REGZAM means “ACTIVE MACHINE” with 5 essential design features

- User-friendly design

- Reliable Mitsubishi Engine (6D34-TLE2A)

- New APC Control

- Fatigue Free & Comfortable Cabin

- Powerful Operation

Technical Specifications

ENGINE

| Model | Mitsubishi 6D34-TLE2A, 4 cycleintercooler turbo charged diesel engine |

| Number of cylinders | 6 |

| Bore & Stroke | 104mm × 115mm |

| Total Displacement | 5.86 L |

| Rated output | 110kW/2,050min–1 (ISO Net) |

| Max. torque | 580N・m/1,400min–1 (ISO Net) |

| Compression ratio | 18.2:1 |

| Combustion system | Direct injection |

| Specific fuel consumption | 225g/kW-hour |

| Cooling system | Pressurized water circulated by a centrifugal pump with thermostat |

| Lubrication system | Pressurized oil fed by a gear pump through full-flow and by-pass cartridge filter |

| Starter | Electric, 24V-5kW |

| Generator | Alternator, 24V-35A |

| Governor | Mechanical |

| Air cleaner | Dry type filter |

HYDRAULIC SYSTEM

| Pumps | Double variable piston pump and gear pump |

| Max. discharge flow | 2×235 L/min |

| Max. discharge pressure | 31.4MPa |

| Max. discharge pressure (High power) | 32.4MPa |

| Oil filtration | Full-flow filter with replaceable element, drain cartridge filter, pilot line filter and suction strainer |

| Control valves | 5+4 section multiple control valves (with one free service circuit) |

| Pilot pump | Gear type |

| Oil cooler | Finned tube, forced ventilation |

| Pressure relief valves | Primary and secondary on each circuit |

CAB & CONTROLS

| Type | All weather & sound suppressed, 1,000mm wide pressed steel cab mounted on 6 point viscourse mounting |

| Right hand levers | Controls the boom & bucket |

| Inner right hand lever (with foot pedal) | Controls the right hand track |

| Inner left hand lever (with foot pedal) | Controls the left hand track |

| Left hand lever | Controls the arm & swing |

| Pilot control | Travel, boom, arm, bucket and swing |

| Engine throttle | Electric “Accell dial” |

| Meter & gauges | Hour meter, water temperature and fuel level |

| Working lights | Provided on the boom left side and mounted on the frame |

| Lubrication chart | Inside the tool box |

APC150

● Quick Selection of Working Modes

P: Professional Mode for heavy duty application (H Mode)

A: All-around Multi Purpose Mode for all application from precision work to heavy duty work by stroke of operation levers

