Introduction

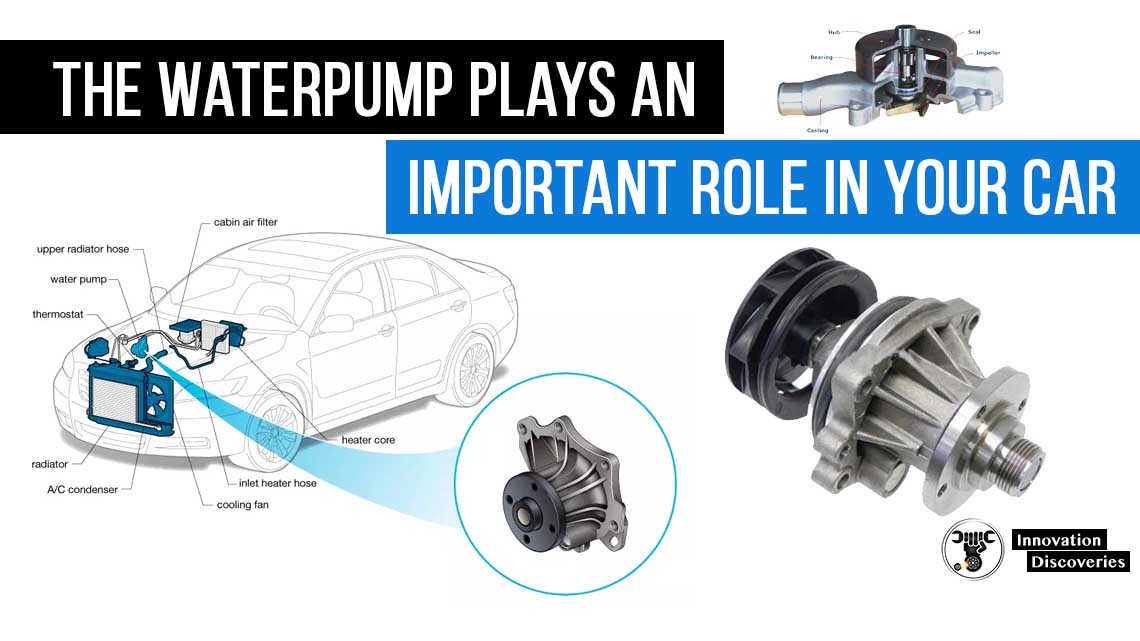

In every internal combustion engine, heat management is critical. Without a proper cooling system, combustion temperatures can soar beyond safe limits, leading to warped cylinder heads, oil breakdown, and even catastrophic engine failure. At the center of this cooling network lies the engine water pump — a compact yet vital component responsible for circulating coolant between the engine block and the radiator.

While often overlooked, the water pump’s design is a marvel of mechanical engineering, balancing fluid dynamics, durability, and precise synchronization with engine operation. In this article, we’ll dive deep into the construction, components, working principle, and technical nuances of the modern engine water pump.

Purpose of the Engine Water Pump

A running engine can produce temperatures exceeding 2,000°C inside the combustion chamber. Though most of this heat escapes via exhaust gases, a large portion transfers to the cylinder walls, pistons, and cylinder head.

The water pump ensures a continuous flow of coolant through passages around these hot components, then to the radiator where heat dissipates to the atmosphere. Without this circulation, hotspots form, leading to detonation, thermal expansion, and engine seizure.

