The steering system in an automobile is a crucial component that enables the driver to control the direction of the vehicle. It plays a vital role in ensuring safe and efficient maneuverability. In this article, we will explore the requirements of a steering system, discuss different types of steering systems, and delve into the concept of power steering.

Requirements of a Steering System

A steering system must meet several essential requirements to ensure optimal vehicle control and handling. These requirements include:

1. Responsiveness:

The steering system should respond quickly to the driver’s input, allowing precise control of the vehicle’s direction.

2. Stability:

The system must provide stability to the vehicle during normal driving conditions, ensuring it maintains a straight path.

3. Ease of Operation:

The steering effort required by the driver should be reasonable and comfortable, even at low speeds or during parking maneuvers.

4. Reliability:

The steering system should be robust and reliable, capable of withstanding various driving conditions and loads.

5. Safety:

The system should enable the driver to maintain control of the vehicle even in emergency situations, such as sudden turns or evasive maneuvers.

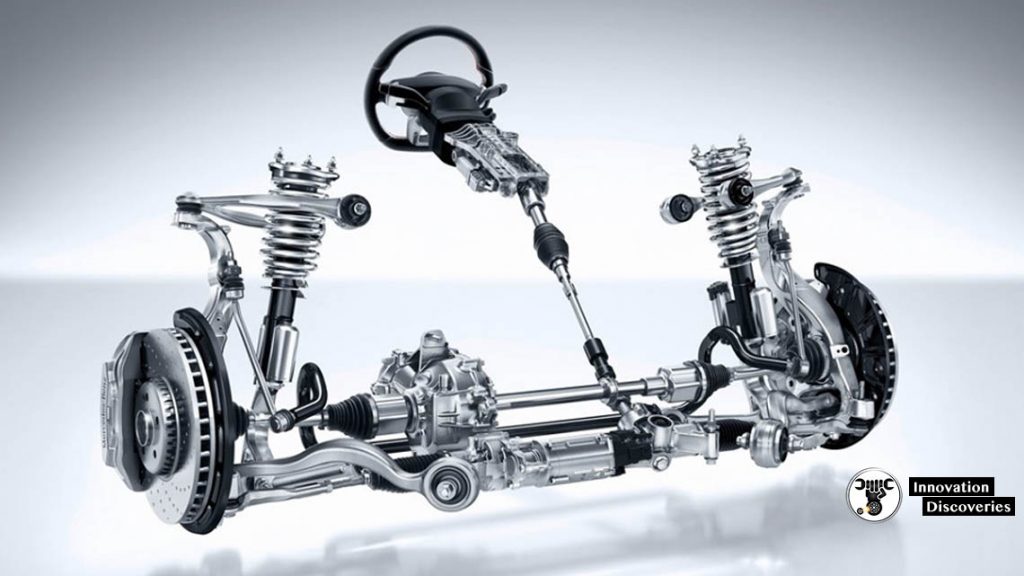

STEERING COMPONENTS

Steering systems in automobiles consist of various components that work together to enable the driver to control the direction of the vehicle. Here are some key steering components:

1. Steering Wheel:

The steering wheel is the primary interface between the driver and the steering system. It is typically a circular device that the driver grips to turn the wheels.

