Introduction

Internal combustion engines are the heart of many vehicles and machines, powering everything from cars to lawnmowers. Among the various types of engines, two prominent designs stand out: the 4-stroke engine and the 2-stroke engine. These engines differ in their operation, efficiency, emissions, and applications.

In this article, we’ll delve into the intricacies of both engine types to understand their characteristics and uses better.

The Basics: How They Work

4 STROKE ENGINES

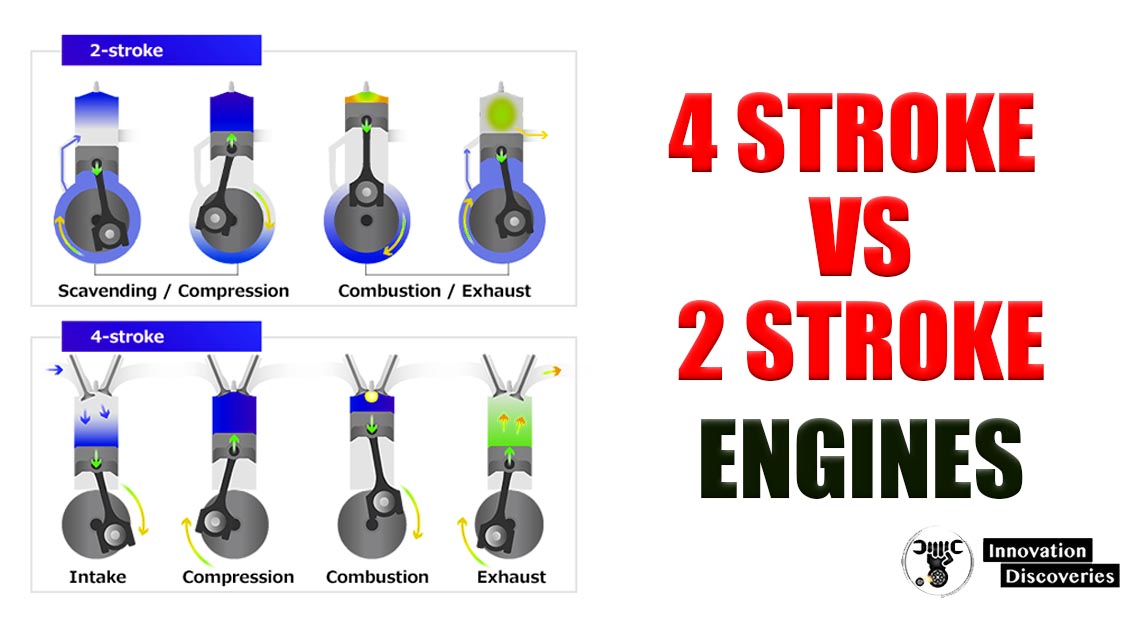

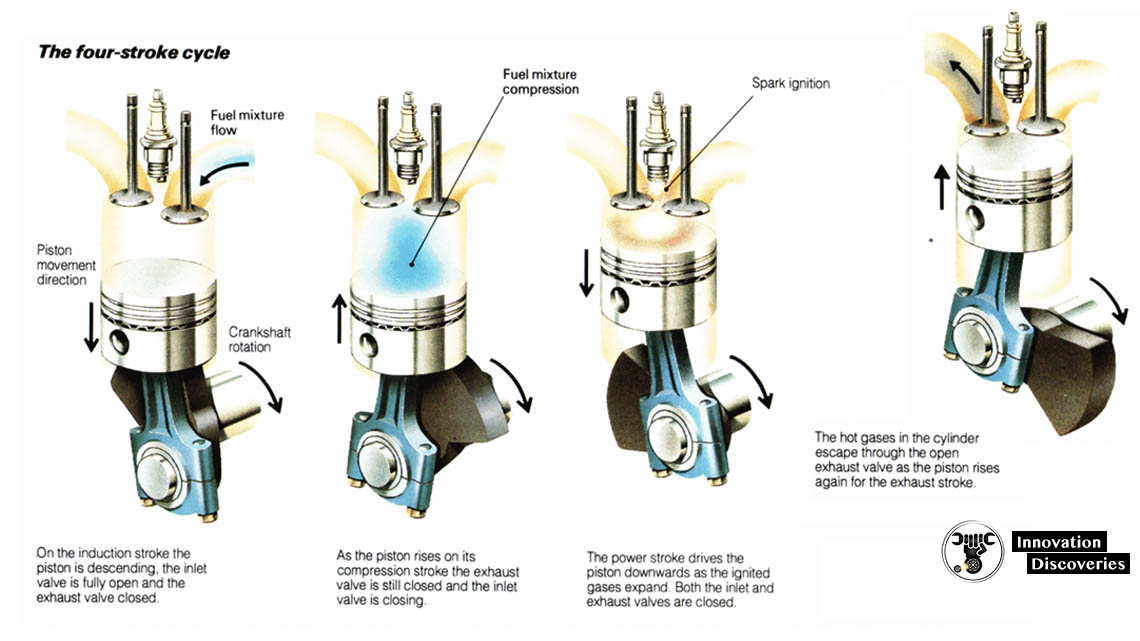

The 4-stroke engine operates through a systematic four-step process: intake, compression, combustion, and exhaust. Each of these steps is accomplished by a distinct piston movement within the engine cylinder.

Intake involves drawing the air-fuel mixture into the cylinder, compression compresses this mixture, combustion ignites the mixture to generate power, and exhaust releases the burnt gases.

