Synchromesh gearbox is the latest version of Constant mesh type.

It is a manually operated transmission in which change of gears takes place between gears that are already revolving at the same speed.

In this type of gearbox, gears can rotate freely or it is locked on layout shaft.

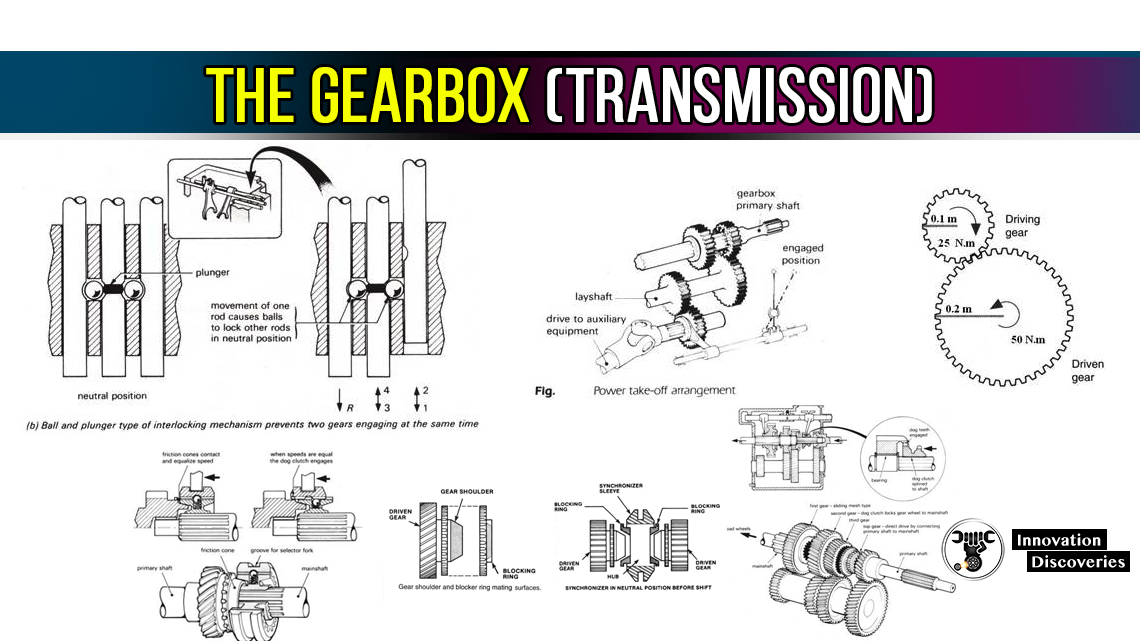

Synchromesh is an improvement on dog clutch.

The synchronizer is the main part of this gearbox that stabilizes the speed.

A synchronizer is a kind of clutch which lets components turning at different speeds.

To synchronize the speeds cone friction is used.

Also, read – How manual gearboxes work

This synchronizer consists of two parts, Synchro cone, and Baulk ring.

Cone is the part of a gear and ring is the part of the synchronizer.

The balk ring prevents the gears from engaging before they are rotating at correct speeds.

While engaging, the ring will gradually slide into the cone and the friction will slow or speeds up the gear wheel.

Finally, it stabilizes the speed of synchronizer and gear and thus, it revolves at the same speed.

The gears on the layshaft are fixed to it while those on the main shaft are free to rotate on the same.

Synchromesh Gearbox:

Principle:

In a gearbox, there is always a difficulty in engaging the stationary gear with the gears already rotating at a high speed.

The principle states that ”Before engaging the gears they are brought in frictional contact with each other and after equalizing the speed the engagement is done.”