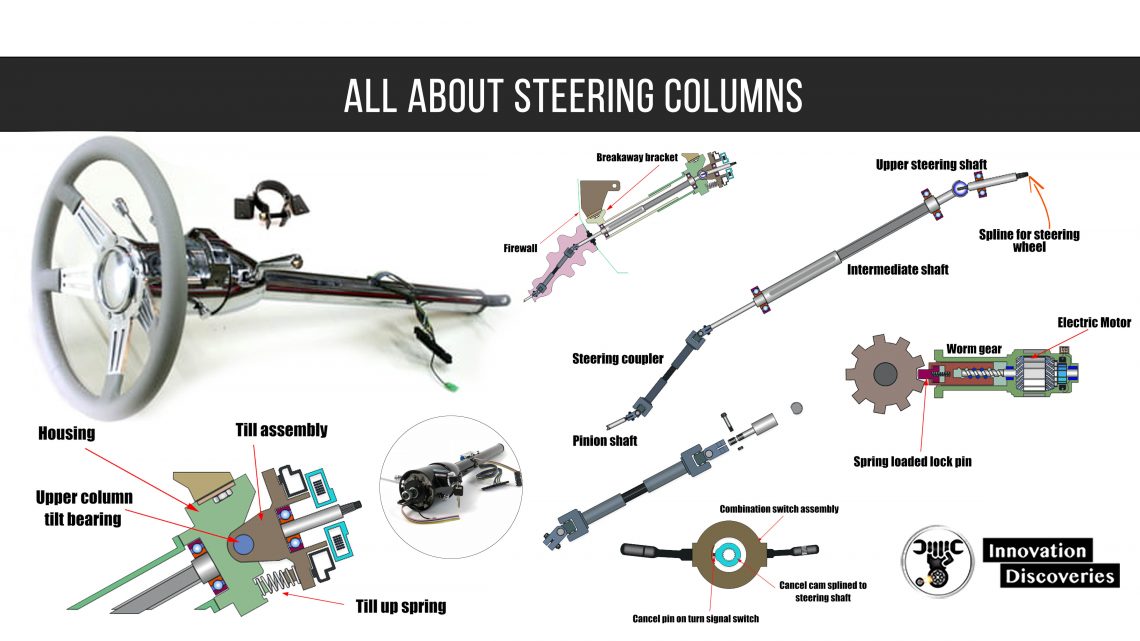

2. Steering Column:

The steering column connects the steering wheel to the steering mechanism. It houses components such as the steering shaft, universal joints, and intermediate shafts, allowing the transfer of rotational motion from the steering wheel to the steering mechanism.

3. Steering Gearbox:

The steering gearbox, also known as the steering gear, is responsible for converting the rotational motion from the steering wheel into the linear motion required to turn the wheels. It is a mechanical device that can be either rack-and-pinion or recirculating ball type, depending on the steering system.

4. Rack and Pinion:

In a rack-and-pinion steering system, the rack is a toothed bar that meshes with a pinion gear. As the steering wheel turns, the pinion gear moves the rack, translating the rotational motion into linear motion to steer the wheels.

5. Power Steering Pump:

In power steering systems, there is a power steering pump that assists the driver in turning the wheels. The pump generates hydraulic pressure to provide additional force, reducing the effort required by the driver.

6. Power Steering Fluid:

Power steering systems use power steering fluid, which is a special hydraulic fluid that transfers pressure and lubricates the components within the steering system. It helps in smooth operation and minimizes wear.

7. Steering Linkage:

The steering linkage consists of various components that transmit the motion from the steering gearbox to the wheels. These include tie rods, pitman arms, idler arms, and center links. They connect the steering mechanism to the steering knuckles and ensure synchronized movement of the wheels.