E: ECO Mode for economical works

● Color monitor display with back up light

● Engine oil pressure

● Engine oil filter

● Hydraulic oil filter

● Engine Preheater

● Hydraulic oil temperature

● Water temperature

● Water level

● Fuel level

● Battery charge

● APC monitor and air cleaner

● Calendar

BOOM, ARM AND BUCKET

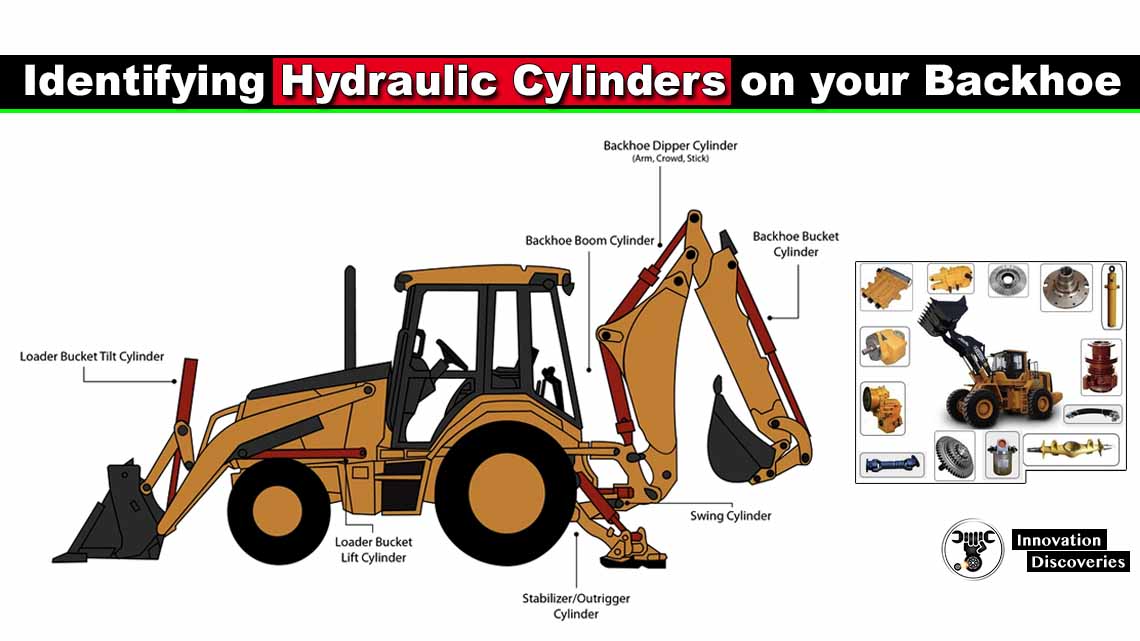

| Boom cylinders | Two, double acting |

| Bore & Stroke | 125mm×1,315mm |

| Arm cylinder | One, double acting |

| Bore & Stroke | 135mm×1,630mm |

| Bucket cylinder | One, double acting |

| Bore & Stroke | 120mm×1,090mm |

| Lubrication | Grease nipples and/ or centralized greasing for remote points |

| Bucket digging force | 136kN |

| (High power) | 144kN |

| Arm digging force | 99kN |

| (High power) | 104kN |

Note: High power can be used with STD arm and short arm.

SWING SYSTEM

| Drive | Axial piston motor with shock-less valve and reduction gear |

| Brake | A hydraulic brake that locks automatically when the swing control lever is in the neutral position and a mechanical parking brake which is applied when the safety lock lever is pulled backwards, the engine is turned off or the swing control lever is in the neutral position |

| Lubrication | Completely housed and grease bathed |

| Max. swing speed | 13min-1 |

| Tail swing radius | 2,750mm |

| Min. front swing radius | 3,460mm |

TRAVEL SYSTEM

| Drive | Independent axial piston motor with reduction for each side |

| Brakes | Independent disk parking brake for each side, applied automatically when the travel levers are in the neutral position |

| Track shoes | 46 each side HD820R 49 each side HD820RLC |

| Track adjustment | Grease cylinders with recoil springs |

| Lubrication | Sealed-for-life rollers and front idlers with floating seals |

| Travel speed | High 0~5.5km/h Low 0~3.6km/h |

| Gradeability | 70% (35°) |

| Max. drawbar pull | 179.5kN |

| Ground clearance (less grouser bar) | 465mm |

| Track length | 4,170mm HD820R 4,460mm HD820RLC |

SERVICE DATA

| Fuel tank | 320 L |

| Cooling system | 23 L |

| Engine oil | 22 L |

| Track drives | 2×5 L |

| Swing drive | 4.0 L |

Hydraulic oil tank

| ( level ) | 165 L |

| ( system ) | 260 L |

In standard figure, with the 2.93m arm, 600mm grouser shoes and 0.8m3 (HD820RLC: 0.9m3)ISO, bucket.

| Operating weight | 19,500kg: HD820R 20,300kg: HD820RLC |

| Ground pressure | 43kPa: HD820R 42kPa: HD820RLC |

Equipment

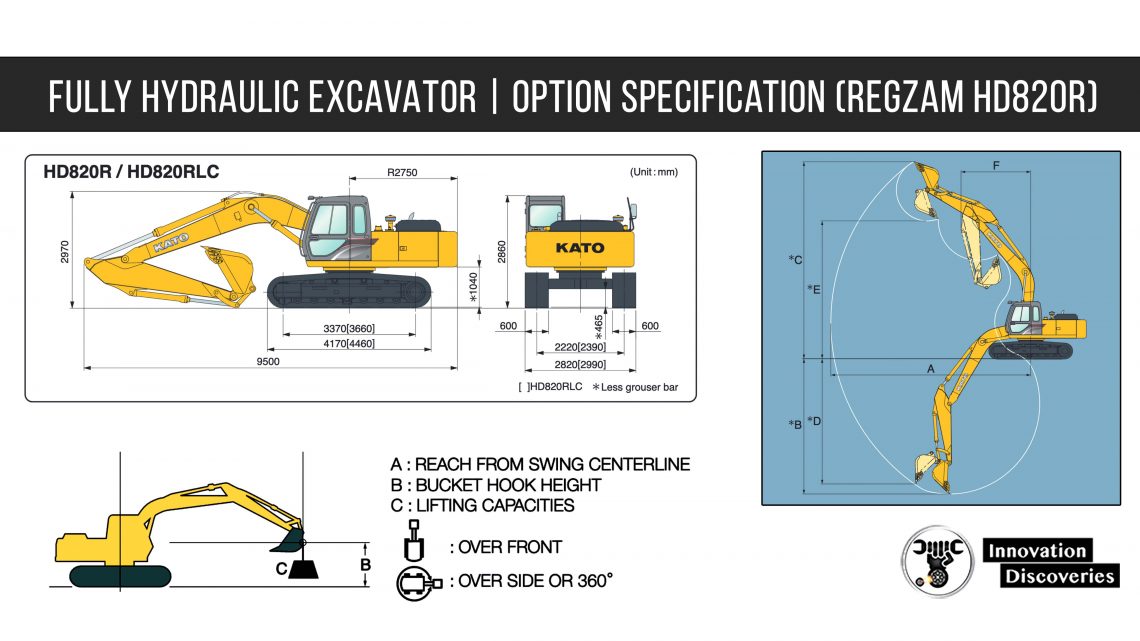

