A Fuel Injector is a mechanical device that controls the injection of fuel into the combustion chamber of the engine.

Modern fuel injectors controlled electronically with the help of an ECU (Engine control unit).

Injector responsible for the proper mixing of air and fuel and it also controls the pressure and timing of fuel injection.

The requirement of injection of Fuel into the engine after compression Stroke is completed or just before the expansion stroke is started.

- For proper atomization of fuel before entering into the combustion chamber.

- A proper measured quantity of fuel should be delivered for the best economy.

- Injection of fuel into the combustion chamber at a particular interval of time as per requirements.

- Injector controls the quantity of fuel at different speeds and at various load conditions.

- For proper mixing of air and fuel before entering into the combustion chamber.

- In the case of multi-cylinder engines for proper distribution of fuel in all the cylinders.

In automobiles, various types of injectors are used Having almost the same construction and working because of the basic principle of All types of injectors are the same.

A general type of injector is discussed below.

Injector:

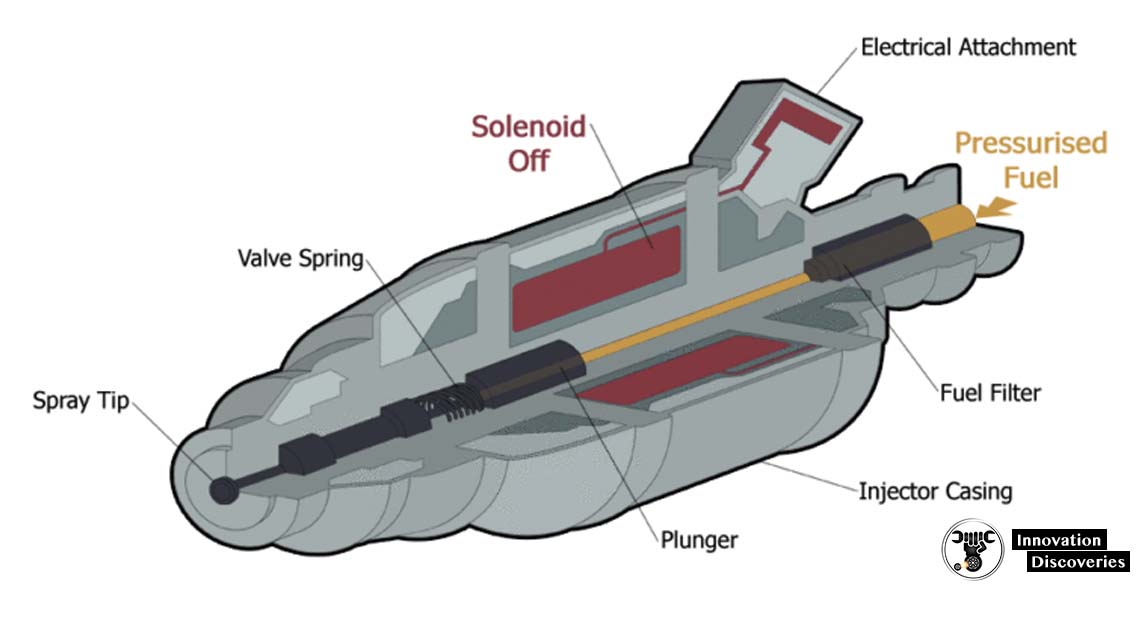

Construction:

The barrel has two radial opposite holes one is for inlet port and other for controlling port for fuel supply.

For varying the quantity of fuel in different strokes and at different speeds a vertical channel attached which extending from the top face of the plunger to an annular groove that is on the upper side of the plunger.

Generally, the top edge is machined in the form of a helix.

This upper end also called a control edge.

During delivery of fuel, The cam rotates due to which piston goes up and supply high pressurized fuel forward this time spring is at its bottom position.

Cam raises the plunger up during the delivery stork and plunger returns he spring back to the bottom position.

Working:

In fuel injection fuel is drawn from the fuel tank using a fuel pump then pressure is checked by fuel regulators.

Before entering into the combustion chamber fuel is goes through injectors. In the case of multi-cylinder engines, fuel is divided using fuel rails to supply an equal amount of fuel in all the cylinders of the engine.

Working of the injector is very simple like a reciprocating pump when the plunger is at rest position i.e. at the bottom the fuel goes through the inlet port into the barrel and fills the whole space into the cylinder.