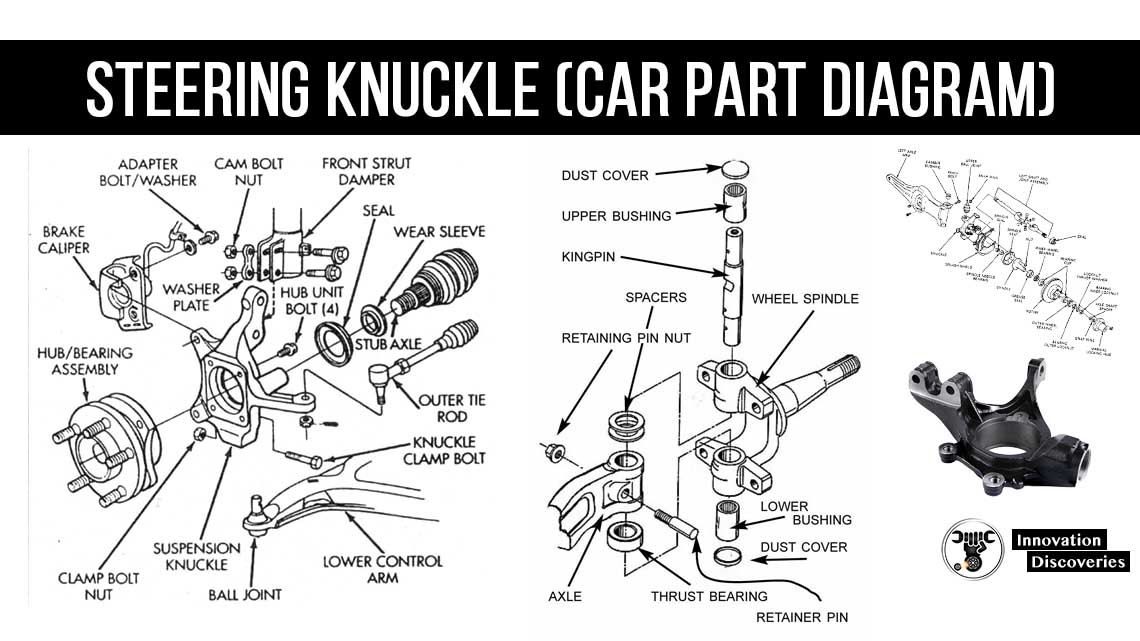

8. Steering Knuckles:

The steering knuckles are part of the front suspension system and serve as the connection point between the steering linkage and the wheel hub assembly. They allow the wheels to pivot for steering and also support the weight of the vehicle.

9. Steering Boots:

Steering boots, also known as steering rack boots or bellows, protect the steering rack and tie rod ends from dirt, debris, and moisture. They are flexible rubber covers that enclose the steering components.

10. Steering Wheel Position Sensor:

Some modern vehicles are equipped with steering wheel position sensors, which provide feedback to the vehicle’s electronic control systems. These sensors help in stability control, traction control, and other advanced driver assistance systems.

These are just a few of the key components involved in a typical steering system. The specific components and their arrangement can vary depending on the type of steering system used in a vehicle.

TYPES OF STEERING SYSTEM

There are several types of steering systems used in automobiles, each with its own characteristics and mechanisms. Here are some common types of steering systems:

1. Rack-and-Pinion Steering:

Rack-and-pinion steering is one of the most widely used steering systems in modern vehicles. It consists of a rack (a toothed bar) and a pinion gear. When the driver turns the steering wheel, the pinion gear moves the rack, converting the rotational motion into linear motion. This linear motion is then used to steer the wheels. Rack-and-pinion steering systems are known for their simplicity, compactness, and responsiveness.

2. Recirculating Ball Steering:

Recirculating ball steering systems use a worm gear and sector gear arrangement to convert the rotational motion of the steering wheel into the desired wheel movement. The steering wheel is connected to a worm gear that engages with a sector gear. As the worm gear rotates, it moves the sector gear, which in turn moves the pitman arm and steering linkage, resulting in the steering of the wheels. Recirculating ball steering systems offer better durability and load-carrying capacity than rack-and-pinion systems, but they may be slightly less responsive.

3. Electronic Power Steering (EPS):

Electronic Power Steering systems use an electric motor to assist the driver’s steering efforts. EPS systems provide variable power assistance based on driving conditions and input from various sensors. They can adjust the level of assistance depending on factors such as vehicle speed, steering angle, and road conditions. EPS offers benefits such as reduced steering effort, improved fuel efficiency, and the ability to integrate with advanced driver assistance systems.

4. Hydraulic Power Steering:

Hydraulic Power Steering (HPS) systems use hydraulic pressure to assist the driver in turning the wheels. These systems employ a hydraulic pump, usually driven by a belt connected to the engine, to generate pressure. The hydraulic fluid is directed to a power steering gearbox or rack-and-pinion assembly, where it assists in steering effort. While hydraulic power steering has been commonly used in the past, it is gradually being replaced by EPS due to its higher energy consumption.

5. Active Front Steering:

Active Front Steering (AFS) is an advanced steering system that incorporates electronic control to actively adjust the steering response. AFS systems can modify the steering ratio and assist level based on driving conditions. They can enhance vehicle stability, improve maneuverability, and provide more precise control in different situations. AFS systems often work in conjunction with other vehicle control systems, such as stability control and adaptive suspension systems.