Construction:

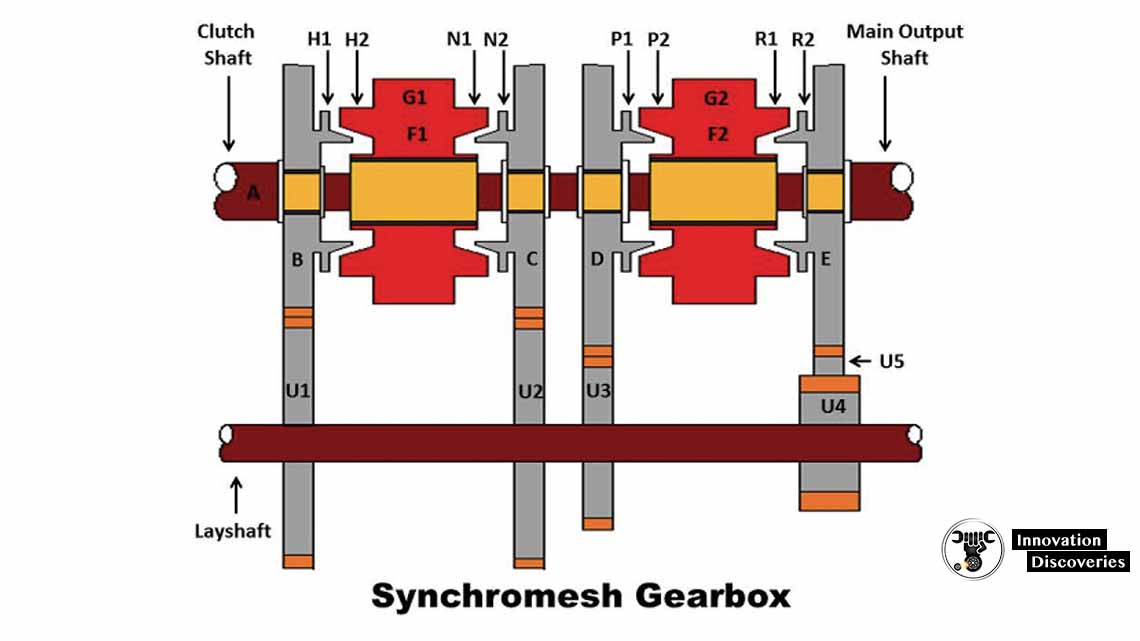

The synchronizer is placed between two gears. So, we can use one unit for two gears.