2 STROKE ENGINES

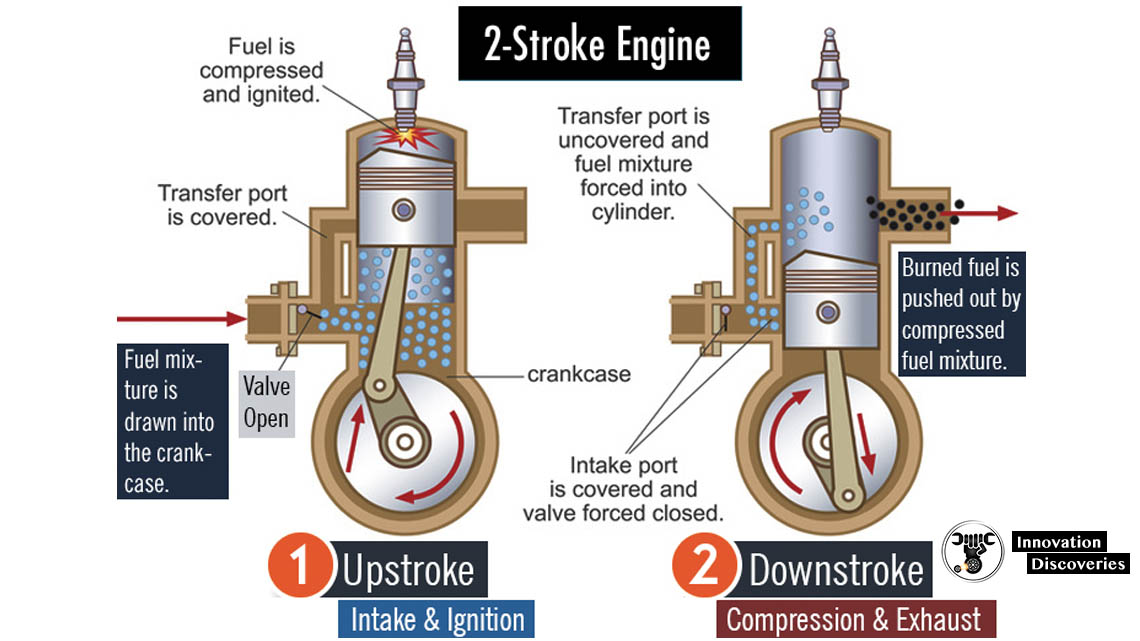

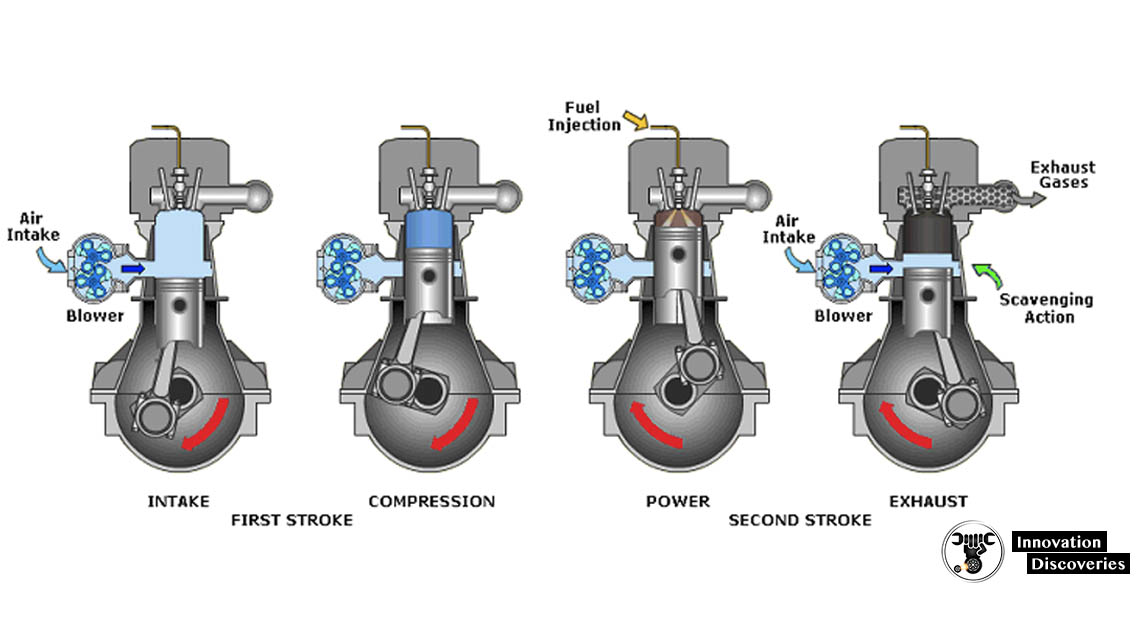

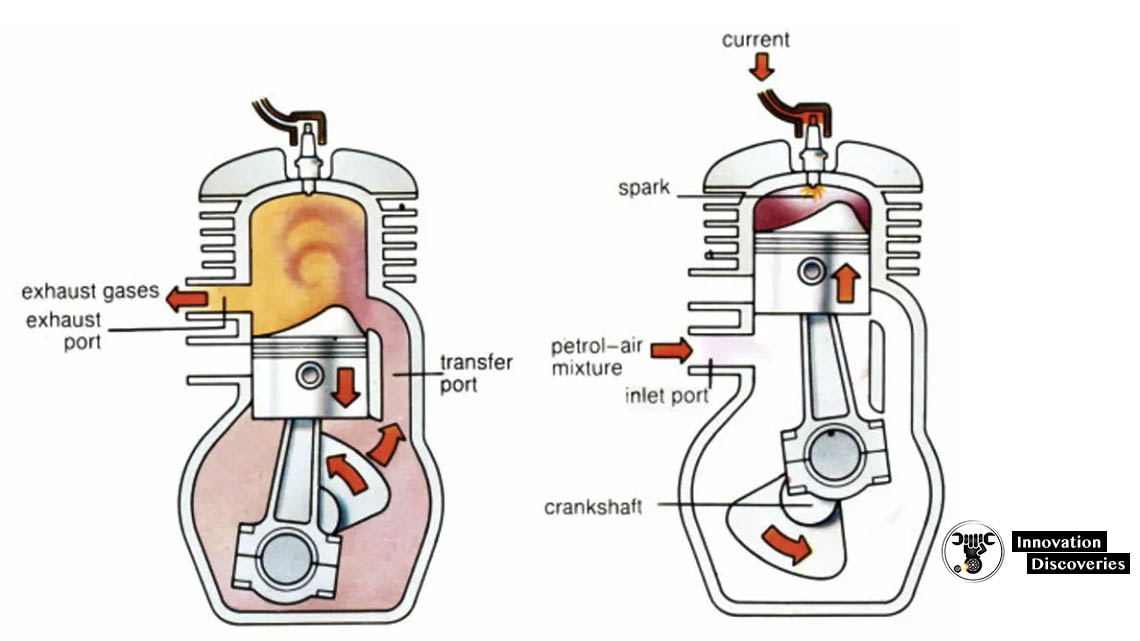

In contrast, the 2-stroke engine completes its power cycle in just two strokes: compression and combustion/exhaust.

These engines typically employ ports or reed valves for intake and exhaust processes, effectively combining the functions of the four strokes of the 4-stroke engine into two.

Efficiency and Power

4-Stroke Engine:

4-stroke engines are renowned for their fuel efficiency and power output. Due to their more controlled combustion process and separate intake and exhaust strokes, they achieve better thermal efficiency and produce more power per stroke.

2-Stroke Engine:

However, 2-stroke engines often fall behind in terms of efficiency and power. Their design and operation result in a less controlled combustion process, leading to lower thermal efficiency and reduced power output compared to their 4-stroke counterparts.

Emissions and Environmental Impact

4-Stroke Engine:

The 4-stroke engine has an upper hand in terms of emissions. Its separate intake and exhaust strokes facilitate better scavenging of exhaust gases, resulting in lower emissions of harmful pollutants.

2-Stroke Engine:

On the other hand, 2-stroke engines are notorious for producing higher emissions. The fuel-oil mixture used in these engines can escape through the exhaust, leading to increased levels of unburned hydrocarbons and particulate matter.

