A propeller works in a similar way that a screw works.

The blades of the propeller are an aerofoil,

Which generates an aerodynamic force as they spin,

The same as any other aerofoil that is moving through the air. The blades of a propeller are slightly angled. As the blade rotates, air accelerates over the front surface,

Causing a reduced static pressure ahead of the blade. This results in a forward thrust, which pulls the aircraft along.

When the aircraft is stationary,

The spinning propeller blades cause purely rotational velocity.

As the aircraft moves forward in flight,

The propeller produces both rotational and forward velocity. The combined vector of these forces is called the pitch, the angle of advance. As a result of this combined rotational and forward velocity,

Each propeller blade section follows a ‘corkscrew’ path through the air.

Different points along the blade will have an optimal angle to the relative airflow to

Operate efficiently at a given airspeed. Propellers are designed to have the most efficient

Angle of attack along the entire length. To achieve this, blades are designed with a twist,

Which reduces the blade angle from the centre to the tip.

Fixed-pitch propellers have only one forward velocity (airspeed)

For a given rpm at which they will operate efficiently. Some propellers are designed with the ability for pilots to adjust the pitch in flight,

Allowing the propeller to operate most efficiently over a wider range of airspeeds.

A spinning propeller will generate two reaction forces:

One force perpendicular to the plane of rotation,

Known as thrust and one component in the plane of rotation, known as propeller torque. Propeller torque is the resistance to motion in the plane of rotation.

For a propeller to work and to provide thrust,

The propeller torque must be overcome or be balanced by engine torque. Adding power causes the engine to rotate faster, increasing engine torque. As the engine rotates faster, the propeller also rotates faster,

Increasing propeller torque until the point where it comes into balance with

Engine torque and rpm stabilizes.

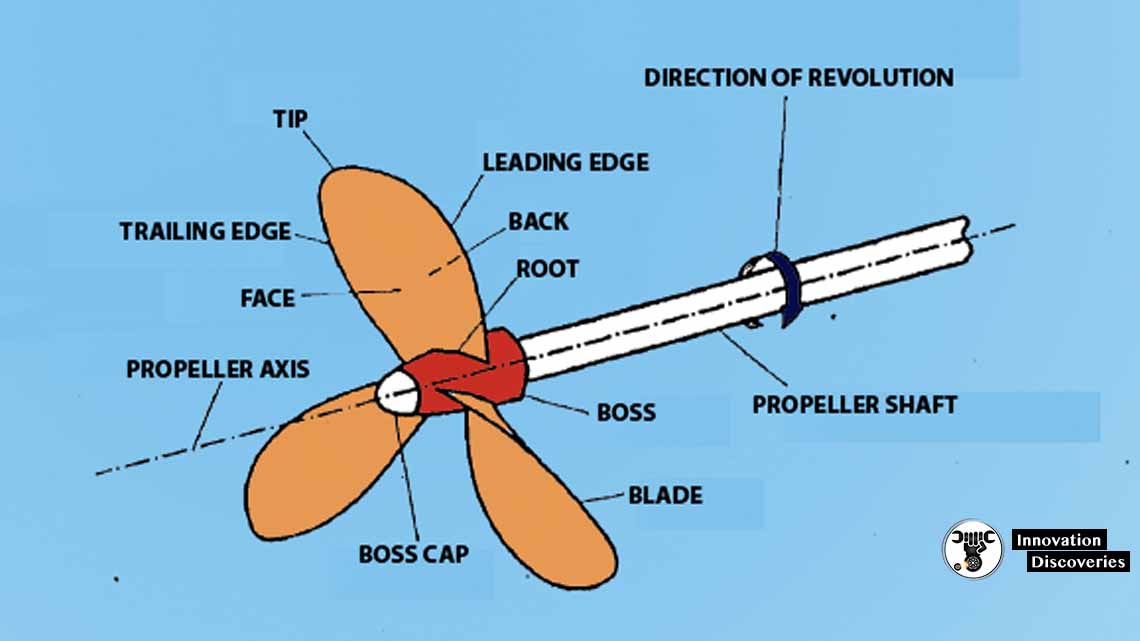

Functions Propeller Shaft:

The propeller shaft’s main function is to connect two mechanical elements or components, i.e. one is a driving element and another is the driving element. We can transmit torque/turning moment and power from one component to another

Which are apart at some distance. Propeller shaft in vehicle and ship just connects the

Main engine to the power drive which drives the vehicle or ship.

The main failure which is generally observed in the propeller shaft is a twisting moment due to excessive shear stress. By proper designing of shaft, we can overcome this failure.

See More:

One Comment