The high-tension leads from the coil to the distributor and

From there to the plugs may start to deteriorate after long service,

Causing bad starting, misfiring and radio interference.

There are two types. Stiff, durable copper-cored leads are used on older cars.

To prevent radio interference with this type of lead,

Fit an in-line suppressor between the coil and the distributor,

And use resistive plug caps on all the plugs

Also, read

- Magneto Ignition System – Parts, Working Principle, Advantages, and Disadvantages with Application

- How the ignition system works

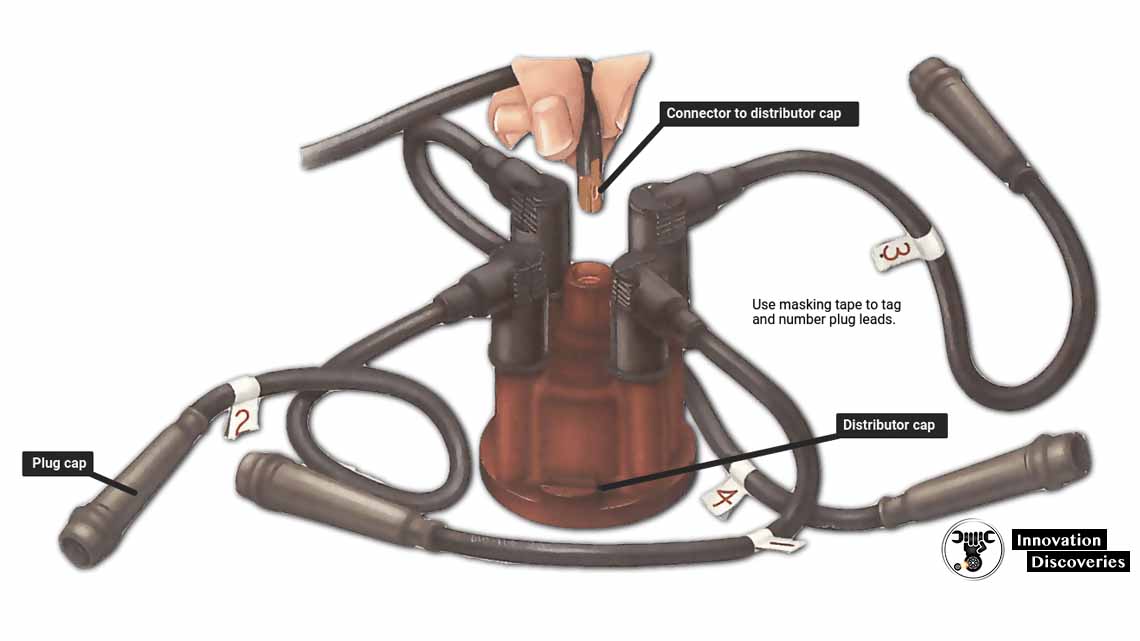

Numbering the plug leads

Wrap masking tape around each plug lead and write the cylinder number on it with a ballpoint pen. Pull the leads off the plugs, disconnect the coil lead from the coil,

Unclip (or unscrew) the distributor cap and remove it with all the leads attached to it. Replace the leads one at a time, to avoid confusion,

With new leads of the right length. Number each new plug lead as you install it.

Later cars usually have more flexible carbon-cored leads,

Though the core can break easily if roughly treated. Such leads have a built-in resistance

And generally do not need extra suppressors.

Carbon leads are sold as complete sets, with the distributor and coil connections and

Plug caps already crimped on.

Simply remove the old leads, one at a time to avoid confusion,

And replace it with the new ones.

To replace copper leads, buy the right total length of cable,

A new set of resistive plug caps and an in-line suppressor

And any terminals you may need.

Note that when fitting or removing plug leads

You should always push or pull the cap, Not the lead,

To avoid straining the lead and possibly pulling

It away from its terminal connector.

Leads sometimes run through guides that hold them apart or away from hot, areas. Always refit them in their guides.