After that when the cam rotates; the plunger starts moving up and closes the inlet port and pushed the fuel up and injects the fuel into the combustion chamber of an engine through a nozzle.

Nozzle injects the fuel at sufficient pressure with high velocity because at a high velocity smaller droplets will form or better atomization is done. Smaller droplets have less momentum so no chances of the penetration in the body of the engine.

The injection process continues until the end of the upward stroke of the plunger and the lower end of helix uncovers the spill port.

After the uncovering of the spill port, the pressure of the fuel in the barrel drops down when fuel travels back to the suction chamber through the vertical slots on the plunger.

At that time both the spring-loaded injector and spring-loaded delivery vales are closed and stop the injection process.

This closing process is necessary to avoid further addition of fuel into the combustion chamber. This process continually repeated while working on the engine.

Types of injectors:

The main types of injectors which are used in automobiles are as follow

Automatic injectors:

Now day’s automatic injectors are used worldwide in automobiles because of their fast and accurate working.

Almost all the automatic injectors are the same in construction these are consist of a spring-loaded needle valve that is hydraulically operated by the fuel pressure.

This pressure lifts the spring-loaded needle; the spring force closes the needle when the pressure drops below a certain limit or required limit.

Blast injectors:

This is an old type of fuel injection used in automobiles.

The quantity of fuel is measured by the fuel pump or a special mechanism assembled for it after measurement fuel is pumped to the fuel valve by a camshaft which driven the fuel pump.

A special type of mechanism used for opening the fuel valve which controls the timing of injection. This mechanism is run by the camshaft which opens and closes the fuel valves.

Secondly, the fuel valves are also connected with the pressurized airline through a compressor that supplies air at high pressure generally it is up to 65 bar.

When camshaft rotates the fuel valves are open and the blast air mix with fuel and atomize it after that a fine spray of fuel goes into the combustion chamber.

Mechanical injectors:

This is an example of advancement in technology in the field of a fuel injection system.

It is almost similar to the blast injectors as above discussed but the only difference in some mechanisms which are installed in mechanically operated injectors.

These are run by camshaft, gears and some special types of cams.

All these combine work and controls the time of fuel injection by opening and closing of the valve.

Applications:

Injectors are used in almost every automobile for example in cars, buses, trucks, and tractors.

Injector delivers the fuel into the injection system of automobiles and it is located on the head of the engine or sometimes threaded into the combustion chamber with the nozzle inside.

This is all about injector construction, working, types, etc. If you have any queries regarding this article, ask by commenting.

Related Posts – How to make spark plug wires

Difference Between Crankshaft And Camshaft

INTER-COOLER: TYPES AND WORKING PRINCIPLE

REPAIR GUIDE FOR DENSO COMMON RAIL INJECTOR REPAIR

DISCLAIMER

THE FOLLOWING DOCUMENT IS BASED ON THE RESULTS AND EXPERIENCE GAINED FROM STRIPPING, REBUILDING AND TESTING NEW GENUINE DENSO INJECTORS USING HARTRIDGE ALL‐MAKES TEST EQUIPMENT.

THE INFORMATION CONTAINED WITHIN IS NOT INTENDED FOR USE AS A SUBSTITUTE TO THE GENUINE DENSO REPAIR PROGRAM.

IT’S CONTENT IS FOR INFORMATION PURPOSES ONLY AND IS TO BE USED AS A GUIDE AND INTRODUCTION TO DENSO COMMON RAIL INJECTOR REPAIR.

DIESEL DISTRIBUTORS AUSTRALIA PTY LIMITED AND DIESEL DISTRIBUTORS LIMITED IN NEWZEALAND ACCEPTS NO RESPONSIBILITY FOR ANY DAMAGE OR INJURY THAT MAY OCCUR FROM THE UNAUTHORISED REPAIR/ADJUSTMENT OF DENSO CR INJECTORS.

Download Link

Read More:

- HOW TO CHANGE COOLING-FAN SWITCH IN YOUR VEHICLE

- HOW TO REPLACE DEFECTIVE HOSES AND WEAKENED COOLANT IN AN AUTOMOBILE

- WORKING OF THERMOSTATS

Also, read:

Visit Forum

Visit Our Friendly Website

3 Comments