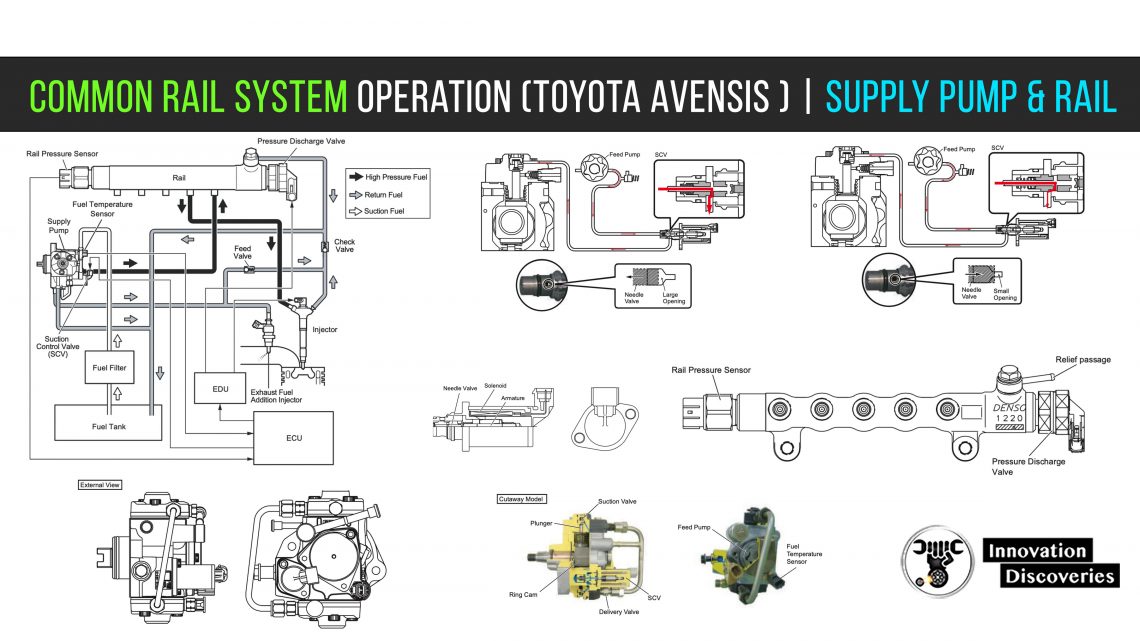

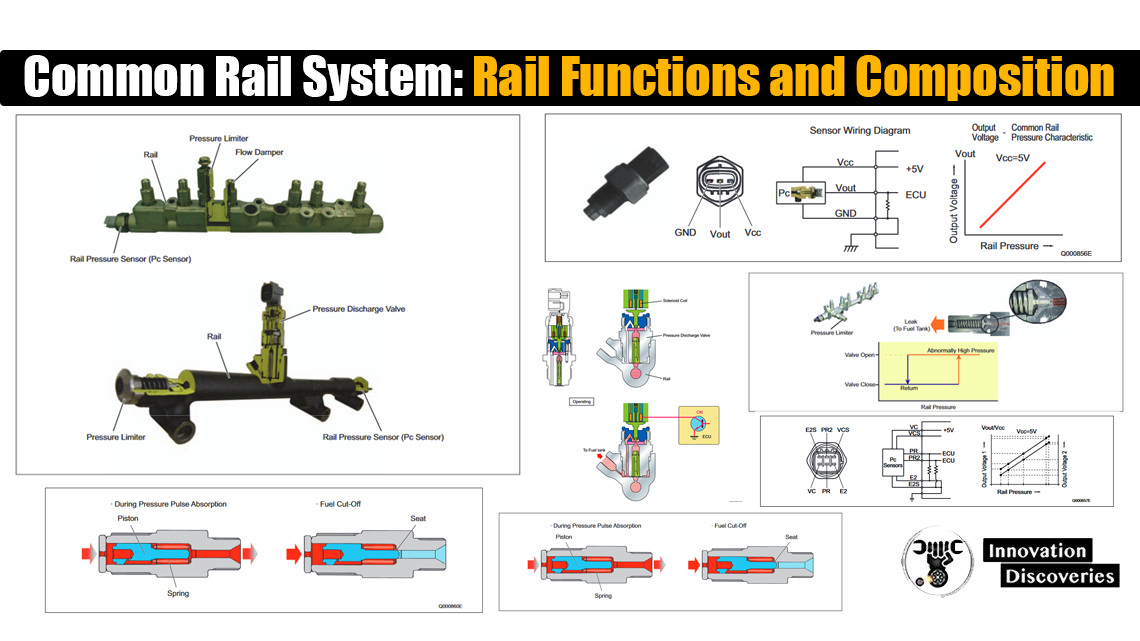

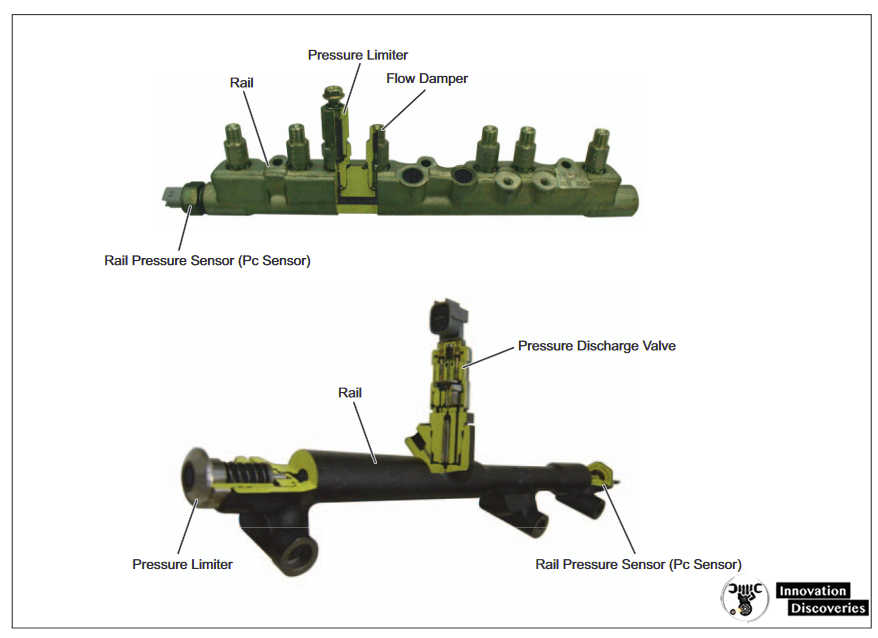

- The function of the rail is to distribute fuel pressurized by the supply pump to each cylinder injector.

- The shape of the rail depends on the model and the component parts vary accordingly.

- The component parts are the rail pressure sensor (Pc sensor), pressure limiter, and for some models a flow damper and pressure discharge valve

Component Part Construction and Operation

| Component Parts | Functions |

|---|---|

| Rail | Stores pressurized fuel that has been pumped from the supply pump and distributes the fuel to each cylinder injector. |

| Pressure Limiter | Opens the valve to release pressure if the pressure in the rail becomes abnormally high. |

| Rail Pressure Sensor (Pc Sensor) | Detects the fuel pressure in the rail. |

| Flow Damper | Reduces the pressure pulsations of fuel in the rail. If fuel flows out excessively, the damper closes the fuel passage to prevent further flow of fuel. Mostly used with engines for large vehicles |

| Pressure Discharge Valve | Controls the fuel pressure in the rail. Mostly used with engines for passenger cars. |