Key Construction Components

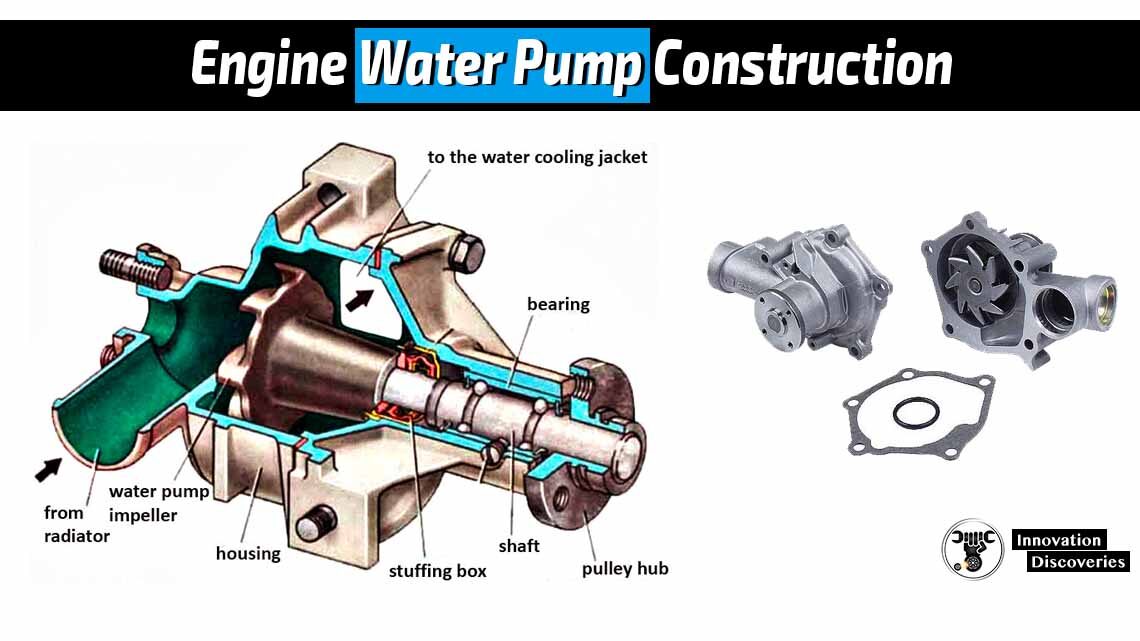

1. Housing:

The water pump housing serves as the body of the pump and provides mounting points. It’s typically made from cast iron or aluminum due to their excellent heat dissipation properties. The housing encases most of the internal components and connects to both the engine and the radiator.

Function: Provides structural support and channels coolant flow.

Materials: Typically cast aluminum (lightweight, corrosion-resistant, good heat transfer) or cast iron (durable for heavy-duty engines). Some performance pumps use magnesium alloys or composite plastics.

Design considerations:

- Must withstand continuous exposure to hot coolant (80–110°C).

- Integrated with mounting flanges for precise alignment to the engine block.

- Incorporates coolant passages and sealing surfaces to prevent leaks under pressure (~1–2 bar in most cooling systems).

2. Impeller:

The impeller is the heart of the water pump. It’s a rotating component that propels coolant throughout the system. Impellers are usually made from cast iron or plastic, with carefully designed vanes or blades to optimize coolant flow. The shape and size of the impeller’s vanes play a critical role in determining the pump’s efficiency.

Function: The pump’s “heart” that imparts kinetic energy to the coolant.

Materials:

- Stamped steel or cast iron for durability.

- Engineered plastics or composites in modern designs to reduce weight and resist corrosion.

Design:

- Closed impellers improve efficiency by reducing recirculation losses.

- Vane geometry (straight vs. curved) is optimized for flow rate (measured in liters per minute, typically 80–150 L/min in passenger cars).

- Clearance between impeller and housing is tightly controlled to minimize cavitation.

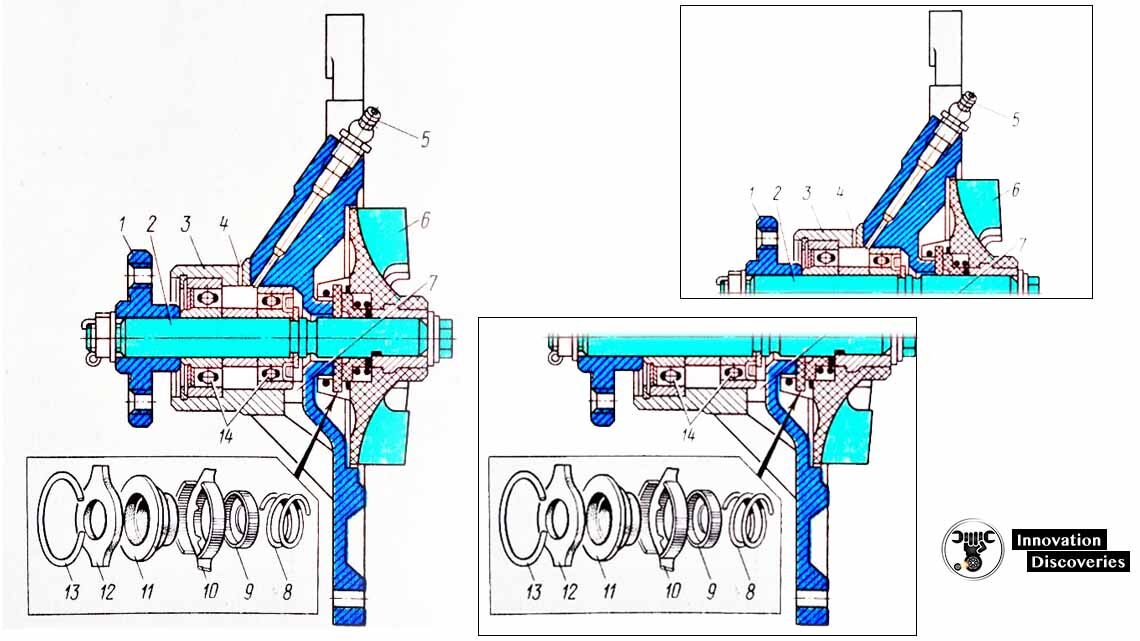

3. Shaft, Bearings, and Seals:

To prevent coolant leaks and maintain a tight seal between the rotating impeller shaft and the stationary housing, water pumps incorporate various seals, such as gaskets and O-rings. Bearings support the impeller shaft, allowing it to spin smoothly and without excess friction. High-quality bearings ensure longevity and reduce the chances of premature failure.

Bearings:

- Usually double-row ball bearings designed to support both radial (belt tension) and axial (impeller thrust) loads.

- Sealed and pre-lubricated for life, since lubrication is not possible after assembly.

Seals:

- Mechanical seals prevent coolant from leaking along the shaft.

- Made from materials like ceramic, carbon, or silicon carbide for wear resistance.

Failure modes:

- Worn bearings → wobbling impeller, noise, eventual leakage.

- Seal failure → external coolant leak or contamination of bearings.

4. Drive Mechanism:

Most water pumps are driven by the engine’s crankshaft through a belt, pulley, or a more modern serpentine belt system. The drive mechanism transfers rotational power from the engine to the water pump, enabling it to circulate coolant efficiently.

The pump must rotate in sync with engine speed:

- Belt-driven pumps (most common):

- Powered by serpentine belts or dedicated V-belts.

- Speed ratio between crankshaft pulley and pump pulley determines coolant flow rate.

- Gear-driven pumps (heavy-duty engines):

- Direct drive from the camshaft or crankshaft gears.

- Offers durability but increases manufacturing cost.

- Electric water pumps (modern vehicles):

- Independent of engine speed.

- Controlled by ECU for on-demand cooling, reducing parasitic drag and improving fuel efficiency.

5. Coolant Inlet and Outlet Ports:

The water pump features inlet and outlet ports to connect to the engine and the radiator. These ports facilitate the flow of coolant into and out of the pump, helping to regulate the engine’s temperature.

Inlet (from radiator): Draws cooled liquid back into the engine.

Outlet (to block/head passages): Forces coolant under pressure into the hottest areas.

Ports are shaped and angled to minimize turbulence and flow restriction.

6. Back Plate (Rear Housing)

- Acts as a cover for the impeller chamber.

- Ensures a sealed coolant pathway.

- Designed to guide flow efficiently toward the outlet and reduce recirculation losses.

Working Principle

As the engine runs, the water pump is activated by the drive mechanism. The impeller starts to rotate within the housing, drawing coolant from the engine’s outlet port and forcing it into the radiator.

As the coolant passes through the radiator, excess heat is dissipated, lowering the temperature of the coolant. The now-cooled coolant returns to the engine through the inlet port, completing the circulation cycle.

- Rotation initiated – As the engine runs, crankshaft motion (or an electric motor) drives the pump shaft.

- Coolant suction – Impeller blades create a low-pressure region, pulling coolant from the radiator via the inlet port.

