Condition: Hard Brake Pedal

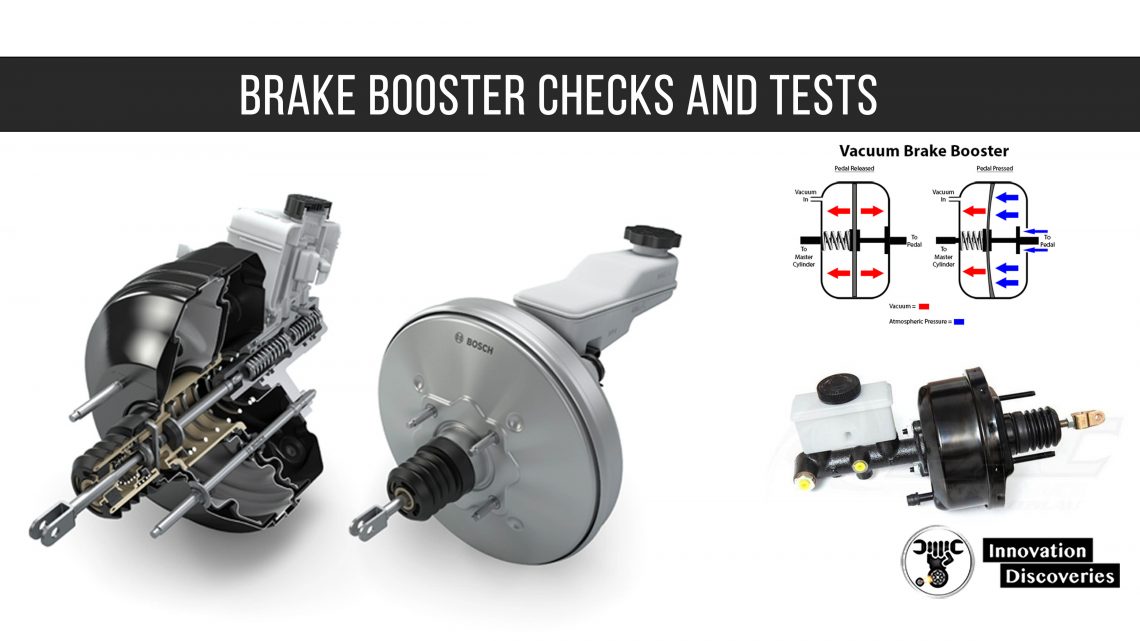

Brake boosters, also called vacuum brake boosters, help improve braking performance and safety.

The brake booster uses an engine vacuum to give the brake pedal added force.

This counteracts the high pressure found in the brake system.

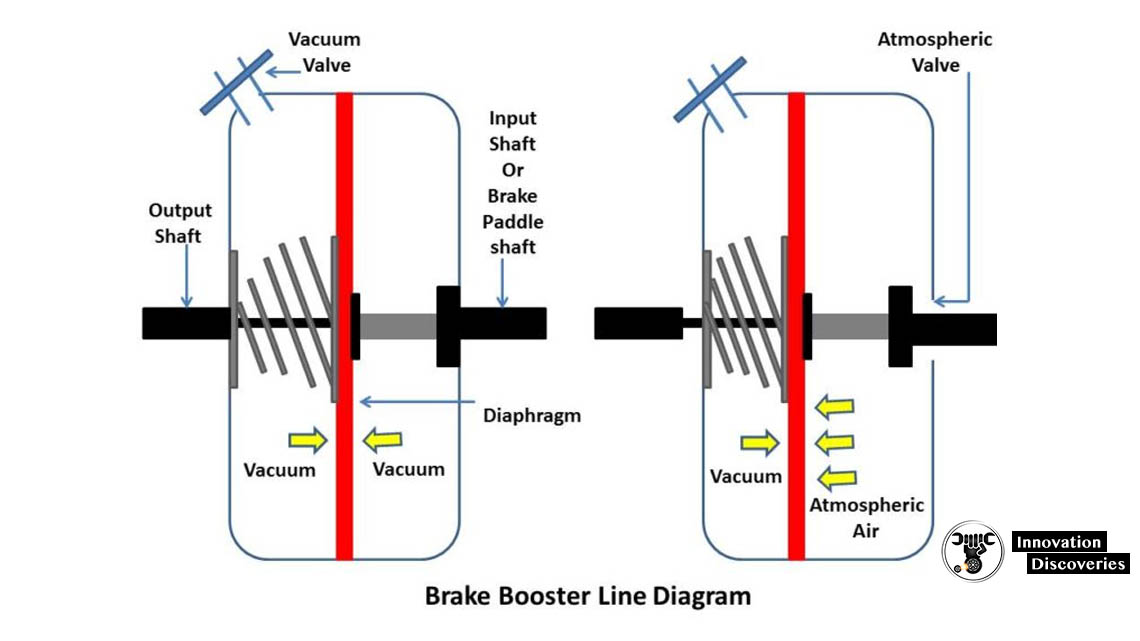

The brake booster itself contains a diaphragm separating the interior into two parts.

