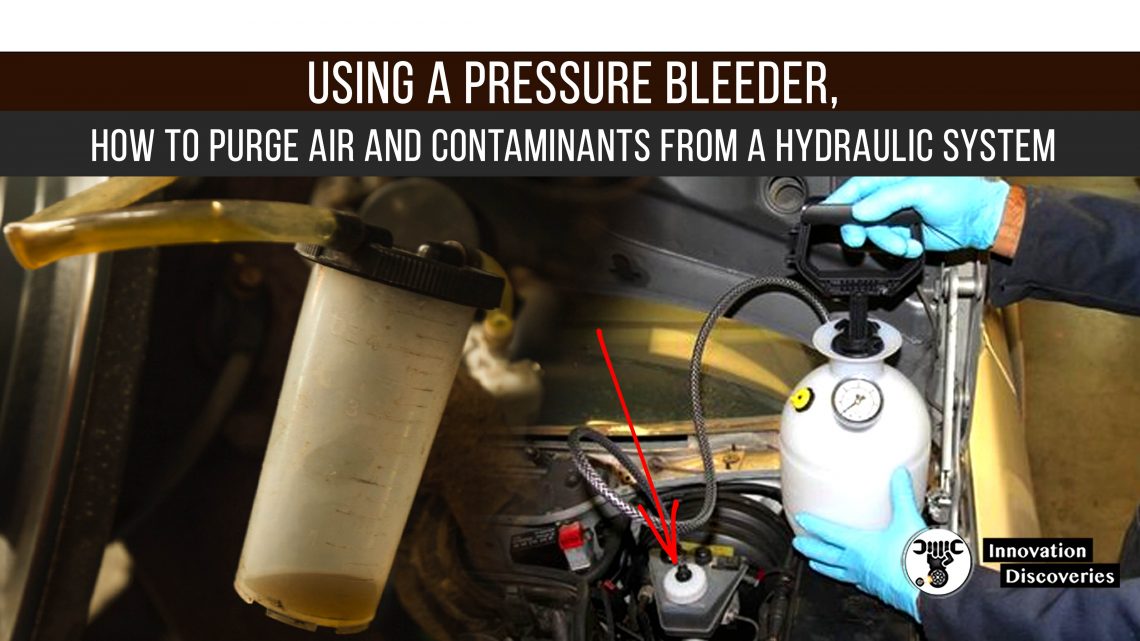

Pressure bleeders may be used to purge air or contaminate a vehicle’s hydraulic brake system very effectively.

The fluid is stored in a sealed chamber in the bleeder, preventing contamination of the fluid.

A diaphragm is used to separate the air chamber from the fluid chamber. Air is introduced into this chamber through a Schrader valve.

Damage may be done to the diaphragm if excessive air is applied when the tank is empty.

After filling the fluid chamber of the pressure bleeder with the proper fluid, air must be bled out of the fluid chamber so that no air will be introduced into the brake system through the bleeder hose connection.

Holding the end of the hose above the bleeder and opening the outlet valve until all the air is removed can do this.

With the use of appropriate adapters, the pressure bleeder hose is connected to the master cylinder.

The outlet valve is then opened pressurizing the hydraulic system with the pressure in the bleeder. Be sure adaptors fit properly since brake fluid will harm paint.

Download: BRAKES, BRAKE CONTROL AND DRIVER ASSISTANCE SYSTEMS: FUNCTION, REGULATION AND COMPONENTS

Bleeding the air out:

The bleeder screws at the wheels should then be opened allowing fluid to flow until the air in the hydraulic system is eliminated.

This should be done at low pressure 10 to 15 PSI, so as not to agitate contaminants in the system and/or mix the air with the fluid.

Flushing contaminates out:

The lines from the master cylinder should be opened first, to flush any contaminants from the master cylinder.

The bleeder screws at the wheel are then opened allowing fluid to flow until contaminates in the hydraulic system are eliminated.

This should be done at high pressure, 25 PSI for conventional systems and 35 PSI for ABS systems, to agitate the contaminates in the system or the fluid and to flush them out.