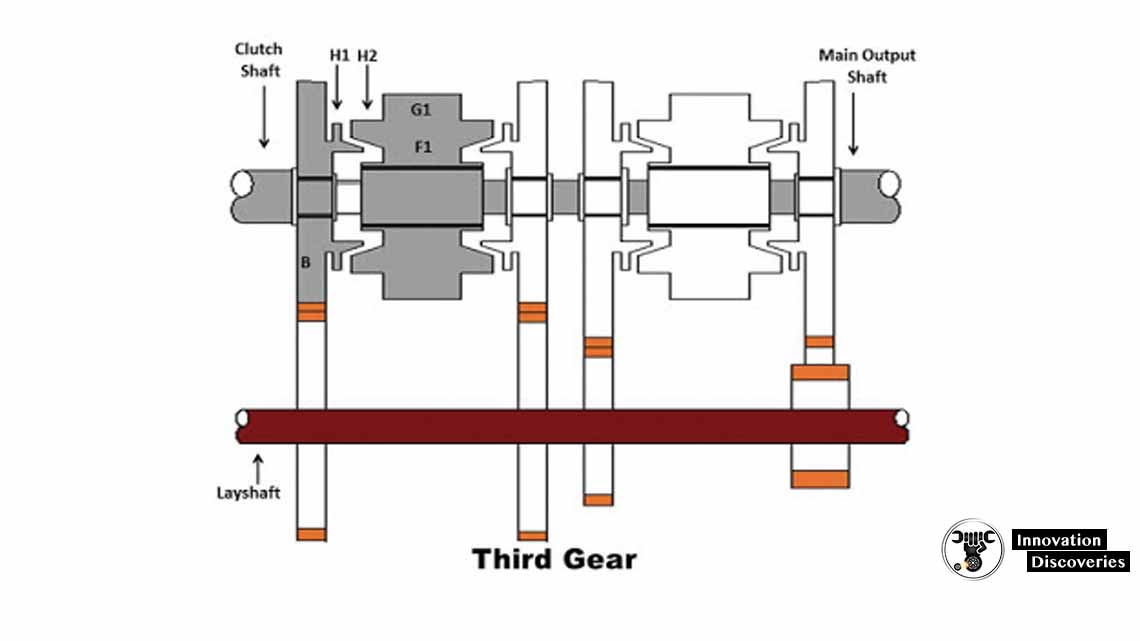

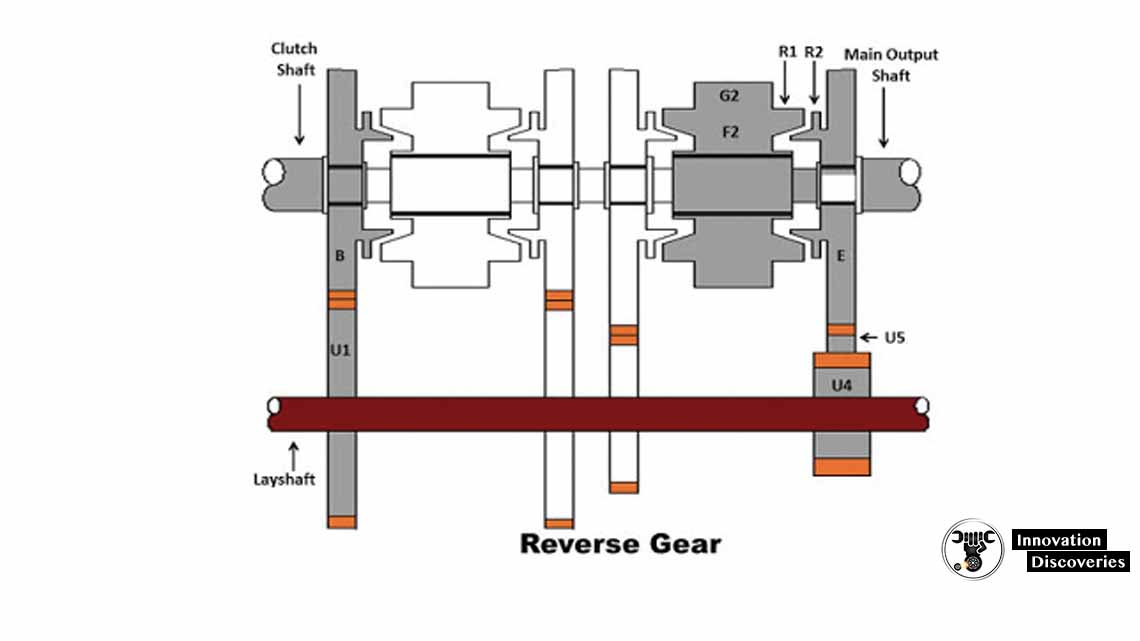

G1 and G2 are the ring-shaped members who are having the internal tooth that fits onto the external teeth.

F1 and F2 are the sliding members of the main shaft.

H1, H2, N1, N2, P1, P2, R1, R2 are the friction surface.

1. Main shaft Gears:

A spline shaft is used as the output shaft over which the synchronizers and Gears are mounted.

According to Fig. B, C, D, E are the gears that can freely rotate on the main shaft in mesh with corresponding gears in the layshaft.

As long as shaft A is rotating all the gears in the main shaft and layshaft rotates continuously.

2. LayShaft Gears:

It is the intermediate shaft over which gears with suitable size are mounted and is used to transmit the rotational motion from clutch shaft to the final output shaft.

According to Fig. U1, U2, U3, U4 are the fixed gears on the countershaft (layshaft).

3. Clutch Shaft:

It is the shaft used as an input shaft in the gearbox as it carries the engine output to the gearbox.

4. Cone Synchromesh:

The side of the gear to be engaged has two features.

One is hollow-cone, and the other is cone surrounded by the ring of dog teeth.