Fitting resistive plug caps and an in-line suppressor

Which simply screw into the ends of the lead, without any need to remove insulation.

Fit the in-line suppressor anywhere in the coil lead.

Types of lead and connectors

You can tell copper-cored cable by its stiffness, especially when cold,

And by the type of connectors fitted to it. Carbon-cored cable is quite flexible – but do

Not kink it, as the core snaps easily. Carbon cable has resistance marked on the insulating sheath.

Carbon-cored cable has terminals already crimped on. These are a push-in fit to the

Distributor and coil, and are covered by rubber dust seals. Ease back the seals along the

Lead and fit the connectors into the coil and distributor caps. Fix the dust seals.

Copper-cored cable uses screw-on connectors which you fit yourself

After cutting the cable to the correct length. There may be a screw collar over a terminal which you crimp

On with pliers, or a terminal washer over which the strands are splayed. A screw collar then clamps the washer on to its connection. A third type has a screw which pierces the strands of the core.

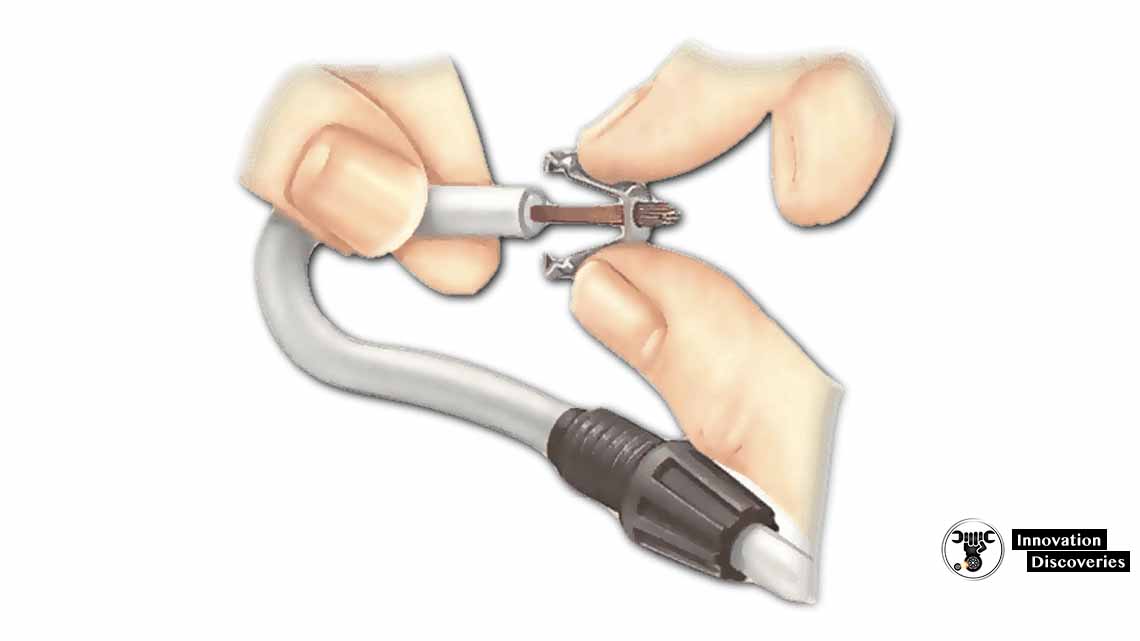

Fitting a connector to copper-cored cable

When fitting a screw-on connector to copper-cored cable using a crimp-on terminal

Or a washer, remove about z in. (13 mm) of insulation from the end of the lead with a sharp knife. Take care not to cut into the wire core. Thread on the collar.

Fit a crimp-on terminal by folding up the wings and flattening them with pliers.

Fit a terminal washer by threading the core through,

The washer and bending the strands back around it.

Pass the core wires through the centre hole.

For a screw terminal, do not remove any insulation. Insert the lead into the connector,

Making sure that the screw is in line with the cable core. Tighten the screw to pierce the core.

So that the spikes bite into the insulation. Splay the wires around the terminal end.

SEE MORE: