Stray current is an invisible enemy to many mechanical and electrical systems. While often discussed in pipelines, motors, and reinforced structures, one of the most common and costly effects shows up in vehicle cooling systems.

A simple stray current check in coolant can save you from expensive radiator replacements, water pump failures, and premature corrosion. In this guide, we’ll cover:

- What stray current is

- Why coolant systems are highly vulnerable

- Step-by-step method to check stray current in coolant

- Broader effects of stray current in mechanical systems

- Prevention strategies

🔹 What is Stray Current?

Stray current is unintended electrical current that flows through paths other than the designed electrical circuit.

Instead of traveling along wires, electricity escapes into mechanical parts, fluids, or structures.

- In vehicles → coolant, chassis, or radiators become conductors.

- In industries → bearings, pipelines, or reinforced concrete are affected.

👉 Think of it as electricity “taking a shortcut” through places it shouldn’t.

🔹 Why Stray Current Matters in Coolant Systems

Coolant is a mix of water + additives. Over time, or if contaminated, it becomes electrically conductive. If there is poor grounding or faulty insulation, electricity will pass through coolant.

This leads to electrolysis, causing:

- Radiator corrosion and pinholes

- Water pump bearing and seal damage

- Cylinder head or gasket erosion

- Premature coolant degradation

⚙️ Real-world example: A bus fleet experienced multiple radiator leaks within 6 months. The root cause wasn’t poor coolant but stray current entering the cooling system due to a missing ground strap.

🔹 How to Perform a Stray Current Check with Coolant

You only need a digital multimeter (DMM).

Step 1 – Preparation

- Turn ignition ON (engine running is best, with accessories operating).

- Remove the radiator cap or open the coolant reservoir (engine cool).

- Set your multimeter to DC Volts (0–20V range).

Step 2 – Connect Multimeter

- Attach the black lead to the battery negative terminal (ground).

- Insert the red lead into the coolant — avoid touching any metal parts.

Step 3 – Interpret Results

- 0.0 – 0.2 V → Normal, no problem. ✅

- 0.3 – 0.5 V → Warning zone, inspect grounding. ⚠️

- >0.5 V → Dangerous stray current present → risk of electrolysis. ❌

🔹 What to Do if Voltage is High?

- Check Electrical Grounds

- Ensure engine block, chassis, and radiator have strong ground straps.

- Replace corroded or missing grounds.

- Inspect Electrical Accessories

- Auxiliary lights, stereos, or AC units may be poorly grounded.

- Check Coolant Quality

- Old or contaminated coolant increases conductivity.

- Flush and refill with OEM-approved coolant.

- Install Protective Measures

- Some heavy-duty vehicles use sacrificial anodes inside radiators to absorb electrical current.

🔹 Stray Current in Other Mechanical Systems

While coolant systems are a prime victim, stray current also damages other areas:

1. Motor Bearings

- Current passes through rolling elements.

- Causes pitting, fluting, and micro-welding.

- Leads to vibration and premature failure.

2. Pipelines

- DC current leakage causes electrolytic corrosion.

- Requires cathodic protection or insulated joints.

3. Vehicle Chassis

- Poor grounding can route current through steering or suspension components.

- Causes galvanic corrosion, especially in aluminum parts.

4. Concrete Reinforcement

- Stray current accelerates rusting of rebar.

- Weakens structural integrity in underground or metro systems.

🔹 Detection Beyond Coolant

- Voltage drop measurements between structures and ground.

- Clamp meters for leakage paths.

- Vibration analysis for bearing erosion.

- Thermal imaging for abnormal heating spots.

🔹 Prevention Strategies

- Proper grounding & bonding across all components.

- Regular coolant stray voltage checks with a multimeter.

- Scheduled coolant replacement to maintain low conductivity.

- Bearing insulation or grounding rings in motors.

- Cathodic protection for pipelines.

❓ Frequently Asked Questions (FAQ) on Stray Current Check Coolant

1. What causes stray current in coolant?

Stray current in coolant is usually caused by poor grounding, faulty electrical connections, or deteriorated wiring insulation. In some cases, improperly installed aftermarket accessories can also force current to flow through the coolant.

2. Can coolant itself cause stray current?

Coolant does not generate stray current, but it can conduct electricity if it becomes old, contaminated, or mixed with the wrong additives. The higher its conductivity, the more damage stray current can cause.

3. How often should I check for stray current in coolant?

It’s recommended to perform a stray current check every 6–12 months or whenever you notice early signs of electrolysis (pitting, leaks, or unusual coolant discoloration). Fleet operators often check during every major service.