The gear is made the cone and teeth that the synchromesh mechanism contacts.

5. Synchronizers:

They are the special shifting devices used in the synchromesh gearbox which has conical grooves cutover.

It’s surface that provides frictional contact with the gears which is to Mesh to equalize the speed of the main shaft, Layshaft and clutch shaft which in turn provides smoother shifting of gears.

6. Gear lever:

It is the shifting lever operated by the driver and is used to select the appropriate gear i.e. 1, 2, 3, 4, 5 or reverse gear.

Working:

In the synchromesh gearbox, the Layshaft is connected to the engine directly, But it rotates freely when the clutch is disengaged.

Because the gears have meshed all the time, The synchro brings the layshaft to the right speed for the dog teeth to mesh to achieve the desired speed of the output shaft.

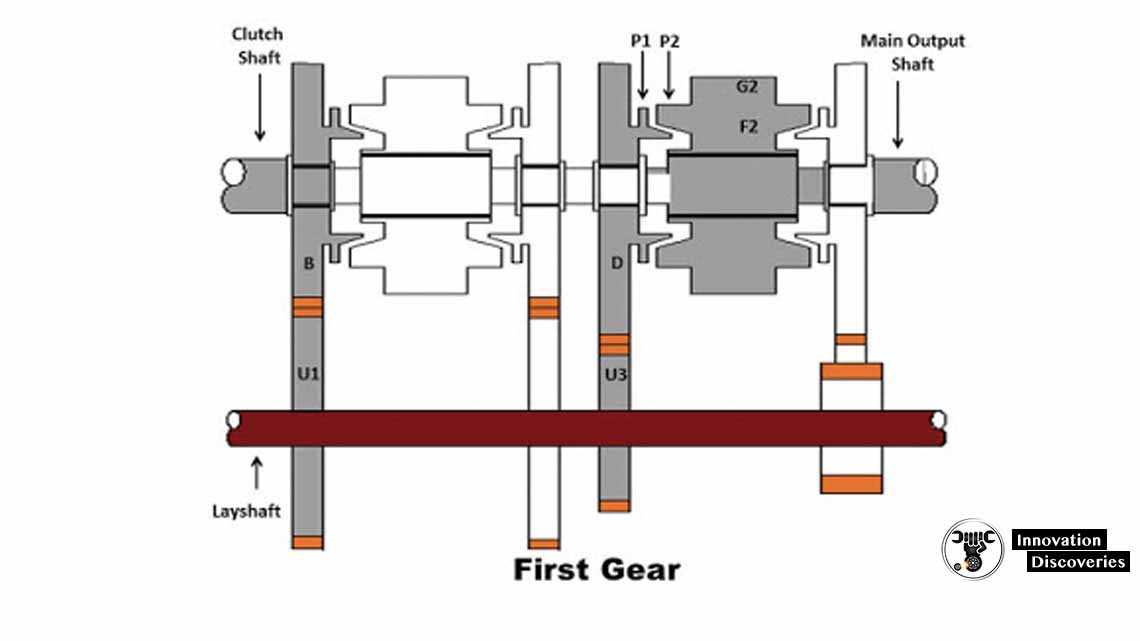

1. Working of First Gear:

For the first gear, the ring shaft member and the sliding members i.e., G2 and F2 moves towards the left till the cones P1 and P2 rub each other.

Then friction makes their speed equal.

Once their speeds are equal G2 is further pushed towards the Left and it engages with the teeth L2.

A motion is carried from clutch gear B to the layshaft gear U1.

Then it goes to layshaft U3, and the motion is moved to the main shaft gear D.

From there the motion is transferred to F2 which is the sliding, member and then to the main shaft for the final drive.

