Understanding Bucket Tappets

Precise valve operation is critical to engine performance, efficiency, and durability. One of the key components responsible for maintaining accurate valve timing and clearance is the bucket tappet. Widely used in modern high-speed engines, bucket tappet systems provide direct valve actuation with minimal mass and exceptional rigidity.

This article explores the design, operating principles, and variations of bucket tappets, including mechanical and hydraulic designs, as well as advanced configurations used to improve durability and start-up performance.

What Is a Bucket Tappet?

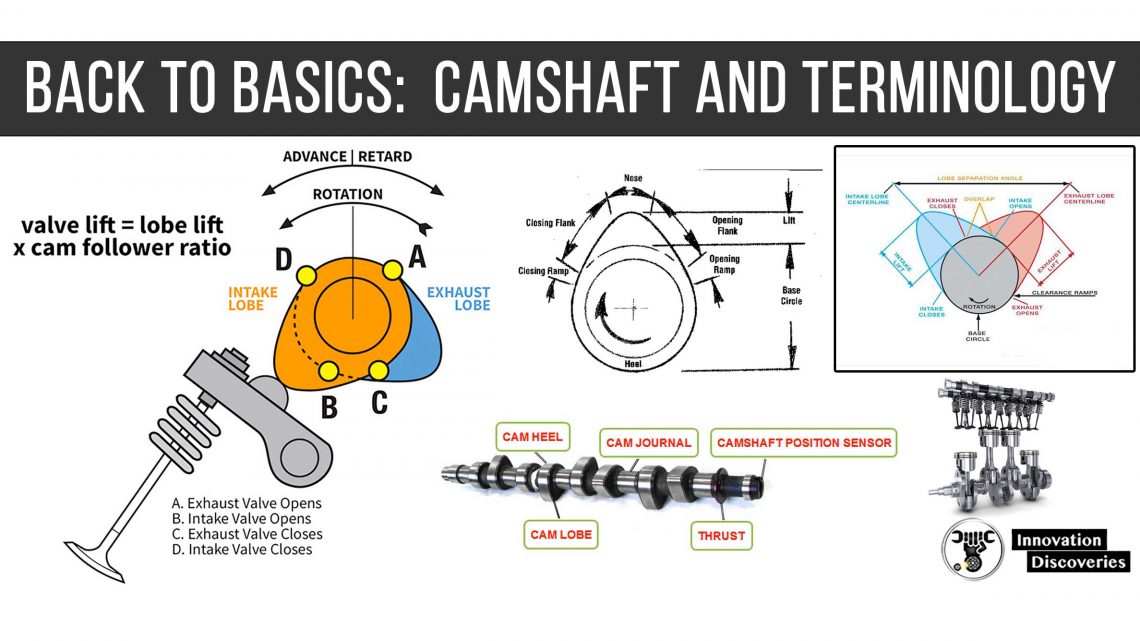

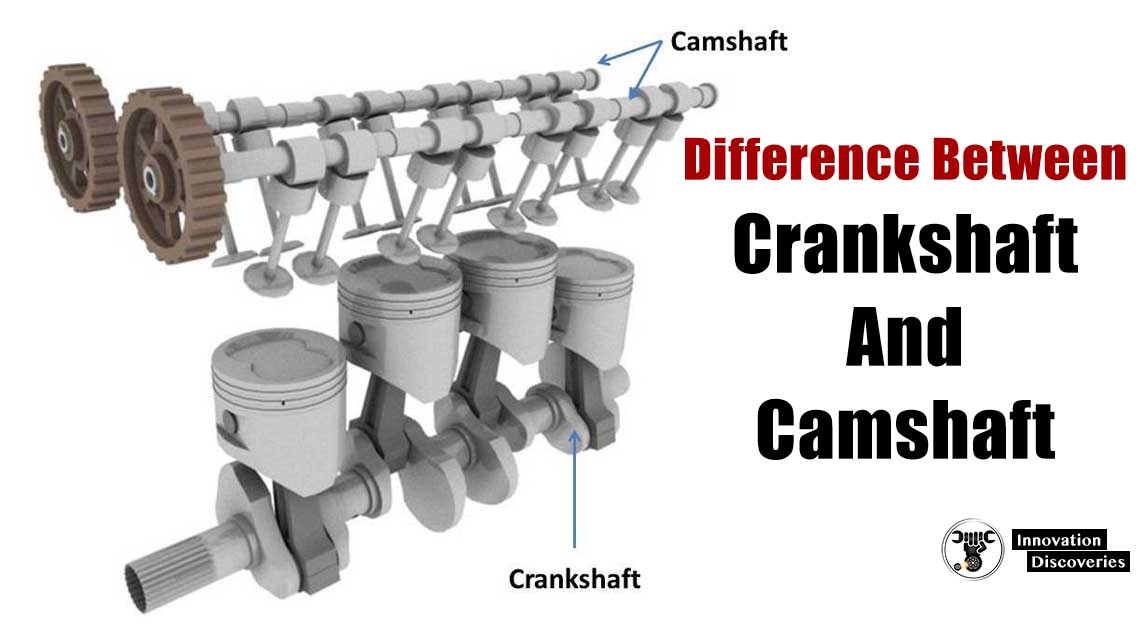

In a bucket tappet valve train, the camshaft acts directly on the valve without any intermediate transmission mechanism such as rocker arms or pushrods. The cam lobe transfers its motion straight to the valve through the bottom surface (crown) of the bucket tappet.

Key Advantages of Direct Valve Actuation

- High valve train rigidity

- Very low moving mass

- Excellent performance at high engine speeds

- Improved valve timing accuracy

Because the cam lobe slides directly on the tappet crown, friction losses occur at the contact surface. To reduce wear and ensure uniform contact, cam lobes are typically bevelled and installed with slight lateral offset. This design causes the tappet to rotate a few degrees with each cam stroke, distributing wear evenly and extending service life.

