Railways Track Bed Formations – Basics Railway Track bed formation foundations,

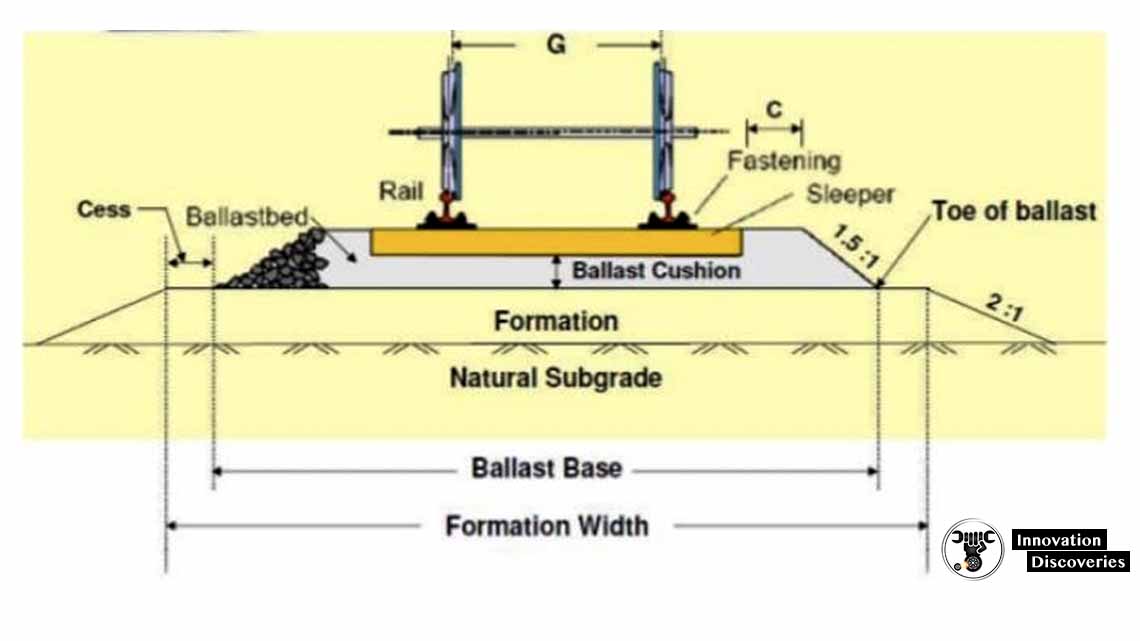

And the formation of the trackbed can affect the

Actual track quality and performance of railways.

Earthwork:

Usual forms of cross-sections:

The Naturally occurring soil is known as subgrade and,

When it is prepared to receive the ballast and track, it is called ‘Formation’.

When a formation is raised on bank of earth,

It is called an embankment. When it is made after cutting the ground,

It is called ‘cutting’. In case of cutting the track is laid below ground level,

Thus, the required portion to be excavated.

Normally a railway line will be constructed on a flat ground,

Or on embankment or cutting or in a combined section.

Features of Rail Track bed level:

When the formation is to be made on embankment or cutting,

Various features should be carefully considered.

- 1. Width of formation: With normally depends on the number of tracks,

Gauge of tracks, centre to centre distance between the tracks,

Width of ballast layer, a width of trenches if needed. - 2. Slopes of sides: Stability of the earthwork depends mainly on, Two factors namely ‘cohesion’ and ‘friction’. For temporary stability, cohesion is useful and reliable, But permanent stability is achieved only by friction which keeps the Natural angle of repose of the material.

Sloped to be provided to the sides of the formation should be

Slightly flatter than the angle of repose of the material. The slopes in cutting vary from 1.5 to 1 or steeper.

- 3. Drains: The accumulation of water reduces friction in all sorts of soils. In the case of embankments, the rainwater is easily drained off but in cutting, drains to be provided. The side drains are constructed along the track at a depth of approx. 1200 mm from the rail level.

The size of the drain depends on the rainfall data.

Stabilization of track on poor soil

Sometimes it becomes unavoidable to lay tracks on a very poor (or undesirable) soil.

In such cases, it becomes necessary to improve and,

Strengthen the nature of soil by some suitable methods.

Under such circumstances, the following methods are used.

- Layer of Moorum

- Cement Grouting

- Sand Piles

- Use of Chemicals

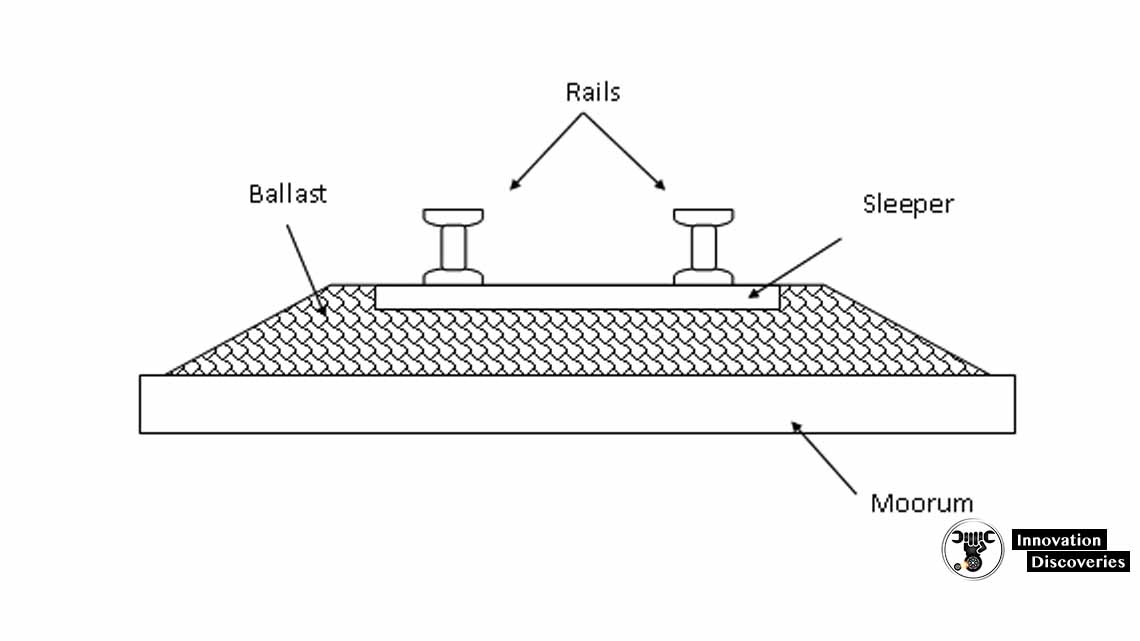

Layer of moorum:

This method is widely used and is adopted if a poor quality soil comes across a track

Such as black cotton soil which is a fine black loamy soil.

This soil tends expanding (or swelling)

When moist and of caking and cracking heavily when dry.

Tracks laid on the formation of maintain.

In rainy season, the soil fills up ballast interest less,

The track in the worst places gets sodden and spongy track is reduced. In hot weather, the cracks are formed and the ballast is lost in filling up these cracks.

Thus, the alignment as well as level is disturbed and with mud filling the interstices, the track loses. Its resiliency, therefore, for these very reasons,

A layer of moorum varying in thickness from 300 mm ” ” to 600 mm is laid under the ballast. This layer distributes the pressure of the load and prevents the ballast

From being lost in the cracks of the soil.

Instead of moorum, other materials such as ashes, concrete,

Slabs, rubber, unserviceable sleepers, etc…

They are also used and are found quite satisfactorily.

