Tired of hearing about electric vehicles but don’t understand how they actually work? Let’s break down the entire powertrain system—from the battery to the wheels—and reveal the silent power behind the electric revolution.

🚗 The Evolution of EV Powertrains: From Sparks to Speed

The electric vehicle (EV) is not a modern novelty—it’s a story of reinvention. Early EVs in the late 19th century used lead-acid batteries with crude motors, offering limited range and performance. But today’s EVs are powered by sophisticated lithium-ion packs, high-efficiency permanent magnet motors, and advanced power electronics that rival the complexity of any internal combustion engine (ICE).

Key Milestones in EV Powertrain Evolution:

- Lead-Acid to Lithium-Ion: A leap in energy density and cycle life.

- DC Motors to AC Induction & PMSMs: Efficiency and performance improvements.

- Power Electronics Breakthroughs: Silicon carbide (SiC) MOSFETs revolutionizing inverter design.

- Software Integration: Real-time control through vehicle ECUs and motor controllers.

🔧 Dissecting the EV Powertrain: Components That Drive the Future

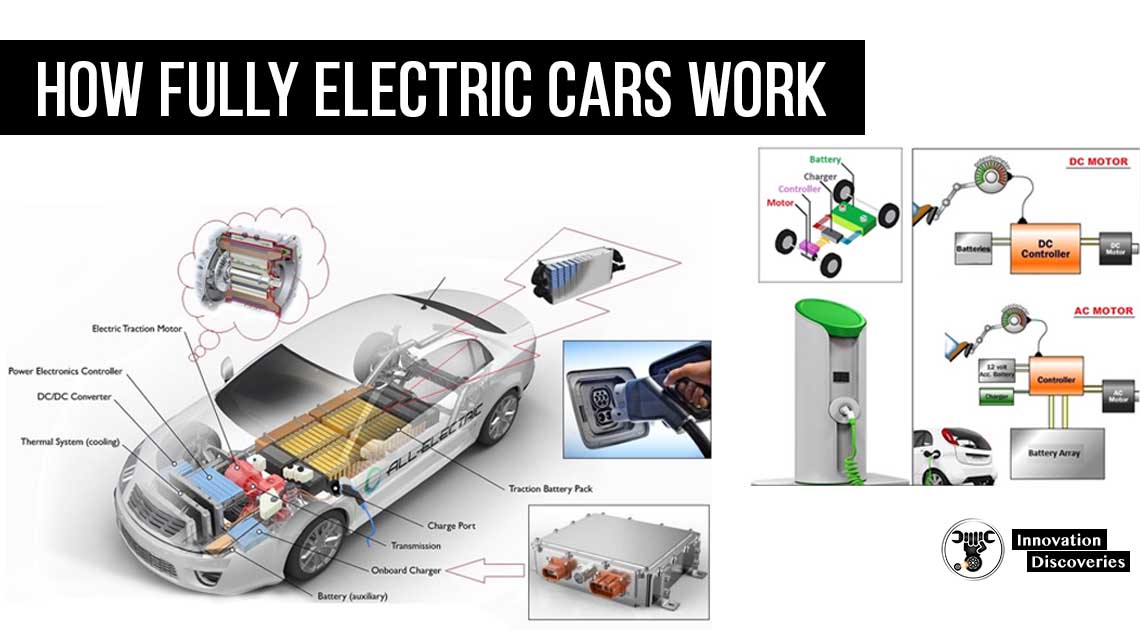

An EV powertrain may seem simpler than a traditional ICE system (fewer moving parts, no transmission gears, no exhaust), but it’s a highly coordinated symphony of cutting-edge technology.

🔋 1. Battery Pack (The Energy Reservoir)

The battery pack is the heart of an EV, functioning as its fuel tank. It stores electrical energy in rechargeable cells, typically Lithium-Ion NMC (Nickel Manganese Cobalt) or LFP (Lithium Iron Phosphate). These cells are grouped into large arrays called modules and are continuously monitored by a Battery Management System (BMS) for safety, performance, and efficiency.

🔧 Key Functions:

- Supplies high-voltage direct current (DC) to the inverter.

- Enables regenerative braking to capture and store kinetic energy.

- Powers onboard electronics via a DC-DC converter.

⚙️ Technical Notes:

- Uses NMC or LFP cells, selected based on cost, thermal stability, and energy density.

- All modules are supervised by a BMS that tracks voltage, temperature, current, and SoC (State of Charge).

- Since most motors require AC, the battery’s DC output is sent to an inverter for conversion.

Think of it as the fuel tank, brain, and safety system—combined.

🔁 2. Inverter (The Converter)

The inverter is the power flow controller in an EV, responsible for converting DC electricity from the battery into AC (Alternating Current) needed by most electric motors. During regenerative braking, it performs the opposite function, converting AC from the motor back into DC to recharge the battery.

🔧 Key Functions:

- Converts DC to AC to drive the electric motor.

- Enables regenerative braking by converting AC back to DC.

- Controls motor torque, speed, and phase timing.

⚙️ Technical Notes:

- Utilizes IGBTs (Insulated-Gate Bipolar Transistors) or SiC MOSFETs (Silicon Carbide Metal-Oxide-Semiconductor Field-Effect Transistors) for high-efficiency and high-speed switching.

- Typically integrated with the motor controller in modern EV drive units for compactness and performance.

- Plays a critical role in motor control strategies like Field-Oriented Control (FOC) for smooth operation.

⚡ 3. Electric Motor (The Workhorse)

The electric motor transforms electrical energy into mechanical motion to drive the wheels. It provides instant torque, high efficiency, and smooth acceleration — key characteristics that define the EV driving experience.