- Coolant acceleration – Rotating vanes impart velocity to the coolant, converting mechanical energy into fluid kinetic energy.

- Discharge – Flow is directed through the outlet into engine coolant passages.

- Heat transfer loop – Heated coolant returns to the radiator, dissipates heat, and re-enters the pump.

Flow is continuous, maintaining stable engine temperatures under all load conditions.

Water Pump Drives: Technical Insights

Types:

- Belt-driven (traditional):

- Simple and reliable, but coolant flow increases directly with engine speed — inefficient at idle or high RPM extremes.

- Gear-driven:

- Found in commercial diesels; robust but adds mechanical complexity.

- Electric:

- Variable-speed operation improves thermal management, especially in stop-start or hybrid vehicles.

- Can run after engine shutdown to prevent heat soak damage.

Design trade-offs:

- Mechanical pumps: Reliable but less efficient due to parasitic losses (~1–2% of engine output).

- Electric pumps: More efficient but require complex electronics and higher manufacturing cost.

The water pump housing consists of two parts:

The water pump housing consists of two essential parts that work together to encase and support the internal components of the pump while also providing crucial connection points for the engine and the cooling system. These two parts are:

Front Housing:

The front housing, also known as the pump body or cover, is the portion of the water pump housing that faces the engine. It is typically bolted or fastened directly onto the front of the engine block. The front housing contains the impeller, bearings, and seals.

The impeller is centrally located within the front housing and is attached to the impeller shaft. As the engine’s drive mechanism powers the impeller shaft, the impeller rotates within the front housing, creating a pumping action that circulates coolant throughout the engine’s cooling system.

The front housing also features the inlet and outlet ports that facilitate the flow of coolant into and out of the pump.

Rear Housing:

The rear housing, also referred to as the back plate or rear cover, is the portion of the water pump housing that faces away from the engine and is usually in contact with the radiator or another heat exchanger. The rear housing encloses the back side of the impeller and helps maintain a sealed environment within the pump.

This housing is connected to the front housing, creating a closed chamber where the impeller operates. The rear housing is designed to ensure that the impeller’s rotation effectively circulates coolant without causing leaks or losing pressure.

Together, these two housing parts create a secure and contained environment for the critical components of the water pump. The front housing interfaces with the engine’s cooling system, while the rear housing interfaces with the external cooling components like the radiator. This design allows the water pump to efficiently and effectively regulate the engine’s temperature, ensuring optimal performance and preventing overheating.

In summary, the water pump housing consists of a front housing and a rear housing that work harmoniously to enclose and protect the pump’s internal components, enabling the efficient circulation of coolant and maintaining the engine’s temperature within the desired range.

Common Failure Modes

- Bearing wear: Causes noise, shaft wobble, eventual impeller damage.

- Seal failure: Coolant leakage, often visible as stains or drips near the pump.

- Impeller erosion/corrosion: Especially with poor-quality coolant.

- Cavitation damage: Pitting and erosion of impeller surfaces when vapor bubbles collapse violently inside the pump.

Maintenance & Service Tips

- Replace the pump when coolant leaks, whining noises, or overheating appear.

- Always replace belts and tensioners with the pump (since they age together).

- Use only the recommended coolant type to avoid corrosion and premature seal wear.

Regular maintenance is essential to ensure the water pump drive system’s longevity and reliability. Belts, in particular, should be inspected for signs of wear and replaced according to the manufacturer’s recommendations. If the water pump drive system fails, it can lead to engine overheating and subsequent damage. Therefore, it’s important to address any issues promptly and replace worn-out components.

In conclusion, the water pump drive is a fundamental component that enables the circulation of coolant within an internal combustion engine’s cooling system. Whether through a belt-driven system or direct drive, its role in maintaining proper engine temperature and preventing overheating cannot be overstated. Regular maintenance and timely replacement of components are essential to ensure the efficient operation of the water pump drive system and the overall health of the engine.

FAQ about Engine Water Pumps

1. How long does an engine water pump last?

On average, a water pump lasts between 60,000 to 100,000 km (or about 5–7 years), depending on the vehicle, coolant quality, and driving conditions.