Each part of the booster has a partial vacuum.

When you hit the brake pedal, a shaft running from the brake pedal, through the brake booster, and to the master cylinder is pushed forward, opening a valve inside the booster.

This allows air into one side of the vacuum booster. The difference in pressure on this side pushes the rubber diaphragm to the other side of the booster.

This helps push the piston inside the master cylinder, which displaces fluid throughout the brake system and applies the brakes.

READ: What is Brake Booster? How Brake Booster Works?

The brake booster helps increase the force placed on the master cylinder when you hit the brakes.

Without the brake booster, the amount of force it takes for you to stop your car using the brake pedal increases.

Therefore, a malfunction in your brake booster can be the cause of a hard brake pedal.

Repair Procedure: Brake Booster Checks and Tests

Check Engine Vacuum

The first thing you want to do is make sure the engine can produce at least 16 to 18-inches of vacuum.

Use a vacuum gauge to perform this test.

If your engine can’t produce 16 to 18-inches of vacuum, make sure to check the vacuum hose for leaks.

Additionally, make sure you are using the right-sized hose.

Many people assume that the vacuum hose is a 3/8” ID hose. Most vacuum hoses for brake boosters are sized at 11/32”.

If you use the wrong sized hose, you run the risk of the hose sucking shut.

Check-Valve Test

The check valve on the brake booster holds a vacuum inside the brake booster even when the engine is off.

This is a safety feature in the rare case that your engine fails. Without the engine, you lose your vacuum source.

The vacuum stored in the booster- thanks to the check valve- will allow you to stop your vehicle safely.

An easy way to test the operation of the check valve is to disconnect the hose from the brake booster with the engine off.

If you hear a whooshing sound when you disconnect the hose, this is an indicator that the check valve is working.

If you don’t hear that sound, the check valve is defective and will need to be replaced.

Brake Booster Check

With the car turned off, pump the brake pedal four or five times until you get a hard brake pedal.

Continue to hold the brake pedal down with moderate pressure and start the vehicle.

The brake pedal should drop. If this brake pedal remains hard, there is a problem with the brake booster, such as a ripped diaphragm.

READ: What is Brake Booster? How Brake Booster Works?

Read More:

- HOW HYDRAULIC BRAKE WORKS?

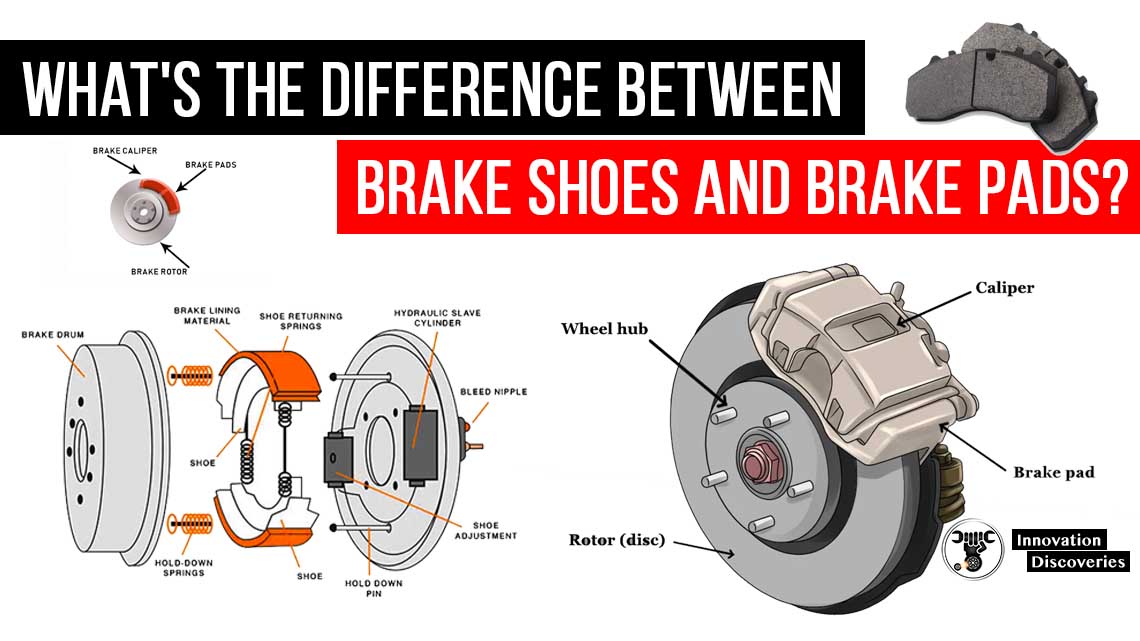

- WHAT’S THE DIFFERENCE BETWEEN BRAKE SHOES AND BRAKE PADS?