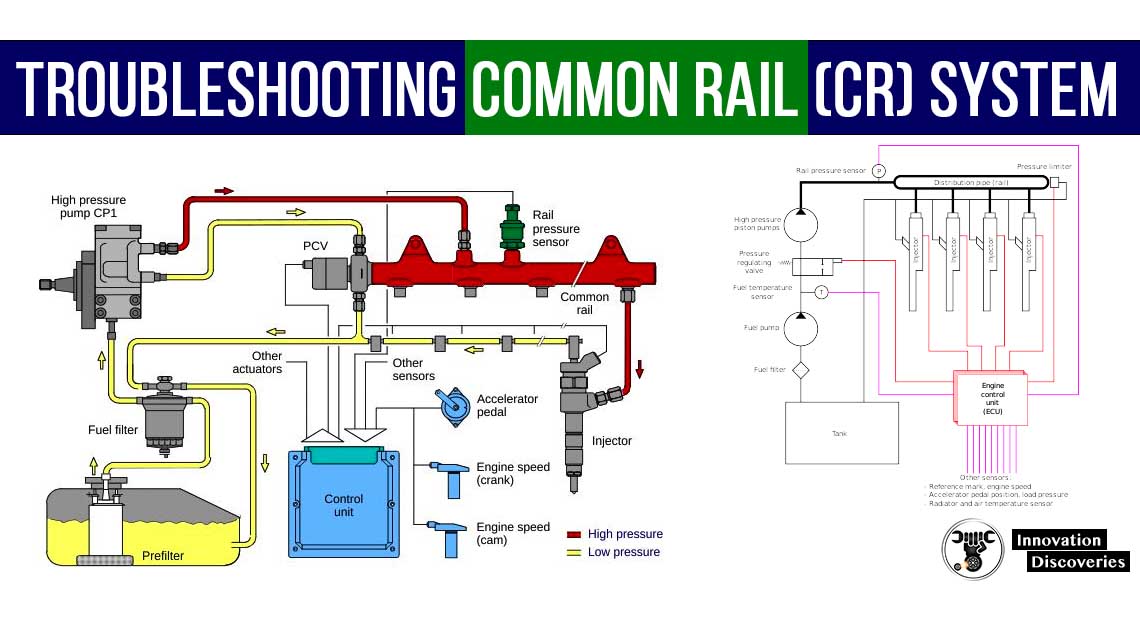

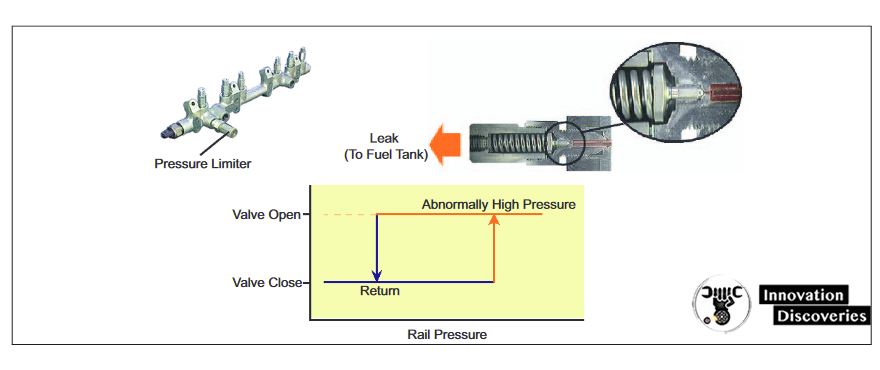

(1) Pressure Limiter

The pressure limiter opens to release the pressure if abnormally high pressure is generated. If pressure within the rail becomes abnormally high, the pressure limiter operates (opens).

It resumes operation (closes) after the pressure falls to a certain level. Fuel released by the pressure limiter returns to the fuel tank.

NOTE : The operating pressures for the pressure limiter depend on the vehicle model and are approximately 140-230MPa for the valve opening pressure, and approximately 30-50MPa for the valve closing pressure.

