Introduction

In the intricate world of internal combustion engines, a component plays a crucial role in maintaining optimal operating temperatures and preventing overheating – the water pump. This unassuming yet essential device ensures that the engine remains within the desired temperature range by circulating coolant throughout the system.

In this article, we’ll take a comprehensive look at engine water pump construction, its components, and its functioning.

The Basics of Engine Water Pumps

Before delving into the construction details, it’s important to understand the fundamental purpose of an engine water pump. In a typical automotive engine, combustion generates a substantial amount of heat.

To prevent the engine from becoming dangerously hot, a cooling system is employed, which relies on the water pump to circulate coolant fluid between the engine and the radiator.

Construction Components

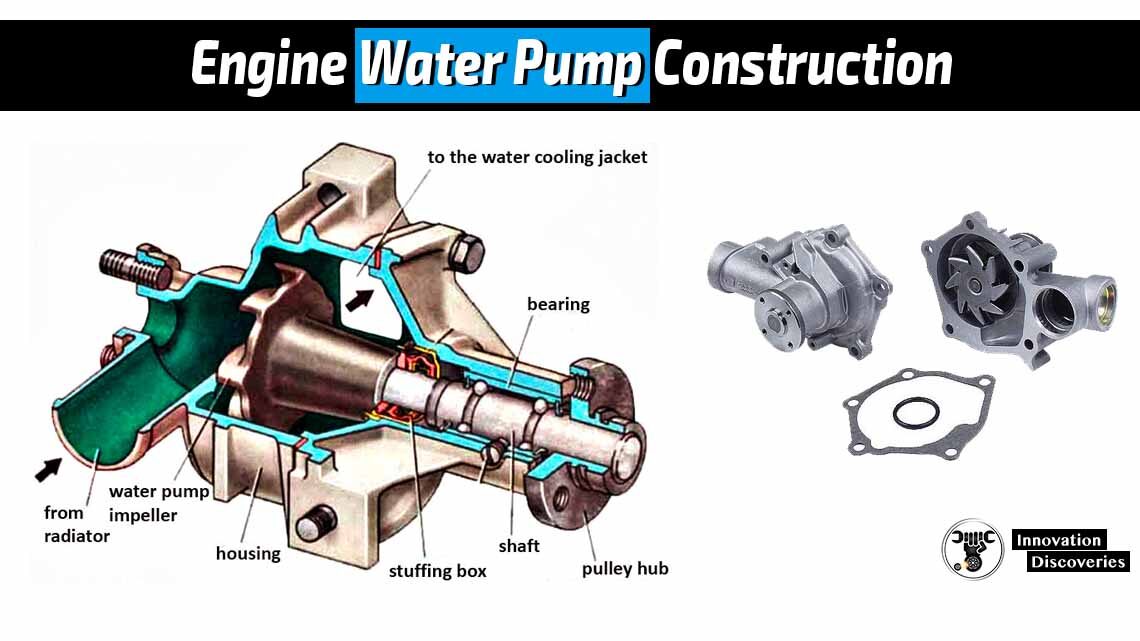

1. Housing:

The water pump housing serves as the body of the pump and provides mounting points. It’s typically made from cast iron or aluminum due to their excellent heat dissipation properties. The housing encases most of the internal components and connects to both the engine and the radiator.

2. Impeller:

The impeller is the heart of the water pump. It’s a rotating component that propels coolant throughout the system. Impellers are usually made from cast iron or plastic, with carefully designed vanes or blades to optimize coolant flow. The shape and size of the impeller’s vanes play a critical role in determining the pump’s efficiency.

3. Seals and Bearings:

To prevent coolant leaks and maintain a tight seal between the rotating impeller shaft and the stationary housing, water pumps incorporate various seals, such as gaskets and O-rings. Bearings support the impeller shaft, allowing it to spin smoothly and without excess friction. High-quality bearings ensure longevity and reduce the chances of premature failure.

4. Drive Mechanism:

Most water pumps are driven by the engine’s crankshaft through a belt, pulley, or a more modern serpentine belt system. The drive mechanism transfers rotational power from the engine to the water pump, enabling it to circulate coolant efficiently.

5. Coolant Inlet and Outlet Ports:

The water pump features inlet and outlet ports to connect to the engine and the radiator. These ports facilitate the flow of coolant into and out of the pump, helping to regulate the engine’s temperature.

Working Principle

As the engine runs, the water pump is activated by the drive mechanism. The impeller starts to rotate within the housing, drawing coolant from the engine’s outlet port and forcing it into the radiator.

As the coolant passes through the radiator, excess heat is dissipated, lowering the temperature of the coolant. The now-cooled coolant returns to the engine through the inlet port, completing the circulation cycle.

The water pump housing consists of two parts:

The water pump housing consists of two essential parts that work together to encase and support the internal components of the pump while also providing crucial connection points for the engine and the cooling system. These two parts are:

Front Housing:

The front housing, also known as the pump body or cover, is the portion of the water pump housing that faces the engine. It is typically bolted or fastened directly onto the front of the engine block. The front housing contains the impeller, bearings, and seals.

The impeller is centrally located within the front housing and is attached to the impeller shaft. As the engine’s drive mechanism powers the impeller shaft, the impeller rotates within the front housing, creating a pumping action that circulates coolant throughout the engine’s cooling system.

The front housing also features the inlet and outlet ports that facilitate the flow of coolant into and out of the pump.

Rear Housing:

The rear housing, also referred to as the back plate or rear cover, is the portion of the water pump housing that faces away from the engine and is usually in contact with the radiator or another heat exchanger. The rear housing encloses the back side of the impeller and helps maintain a sealed environment within the pump.

This housing is connected to the front housing, creating a closed chamber where the impeller operates. The rear housing is designed to ensure that the impeller’s rotation effectively circulates coolant without causing leaks or losing pressure.

Together, these two housing parts create a secure and contained environment for the critical components of the water pump. The front housing interfaces with the engine’s cooling system, while the rear housing interfaces with the external cooling components like the radiator. This design allows the water pump to efficiently and effectively regulate the engine’s temperature, ensuring optimal performance and preventing overheating.

In summary, the water pump housing consists of a front housing and a rear housing that work harmoniously to enclose and protect the pump’s internal components, enabling the efficient circulation of coolant and maintaining the engine’s temperature within the desired range.

Engine Water Pump Construction

Engine water pumps are intricate devices crucial for maintaining the optimal operating temperature of internal combustion engines. These pumps are responsible for circulating coolant throughout the engine’s cooling system, preventing overheating and ensuring efficient performance. Let’s explore the construction of engine water pumps in more detail.

1. Housing:

The foundation of an engine water pump is its housing. Typically made from durable materials such as cast iron or aluminum, the housing encases all the internal components of the pump.

It features inlet and outlet ports through which coolant enters and exits the pump. The housing also provides mounting points for the pump within the engine bay.

2. Impeller:

The impeller is the heart of the water pump, and its design significantly influences the pump’s efficiency. Constructed from materials like cast iron, steel, or plastic, the impeller consists of carefully crafted vanes or blades. These vanes play a critical role in propelling coolant through the system.

As the impeller rotates within the pump housing, it creates a low-pressure area that draws coolant from the engine through the inlet port. The rotating vanes then push the coolant towards the outlet port, facilitating circulation.

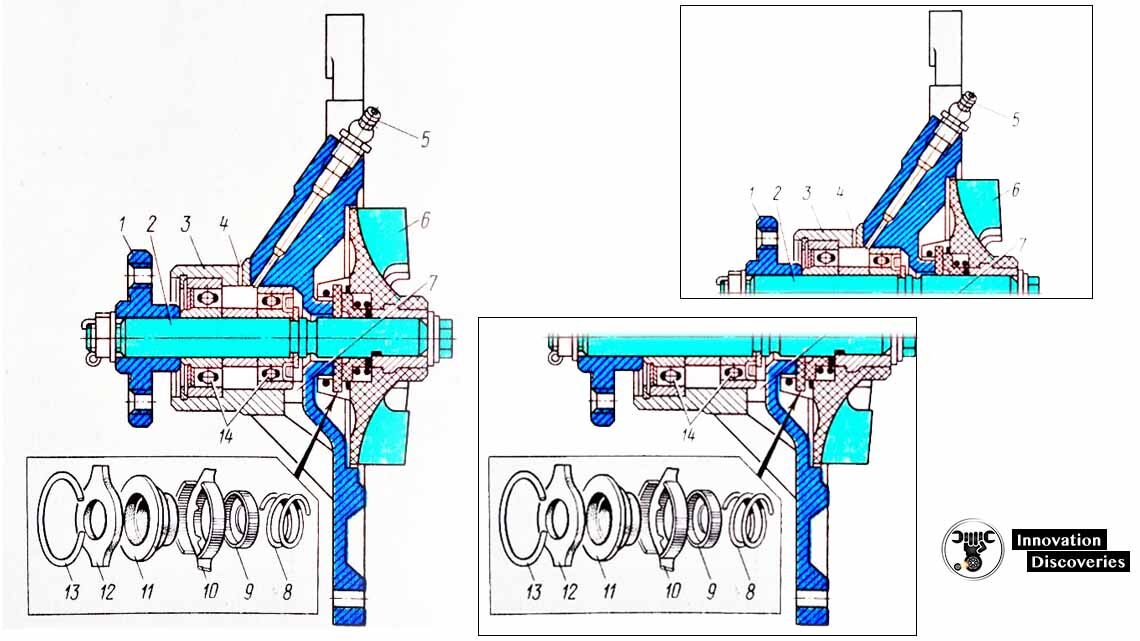

3. Seals and Bearings:

Seals are vital components that prevent coolant leaks and maintain a sealed environment within the water pump. They are positioned around the impeller shaft, ensuring a watertight seal between the rotating impeller and the stationary housing.

