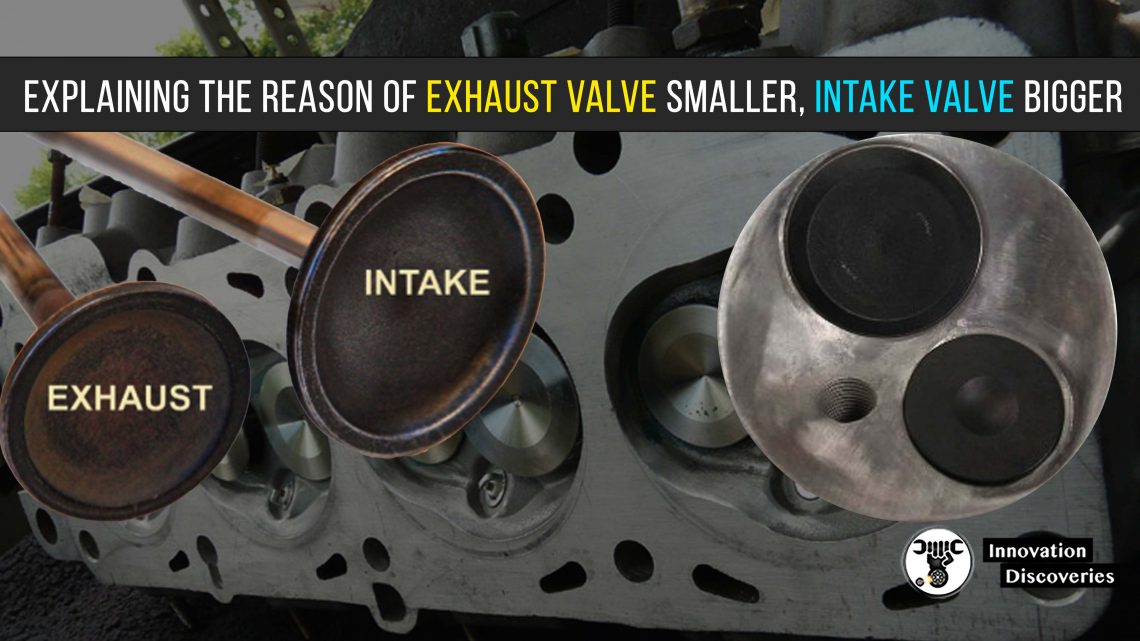

Why is the intake valve larger than the exhaust valve?