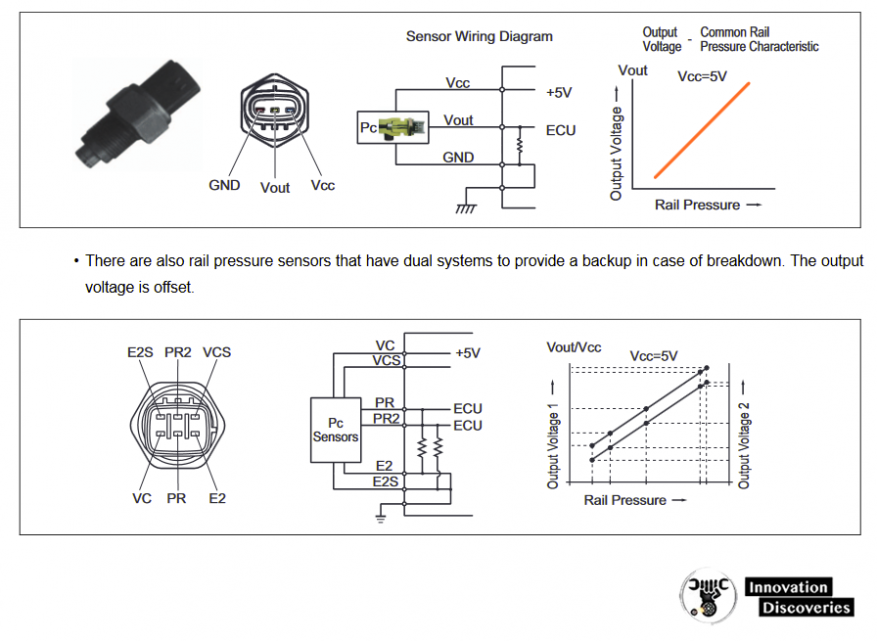

(2) Rail Pressure Sensor (Pc Sensor)

The rail pressure sensor (Pc sensor) is installed on the rail. It detects the fuel pressure in the rail and sends a signal to the engine ECU.

This is a semi-conductor sensor that uses the piezo-electric effect of the electrical resistance varying when pressure is applied to a silicon element.

(3) Flow Damper

The flow damper reduces the pressure pulsations of the fuel in the pressurized pipe and supplies fuel to the injectors at a stabilized pressure.

The flow damper also presents abnormal discharge of fuel by shutting off the fuel passage in the event of excess fuel discharge, for example due to fuel leaking from an injection pipe or injector.

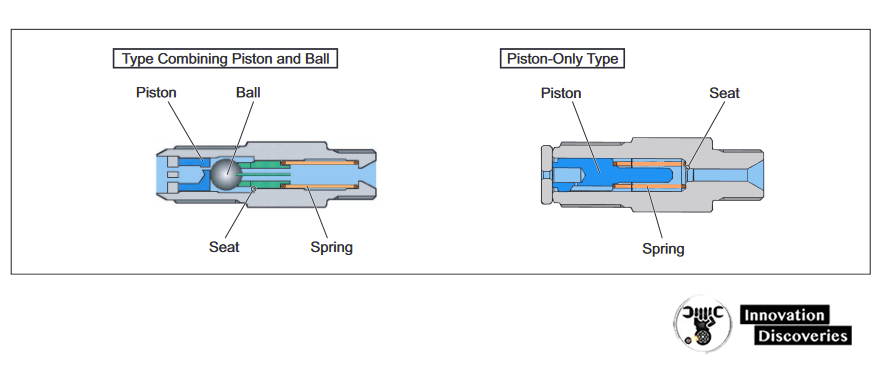

Some flow dampers combine a piston and ball, and some have only a piston.

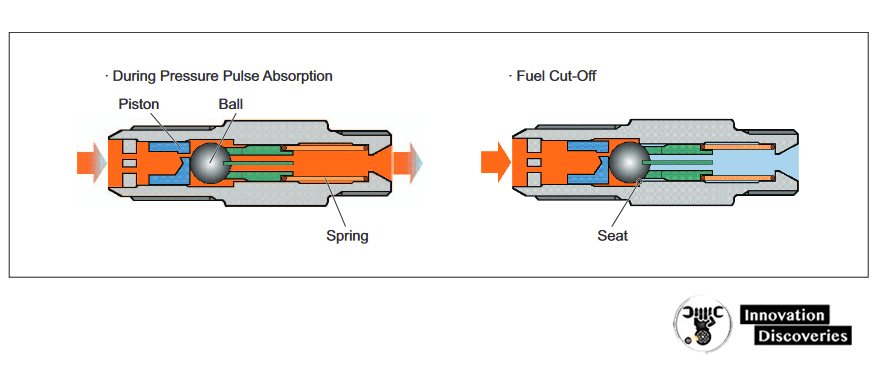

– Operation of Piston-and-Ball Type

When a pressure pulse occurs in a high-pressure pipe, the resistance of it passing through the orifice disrupts the balance between the rail side and injector side pressures, so the piston and ball move to the injector side, absorbing the pressure pulse.

