A Turbocharger is a device that is used to increase the power of the engine or one can say the efficiency of an engine by increasing the amount of air entering into the combustion chamber.

More air into the combustion chamber means more amount of fuel will be admitted into the cylinder and as a result, one will get more power from the same engine if the turbocharger is installed in it.

Very simply, a turbocharger is a kind of air pump taking air at ambient pressures (atmospheric pressure), compressing to a higher pressure and passing the compressed air into the engine via the inlet valves.

At the present time, turbos are used mainly on diesel engines, but there is now a move towards the turbocharging of production petrol engines.

The amount of engine that actually goes into the engine’s cylinder, compared with the theoretical amount if the engine could maintain the atmospheric pressure, is called volumetric efficiency and the aim of the turbocharger is to improve an engine’s volumetric efficiency by increasing density of the intake gas.

The turbocharger draws the air from the atmosphere and compresses it with the help of centrifugal compressor before it enters into the intake manifold at increased pressure.

This results in more amount of air entering into the cylinders on each intake stroke.

The centrifugal compressor gets power from the kinetic energy of the engine’s exhaust gases.

COMPONENTS OF TURBOCHARGER

The turbocharger has three main components

- The turbine, which is almost a radial inflow turbine.

- The compressor is almost a centrifugal compressor.

- The center hub rotating assembly.

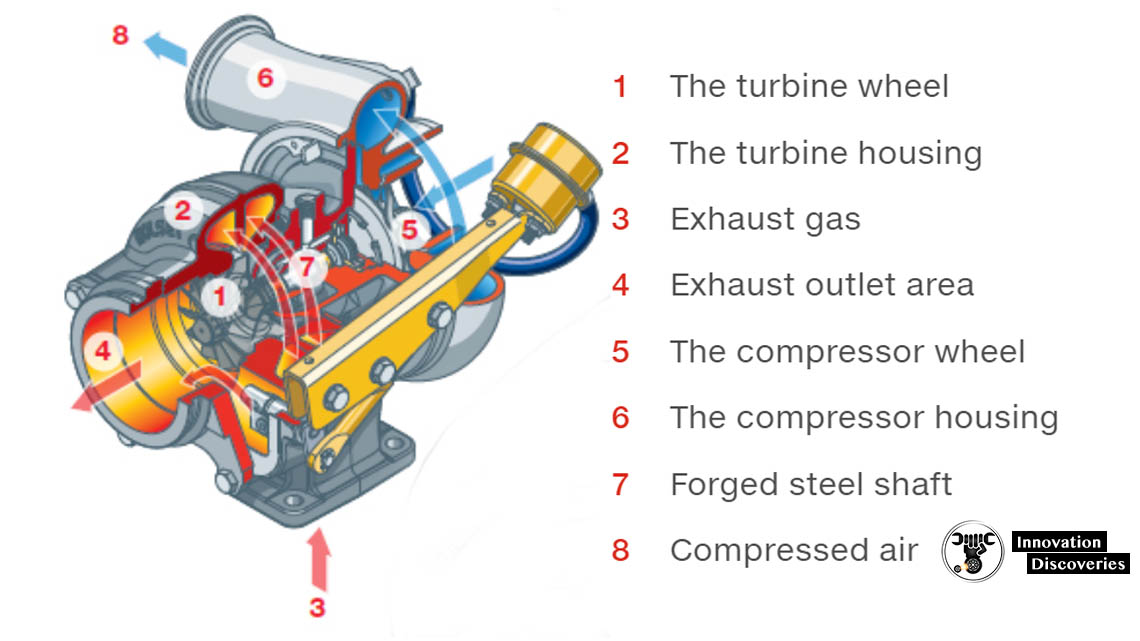

A turbocharger is made up of two main sections: the turbine and the compressor.

The turbine consists of a turbine wheel and turbine housing.

It is the job of the turbine housing to guide the exhaust gas into the turbine wheel.

The energy from the exhaust gas turns the turbine wheel, and the gas then exits the turbine housing through an exhaust outlet area.

The compressor also consists of two parts: the compressor wheel and the compressor housing.

The compressor’s mode of action is opposite that of the turbine.

The compressor wheel is attached to the turbine by a forged steel shaft, and as the turbine turns the compressor wheel, the high-velocity spinning draws in air and compresses it.

The compressor housing then converts the high-velocity, low-pressure air stream into a high-pressure, low-velocity air stream through a process called diffusion.

The compressed air is pushed into the engine, allowing the engine to burn more fuel to produce more power.

WORKING PRINCIPLE

Click 2nd page ———-

9 Comments