- THE IMPORTANCE OF MEASURING BRAKE PAD THICKNESS

- ELECTRONIC BRAKEFORCE DISTRIBUTION (EBD)

AIR BRAKE ADJUSTMENT IN EASY STEPS

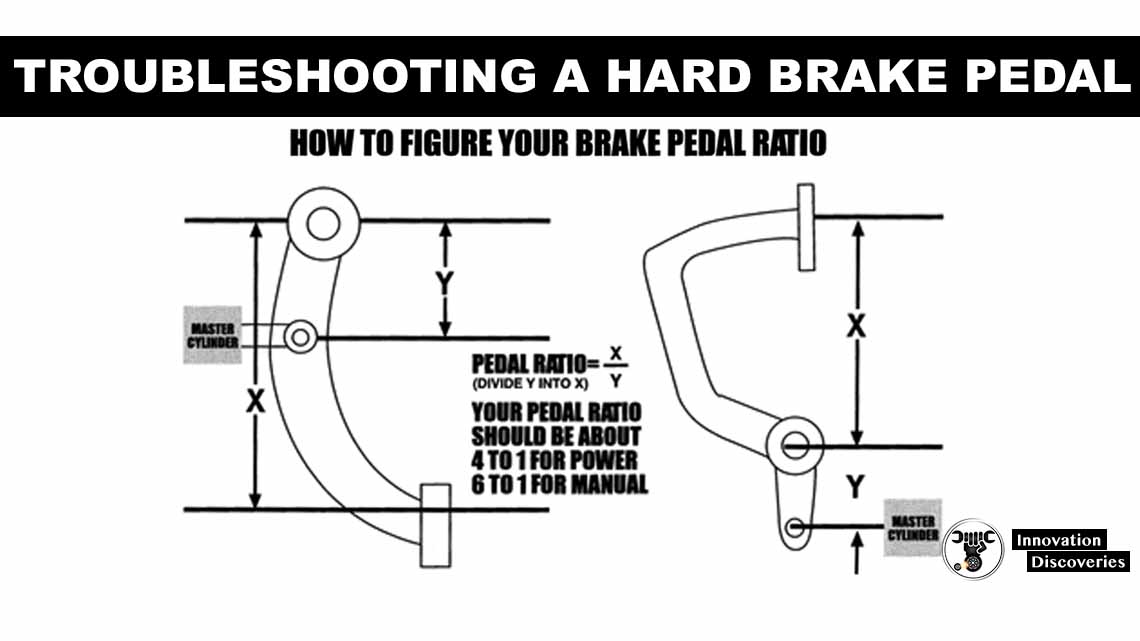

Read: TROUBLESHOOTING A HARD BRAKE PEDAL

Read More: WHAT’S THE DIFFERENCE BETWEEN BRAKE SHOES AND BRAKE PADS?

- RENEWING DRUM-BRAKE SHOES

- DIFFERENCE BETWEEN DRUM BRAKE AND DISC BRAKE

- WHAT IS BRAKE BOOSTER? HOW BRAKE BOOSTER WORKS?

- DISC BRAKES: CONSTRUCTION, WORKING PRINCIPLE, TYPES, AND ROTOR MATERIALS

DISC BRAKES: CONSTRUCTION, WORKING PRINCIPLE, TYPES, AND ROTOR MATERIALS

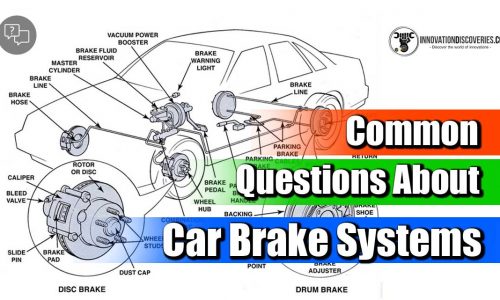

Common Questions About Car Brake Systems

Visit Forum

Visit Our Friendly Website