Here’s a scary scenario we all dread as drivers. You’re cruising down the highway,

Wind flowing through your hair and “Born to be Wild” pumping from the stereo. Up ahead traffic begins to slow and you gently tap the brakes. To your horror, nothing happens! The pedal is stiff as a plank of wood.

You have to practically stand on the brake to slow the vehicle down,

But it does so eventually.

Let’s take a better check out diagnosing the foremost frequent causes and,

Solutions related to a hard brake pedal.

Also, read:

- Difference between Drum Brake and Disc Brake

- What is the Brake Booster? How Brake Booster Works?

- DISC BRAKES: CONSTRUCTION, WORKING PRINCIPLE, TYPES, AND ROTOR MATERIALS

VACUUM PRESSURE

Vacuum or really lack of vacuum pressure is the most common cause of a hard brake pedal,

And therefore the first thing to look at when a hard pedal is present.

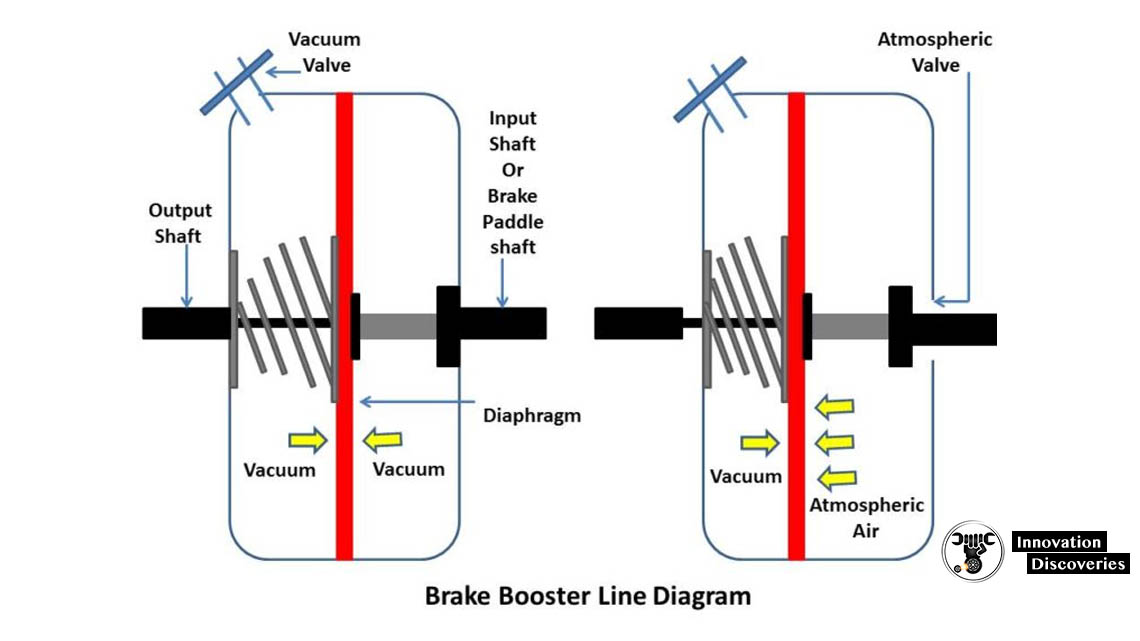

Any brake booster (whether from Master Power or

Any other supplier) needs a vacuum source to operate.

In gasoline-powered cars,

The engine provides a partial vacuum suitable for the brakes’ power booster. The booster requires ”18′ of vacuum to operate at full efficiency.

Without the proper vacuum level, a brake booster will get a progressively harder pedal

And eventually, end up at a point where you feel like you are pushing against a wall. Your brake system’s booster

Works by a series of diaphragms inside the booster and air on both sides of the diaphragm. An improper amount of vacuum creates a scenario,

Where the diaphragms can’t move the pushrod into the master cylinder. When this happens, the pedal gets harder.

Also, read:

If sufficient vacuum isn’t being supplied within the booster,

You may have to consider installing an electric vacuum pump,

Or canister depending on how far below 18-inches the vacuum pressure has dropped. An external vacuum pump is an electric motor built to provide a vacuum to the booster that your engine can’t provide. It plumbs into the brake system using a vacuum hose going from the booster directly to the pump. This completely removes the engine from the equation and provides the proper vacuum level to the system.