These are some of the primary types of steering systems found in automobiles. The choice of steering system depends on factors such as the vehicle’s design, intended use, and technological advancements. Manufacturers continue to innovate and develop new steering technologies to enhance vehicle handling and driver experience.

STEERING MECHANISMS

Steering mechanisms are the mechanical systems that enable the driver to control the direction of a vehicle. They provide a means of converting the rotational motion of the steering wheel into the necessary movement of the wheels. Here are some common steering mechanisms:

1. Rack and Pinion:

The rack and pinion steering mechanism is widely used in modern vehicles. It consists of a rack, which is a toothed bar, and a pinion gear. When the driver turns the steering wheel, the pinion gear engages with the rack, causing it to move either left or right. This linear motion of the rack is then transmitted to the steering linkage, which turns the wheels accordingly. Rack and pinion steering mechanisms are known for their simplicity, efficiency, and responsiveness.

2. Recirculating Ball:

Recirculating ball steering mechanisms utilize a worm gear and a sector gear to convert the rotational motion of the steering wheel into the desired wheel movement. The steering wheel is connected to a worm gear, which meshes with the teeth of a sector gear. As the steering wheel turns, the worm gear rotates, moving the sector gear back and forth. This movement is then translated into the rotation of the pitman arm, which controls the steering linkage and turns the wheels.

3. Cam and Lever:

Cam and lever steering mechanisms were used in older vehicles but are less common in modern cars. They employ a rotating cam and a lever arm to transfer the motion from the steering wheel to the wheels. When the driver turns the steering wheel, the cam rotates, causing the lever arm to move. The lever arm then transmits this motion to the steering linkage, resulting in the desired wheel movement.

4. Mechanical Linkage:

Mechanical linkage steering mechanisms use a combination of rods, arms, and joints to transfer the steering input from the steering wheel to the wheels. These systems often incorporate a series of connecting rods, tie rods, and various pivot points to transmit the motion effectively. Mechanical linkage steering mechanisms can be found in older vehicles and some heavy-duty applications.

5. Electronic Steering:

Electronic steering mechanisms, such as Electric Power Steering (EPS), use electronic control systems and an electric motor to assist the driver in steering. The steering input from the driver is detected by sensors, and the electronic control unit (ECU) calculates the required level of assistance. The electric motor then provides the necessary power assistance to the steering mechanism, resulting in reduced steering effort.

6. Steer-by-Wire:

Steer-by-wire is an emerging steering technology that eliminates the physical connection between the steering wheel and the wheels. Instead, electronic sensors detect the driver’s input, and the information is transmitted to an electronic control system. The control system interprets the input and sends commands to actuators, which directly control the steering of the wheels. Steer-by-wire systems offer the potential for more flexibility and integration with advanced driver assistance systems.

These are some of the common steering mechanisms found in vehicles. The choice of steering mechanism depends on factors such as the vehicle type, design, and technological advancements. Manufacturers continue to innovate and develop new steering mechanisms to improve vehicle handling, safety, and driver comfort.

Summary:

Steering mechanisms are mechanical systems that enable the driver to control the direction of a vehicle. Common types of steering mechanisms include rack and pinion, recirculating ball, cam and lever, mechanical linkage, electronic steering, and steer-by-wire.

Rack and pinion steering is widely used in modern vehicles, with a toothed rack and pinion gear converting the rotational motion of the steering wheel into linear motion to turn the wheels. Recirculating ball mechanisms utilize a worm gear and sector gear arrangement for the same purpose.

Cam and lever mechanisms, found in older vehicles, use a rotating cam and lever arm to transfer the motion from the steering wheel to the wheels. Mechanical linkage steering employs a combination of rods, arms, and joints to transmit steering input.

Electronic steering mechanisms, such as Electric Power Steering (EPS), use electronic control systems and an electric motor to assist steering. Steer-by-wire technology eliminates the physical connection between the steering wheel and the wheels, relying on electronic sensors and actuators for steering control.

The choice of steering mechanism depends on factors such as the vehicle type, design, and technological advancements. Manufacturers continuously develop new steering mechanisms to enhance vehicle handling, safety, and driver comfort.

Visit Forum

Visit Our Friendly Website

6 Comments