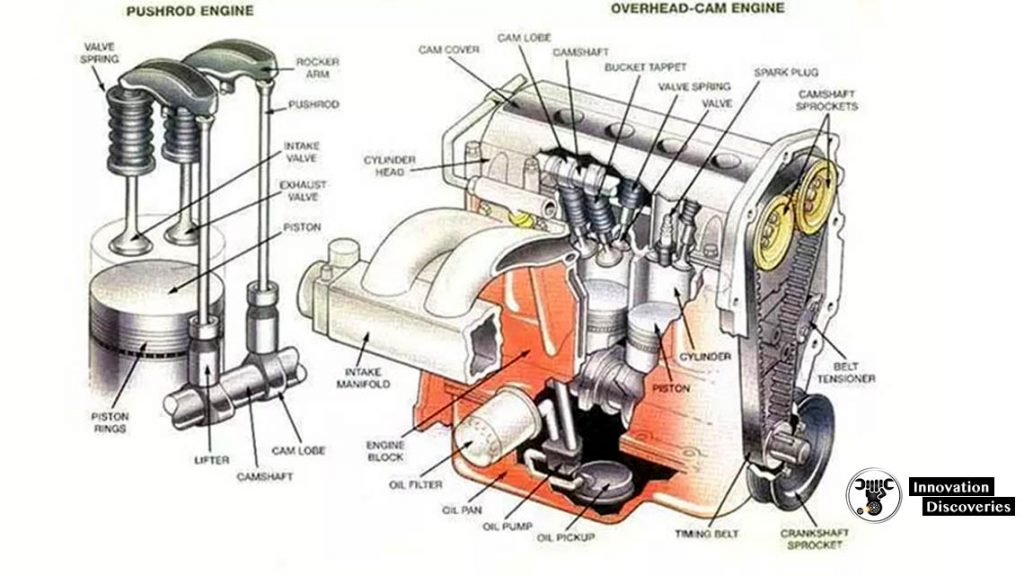

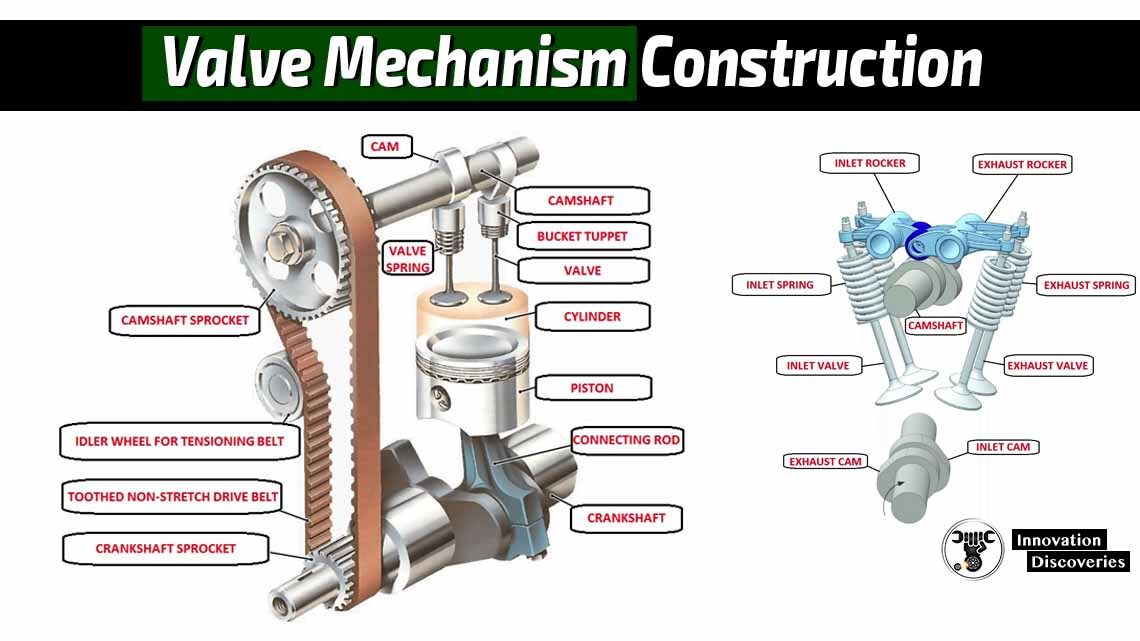

The valve is opened by the cam and the valve spring is closed. When the mixture needs to be sucked into the cylinder, the intake valve will open.

When the exhaust gas after combustion needs to be discharged, the exhaust valve will open.

Since the intake air is “sucked in” and the exhaust gas is “pushed” out, the intake air is more difficult than the exhaust gas, and the more intake air, the better the combustion and the better the engine performance.

The intake air is sucked by vacuum, and the exhaust gas is pushed out to push the exhaust gas.

Therefore, the exhaust is easier than intake.

To get more fresh air to participate in the combustion, therefore, more intake air is needed.

For this reason, the intake valve needs to be larger, and the overall size has not changed, and the exhaust valve can only be made smaller.

Therefore, the intake valve is generally designed to be larger than the exhaust valve to reduce the difficulty of intake and increase the amount of intake of air.

Some simply design an additional intake valve, which only has 3 valves (2 into 1 row) and 5 valves (3 into 2 rows) design.

Influence of airflow resistance

In theory, the amount of inflation and the amount of exhaust are equal, and the opening and closing time of the exhaust valve and the opening and closing time of the intake valve is also equal.

But this is not the case, because the throttle valve controls the rotation speed, the valve opening and closing are large and small, and the cylinder should be filled with a mixture of air equal to atmospheric pressure (about 1 kg / cm2) when the suction is completed.

But when the gas flows through the intake pipe and the intake valve, it is subject to resistance.

In order to overcome these resistances and allow the mixture to flow at a certain speed, part of the pressure must be consumed by the wave,

So the air pressure in the cylinder is always lower than atmospheric pressure.

The gas density changes with the pressure and the low-pressure density are reduced, and the actual weight of the mixed gas is reduced.

To solve and reduce the influence of airflow resistance, the cross-sectional area of the airflow path at the intake valve must be increased,

That is, the area of the air valve should be increased.

In the case of thin air in the plateau area, the area of the air intake passage should be increased, otherwise, the engine will not reach its rated power in these areas.

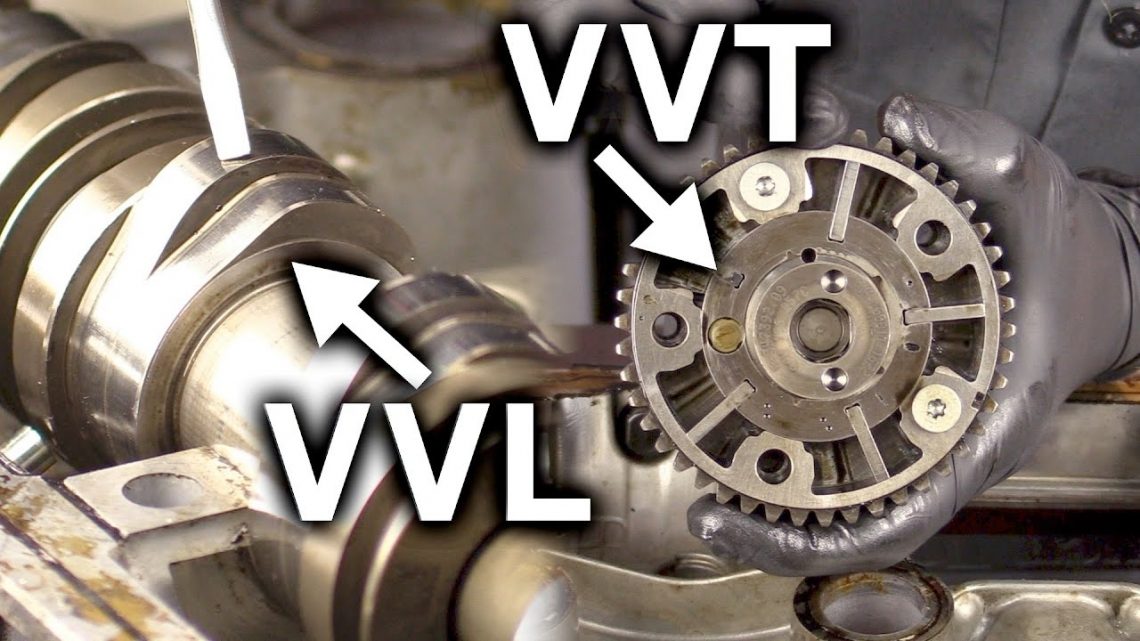

Influence of engine speed

In the case of the original airway size unchanged, the suction pressure will also change according to the speed and load.

When the throttle valve is kept fully open, the speed varies with the load.

Assuming that the inflation weight is 1, the speed is increased from 700 to 2 per minute, and the pressure is reduced from 0.95 to 0.80 at 100 rpm, which shows that the cylinder

The density of stick air is reduced, and the airflow can not keep up with the need of the inflation amount.

Because when the rotation speed is tripled, the piston movement speed is also tripled, and the airflow speed is also tripled to ensure that the same weight air rest enters the cylinder.

However, due to the increased force in the airway at high speeds, the airflow cannot be increased in the same proportion.

That is, the inflation effect is better when decelerating, and as a result, the average effective pressure and torque are also larger (torque is proportional to the average effective pressure).

READ MORE

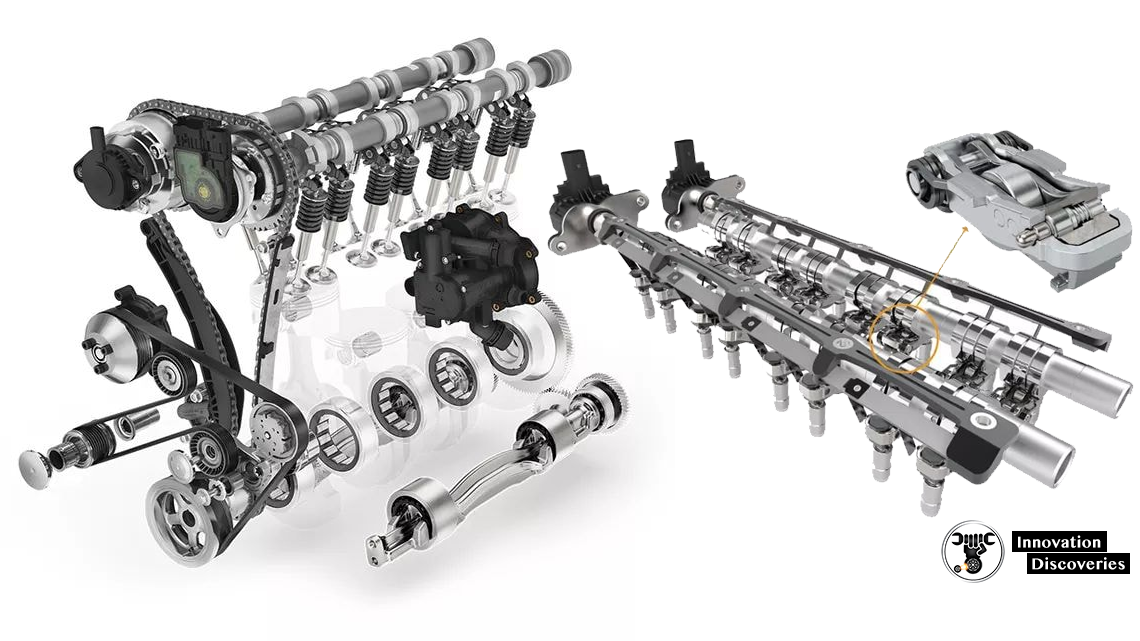

VALVE TRAIN: COMPONENTS TYPES AND THEIR FUNCTION

Visit Forum

Visit Our Friendly Website