Radial engines, also known as radial piston engines, are a type of internal combustion engine that was widely used in aircraft during the early to mid-20th century. While they have been largely replaced by more modern engine designs, radial engines remain fascinating examples of engineering prowess.

In this article, we will delve into the workings of a radial engine, exploring its key components, operation principles, and advantages.

Basic Design and Layout:

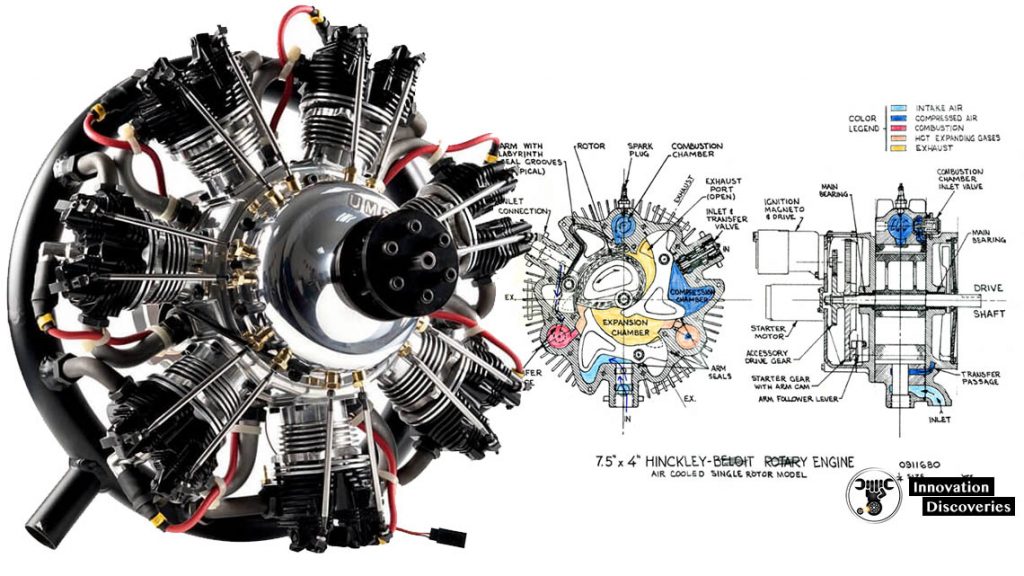

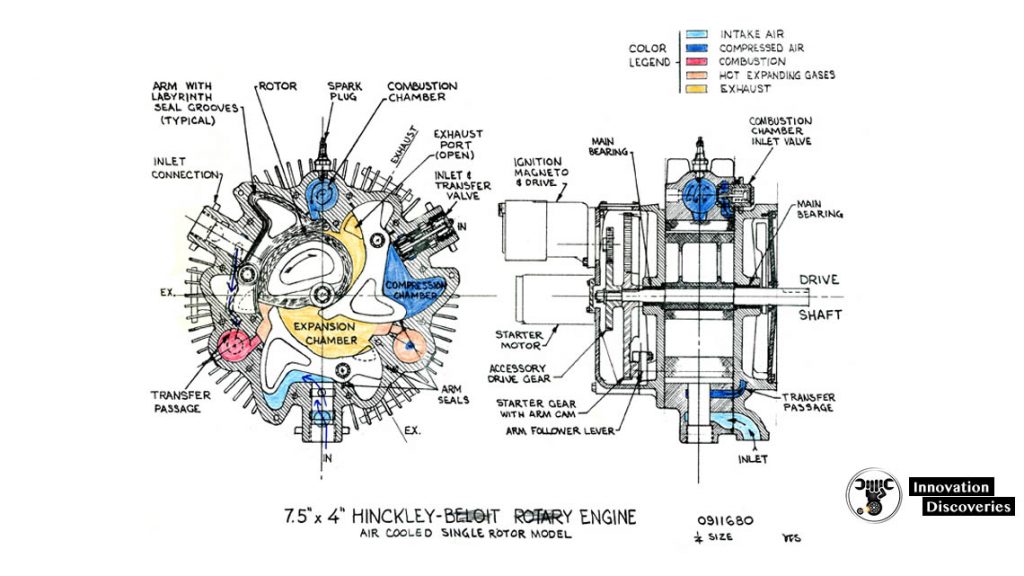

A radial engine features a unique design characterized by a centrally located crankshaft and an odd number of cylinders arranged in a circular pattern around the crankshaft.