Mechanical Bucket Tappets

Mechanical bucket tappets rely on manual valve lash adjustment and are typically constructed with a steel body for strength and durability.

Characteristics of Mechanical Bucket Tappets

- Steel construction

- Direct valve actuation

- Mechanical valve lash adjustment

- High reliability and simplicity

Depending on how valve clearance is set, mechanical bucket tappets are available in several configurations.

Mechanical Bucket Tappet with Top Adjusting Shim

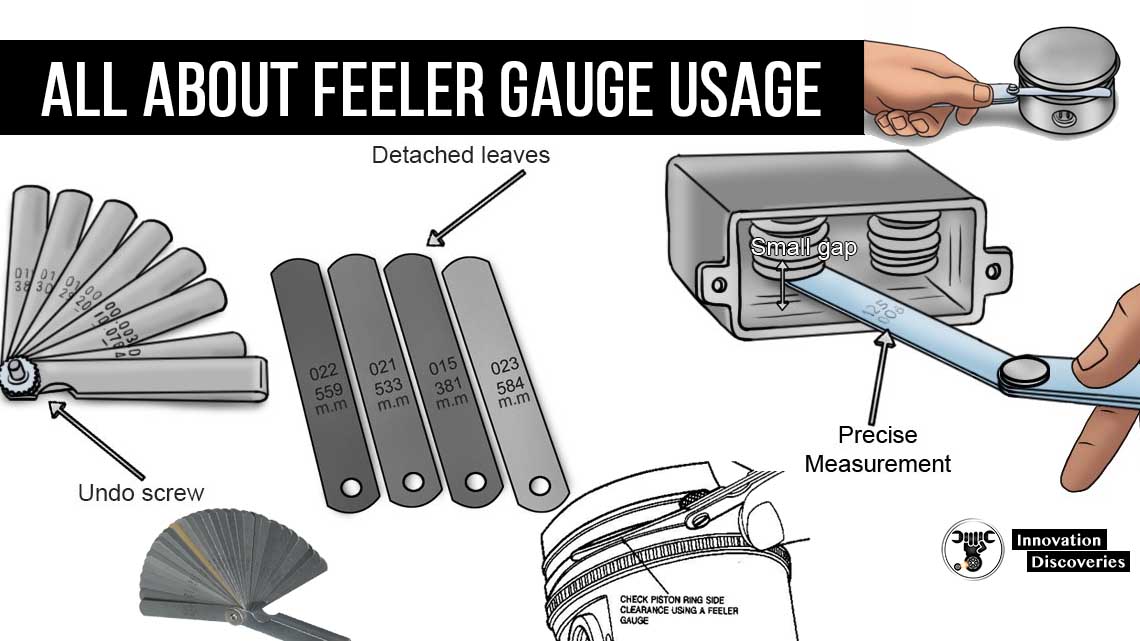

This tappet design uses a shim placed at the top of the tappet to set valve clearance. The shim acts as a spacer between the cam lobe and tappet crown, allowing precise manual adjustment. Available in various thicknesses, it ensures accurate valve lash but requires periodic inspection and replacement to maintain optimal engine performance.

Characteristics

- Adjusting shim loosely inserted into the tappet body

- Shims available in various thicknesses

- Individual shim selection based on material and heat-treatment requirements

- Valve clearance maintained by shim thickness

This system allows precise valve clearance control but requires manual adjustment during servicing.

