Francis turbine is a sort of hydraulic turbine which is utilized to change overpressure

Driven vitality of water into mechanical vitality. This mechanical vitality is additionally

Utilized for various reasons like power age. Francis turbine is a kind of response turbine i.e. here weight doesn’t stay the same all through the turbine.

Francis turbine is named on James B.

Francis. He grew an internal outspread stream response turbine called as Francis turbine. Later on, some alteration was made on it then it is called a current Francis turbine. In current Francis, turbine water goes into the turbine sprinter radially and

Leaves pivotally through its inside. Because of this reason at some point, it is known

As a blended stream response turbine.

Francis turbine takes a shot at medium head and medium release i.e. it chips away at 30-600 meter head. Presently multi day’s Francis turbine is the most regularly utilized

Turbine as a result of its working conditions. The packaging of this turbine ought to be

Water/air proof since weight fluctuates consistently all through the sprinter. At the passage of the turbine, weight is a lot higher than the weight at exit.

At the point when water begins to move through the sprinter the weight vitality begin

Changing over into dynamic vitality. This turbine utilizes both active vitality and weight vitality for working i.e. Francis turbine requires both response power and drive constraint for power age.

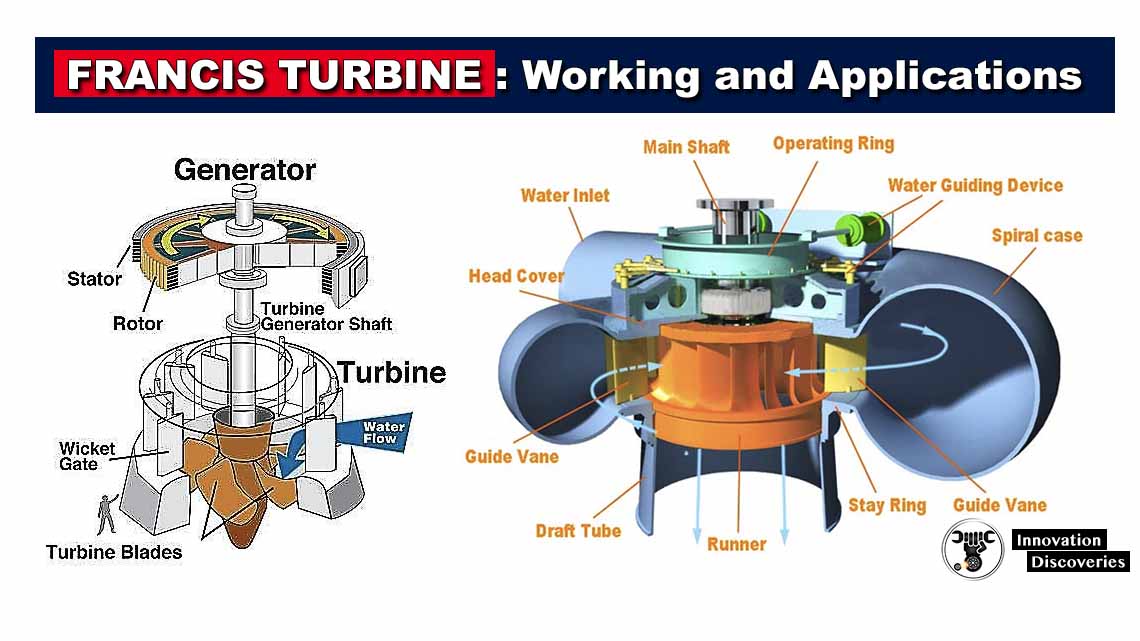

CONSTRUCTION:

Development of Francis turbine is very confused,

It has different segments which ought to be masterminded inappropriate way and

Ought to be fabricated with high exactness. The following are the primary segments of Francis turbine.

PENSTOCK:

Penstock exchange water from supply to the turbine.

It is an extensive distance across the pipe,

By and large, made up of cement or cast steel.