Read More:

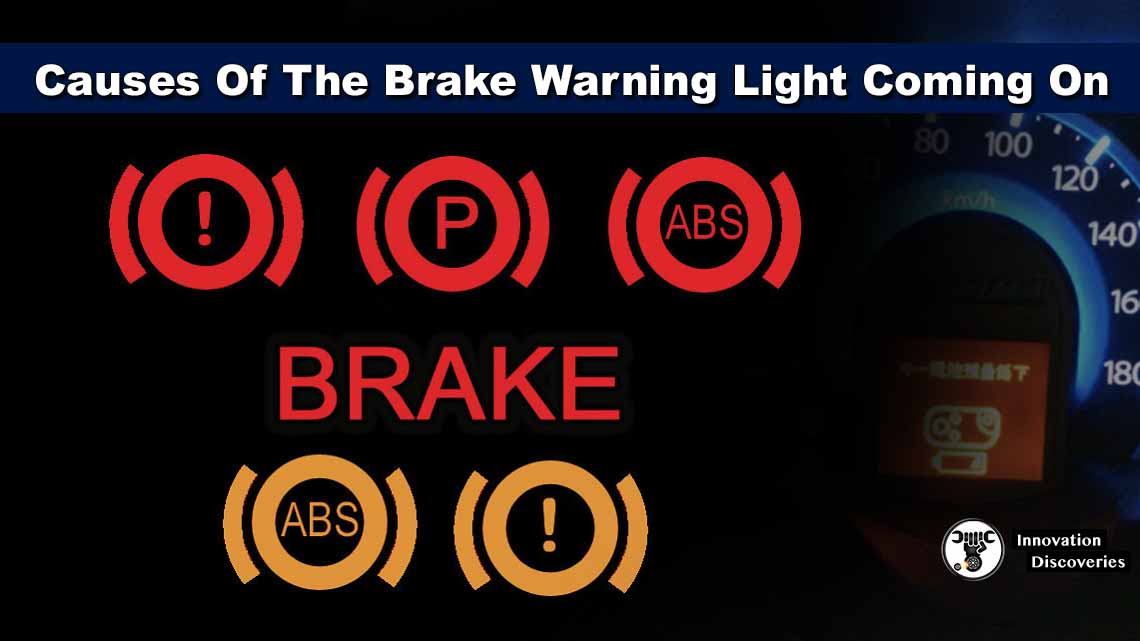

- Causes Of The Brake Warning Light Coming On

- Electronic Brakeforce Distribution (EBD)

- Here’s Exactly How Hot Your Brakes Get When You Pull the Handbrake

Before jumping directly to a vacuum pump though,

There are a couple of quick and simple things that should be investigated. You should look at things like the hose supplying the booster from the engine. The most common problem we see is a person will be using a 3/8” fuel hose. Fuel hose is designed to resist expansion but won’t resist sucking closed as vacuum hose will. The proper hose to ask for is 11/32” vacuum hose.

If you are running a fuel hose,

When the engine is running and pulling a vacuum on the booster,

There is a good chance that the hose is sucking shut. If it is sucking shut, there is no chance of a vacuum being pulled on the unit.

See More:

An obstruction in the hose could also be limiting vacuum contributing to the brake problem,

So, be sure to check this area thoroughly. Another quick check would be the location of the vacuum source within the engine,

And the fittings used to install the vacuum hose.

We have seem many instances where people will use a port that is way too small,

Not allowing the engine to pull the proper vacuum through the fittings. Make sure you are using a port in the intake manifold that is no smaller than a 3/8” NPT. If all of those things check out within the system,

Another thing to look at is the actual size of the vacuum booster. Not enough assistance within the booster can cause a problem. A brake booster must be properly sized to the automobile that it is installed on.

If the booster isn’t of the proper size, proper assist can’t be provided and,

Go Pro For More HighlightsThe pedal will become hard because the system is tapped out. At this point, the pedal becomes hard as the booster has done all it can but the vehicle still needs more. This can be the scariest of all scenarios when driving a vehicle.

The vacuum present in the booster is the first,

And the most obvious problem to consider. Brake boosters require a minimum 18-inch vacuum to operate optimally. The further you dip below this the harder the brake pedal becomes.

Following our advice above should set you on the right path,

But as always, we are here to get you the right equipment if you need it.

VALVING ISSUES

Another culprit liable for a tough pedal might be the mixture valve,

And especially the Pressure Differential Valve within that valve. This valve is there for safety reasons but can cause headaches if things aren’t working properly.

The Pressure Differential Valve is meant to maneuver should pressure

Drop on the front side of the valve versus the rear side and the other way around. When this happens, fluid coming from the brake cylinder hits a wall.