4. What voltage reading is dangerous in a coolant stray current test?

- 0.0 – 0.2 V → Safe

- 0.3 – 0.5 V → Warning zone

- >0.5 V → Dangerous, electrolysis risk

If you measure more than 0.3 V, it’s time to inspect grounding and coolant condition.

5. Can stray current damage parts other than the radiator?

Yes. Stray current can also damage water pumps, gaskets, heater cores, engine blocks, and even sensors. Beyond coolant, stray current can harm motor bearings, pipelines, and reinforced concrete structures.

6. How do I fix stray current problems in a vehicle?

- Check and repair all grounding connections.

- Inspect for faulty electrical accessories.

- Flush and refill with OEM-approved coolant.

- In heavy-duty systems, consider installing a sacrificial anode to reduce electrolysis damage.

7. Is stray current the same as galvanic corrosion?

Not exactly.

- Galvanic corrosion happens when two dissimilar metals interact in a conductive fluid.

- Stray current corrosion is caused by unintended electrical current flowing through a conductive medium (like coolant).

Both lead to material damage, but the causes differ.

🔹 Conclusion

Stray current is a silent killer of both automotive and industrial mechanical systems.

For vehicles, the stray current check with coolant is a quick, inexpensive diagnostic step that can prevent thousands in radiator and engine repairs. For broader systems, understanding stray current effects on bearings, pipelines, and reinforced structures is equally critical.

👉 As mechanical engineers and technicians, performing regular stray current checks and maintaining proper grounding are key to extending equipment life, improving reliability, and reducing downtime.

Discover More:

Discover More:

Read More:

- WORKING OF THERMOSTATS

- CAR THERMOSTAT FUNCTIONS, FAILURE SYMPTOMS, AND REPLACEMENT COST

- PISTON DAMAGE FROM OVERHEATING

- SYMPTOMS OF AN EXHAUST LEAK

- EXHAUST GAS RECIRCULATION (EGR)

- HOW AN ENGINE COOLING SYSTEM WORKS

- WATER COOLING VS AIR COOLING

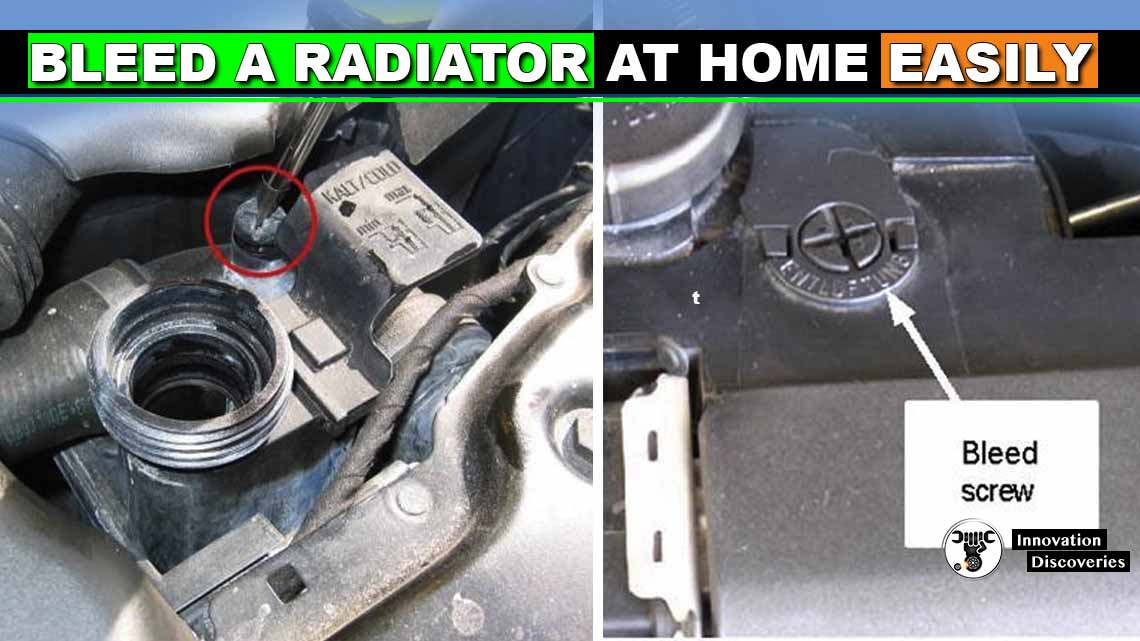

Read: BLEED A RADIATOR AT HOME EASILY

HOW TO APPLY A TEMPORARY REPAIR FOR UPPER RADIATOR HOSE?

Visit Forum

Visit Our Friendly Website