Introduction:

In the world of automotive suspension systems, shocks play a crucial role in providing stability, control, and comfort to vehicles. Gas shocks and oil shocks are two common types of shock absorbers used in various applications.

While both serve the same purpose, there are significant differences between them in terms of construction, performance, and characteristics.

This article aims to explore the disparities between gas shocks and oil shocks, shedding light on their advantages, disadvantages, and suitable applications.

Construction and Working Principle

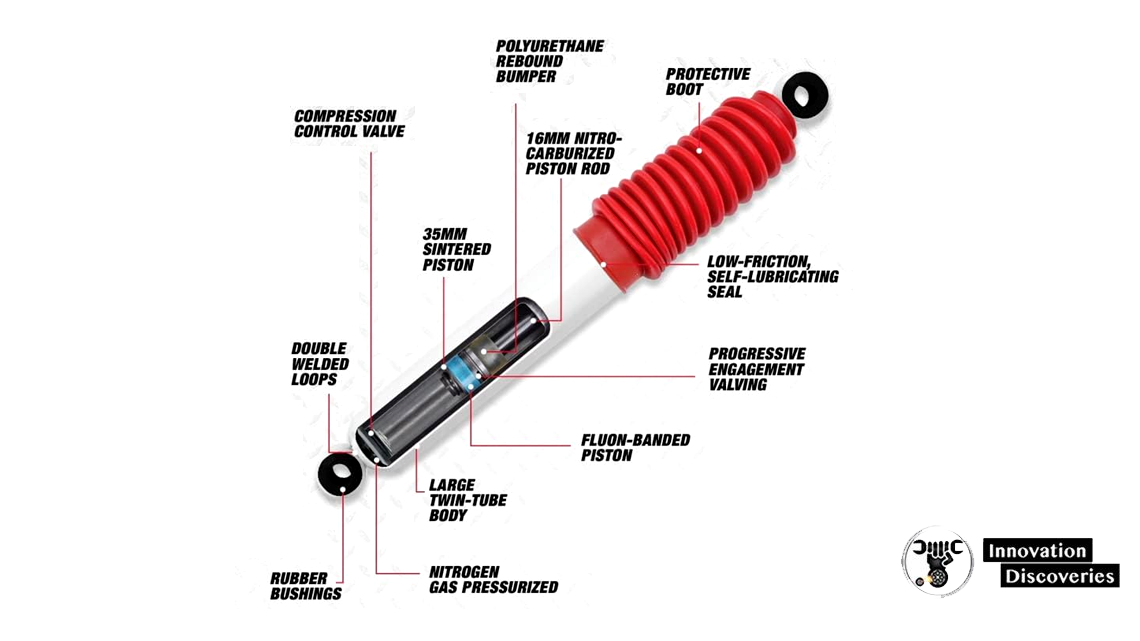

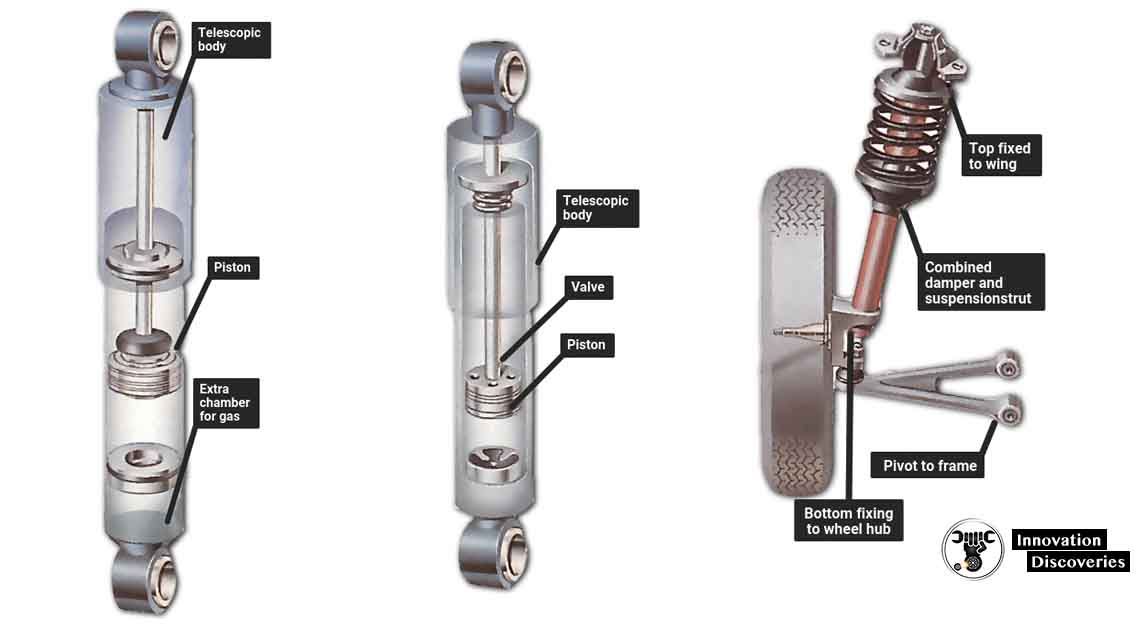

1. Gas Shocks:

Gas shocks, also known as gas-charged shocks or gas-pressurized shocks, incorporate a nitrogen gas charge in addition to the hydraulic fluid.

The gas charge is typically under pressure, acting as a supplemental spring to enhance the shock’s performance. It reduces aeration and foaming of the hydraulic fluid, ensuring consistent damping characteristics.

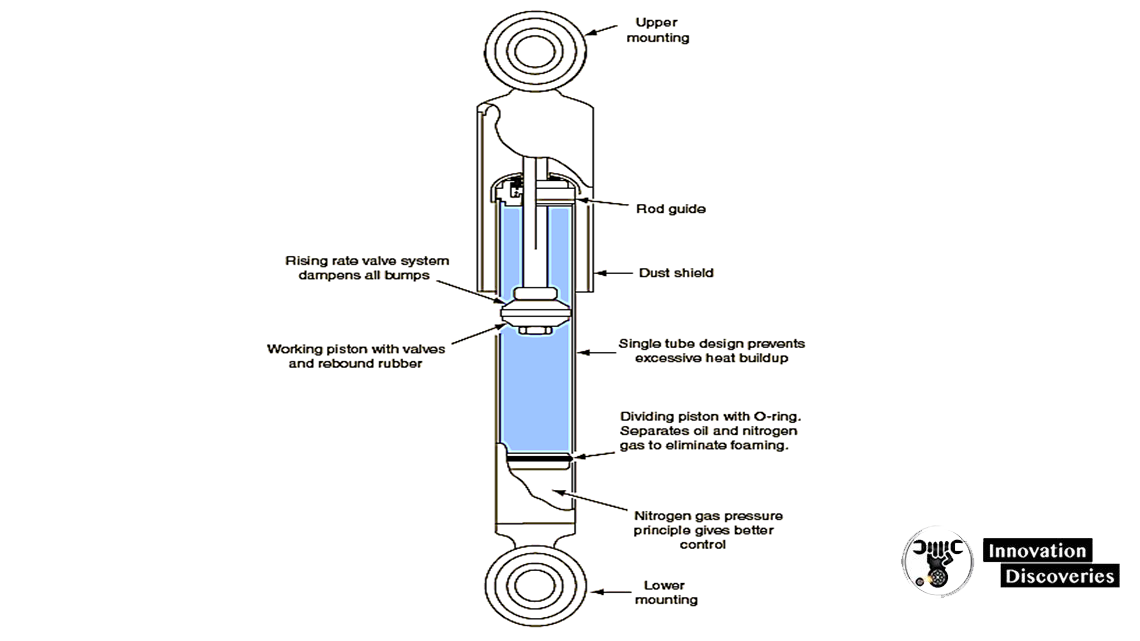

2. Oil Shocks:

Oil shocks, also referred to as hydraulic shocks or twin-tube shocks, consist of two cylindrical chambers. The outer chamber holds hydraulic fluid, while the inner chamber contains a piston connected to a rod.

When the suspension compresses or extends, the piston moves through the oil, generating resistance to dampen the suspension movement.

Performance and Characteristics

Gas Shocks:

- Improved response: Gas shocks have a faster response time due to the additional gas pressure. They offer better control over the suspension movement, particularly during rapid compression and rebound.

- Reduced fade: The presence of the gas charge reduces the likelihood of shock fade, which occurs when the damping performance deteriorates under continuous use.

- Enhanced stability: Gas shocks provide increased stability and reduced body roll, making them suitable for applications requiring precise handling, such as sports cars or performance-oriented vehicles.

- Firmer ride: Gas shocks tend to provide a firmer ride compared to oil shocks, which may be preferable for drivers seeking a sportier or more responsive feel.