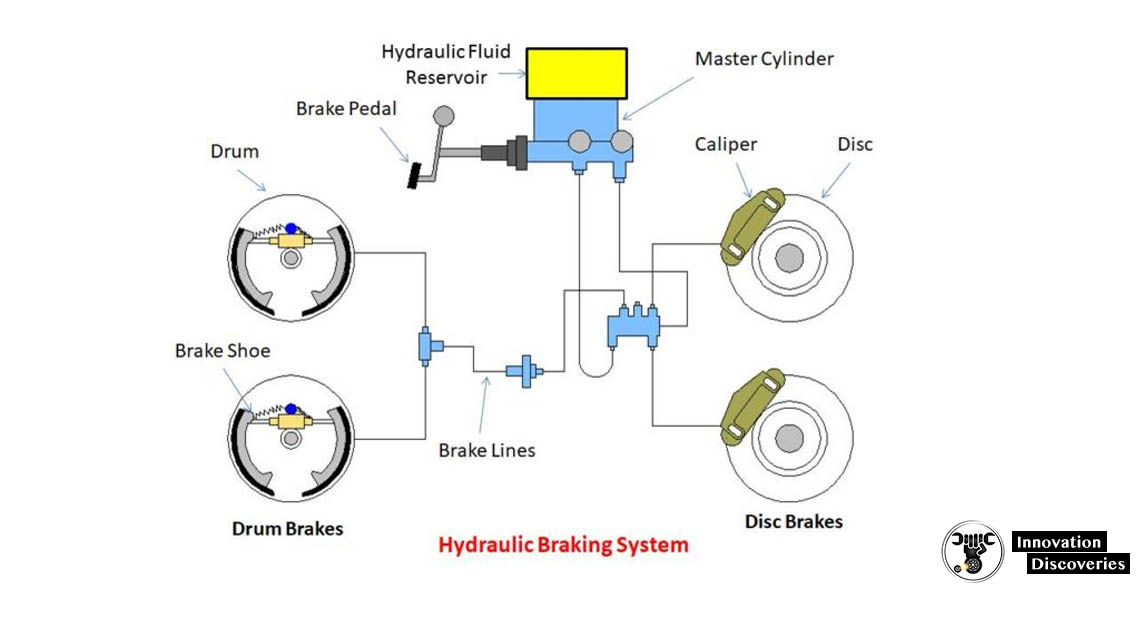

READ: HOW HYDRAULIC BRAKE WORKS?

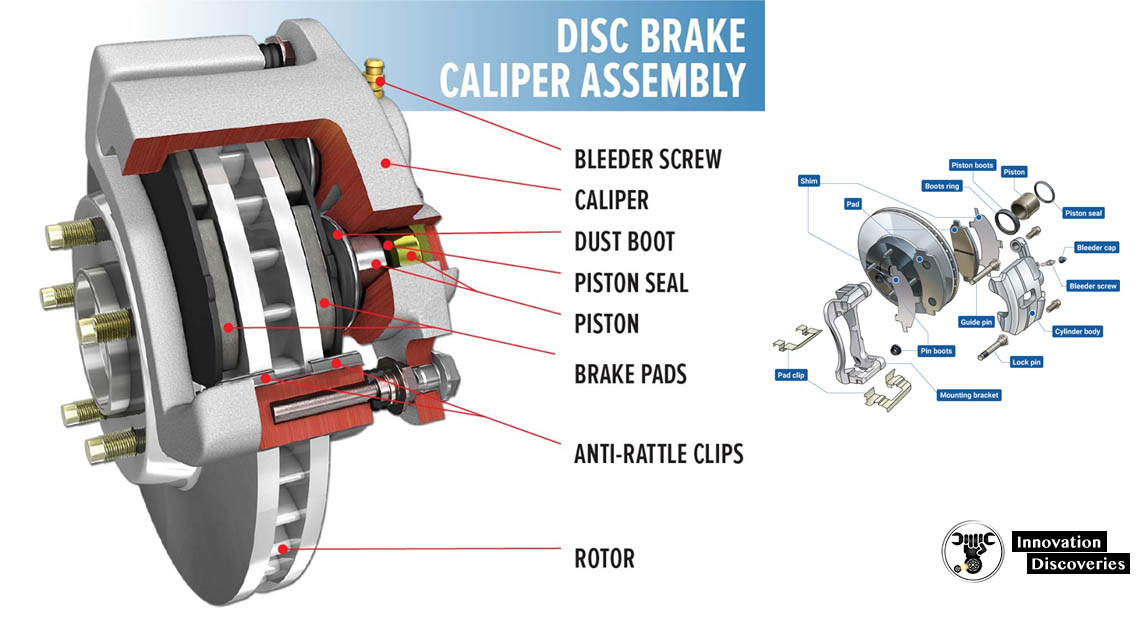

DON’T MISS | DISC BRAKE CALIPER ASSEMBLY

Read More:

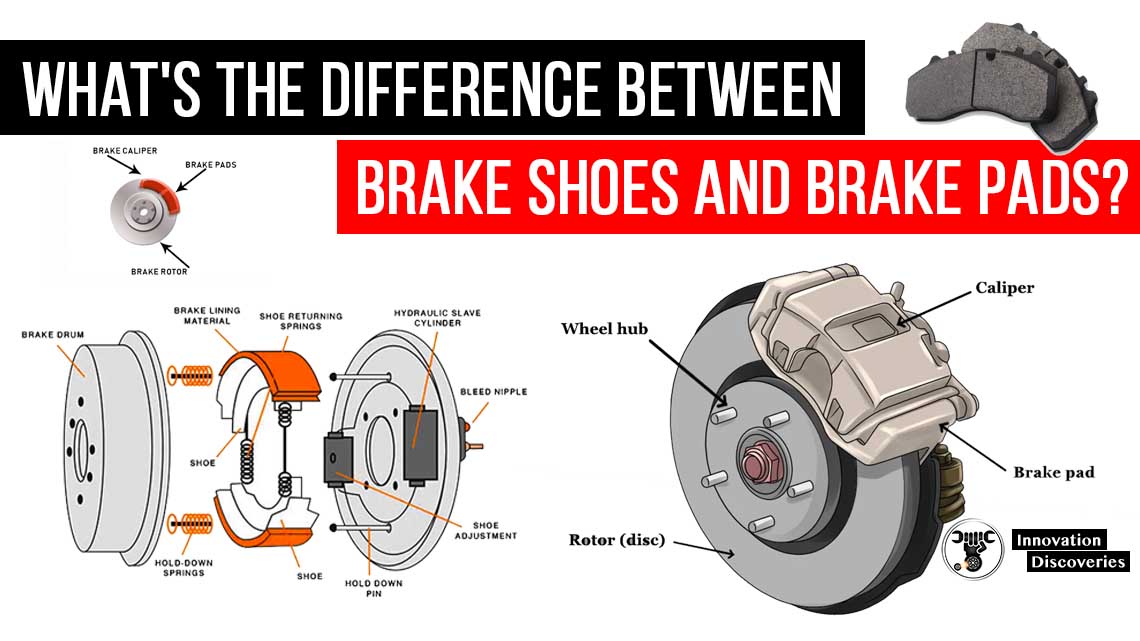

Also, read: DIFFERENCE BETWEEN DRUM BRAKE AND DISC BRAKE

Also, read: The Importance of Measuring Brake Pad Thickness

More About Braking Systems

- Top 5 Causes of Steering Wheel Shakes at Low and High Speeds

- HOW HYDRAULIC BRAKE WORKS?

- AIR BRAKE SYSTEM: COMPONENTS, WORKING PRINCIPLE, AND APPLICATIONS

- HOW DOES REGENERATIVE BRAKING WORK?

- 8 REASONS YOUR CAR IS MAKING GRINDING NOISE WHEN BRAKING

- Regenerative Braking System

- JAKE BRAKE VS. EXHAUST BRAKE: WHICH IS BETTER?

- SQUEALING BRAKES AT LOW SPEED: CAUSES AND SOLUTIONS

- TROUBLESHOOTING A HARD BRAKE PEDAL

- CONVERT DRUM BRAKES TO DISC BRAKES IN 3 STEPS!

- CAUSES OF THE BRAKE WARNING LIGHT COMING ON

Visit Forum

Visit Our Friendly Website