Gaskets, O-rings, and mechanical seals are commonly used to achieve this seal. Bearings, on the other hand, provide support for the impeller shaft, allowing it to rotate smoothly with minimal friction. High-quality bearings are crucial for the pump’s longevity and efficient operation.

4. Drive Mechanism:

The water pump’s drive mechanism connects it to the engine’s power source, which is usually the crankshaft. This connection ensures that the pump operates in synchronization with the engine’s RPM.

Depending on the vehicle’s design, the drive mechanism can involve belts, pulleys, or a serpentine belt system. As the engine runs, the drive mechanism transfers rotational energy to the water pump, enabling the impeller to circulate coolant.

5. Coolant Flow Control:

Some water pumps include features to regulate coolant flow based on engine conditions. These features can include thermostatic valves that control the flow rate based on coolant temperature.

Such mechanisms optimize cooling efficiency by adjusting the coolant circulation rate according to the engine’s needs.

6. Back Plate:

The back plate, also known as the rear housing or back cover, completes the pump’s enclosure. It is positioned on the opposite side of the impeller from the inlet port and helps maintain the pump’s sealed environment. The back plate ensures that coolant is efficiently directed towards the outlet port after passing through the impeller.

In essence, the construction of an engine water pump involves several critical components working in harmony. From the impeller’s rotational movement to the housing’s precision design, each element plays a vital role in maintaining the engine’s temperature and preventing overheating.

As engines continue to evolve, so does water pump technology, with advancements aimed at improving efficiency, durability, and overall performance.

Water pump drive

The water pump drive is a crucial component of an internal combustion engine’s cooling system. It refers to the mechanism responsible for transmitting power from the engine to the water pump, enabling the pump’s impeller to circulate coolant and regulate the engine’s temperature. Let’s explore the various aspects of water pump drives and their significance in engine operation.

Types of Water Pump Drives:

- Belt-Driven System: In many traditional engines, a belt-driven system is used to transmit power from the engine’s crankshaft pulley to the water pump. A serpentine belt or multiple V-belts connect the crankshaft pulley to the water pump pulley. As the engine runs, the crankshaft’s rotational motion is transferred to the water pump pulley, which then drives the water pump’s impeller.

- Direct Drive: Some modern engines, especially those equipped with electric water pumps, use a direct drive mechanism. In this setup, the water pump is directly connected to an electric motor or an auxiliary drive unit. This eliminates the need for a mechanical belt connection and allows for more precise control over the water pump’s operation.

Importance of the Water Pump Drive:

- Coolant Circulation: The primary purpose of the water pump drive is to ensure the continuous circulation of coolant throughout the engine’s cooling system. As the engine operates, it generates heat, and the coolant absorbs this heat. The water pump drive ensures that the coolant is constantly circulated, transferring heat away from the engine components to maintain the desired operating temperature.

- Preventing Overheating: Proper coolant circulation is vital for preventing engine overheating. If the water pump drive fails or the coolant isn’t circulated effectively, the engine temperature can rise to dangerous levels, potentially causing engine damage. The water pump drive, by powering the pump’s impeller, plays a critical role in preventing such scenarios.

- Efficiency and Performance: An efficient water pump drive system ensures that the water pump operates optimally, promoting efficient cooling and overall engine performance. Engines that run at the right temperature operate more smoothly, achieve better fuel efficiency, and produce fewer emissions.

Maintenance and Replacement:

Regular maintenance is essential to ensure the water pump drive system’s longevity and reliability. Belts, in particular, should be inspected for signs of wear and replaced according to the manufacturer’s recommendations. If the water pump drive system fails, it can lead to engine overheating and subsequent damage. Therefore, it’s important to address any issues promptly and replace worn-out components.

In conclusion, the water pump drive is a fundamental component that enables the circulation of coolant within an internal combustion engine’s cooling system. Whether through a belt-driven system or direct drive, its role in maintaining proper engine temperature and preventing overheating cannot be overstated. Regular maintenance and timely replacement of components are essential to ensure the efficient operation of the water pump drive system and the overall health of the engine.

One Comment