Oil Shocks:

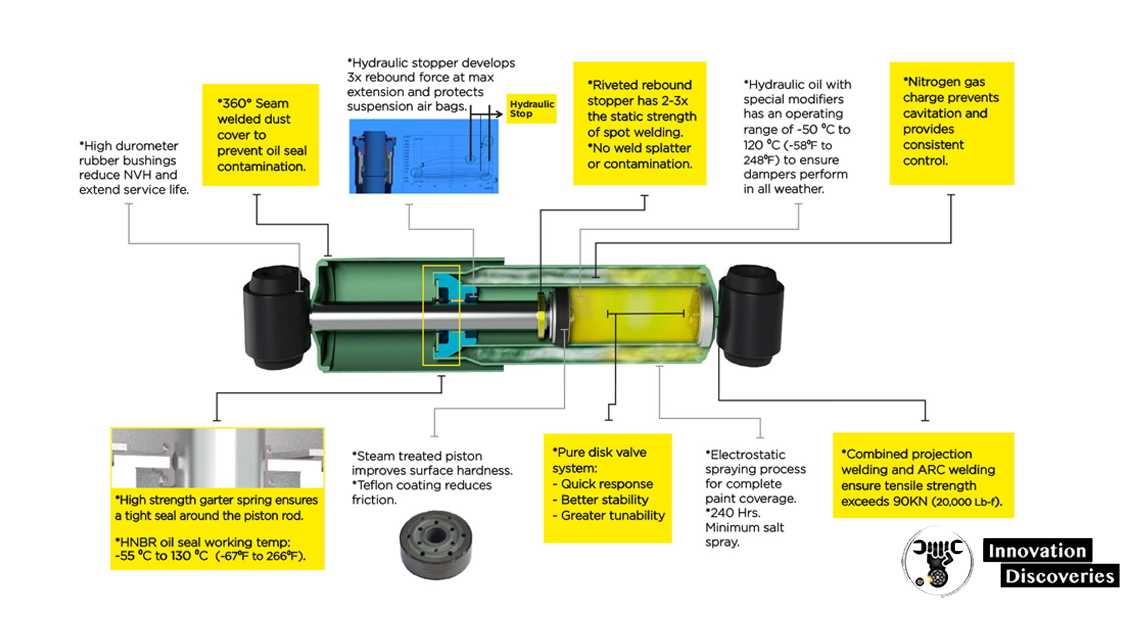

- Better heat dissipation: The twin-tube design of oil shocks allows for better heat dissipation, making them less prone to overheating during extended or aggressive use.

- Smoother ride: Oil shocks generally offer a smoother ride quality due to their design and damping characteristics. They can absorb smaller road imperfections effectively, resulting in a more comfortable driving experience.

- Cost-effective: Oil shocks are often more affordable compared to gas shocks, making them a popular choice for many vehicles, especially in standard daily driving scenarios.

