Introduction

“Old is gold” very rightly said as when it comes to the automobile old inventions are the source of improved technology that we are using today.

One of those inventions is the Sliding mesh gearbox which gave rise to a very essential system of the the automobile i.e. Transmission system or gearbox.

But from where did the idea come from?

How does it work? Let’s just find out.

The idea of a transmission system is given by French inventors Louis-Rene and Emile Levassor who invented the world’s first-ever transmission system with 3-speed Sliding mesh transmission in 1894 which was the boom in the automobile industry.

Sliding mesh gearbox is a transmission system that consists of various sets of gears and Shafts that are arranged together in an organized fashion and shifting or meshing of different gear ratios is done by the Sliding of gears towards the right and left over the splined shaft with the help of a gear lever operated by the driver.

Need for Sliding Mesh Transmission

The introduction of an IC engine had led to the introduction of an automobile that was the replacement of the horse carriage which was used as the Traveling medium by the people in the early 18th century.

But still, the automobile was lacking behind when it came to facing the challenges (Turns, elevations, roughness, etc.) given by the roads as there was no such mechanism.

Fitted in early vehicles that could provide different torque and speed ratios as demanded by the road conditions.

In 1894 the first transmission system named the Sliding mesh transmission system was introduced which was designed to provide different speed and torque ratios to overcome those road challenges.

The various problem solved by these types of gearbox is.

- Fuel consumption of an automobile increased as the load on the engine is decreased or shared by the intermediate system known as sliding mesh gearbox.

- Due to the varying torque ratios provided by this gearbox, the automobile vehicle is made to go to the hill stations which was not possible earlier.

- Time taken to reach the destination was decreased as overall speed of the vehicle increased due to the high-speed ratios provided by it.

- Reverse of the car made possible with the introduction of this transmission system.

- Jamming of the vehicle due to the rough road conditions was solved after the introduction of the sliding mesh gearbox.

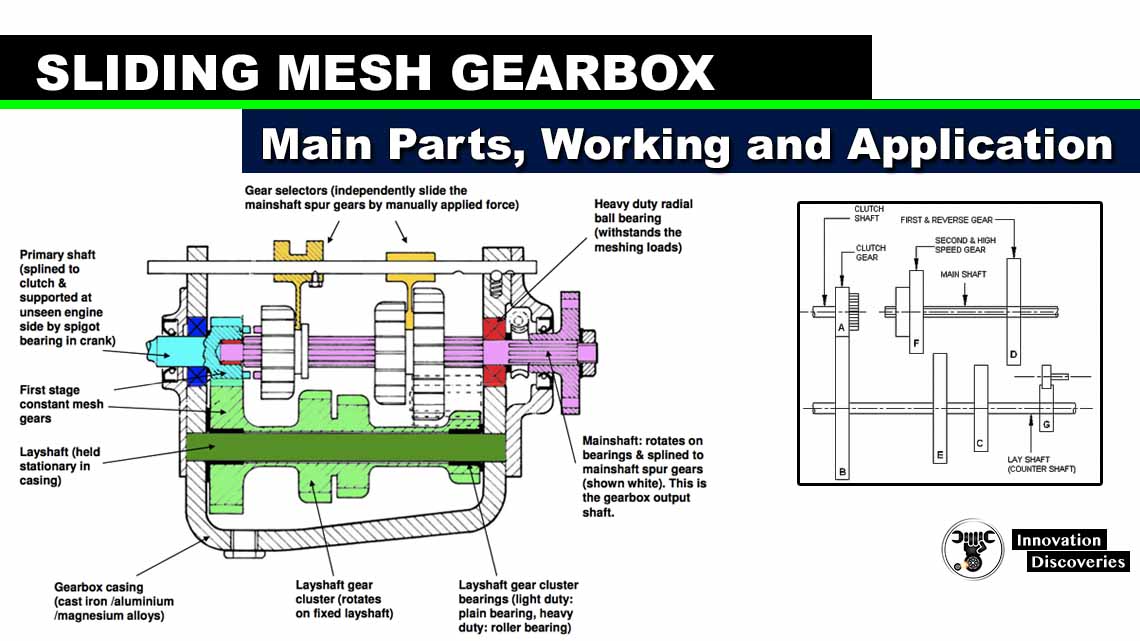

Components of a Sliding Mesh Gearbox

The main parts of sliding mesh gearbox are:

i) Shafts

There are 3 shafts present in Sliding Mesh Gearbox:

a) Clutch Shaft

It is an input shaft in the sliding mesh gearbox.

The clutch shaft carries the engine output to the gearbox with the help of enaging and disengaging clutch which is mounted at the engine end.

A gear is mounted over this shaft known as clutch gear which is used to transmit rotational motion to the lay shaft.

b) Lay Shaft or Counter Shaft

After the input shaft comes the Lay Shaft. Lay shaft is an intermediate shaft between the Clutch Shaft and Main Shaft.

In the lay shaft, the gears are rigidly fixed and rotates with the lay shaft.

One of the gear of this shaft is always in contact with the gear of the clutch shaft.

So when the clutch shaft rotates, the lay shaft also rotates.

Layshaft rotates in a direction counter to the engine rotation. So, it is also known as Counter Shaft.

Other gears of layshaft mesh with different gears of the main shaft to obtain different gear ratios.

Also, layshaft has reverse gear which has idler gear attached to it.

c) Main Shaft

This shaft is used as an output shaft in sliding mesh gearbox. In this shaft the gears are not rigidly fixed.

The gears of this shaft have internally splined grooves and the outer surface of this shaft is made splined so that the gears can easily slide over the shaft.

The gears of the main shaft slide over the shaft to mesh with the appropriate gears of the layshaft so that the required gear ratio is obtained.

ii) Gears:

Usually, two types of gears were used in sliding mesh gearbox.

They are:-

a) Spur gear

Spur gears have straight teeth that are produced parallel to the axis of the gear.

These gears are the most economical types of gear but tend to vibrate and become noisy at high speed.

b) Helical gear

The teeth of helical gears are not parallel to gear axis. The tteth of this gear type are at angle to the gear axis.These gears are less noisy and have a smoother operation than spur gear. Also these gears have higher tooth strength and a higher load carrying capacity.

iii) Gear Lever

It is used slide the gears in the main shaft to obtain appropriate gear ratio. It is operated by the driver.

Also Read:

Working of Sliding Mesh Gearbox

At first, the clutch shaft is driven by engine.

It carries the engine output and rotates in the same direction as that of engine.

The gear connected to the clutch shaft also rotates.

As gear of clutch shaft rotates, the lay shaft gear which is connected to the clutch shaft gear also rotates but in opposite direction.

So the lay shaft rotates due to rotation of lay shaft gear that is rigidly fixed in the lay shaft.

Due to rotation of layshaft other gears of layshaft also rotates as all the gears in layshaft are rigidly fixed including the reverse gear.

The gears of the main shaft are internally splined and the main shaft is also splined, so the gears of main shaft can slide over it.

The gear of the main shaft is shifted and meshed with different gears of layshaft to obtain different gear ratios required to face different road problems.

Different gears of Sliding Mesh Gearbox:

First gear

First Gear is used at the time when vechile starts its movement in forward direction.

1st Gear provides maximum torque and minimum speed and this gear are obtained when the smallest gear on the layshaft meshes with the biggest gear in the main shaft.

Second gear

The second Gear is obtained when the second-largest gear of the second smallest gear of layshaft meshes with the middle size gear of the main shaft.

Second Gear provides lower torque and higher speed than First Gear.

Third gear

The third gear is the last gear or top gear of the Sliding Mesh Gearbox. This gear is obtained when the biggest gear of layshaft meshes with the smallest gear of the main shaft.

This gear provides maximum speed and minimum power.

Reverse gear

Reverse Gear is used when the vehicle needs to move in the opposite direction.

In this gear, the rotation of the output shaft or main shaft is reversed by placing an idler gear between the layshaft gear and the main shaft gear which changes the direction of rotation of the output shaft.

For a better explanation about sliding-mesh gearbox watch the video given below:

Application

It is the oldest type of gearbox used in the early 19s models of cars. Some of them are-

- Alfa 12HP used a sliding mesh gearbox with 4 -speed manual transmission.

- Fiat 6HP used 3-speed manual transmission.

- Mercedes 35HP used 4-speed manual transmission

- Renault Voiturette used a manual 3-speed transmission.

See More:

- Manual Or Automatic Gearbox: Which Is The Best?

- How manual gearboxes work

- Engine Braking With A Manual Transmission – Is It Bad?

Advantages of Sliding Mesh Gearbox:

1 Since only one gear is in mess in sliding mesh gearbox so less fluctuating loads on shafts causing less vibration and noise

unlike the contant mesh gearbox in which all gears are in constant mesh.

2. Its efficiency is more than constant gearbox as only one gear is in mess unlike the contant mesh gearbox in which all gears are in constant mesh.

2. Its manufacturing is easy as compared to constant mesh gearbox.

3. Its mechanism is simple.

Disadvantages of Sliding Mesh Gearbox:

1 Only spur gears can be used as gears are not in constant mesh-like constant-mesh gearbox in which helical or herringbone gears can be used.

2 More effort is required to engage the gear as the gear has to be slid in a sliding mesh gearbox, unlike a constant mesh gearbox where only dog clutch has to be slid for engagement of different gears.

3 Less life of gear as more wear and tear of gear is caused in sliding mesh gearbox due to friction.

4 It takes more time and money to replace the gears if the gearbox fails but in a constant mesh gearbox only dog clutches are to be replaced at failure which takes less time and money.

3 Comments