With normal pressure pulses, since the rail side and injector side pressures are soon balanced, the piston and ball are pushed back to the rail side by the sprng.

If there is an abnormal discharge, for example due to an injector side fuel leak, the amount of fuel passing through the orifice cannot be balanced out and the piston presses the ball against the seat, so the passage for fuel to the injector is shut off.

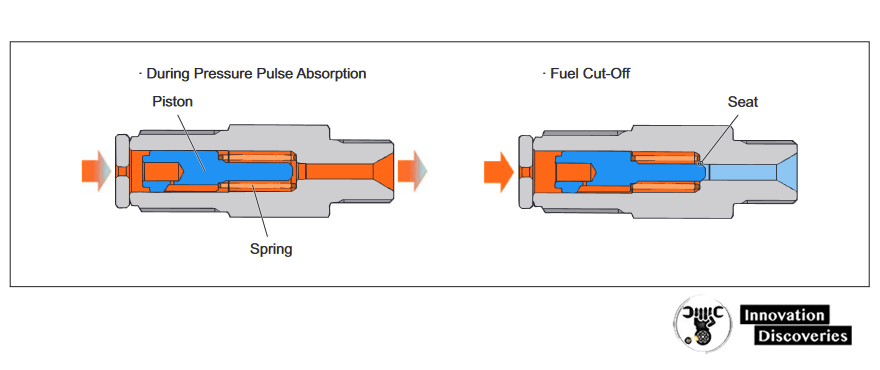

– Operation of Piston-Only Type

The piston contacts the seat directly and the piston shuts off the fuel passage directly. Operation is the same as for the piston and ball type.

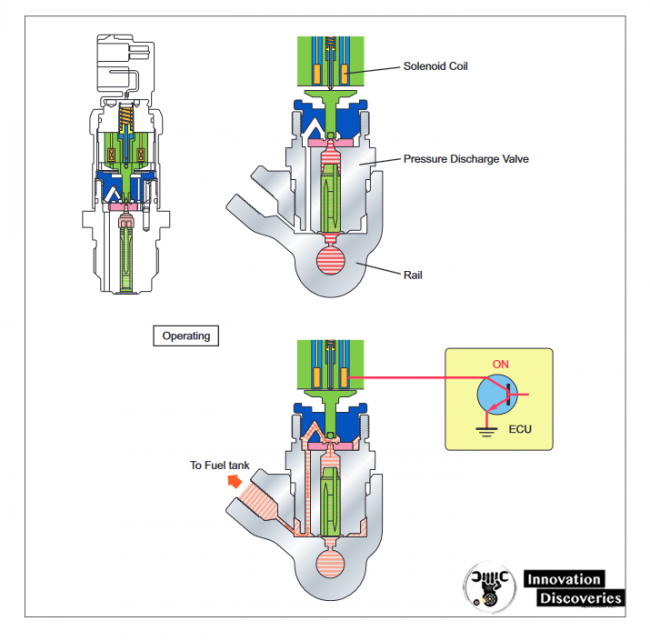

(4) Pressure Discharge Valve

The pressure discharge valve controls the fuel pressure in the rail. When rail fuel pressure exceeds the target injection pressure, or when the engine ECU judges that rail fuel pressure exceeds the target value, the pressure discharge valve solenoid coil is energized.

This opens the pressure discharge valve passage, allowing fuel to leak back to the fuel tank, and reducing rail fuel pressure to the target pressure.