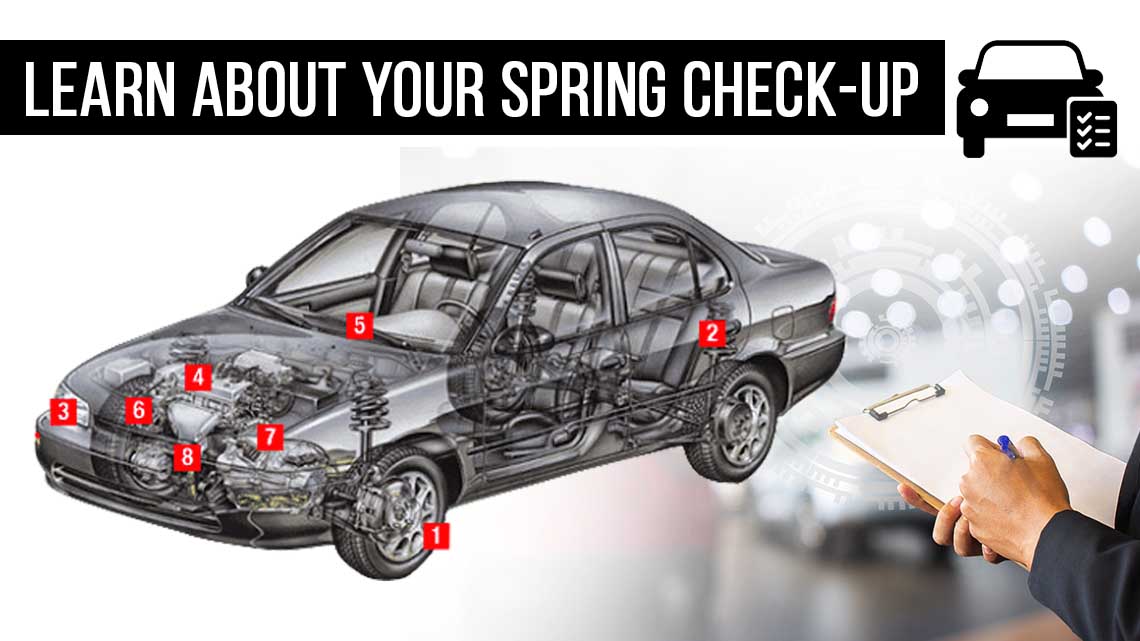

- Versatility: Oil shocks can be found in a wide range of vehicles, including sedans, SUVs, and trucks, as they provide a balanced combination of comfort and performance suitable for everyday driving.

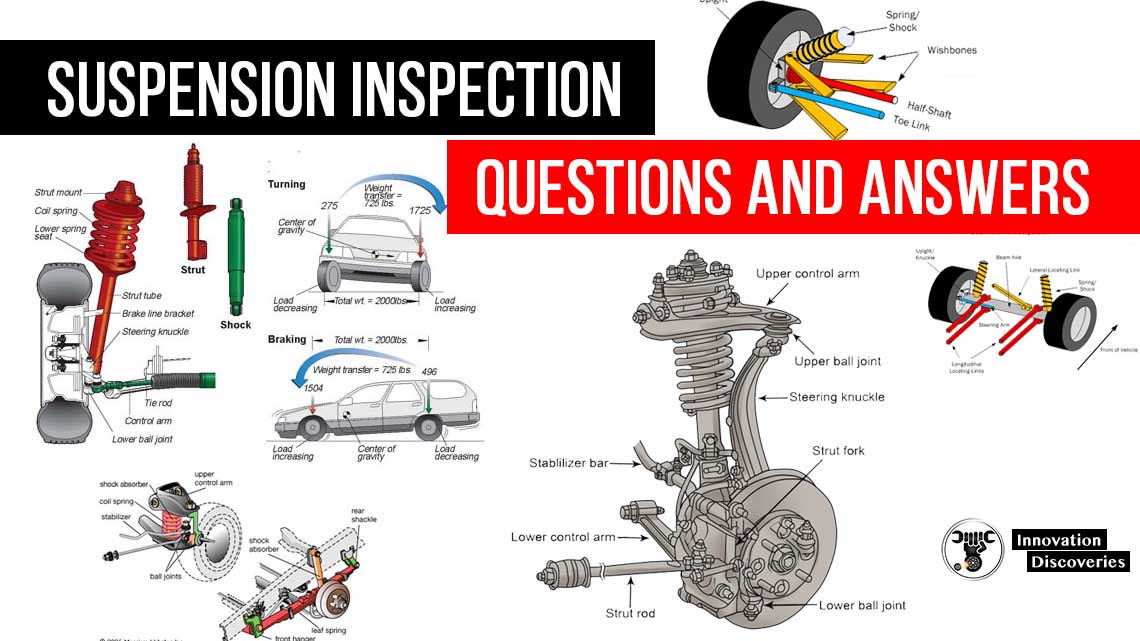

Suitable Applications

– Gas Shocks:

Gas shocks are commonly used in performance vehicles, such as sports cars and high-performance sedans, where precise handling, responsiveness, and stability are essential. They are also favored in off-road vehicles, where the gas charge helps prevent shock fade during intense off-road conditions.

– Oil Shocks:

Oil shocks find extensive use in passenger vehicles, including sedans, hatchbacks, SUVs, and light trucks. Their cost-effectiveness, smoother ride quality, and versatility make them suitable for everyday commuting, family vehicles, and general-purpose driving.

Conclusion:

Gas shocks and oil shocks are two distinct types of shock absorbers, each with its own set of advantages and characteristics. Gas shocks excel in terms of response time, stability, and resistance to fade, making them ideal for performance-oriented applications.

On the other hand, oil shocks offer a smoother ride, better heat dissipation, and affordability, making them a popular choice for everyday driving scenarios.

Ultimately, the choice between gas shocks and oil shocks depends on the specific requirements, driving preferences, and the intended use of the vehicle.

Discover More About Suspension Systems

Visit Forum

Visit Our Friendly Website

One Comment