Maintenance Considerations

4-Stroke Engine:

When it comes to maintenance, 4-stroke engines often require less frequent attention. They feature a separate lubrication system, reducing the need for frequent oil changes. Their controlled combustion also contributes to longer-lasting components.

2-Stroke Engine:

In contrast, 2-stroke engines demand more frequent maintenance. The mixing of oil with fuel necessitates careful management, and components like spark plugs and exhaust systems require closer monitoring due to the simpler scavenging process.

Application Variations

4-Stroke Engine:

4-stroke engines find their place in larger vehicles, such as automobiles, trucks, and industrial equipment. Their efficiency and lower emissions make them ideal choices for these applications.

2-Stroke Engine:

Meanwhile, 2-stroke engines are commonly found in smaller devices like chainsaws, lawnmowers, and small motorcycles. They are favored for their simplicity and lightweight design, making them suitable for applications where efficiency might take a back seat.

Advantages and Disadvantages of 4-Stroke and 2-Stroke Engines

Internal combustion engines come in various designs, each with its own set of advantages and disadvantages. Two popular options are the 4-stroke engine and the 2-stroke engine.

Advantages of 4-Stroke Engines:

- Fuel Efficiency: 4-stroke engines tend to be more fuel-efficient due to their separate intake, compression, combustion, and exhaust strokes. This design allows for better control over the combustion process, leading to improved thermal efficiency.

- Power Output: These engines generate more power per stroke due to their controlled combustion process. This makes them suitable for applications that require higher torque and horsepower.

- Lower Emissions: 4-stroke engines generally produce lower emissions compared to 2-stroke engines. The separate exhaust stroke enables better scavenging of exhaust gases, resulting in reduced emissions of pollutants.

- Durability: The controlled combustion and lubrication systems in 4-stroke engines contribute to longer engine life and less wear and tear on internal components.

- Reduced Maintenance: With separate lubrication systems and more controlled combustion, 4-stroke engines usually require less frequent maintenance, resulting in lower long-term operating costs.

Disadvantages of 4-Stroke Engines:

- Complex Design: 4-stroke engines have more components due to their four distinct strokes, leading to a more complex and heavier design compared to 2-stroke engines.

- Heavier Weight: The additional components and systems make 4-stroke engines heavier, which might not be suitable for applications where weight is a critical factor.

- Lower Power-to-Weight Ratio: Because of their weight and more intricate design, 4-stroke engines can have a lower power-to-weight ratio, affecting their performance in certain applications.

- Higher Initial Cost: The complexity of 4-stroke engines often leads to higher manufacturing and initial costs compared to 2-stroke engines.

Advantages of 2-Stroke Engines:

- Simplicity: 2-stroke engines have fewer moving parts and a simpler design, making them easier to manufacture, maintain, and repair.

- Lightweight: Due to their simpler design, 2-stroke engines are generally lighter than 4-stroke engines, which can be advantageous in applications where weight matters.

- Higher Power-to-Weight Ratio: The lighter weight and fewer components contribute to a higher power-to-weight ratio in 2-stroke engines, making them suitable for applications where power is critical.

- Compact Size: The reduced number of components allows for a more compact engine design, which can be beneficial in tight spaces.

Disadvantages of 2-Stroke Engines:

- Less Fuel Efficiency: 2-stroke engines are often less fuel-efficient than 4-stroke engines due to their less controlled combustion process and the mixing of oil with fuel.

- Higher Emissions: The design of 2-stroke engines leads to higher emissions of pollutants due to the oil-fuel mixture escaping through the exhaust.

- Shorter Lifespan: The simpler design and less controlled combustion process in 2-stroke engines can lead to increased wear and shorter engine lifespans compared to 4-stroke engines.

- More Frequent Maintenance: The need to mix oil with fuel and the simpler components often require more frequent maintenance, resulting in higher long-term maintenance costs.

In conclusion, the choice between a 4-stroke engine and a 2-stroke engine depends on various factors including the application’s requirements, priorities (such as fuel efficiency, power, emissions, and maintenance), and budget constraints.

Careful consideration of these factors will help determine which engine type best suits your needs.

Final Thoughts: Choosing the Right Engine

The choice between a 4-stroke and a 2-stroke engine ultimately depends on the specific needs of the application. If fuel efficiency, power output, and reduced emissions are priorities, a 4-stroke engine might be the better option.

On the other hand, if simplicity, lightweight design, and less demanding maintenance are crucial, a 2-stroke engine could be the way to go.

Both engine types have their own set of advantages and disadvantages.

Engineers, designers, and enthusiasts must carefully evaluate their requirements to make an informed decision that aligns with the intended purpose of the machinery or vehicle.

7 Comments