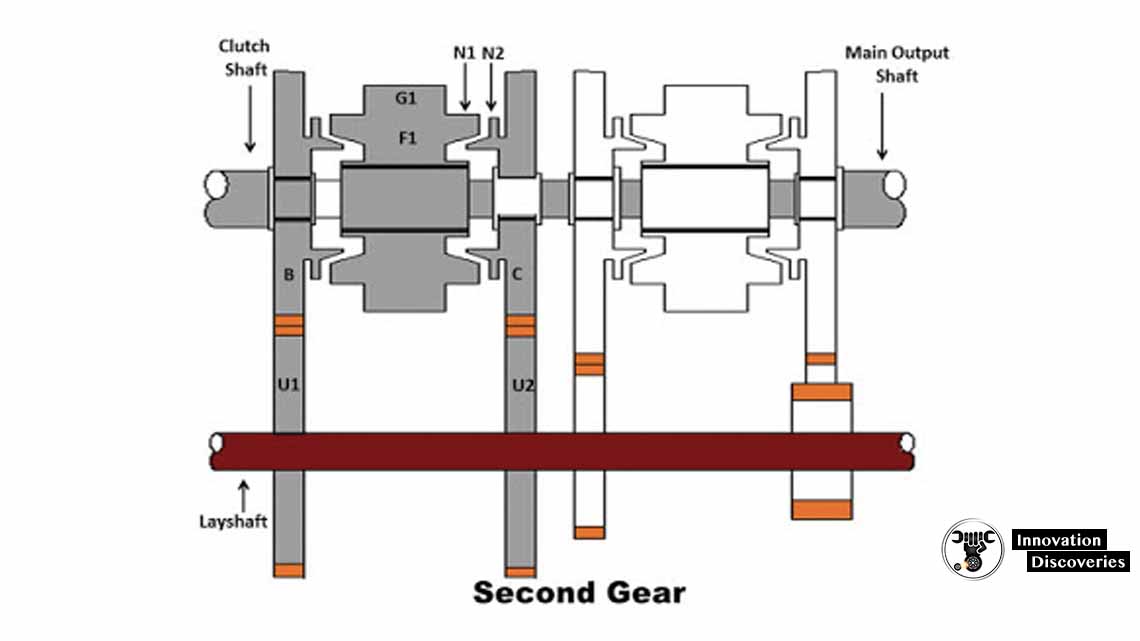

2. Working of Second Gear:

For second gear the ring shaft and the sliding members i.e., G1 and F1 moves towards the right till the cones N1 and N2 rub each other.

Then the friction makes their speed equal.

G1 is further pushed towards the right so that it meshes with the gear.

The motion is transferred from clutch gear B to the layshaft gear U1.

From U1 the motion is transferred to U2.

From U2 it is shifted to the main shaft gear C.

Then the motion is transferred to the sliding member F1.

Then it goes to the main shaft for the final drive.

3. Working of Top Gear:

For top gear or direct gear, the motion is shifted directly from clutch gear B to the sliding member F1.

Then from F1 to the main shaft, This is done by moving G1 and F1 to the left.

4. Working of Reverse Gear:

For reverse gear, the motion is transferred from clutch gear A to the layshaft gear U1.

From there it is transferred to layshaft gear U4 and then to the intermediate gear U5.

From there to the main shaft gear E and then to the sliding member, F2 and then to the main shaft for the final drive.

This is done by moving G2 towards the right.

Intermediate gear helps to achieve the reverse gear.

SEE MORE:

Advantages:

- Smooth and Noise-free shifting of gears which is most suitable for cars.

- No loss of torque transmission from the engine to the driving wheels during gear shifts.

- Double clutching is not required.

- Less vibration.

- Quick shifting of gears without the risk of damaging the gears.

Disadvantages:

- It is extortionate due to its high manufacturing cost and the number of moving parts.

- When teeth make contact with the gear, the teeth will fail to engage as they are spinning at different speeds which causes a loud grinding sound as they clatter together.

- Improper handling of gear may easily prone to damage.

- It cannot handle higher loads.

Read More:

This is all about the synchromesh gearbox.

If you have any queries regarding this article, ask by commenting.

If you like this article Don’t forget to share it with your friends on social networks.

Subscribe our website for more informative articles. Thanks for reading it.

7 Comments