Mechanical Bucket Tappet with Bottom Adjusting Shim

In this design, the shim is positioned beneath the tappet, between the tappet and valve stem. This reduces moving mass at the cam interface, lowers valve spring forces, and minimizes friction. The larger cam contact area improves durability, making it ideal for high-speed engines with frequent valve actuation.

Characteristics

- Valve clearance pre-set by adjusting shim thickness

- Reduced tappet mass compared to top-shim designs

- Lower valve spring forces

- Reduced friction losses

- Increased contact area between cam lobe and tappet

This design improves efficiency while maintaining mechanical simplicity.

Mechanical Bucket Tappet with Graded Bottom Thickness

Valve clearance is set by precisely machining the tappet crown to different thicknesses, eliminating the need for separate shims. This approach reduces tappet mass, friction losses, and valve spring load while maintaining accuracy. It is cost-effective, simple to manufacture, and widely used in mass-produced engines.

Characteristics

- Valve lash adjustment through graded tappet crown thickness

- Lowest mass bucket tappet design

- Reduced valve spring force requirements

- Lower friction losses

- Larger cam contact area

- Highly cost-effective production

This design is commonly used in high-volume manufacturing due to its simplicity and reduced component count.

Hydraulic Bucket Tappets

Hydraulic tappets automatically maintain zero valve clearance using engine oil pressure. An internal plunger expands to fill gaps caused by wear or thermal expansion, ensuring precise valve timing. These tappets are maintenance-free, quiet, and support consistent engine performance and emissions throughout the engine’s life.

Characteristics

- Direct valve actuation

- Very high valve train rigidity

- Automatic valve lash adjustment

- Maintenance-free for the life of the engine

- Very quiet operation

- Consistently low exhaust emissions throughout engine life

Hydraulic systems compensate for wear, thermal expansion, and component tolerances in real time.

Advanced Hydraulic Bucket Tappet Designs

Advanced hydraulic designs improve oil management and performance under varying conditions. They often combine features like anti-drain and bottom-drain mechanisms to maintain hydraulic stiffness, enhance lubrication, and support smooth valve operation during repeated engine start-ups.

Anti-Drain Bucket Tappet

This tappet design prevents oil from draining out of the outer reservoir when the engine is off. The retained oil ensures immediate valve lash compensation and smooth operation during multiple cold starts, reducing engine noise and wear.

Benefits:

- Improved lubrication during repeated engine start-ups

- Reduced valve train noise on cold starts

Bottom-Drain Bucket Tappet

Bottom-drain tappets optimize the reservoir oil volume for better distribution and faster response during frequent engine start-stop cycles. This improves lubrication efficiency and maintains stable valve actuation under challenging operating conditions.

Benefits:

- Improved operating behaviour during multiple engine start-ups

- Better oil control within the tappet

Labyrinth-Type Bucket Tappet

Labyrinth tappets combine anti-drain and bottom-drain mechanisms for maximum oil retention and reliability. The complex oil path ensures consistent hydraulic stiffness, smooth valve operation, and enhanced performance during repeated cold starts or stop-start engine cycles.

Benefits:

- Significantly improved start-up behaviour

- Enhanced oil retention and distribution

- Greater operational reliability

3CF Bucket Tappet (Cylindrical Cam Contact Face)

The 3CF tappet features a cylindrical cam contact face with anti-rotation guidance, reducing peak surface pressure and friction. Optimized oil flow reduces throughput by up to 80%, allowing higher valve lift and faster opening/closing while maintaining low tappet mass and high rigidity. Ideal for high-performance engines requiring precise, efficient valve operation.

Key Features

- Cylindrical cam contact face with anti-rotation mechanism

- Simplified and reliable oil supply path

- Accelerated valve opening and closing velocities

- Up to 80% reduction in oil throughput due to optimized plunger guidance

- Lower surface pressure in the cam contact area

Performance Advantages

- Enables higher valve lift using smaller plunger diameters

- Very low tappet mass

- Very high valve train rigidity

- Minimized friction losses

These characteristics allow enhanced valve lift profiles without compromising durability.

Conclusion

Bucket tappets are a cornerstone of modern valve train design, offering precision, efficiency, and reliability. From mechanically adjusted systems to advanced hydraulic and 3CF designs, each variation serves a specific purpose depending on performance, cost, and maintenance requirements.

Proper valve lash control not only improves engine performance and noise characteristics but also plays a vital role in emissions control and long-term engine durability. Understanding these components provides valuable insight into how modern engines achieve high efficiency and reliability.

(Technical concepts referenced from © INA / Schaeffler Group. Diagrams recreated in original vector format for educational purposes)

Discover More:

Visit Forum

Visit Our Friendly Website