SPIRAL CASING:

Spiral packaging has a consistently diminishing cross-sectional region. Packaging is comprised of cast steel,

Plate steel or cement contingent on the prerequisite and working state of the turbine. The fundamental reason for packaging is to give a steady speed of the water at the bay of the sprinter. The primary reason for the diminishing cross-sectional region circumferentially to

Keep up the consistent speed of water all through the sprinter and aides in keeping up a uniform weight. Toward the end, water strikes to the sprinter edge with uniform speed and weight.

FIXED VANES AND GUIDE VANES:

The fundamental capacity of settled vanes and guide vanes is to change overweight vitality into motor vitality. Settled vanes dependably stay stationary at their position and

Aides in conveying a load because of the inner weight vitality of the water. Settled vanes increment the effectiveness of the turbine. They are commonly comprised of solid metal,

Cast steel or at times manufactured steel according to prerequisites. Guide vanes used to manage the water towards the sprinter in a settled guide vane point bearing. In the wake of going through settled vanes water manages by the guide vane before going into a sprinter. Guide vanes are settled yet turn about their own pivot i.e. they can change their plot for the stream of water as indicated by the heap and working conditions.

RUNNER:

The sprinter of the Francis turbine is comprised of cast press,

Cast steel and tempered steel. The state of the sprinter chooses the stream of water through the turbine. Francis turbine has two cases, in initial one straightforward Francis turbine i.e.

It has internal spiral stream type sprinter and in second case blended stream Francis

Turbine or present-day Francis turbine. It has a blended stream i.e. water goes into the sprinter radially and leaves pivotally. The sprinter of the Francis turbine comprises of arrangement of bended

Vanes mounted circumferentially in the rakish space between two plates.

At the point when water alters its course from spiral to hub if there should be an

Occurrence of current Francis turbine then delivers a circumferential power on sprinter which pivots the sprinter. The sprinter is appended with a shaft which is additionally

Connected to a generator for power creation.

DRAFT TUBE:

The draft tube is mounted at the exit of the sprinter. Water turns out through a sprinter goes to the tailrace through a draft tube. Draft tube is a bit by bit expanding cross-segment region

Which joins sprinter exit to the tailrace. It is comprised of give steel or cement a role according to necessities. Draft tube must be impenetrable that is the reason its end

Ought to be into the tailrace and should be submerged underneath the dimension of water in the tailrace. The fundamental motivation behind the draft tube is to change over

Speed vitality rejected from the sprinter into the weight vitality and second primary

A draft tube can make a suction head at the sprinter exit.

In short, we can say that a draft tube is utilized to change over dynamic vitality into

Weight vitality to expand the proficiency of the turbine. It is a significant segment of the Francis turbine.

WORKING:

In the wake of packaging water goes into the sprinter,

Here water first strikes to settled sharp edges at that point control vanes. Settled vanes convert the head accessible with water somewhat into the dynamic head. Settled vanes expel whirls from the water and make a direct stream of the water. After that water strikes to control vanes which are stationary at their place however spins around their own pivot.

Guide vanes chooses the best possible point at which water strikes to the sprinter

Cutting edges and control the stream rate of water into the sprinter.

The guide vanes are controlled by methods for wheel if there should be an occurrence of

Little units or by utilizing some consequently worked representative in the event of bigger units. At the point when a stack builds the stream rate of water increments by

Methods for guide vanes and as the heap diminishes,

The stream rate consequently diminishes.

The sprinter of Francis turbine has an arrangement of bent vanes,

These vanes are structured with the goal that water goes into the sprinter radially and

Abandons it pivotal way if there should arise an occurrence of current Francis turbine yet

In the event of old variant straightforward Francis turbine water in and out both in radially. This adjustment toward sprinter from outspread to pivotal produces a

Circumferential power on the sprinter and sprinter begins turning and yield is taken by Uniting shaft with the sprinter. With the assistance of shaft, control is exchanged to the generator which is utilized for an age of power.

APPLICATIONS:

- Francis turbine can be worked for various heads this is the primary preferred standpoint of this turbine and because of this Francis turbine has different applications.

- It is the most normally utilized turbine in the hydro control plant for power age.

- Blended stream response turbine has some different applications in water system purposes like siphon the water from the beginning some more.

- It is the most effective turbine nowadays, so it tends to be utilized for various purposes for power age by utilizing pressure driven vitality of water.

One Comment