The crankshaft is fixed to the engine’s crankcase, which serves as the central hub, housing various components such as the camshaft, magneto, and oil pump. The cylinders are attached to the crankcase with their pistons moving radially outward.

Cylinder and Piston Arrangement:

The cylinders are typically arranged in one or more rows, with each cylinder having its own combustion chamber. The pistons are connected to the crankshaft through connecting rods, which translate the reciprocating motion of the pistons into rotational motion of the crankshaft. The number of cylinders in a radial engine can vary, with common configurations ranging from 3 to 9 cylinders.

Fuel and Air Intake:

Radial engines employ a carburetor or fuel injection system to mix fuel and air for combustion. Air enters the engine through an intake manifold and is directed to each individual cylinder. The carburetor regulates the fuel flow, ensuring an appropriate air-fuel mixture for combustion.

Ignition and Combustion:

Radial engines typically use spark ignition systems, where a magneto generates electrical sparks to ignite the fuel-air mixture within each cylinder. The ignition timing is precisely controlled to optimize engine performance. Once ignited, the expanding gases force the pistons downward, turning the crankshaft.

Cooling:

Proper cooling is crucial for radial engines due to their high power output and close cylinder arrangement. Radial engines commonly employ an airflow-based cooling system, with an array of cooling fins surrounding each cylinder. The high-speed airflow, generated by the forward motion of the aircraft, passes over the cylinders, dissipating heat and preventing overheating.

Lubrication:

Lubrication is vital to minimize friction and wear within the engine. Radial engines employ an oil pump to circulate oil throughout the engine, lubricating various components such as the crankshaft, connecting rods, and cylinder walls. The oil also helps dissipate heat, ensuring efficient operation.

Advantages of Radial Engines:

- Radial engines offer several advantages, which contributed to their widespread use during the early aviation era:

- a. Compact Size: Radial engines are known for their high power-to-weight ratio and compact design, making them suitable for aircraft with limited engine bay space.

- b. Reliability: The simplicity of design and fewer moving parts make radial engines relatively reliable and easier to maintain compared to other engine types.

- c. High Torque: Radial engines produce high torque at low rotational speeds, making them ideal for applications where a strong power output is required.

Conclusion:

The radial engine’s unique design and operation principles allowed it to play a significant role in aviation history. While they have largely been superseded by more advanced engine designs, their legacy lives on. By understanding the fundamental workings of a radial engine, we gain insights into the engineering marvels of the past and appreciate the progress made in aviation technology.

Watch this video to see the working of Radial Engine-Fundamental working of Radial Engine

Why the radial engine has an odd number of barrels?

The radial engine typically has an odd number of cylinders, often ranging from 3 to 9 cylinders, due to several practical reasons.

Here’s why:

Balanced Firing Order:

An odd number of cylinders allows for a more balanced firing order, which helps reduce engine vibration. In a radial engine, the firing order is determined by the arrangement of the cylinders around the crankshaft. With an odd number of cylinders, the firing intervals can be evenly distributed, resulting in smoother operation compared to an even number of cylinders.

Evenly Spaced Power Strokes:

In a radial engine, each cylinder contributes to the power strokes of the engine as the pistons move outward and push the crankshaft. Having an odd number of cylinders ensures that the power strokes are evenly spaced around the crankshaft, promoting smooth and continuous power delivery.

Efficient Cooling and Airflow:

The odd number of cylinders allows for better cooling and airflow management. The layout of an odd-numbered radial engine enables the placement of an equal number of cylinders above and below the horizontal plane, maximizing the exposure of the cylinders to the airflow. This arrangement aids in more efficient cooling, as the airflow can pass evenly over the cylinders, dissipating heat effectively.

Compact Design:

The odd number of cylinders facilitates a more compact engine design. With an odd number, it is possible to achieve a symmetrical arrangement around the crankshaft, resulting in a more balanced and streamlined engine structure. This compactness is advantageous for aircraft applications where space and weight considerations are critical.

It’s worth noting that although an odd number of cylinders is common in radial engines, there have been instances of engines with even numbers of cylinders, particularly in larger radial engines used in certain applications.

However, the odd-numbered configuration remains more prevalent due to the aforementioned benefits it provides in terms of engine balance, power delivery, cooling, and overall design efficiency.

Visit Forum

Visit Our Friendly Website

thank you 🙂