and generator improves cooling efficiency and enables a more compact, lighter-weight system.

Moreover, They reduced the motor noise and running noise of the EV components in order to ensure quiet running in EV mode.

Traction Battery

They adopted a lithium-ion battery developed for use in their PHEV system.

Consisting of 80 battery cells connected in series, this high-capacity traction battery offers a total voltage of 300 V and a total capacity of 13.8 kWh.

This battery is stored within a battery pack enclosed by a strong frame structure.

The battery pack also has a sealed structure that ensures high waterproofness.

The battery pack tray is made of sheet metal welded to the frame as part of an integrated structure, which achieves excellent strength, rigidity, durability, and electromagnetic wave shielding performance.

Engine

The engine acts as a generator in Series Hybrid Mode, and it primarily serves to drive the vehicle in Parallel Hybrid Mode.

Using an Atkinson cycle achieved through cam profile adjustment and valve timing control, They enabled efficient power generation in the low rpm range.

Moreover, MITSUBISHI MOTORS significantly reduced engine noise to realize the same comfortable, quiet driving experience unique to EVs, even when using the engine to generate power to run the motors.

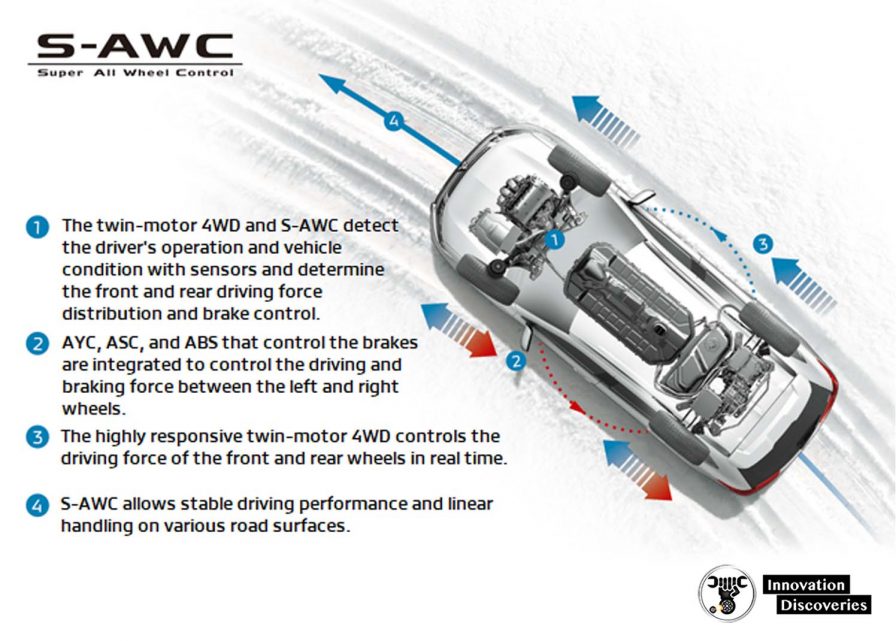

Advanced running performance by twin-motor 4WD and S-AWC

Twin-Motor 4WD drives the front and rear wheels with independent motors.

PHEVs utilize the excellent response of the front and rear independent motors to instantly adjust the front and rear torque distribution in line with the running conditions and the driver’s operations.

This in turn increases the vehicle’s running stability, enables control at the driver’s will, and supports safe and comfortable driving under various road conditions.

S-AWC (Super All Wheel Control) integrated vehicle dynamics control system

Based on their twin-motor 4WD system, They combined Active Stability Control (ASC) and Anti-lock Brake System (ABS) as part of an advanced system that enables integrated Active Yaw Control (AYC), a method of controlling the left and right driving forces generated by the brakes.

Utilizing the front and rear independent twin motors, this system is freed from the physical constraints of the front and rear wheels and thereby enables the ideal front-rear driving force distribution that MITSUBISHI MOTORS sees as the optimal solution for allowing “everyone to enjoy driving with peace of mind.”

100V AC power source (1,500W)

Following the Great East Japan Earthquake in March 2011, MITSUBISHI MOTORS provided 89 units of i-MiEVs to affected areas for use as shelter contact vehicles and transport vehicles for medical personnel.

At the time, They were asked by those on-site if they could use power from the traction battery, in response to which MITSUBISHI MOTORS developed the MiEV Power Box as an external 1,500W power supply device.

MITSUBISHI MOTORS launched commercial sales of this device in 2012, about one year after the Great East Japan Earthquake.

They also equipped this power supply technology as a 100V AC power supply (1,500W) on the OUTLANDER PHEV, the world’s first plug-in hybrid SUV, which MITSUBISHI MOTORS launched the following year.

This device enables a maximum output of 1,500W from the vehicles’ onboard outlets during outdoor leisure activities and emergencies, thereby allowing for the unrestricted use of lights, cooking equipment, and other electrical appliances.