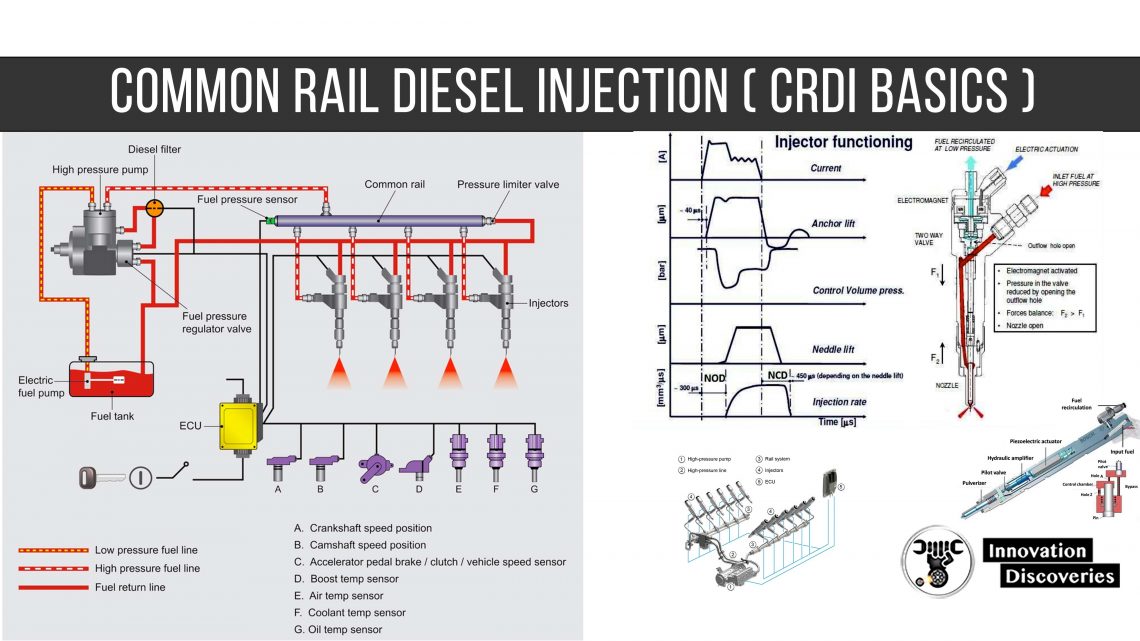

The Common Rail System is a fuel injection system widely used in modern diesel and some gasoline engines. It is designed to improve fuel efficiency, reduce emissions, and increase engine power.

Here’s a breakdown of the common rail system, focusing on the functions and composition of the rail:

Function of the Rail

Fuel Distribution:

The primary function of the rail is to evenly distribute fuel pressurized by the supply pump to each injector. It acts as a storage and distribution hub, ensuring that each injector receives a consistent amount of fuel at the required pressure.

Composition of the Rail

Rail Pressure Sensor (Pc sensor):

This sensor monitors the pressure within the rail, sending signals to the engine control unit (ECU). The ECU uses this information to manage and adjust the fuel injection process, ensuring optimal performance and fuel efficiency.

Pressure Limiter:

This safety component prevents the rail from over-pressurization. If the pressure exceeds a certain threshold, the pressure limiter will release excess fuel back to the return line or tank, avoiding damage to the fuel system.

Flow Damper (if present):

Some rail systems include a flow damper to smooth out pressure fluctuations caused by the injection process. This helps maintain consistent pressure within the rail and reduces noise and vibrations.

Pressure Discharge Valve (if present):

This valve is used to release pressure from the rail, often during engine shutdown or in case of an emergency. It ensures that the rail is not pressurized when it is not required, adding another layer of safety to the system.

Shape of the Rail

- The shape and design of the rail vary depending on the engine model and manufacturer. Generally, it’s designed to fit within the engine compartment while meeting the specific needs of the engine, such as fuel injection timing and injector placement.

In summary, the common rail serves as a critical component in modern fuel injection systems, providing even fuel distribution at high pressure to enhance engine performance while incorporating safety features to manage pressure and prevent damage.

Read More About Common Rail System

Visit Forum

Visit Our Friendly Website