All About Grease: Types, Functions, and the Truth Behind the Colors

In the world of automotive and industrial machinery, grease plays a silent yet critical role in maintaining performance and longevity. While it might look like a simple gooey substance, grease is a complex lubricant engineered for specific tasks—and yes, it comes in many colors. But do those colors actually mean something?

Let’s dive into the science, applications, and the colorful world of grease.

🧪 What Is Grease?

Technically speaking, grease is a semisolid lubricant composed of three primary components:

- Base Oil – Usually mineral or synthetic oil that provides the actual lubrication.

- Thickener – A soap-like substance (e.g., lithium, calcium, aluminum complex) that holds the base oil in a gel-like form.

- Additives – Chemicals that improve properties like oxidation resistance, corrosion protection, pressure handling, and water resistance.

Grease acts as a sealant, lubricant, and protector—especially in situations where liquid lubricants like oil would simply drip away.

🔧 Key Functions of Grease

- Lubrication: Reduces friction between moving parts

- Protection: Shields surfaces from corrosion and contaminants

- Sealing: Keeps out water, dust, and debris

- Temperature Resistance: Operates effectively in both low and high temperatures

- Load Bearing: Suitable for high-pressure applications like wheel bearings or heavy machinery

⚙️ Types of Grease (Based on Thickener)

Here are the most common types of grease categorized by the thickener used:

| Grease Type | Base Thickener | Key Features |

|---|---|---|

| Lithium Grease | Lithium Soap | Multi-purpose, water-resistant, great for automotive use |

| Calcium Grease | Calcium Soap | Excellent water resistance, low temperature performance |

| Aluminum Complex | Aluminum Complex Soap | High-temp stability, good water resistance |

| Polyurea Grease | Polyurea | Long service life, used in electric motors |

| Barium Grease | Barium Complex | High load capacity, chemical resistance |

| Sodium Grease | Sodium Soap | Good high-temperature resistance, poor water resistance |

The Truth Behind Grease Colors

Have you ever noticed red, blue, green, or even purple grease and wondered what they mean? While color doesn’t define the performance, it does serve some practical purposes.

✅ Why Grease Is Colored:

- Identification: Color-coding helps users quickly identify the type of grease, especially in large industrial settings.

- Avoid Cross-Contamination: Mixing incompatible greases can cause breakdown or poor lubrication. Colors reduce mistakes.

- Branding: Manufacturers use unique colors as part of their product identity.

- Visual Inspection: Makes it easier to detect used or contaminated grease during maintenance.

💡 Important Note: The color has no universal standard. A red grease from one manufacturer could have completely different properties than red grease from another.

🔍 Common Grease Colors and Their Typical Associations

| Color | Often Indicates (Not a rule) |

|---|---|

| Red | Lithium complex, high-temp, general-purpose |

| Blue | Marine grease, water-resistant |

| Green | Environmentally friendly or synthetic |

| Black | Molybdenum disulfide (MoS₂), for high-load applications |

| Purple | Heavy-duty, long-lasting synthetic |

| Amber/Brown | Calcium or sodium-based, older formulations |

Again, these associations are not standardized—always refer to the technical data sheet (TDS) of the product before use.

📐 Key Technical Terms You Should Know

- NLGI Grade: Measures the consistency or hardness of grease (e.g., NLGI 2 is the most common for automotive).

- Drop Point: The temperature at which grease transitions to liquid form—higher is better for high-temp applications.

- Base Oil Viscosity: Indicates how thick the base oil is—affects film strength and flow.

- EP Additives: “Extreme Pressure” additives that allow grease to function under high-load conditions.

- Shear Stability: Grease’s resistance to breakdown when subjected to mechanical stress.

🛠️ Where Grease Is Used

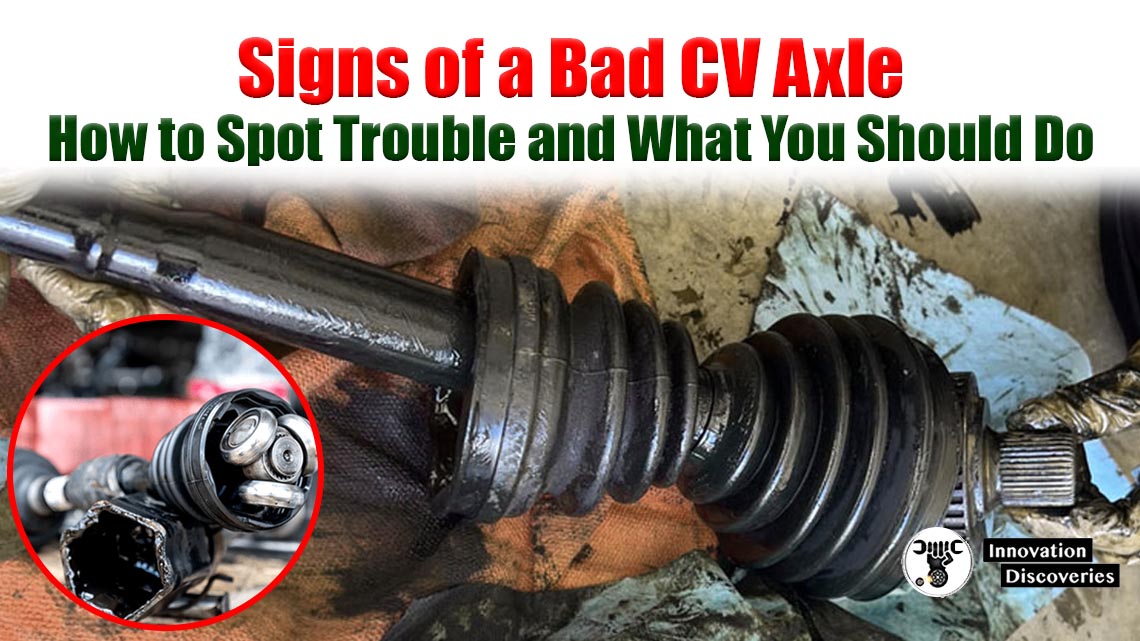

- Automobiles: Wheel bearings, chassis, CV joints, u-joints

- Heavy Machinery: Excavators, bulldozers, cranes

- Electric Motors: Bearings in HVAC and industrial motors

- Marine Applications: Propeller shafts, water pumps, winches

- Agricultural Equipment: Tractors, harvesters, pivot joints

🧼 How to Choose the Right Grease

- Check OEM Recommendations – Always start with what the manufacturer suggests.

- Match Operating Temperature – Use high-temp grease for hot environments.

- Consider Water Exposure – Choose marine-grade grease for wet conditions.

- Don’t Mix Types – Mixing incompatible greases can lead to separation and failure.

- Check Compatibility Charts – Some greases react badly when combined.

✅ Final Thoughts

Grease may seem simple, but it’s engineered to handle complex conditions across multiple industries. While the color can help with identification, it’s not a substitute for understanding chemical composition, base oil type, thickener compatibility, and performance characteristics.

So the next time you’re elbow-deep in maintenance and reach for that red, blue, or green grease—know that there’s more to that color than meets the eye.

Discover More:

Visit Forum

Visit Our Friendly Website