This feature does not simply serve as a convenient function to access electricity, but it has also allowed them to propose a completely new way of using automobiles.

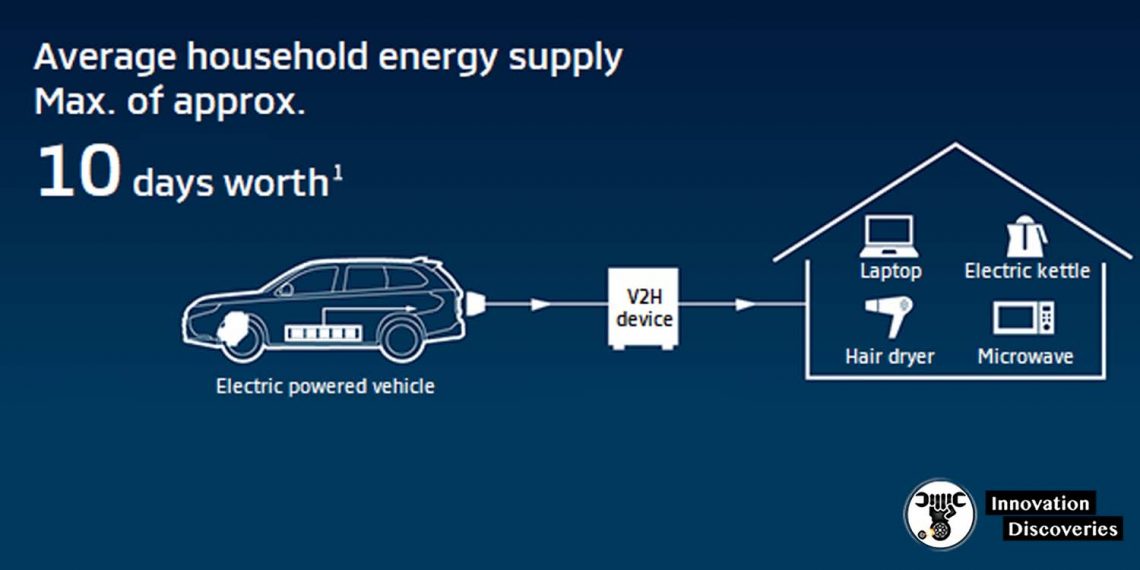

V2H

V2H stands for Vehicle-to-Home, which refers to the ability of electric vehicles and homes to supply power to each other.

The power from a fully-charged traction battery of their PHEV can provide up to one day’s worth1 of power for a general household via a V2H system.

Similarly, combining battery power with power generated1 by the engine on a full tank of gas enables the supply of up to 10 days’ worth1 of power.

This capability allows for house lights, air conditioners, cooking equipment, and baths to be used during power outages and disasters, and provides peace of mind as families can stay safe at home as usual.

Moreover, this capability also allows for more economic lifestyles if the V2H equipment is used to charge the traction battery from a home during power contract discounted time periods and the vehicle is driven during non-discounted time periods.

OUTLANDER PHEV

They launched the OUTLANDER PHEV in Japan in 2013 as the world’s first plug-in hybrid SUV and won multiple accolades including the Japan Car of the Year “Innovation Award” and RJC Technology of the Year Award.

The OUTLANDER PHEV is the world’s best-selling PHEV1 with 277,000 units2 sold in more than 60 countries.

As part of their continuous effort in expanding presence throughout the ASEAN region, They have launched the model in Indonesia in November 2019, the Philippines in August 2020, and will be introduced to Thailand in January 2021.

They are committed to the constant and never-ending improvement of their PHEV systems.

MITSUBISHI MOTORS entered the OUTLANDER PHEV in the 2013 Asia Cross Country Rally, the 2015 Baha Portalegre 500, and other international rallies as a means of verifying the reliability of the mass-production technologies and the potential of advanced technologies.

During the 2017 Tokyo Motor Show, they unveiled triple-motor 4WD as a future high-performance option under the MITSUBISHI eEVOLUTION CONCEPT.

● Major awards

- 2013-2014 Japan Car of the Year “Innovation Award”

- 2014 “RJC Technology of the Year Award” (Japan)

- 2018 Green Car Journal “Best SUV of the Year Award” (US)

- 2018 COMPANY CAR and VAN “2019 Best Plug-in Vehicle Award” (UK)

CLIPSE CROSS (PHEV model)

With its combination of a stylish sleek body and dynamic SUV handling, they equipped the ECLIPSE CROSS with the reliable, high-performance twin-motor 4WD PHEV system developed for the OUTLANDER PHEV.

This is the second PHEV model offered by MITSUBISHI MOTORS.

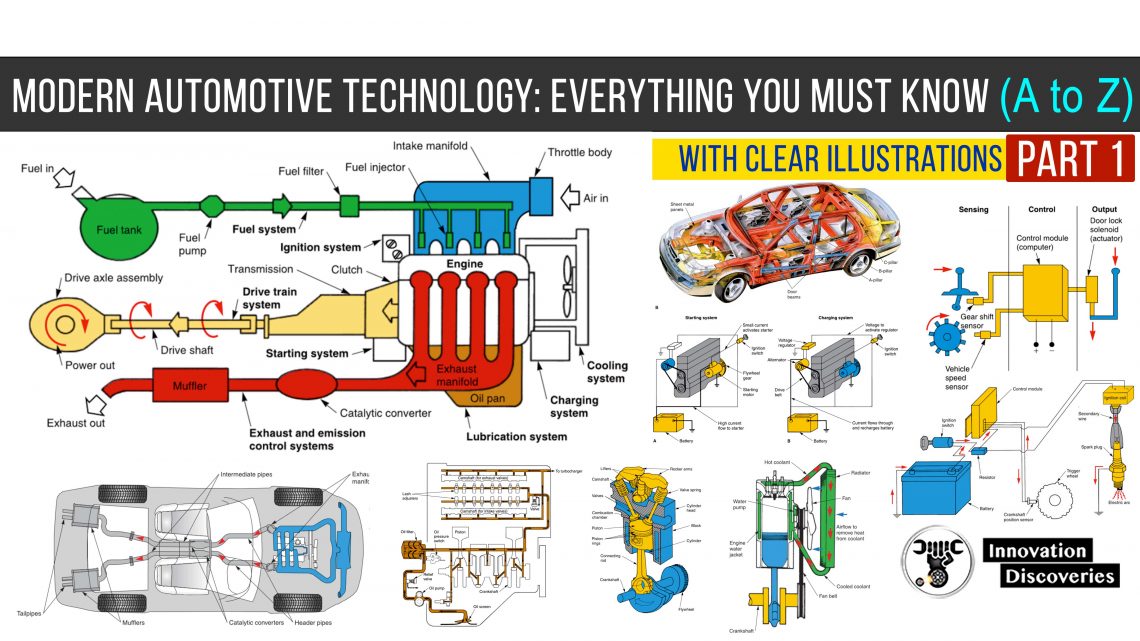

01 – Modern Automotive Technology: Everything You Must Know (A to Z) Part 1

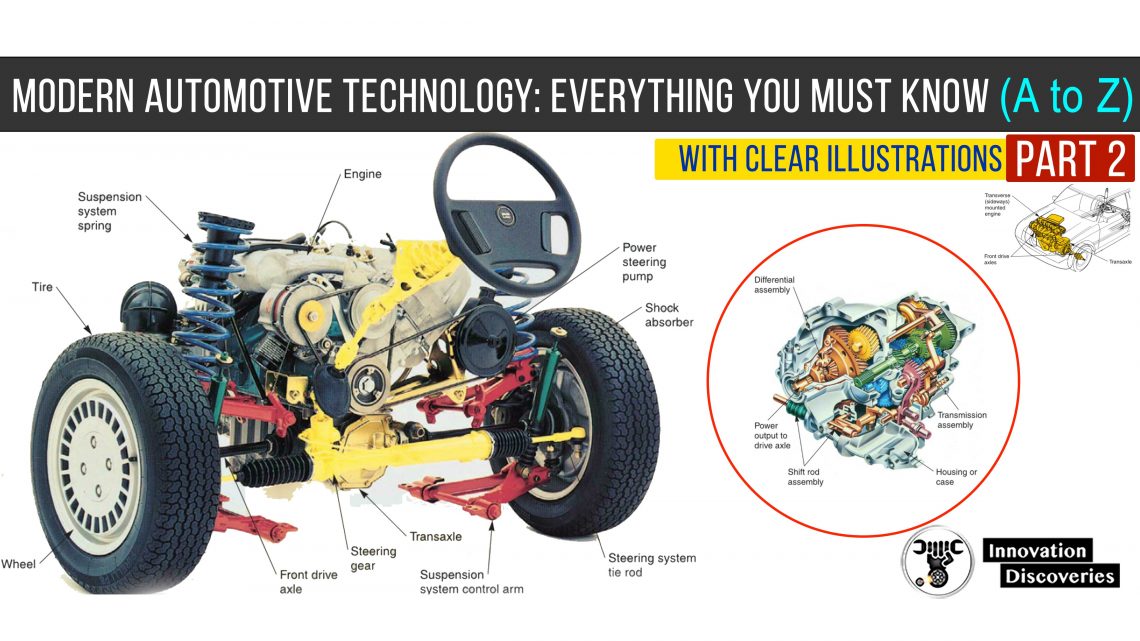

02 – Modern Automotive Technology: Everything You Must Know (A to Z) Part 2

Visit Forum

Visit Our Friendly Website