2. What are the symptoms of a failing water pump?

Common signs include:

- Coolant leaks near the front of the engine

- Grinding or whining noises from the pump area

- Engine overheating

- Steam coming from the radiator

- Visible rust or corrosion around the pump housing

3. Can I drive with a bad water pump?

It is not recommended. A failing water pump can quickly cause engine overheating, leading to warped cylinder heads, blown head gaskets, or complete engine failure.

4. What causes water pump failure?

- Worn bearings or seals

- Poor-quality or contaminated coolant

- Cavitation and corrosion inside the pump

- Misaligned or overly tight drive belts

- Lack of regular coolant changes

5. Should the water pump be replaced with the timing belt?

Yes. In many vehicles, the water pump is driven by the timing belt. Since both parts wear out at similar intervals, replacing them together saves on labor costs and prevents future breakdowns.

6. Are electric water pumps better than mechanical ones?

Electric pumps are more efficient because they are independent of engine speed and can provide on-demand cooling. However, they are costlier and mainly found in modern vehicles, hybrids, and performance cars.

7. Can I repair a water pump instead of replacing it?

Generally, water pumps are not serviceable. Once seals, bearings, or impellers fail, replacement is the best solution.

Conclusion

The engine water pump may be small compared to the engine itself, but it’s the backbone of the cooling system. Its precision construction — from impeller geometry to seal design — ensures that the engine operates within a narrow temperature band, maximizing efficiency, longevity, and emissions control.

As engines evolve, water pump technology is moving toward electronic control and advanced materials, but the core principle remains the same: ensuring steady coolant flow to keep the engine running cool under any condition.

Discover More:

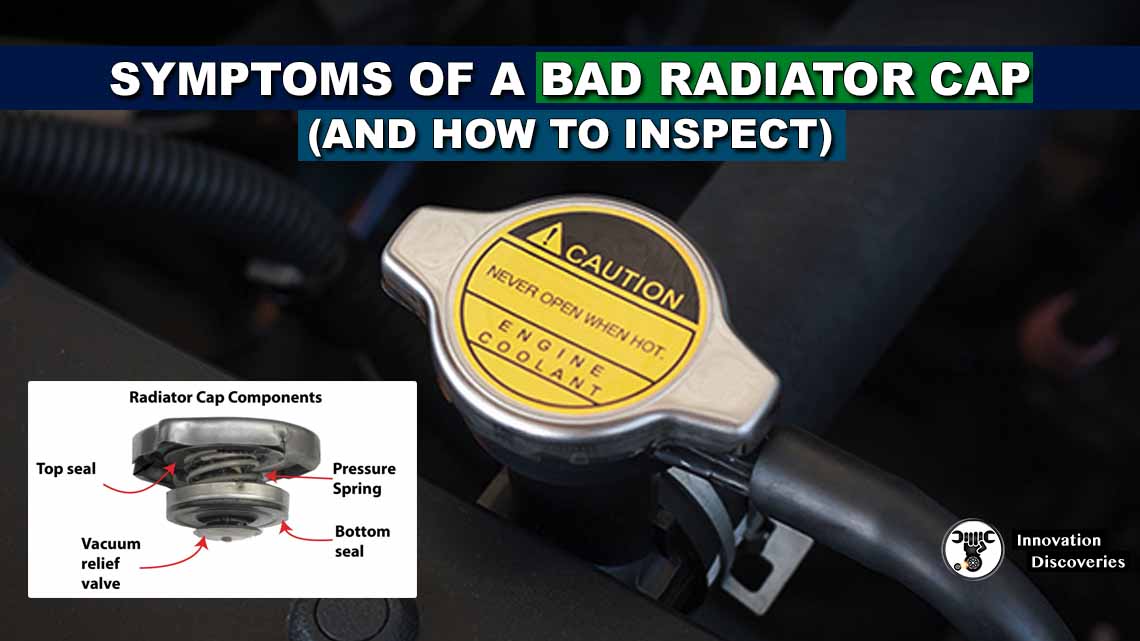

Read: SYMPTOMS OF A BAD RADIATOR CAP (AND HOW TO INSPECT)

Visit Forum

Visit Our Friendly Website

One Comment