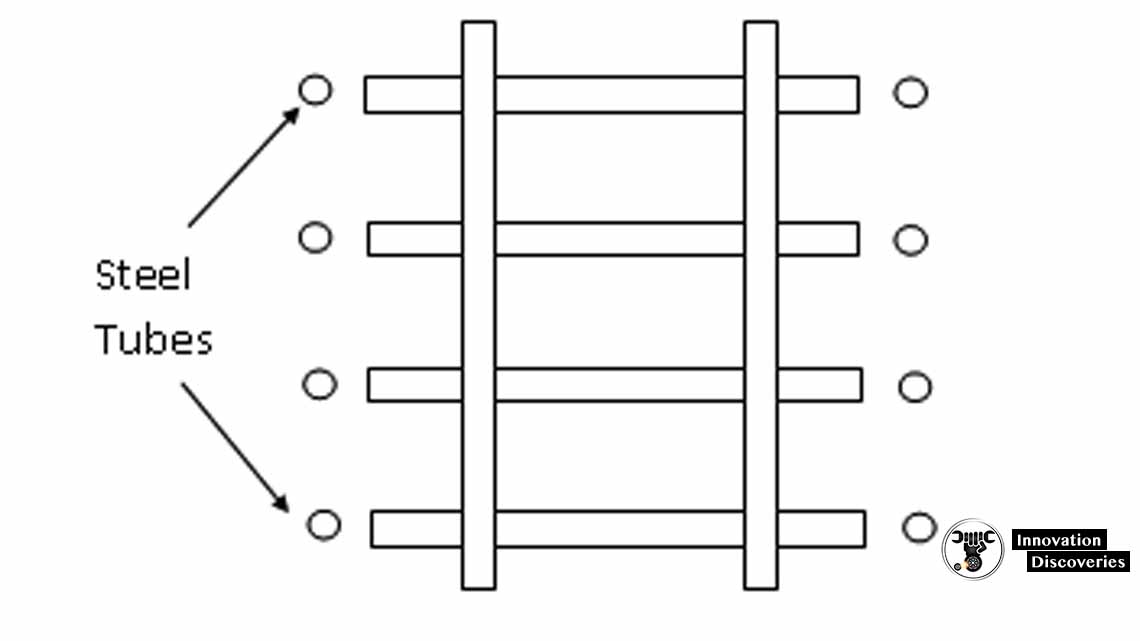

Cement Grouting

In this method, steel tubes of 30 mm in diameter and 1.5 m.

The tubes are driven into the foundation at an angle such,

That the end of the tube is nearly under the rail.

The cement grout is forced under a pressure of 0,7 N/mm2 through these tubes. The proportion of cement grout depends on the type and condition of formation. The concert grout spreads through the poor soil and consolidates it. The steel tubes are then gradually taken out.

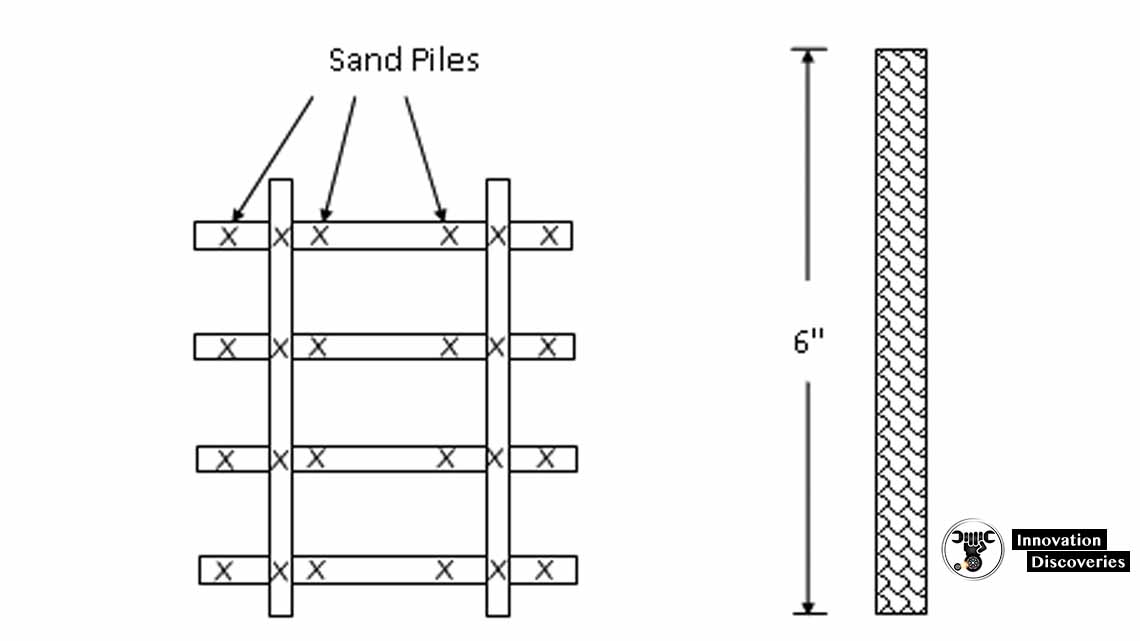

Sand piles

This method of strengthening the track laid on poor is most widely used in

Development countries like America. In this method, a vertical bore about 300 mm “,

Diameter is made in the ground by driving a wooden pile. The wooden pile is then withdrawn and space is filled with sand and is well rammed. The sand piles are driven in the pattern as shown.

It is also arranged that the cross-sectional area of the sand piles is about 20% of the formation area.

Thus, the top section of the formation is covered with sand

Which makes the track stable on poor soil.

Also, read:

Use of chemicals

In this method,

Chemicals are used in place of cement grout to consolidate the soil.

2 Comments