🔧 Key Functions:

- Converts electrical energy into mechanical torque.

- Enables bidirectional operation for regenerative braking.

- Delivers instant torque and high acceleration responsiveness.

⚙️ Common Motor Types:

- AC Induction Motor – Brushless, robust, cost-effective (e.g., early Tesla models).

- Permanent Magnet Synchronous Motor (PMSM) – High torque density and energy efficiency, widely used in modern EVs.

- Switched Reluctance Motor (SRM) – No permanent magnets, highly durable, ideal for high-temperature conditions.

🛠️ 4. Transmission / Reduction Gear

Unlike internal combustion engines, which rely on complex multi-speed transmissions, EVs usually utilize a single-speed reduction gear. This is possible because electric motors produce a broad, flat torque curve across a wide RPM range.

🔧 Key Functions:

- Reduces high-speed motor RPM (e.g., 10,000+ RPM) to appropriate wheel speed.

- Eliminates the need for gear shifting.

- Ensures optimal torque delivery with minimal drivetrain complexity.

⚙️ Technical Notes:

- Most EVs use single-speed gearboxes for simplicity and efficiency.

- Some high-performance models (like the Porsche Taycan) use two-speed transmissions to balance acceleration and top-speed performance.

- Reduction ratios typically range between 8:1 to 10:1, depending on motor characteristics and vehicle weight.

🌀 5. Onboard Charger (AC-to-DC Converter)

The onboard charger is what enables home and public AC charging. It converts grid-supplied AC power into DC power to safely charge the vehicle’s battery pack.

🔧 Key Functions:

- Converts alternating current (AC) to direct current (DC) for battery storage.

- Communicates with the Battery Management System (BMS) for voltage and thermal regulation.

- Manages charging speed, efficiency, and safety based on power source and battery status.

⚙️ Technical Notes:

- Charging rates vary from 3.3 kW to 22 kW, depending on the EV and charger level.

- Integrated into the vehicle’s power electronics and cooling system.

- Required for Level 1 and Level 2 AC charging — DC fast charging bypasses it entirely.

The Electric Motor: Instant Torque at Your Command

At the heart of every EV is its electric motor—a marvel of physics delivering near-instantaneous torque and precise throttle control.

Motor Types Explained:

| Motor Type | Pros | Cons | Examples |

|---|---|---|---|

| AC Induction | Cost-effective, rugged | Less efficient than PMSMs | Tesla Model S (rear motor) |

| PMSM | High efficiency, compact | Requires rare-earth magnets | Hyundai Ioniq 5, Tesla front motor |

| SRM | No magnets, high durability | Noisy, complex control | Niche industrial EVs |

Thanks to regenerative braking, motors also act as generators, recovering energy during deceleration.

⚡ Power Electronics: The Intelligent Middleman

Power electronics in an EV act as the traffic controller of energy, ensuring optimized delivery from the battery to the motor under varying conditions.

Key Components:

- Inverter: Converts battery DC to motor AC.

- DC-DC Converter: Steps down high-voltage pack to 12V for accessories.

- Controller: Uses algorithms and feedback from sensors to manage motor speed, torque, and efficiency.

Recent advances in GaN (Gallium Nitride) and SiC semiconductors are boosting performance with:

- Higher switching speeds

- Lower thermal losses

- Compact design for lighter powertrains

🔮 The Future of EV Powertrains: Innovation in Motion

The next generation of EV powertrains is already on the horizon, promising:

1️⃣ Solid-State Batteries

These are the next-generation batteries that replace the liquid electrolyte in lithium-ion cells with a solid electrolyte.

Advantages:

- Higher energy density → longer range.

- Faster charging with improved ion conductivity.

- Reduced fire risk due to non-flammable materials.

- Longer lifespan and thermal stability.

Still in development for mass production, but being prototyped by Toyota, QuantumScape, and others.

2️⃣ Wireless Charging (Inductive Power Transfer)

This technology allows EVs to charge without cables, using electromagnetic fields. It works by placing a charging pad (transmitter) on the ground and a receiving coil underneath the vehicle.

How it works:

- AC power flows through a coil in the pad, creating a magnetic field.

- This field induces current in the vehicle’s receiver coil (via magnetic resonance coupling).

- The induced AC is converted to DC by the onboard charger.

Potential use cases:

- Static charging in garages or parking lots.

- Dynamic charging embedded in roads.

3️⃣ Advanced Thermal & Energy Management Systems

Managing heat is critical for performance, safety, and battery longevity. EVs use integrated systems to monitor and control temperatures across:

- Battery pack

- Power electronics (inverter, charger)

- Electric motor

Technologies include:

- Liquid cooling circuits with refrigerant or glycol mixtures.

- Heat pumps that recycle energy for cabin conditioning.

- Predictive thermal algorithms for optimizing charging and driving efficiency.

A well-managed EV runs cooler, lasts longer, and performs better.

4️⃣ Integrated Drive Units (IDUs)

An IDU combines the motor, inverter, gearbox, and sometimes differential into one compact housing. This reduces complexity, weight, and assembly costs.

Benefits:

- Space-saving design

- Reduced wiring and thermal losses

- Easier manufacturing and modular scalability

Used in modern EVs like Tesla’s “Palladium” platform and GM’s Ultium Drive systems.

✅ Final Thoughts: Understanding Means Empowerment

Electric vehicles aren’t just a trend—they’re the future of transportation. By understanding the technical foundation of EV powertrains, you’re not only empowering your next buying decision but also appreciating the innovation driving a cleaner, smarter world.

So, the next time someone says, “EVs are just electric motors,” you’ll know better. 😉

Discover More:

Visit ForumVisit Our Friendly Website