Because the brake fluid can’t be compressed, the pedal becomes rock hard. You continue to can generate moderate pressure on the “good” side of the valve

Therefore allowing the car to be driven during a limp home scenario. This condition is what’s commonly mentioned as and referred to as a tripped valve.

If your pressure differential valve has been “tripped”

It must then be re-entered by equalizing pressure on each side of the valve. this is often accomplished by getting the valve to maneuver the right direction and,

Thus, putting the valve back within the center. Of course, the matter that caused the valve to “trip” must even be corrected at this point. If your vehicle has OEM disk brakes it’s highly likely

That it also utilizes some sort of valving within the brakes.

During this case, an equivalent valve that operates the red light on your dash – the pressure differential switch – might be the matter creating a tough pedal.

Follow our plan above on the proper path, but as always, take care and use know if you’re unsure. Properly operating brakes are essential for safety.

We are always here to urge you the proper equipment or additional help if you would like it.

PEDAL RATIO

Previously in this series,

We addressed a hard brake caused by a tripped pressure differential valve,

As well as insufficient vacuum pressure creating a too-hard brake pedal.

Here we take up pedal ratio essentially the relationship

Between your brake pedal length and where it pivots;

An issue that comes to light with some regularity when drivers experience a hard brake.

Pedal ratio is overlooked by most people as a potential root cause of a stiff pedal.

This is less of a problem with later muscle cars and,

More of a problem in earlier street rods when the booster/master is mounted under the vehicle. However, the pedal ratio can be as big a problem in either case,

So, it must be considered as a potential cause for a hard brake pedal.

The pedal ratio refers to the relationship between the pedal’s pivot points and,

The length of the brake pedal. The pedal is used as a lever to apply motion to the booster

(Or directly to the master cylinder if your car does not have a power booster)

Based on the length of the pedal.

If the pedal ratio is incorrect by as little as 1/4”,

This can allow too little pushrod to move through to the booster. This, in turn, prevents the booster from moving the piston into the master cylinder.

The hard pedal you are feeling is the bottoming out of the pedal and,

Its movement

But leaving stroke within the master cylinder and,

Therefore, brake pressure at the wheels. Correcting the pedal ratio can be sometimes

Difficult if it means moving the pedal pivot.

Read More: Replacing a master cylinder and servo unit

The corrective action though can sometimes be as simple as relocating the

A connection point of the pushrod between the pedal and the booster.

For reference, a power system should have a pedal ratio of 4:1,

While a manual brake system should be 6:1. Pedal ratio is not one of the more obvious causes of hard brake pedals. This is particularly true if the brackets

And pedals are all factory installs.

Go Pro For More HighlightsHowever, in cases where modifications have been made,

This definitely may be an area worth looking into.

Unfortunately during some brake modification processes,

Pedal ratio is not taken into consideration.

After having new brake components installed,

You will need to reconfigure the pedal ratio to ensure optimum braking performance.

Use the tips above or consult a professional mechanic.

SOMETHING ELSE

If it’s not associated with the “top 3 reasons” behind a tough pedal,

There are several additional possible problem spots for you to look at and troubleshoot. A radical inspection of the entire system should assist you to identify any such underlying issue. During a rear drum brakes car, a possible area of concern is often your wheel cylinders. As we mentioned before within the article on valving,

The wheel cylinders can similarly create a pressure differential problem. If a wheel cylinder isn’t moving or,

It is frozen, the hydraulic brakes fluid reaches that very same wall. When that happens,

The pedal won’t move any longer because it’s unable to compress a fluid.

Read More:

- Checking and removing a clutch master cylinder

- Common Causes of Car Pulling to the Right or Left When Braking

This will be an easy repair if that’s the case.

It’s also important to seem at what proportion brake fluid is within the system,

And confirm it’s not overfilled.

If the fluid can’t return completely to the brake cylinder,

You’ll have a scenario where the system is hydraulically locked. Like most complex systems, there any number of things,

Go Pro For More HighlightsWhich will fail within the brakes of an influence booster equipped vehicle. Start by analyzing the foremost likely scenarios and problem spots first.

More often than not, a hard-to-push pedal is directly related to the facility booster,

Brake cylinder or pivot point ratio of your pedal. Through a process of elimination, you’ll likely spot the explanation for the hard pedal,

Then take steps to repair it. If you’re unsure of the right action to require,

Engage a knowledgeable mechanic.

Article Courtesy of – Master Power Brakes.

6 Comments