Introduction

“Mechanical components shows wear and tear” this theory wakes up an engineer’s mind

And forces him to innovate more to achieve an ideal system,

Since the moving mechanical components cause wear and

Tear which we count as a limitation of the component

So, the questions arise, Can we avoid the use of distributors in an ignition system?

If yes, then how can we manage the timing of the spark in multiple cylinder engines? Let’s just find out.

Distributorless Ignition System (DIS) is the ignition system in which the distributor of the electronic ignition system is replaced with a number of induction coils i.e. one coil per cylinder or one coil for pair of cylinders,

And the timing of the spark is controlled by

An Ignition controls unit (ICU) and the Engine control unit (ECU),

Which makes this system more efficient and accurate.

Due to the use of multiple ignition coils

Which provides direct voltage to the spark plugs this system is also known as

Direct Ignition System (DIS).

Why Do We Need a Distributorless Ignition System?

As we know all the ignition systems introduced lately that are

- Glow plug ignition system.

- Magneto ignition system.

- Electric coil ignition system.

- Electronics ignition system.

Were a result of improvement in the later system respectively to make the ignition

System of a vehicle more reliable and effective,

The latest of all from the above is, Electronic ignition system

Which is used in almost all the latest super and hyper series cars and

Bikes but it is found that this system also bears some limitations that made it

Necessary to develop a system that can overcome these limitations which are as follows-

(i) Electronic ignition system uses a distributor which is used to distribute the;

High voltage signal from the ignition module to the spark plugs,

The distributor used is a mechanical device having a rotor

That completes the circuit and also controls the spark timing,

Which make this system little less efficient and this system,

Also, it faces mechanical and electrical wear and tear.

(ii) The electronic ignition system requires higher maintenance than the Distributors ignition system i.e. service period for electronic ignition system is 25000 miles (ca. 40,234 km) and that of distributor less ignition system is 100000 miles (ca. 160,934 km).

(iii) Distributor in the electronic ignition system requires periodic check for the distributor’s point gap as they are subjected to wear and tear.

(iv) The spark timing accuracy of the electronic ignition system decreases with time.

These problems gave rise to the development of a smart ignition system named

Distributorless ignition system in which the spark time accuracy is increased using

An electronic control unit along with ignition module and;

The distribution of the voltage signal to the spark plugs is made

Direct using multiple ignition coils, which decreases the wear and tear of the system;

And makes the system the most efficient and reliable ignition system to date.

Also Read:

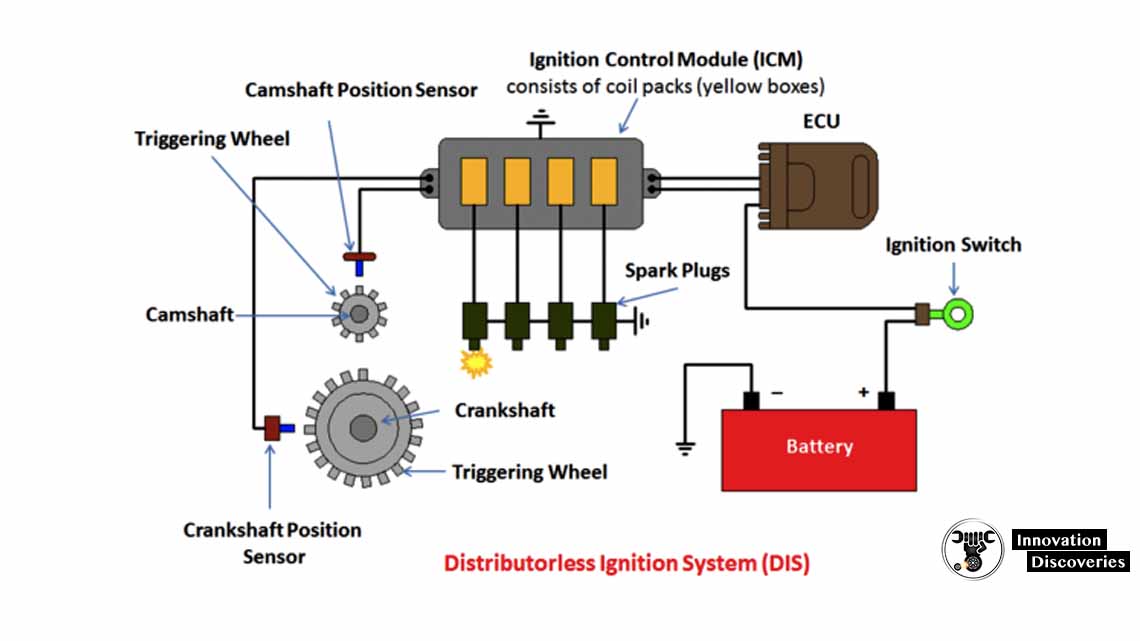

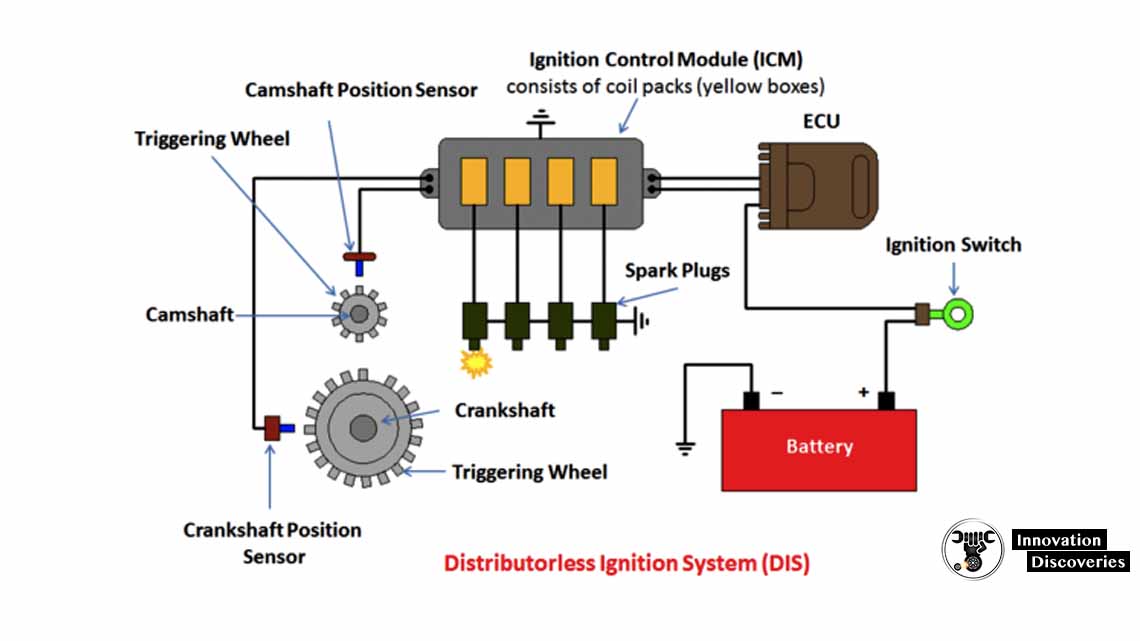

Main Components

The components of this ignition system are the same as the electronic ignition system

But there is no distributor in this system, the components used are,

- Battery: Same as the electronic ignition system,

Battery is used as the powerhouse for the DIS. - Ignition Switch: It governs the ON and OFF of the ignition system,

Same as the electronic ignition system. - In Distributorless ignition system a complete assembly of ignition coils and;

Module is used to make the system compact and less complicated.

(i) Ignition Coils:

Unlike electronic ignition system in which a single ignition coil is used to

Generate high voltage, DIS uses several ignition coils

i.e. each coil per spark plug

Which generates high voltage individually for each spark plug.

(ii) Ignition Control Module (ICM) or Ignition Control Unit:

It is the programmed instruction given to the chipset which is responsible for

Setting the primary coil circuit to ON or OFF,

- Magnetic Triggering Devices:

These are the devices used to control the timing of the spark plug by

Sensing the position of the crankshaft and camshaft both,

A magnetic triggering device consists of triggering

Wheel having teeth along with a sensor,

Two magnetic triggering devices are used in the Distributors ignition system that is-

(i) Camshaft Triggering Device: Mounted on the camshaft and used for sensing valve timing.

(ii) Crankshaft Triggering Device: Mounted on the crankshaft and used for sensing the piston position or stroke.

5. Spark Plug: It is used to generate spark inside the cylinder.

Also Read:

Working of Distributorless Ignition System

(i) When the ignition switch is turned ON, the current from the battery stats to flow

Through the ignition switch to the electric control unit

(Which keeps on processing data and calculating timing) of the vehicle which is

Connected to the ignition module and coils assembly, (which makes and breaks the circuit).

(ii) The triggering wheels mounted on the camshaft and crankshaft have equally spaced teethes with one gap,

And the position sensors which consists of the magnetic coil

That constantly generates a magnetic field as the camshaft and crankshaft rotates.

(iii) When these gaps come in front of the positioning sensors,

Fluctuation in the magnetic field occurs and the signals of both the sensors are

Sent to the ignition module which in turn senses the signals and the current stops to

Flow in the primary winding of the coils.

And when these gaps go away from the sensors the signals of

Both the sensors are sent to the ignition module which turns ON the current to

Flow in the primary winding of the coils.

(iv) This continuous make and break of the signals generate a magnetic field in the coils

Which in turn induced EMF in the secondary winding of the coils and increases the voltage up to 70000 volts.

(v) This high voltage is then sent to the spark plugs and the generation of sparks takes place.

(vi) The timing of the spark plugs is controlled by an electronic control unit by

Continuously processing the data received from the ignition control module.

For Better Explanation Watch the Video Given Below:

Applications

(i) Distributorless ignition system (DIS) is being used for a decade now so almost all the cars with 1.8 L, 2.8 L VR6 AND 2.8 L V-6 engine on the road use this system.

(ii) DIS is first used in 2.8 L VR6 engine equipped Volkswagen Passat.

(iii) Some high-end bikes like Ducati super sports also adopt this system.

Read More:

2 Comments