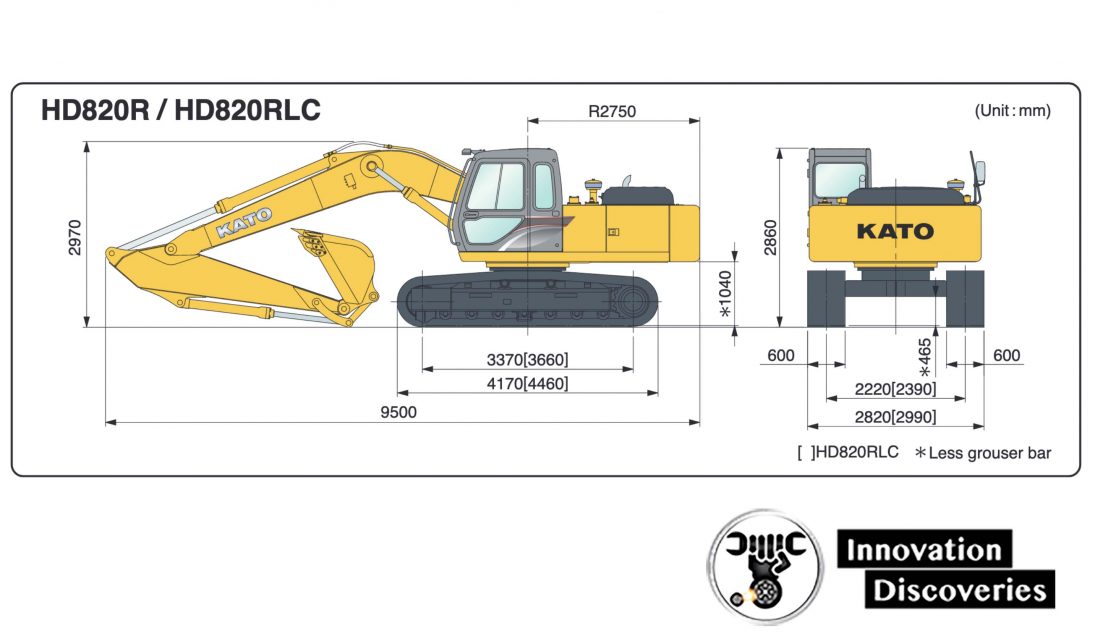

Dimensions

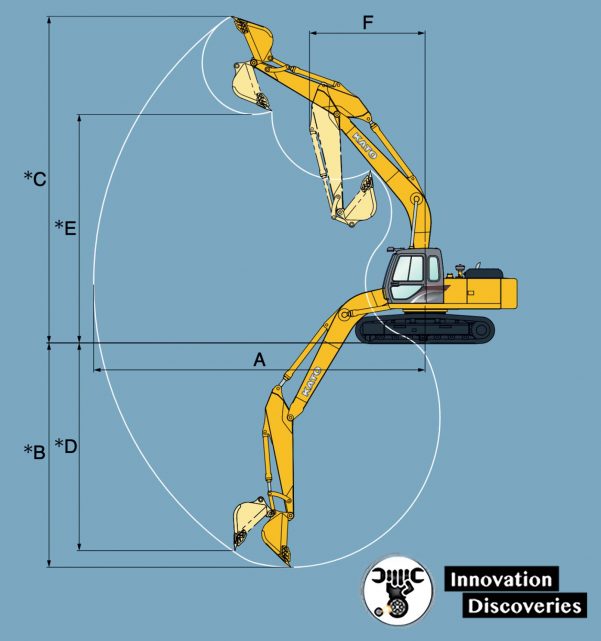

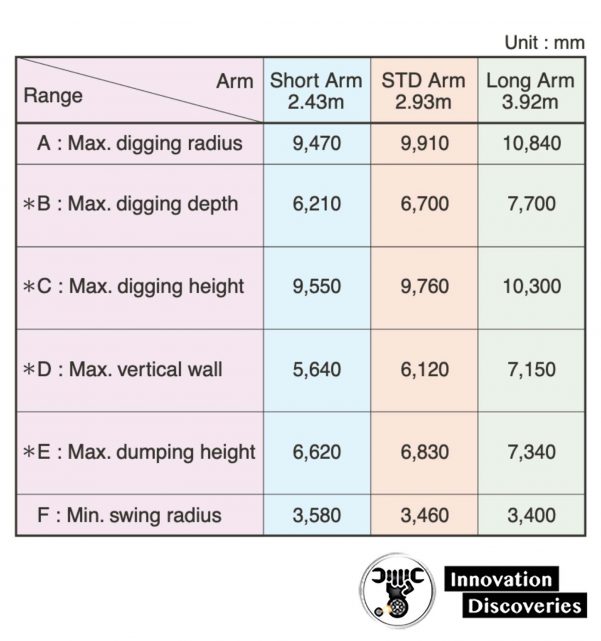

Working Ranges

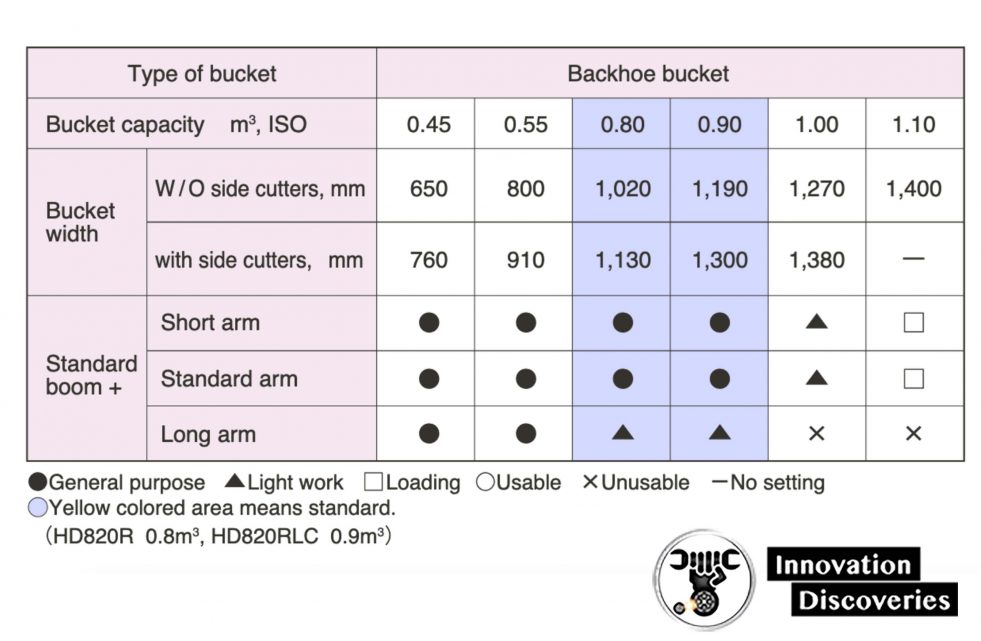

Bucket

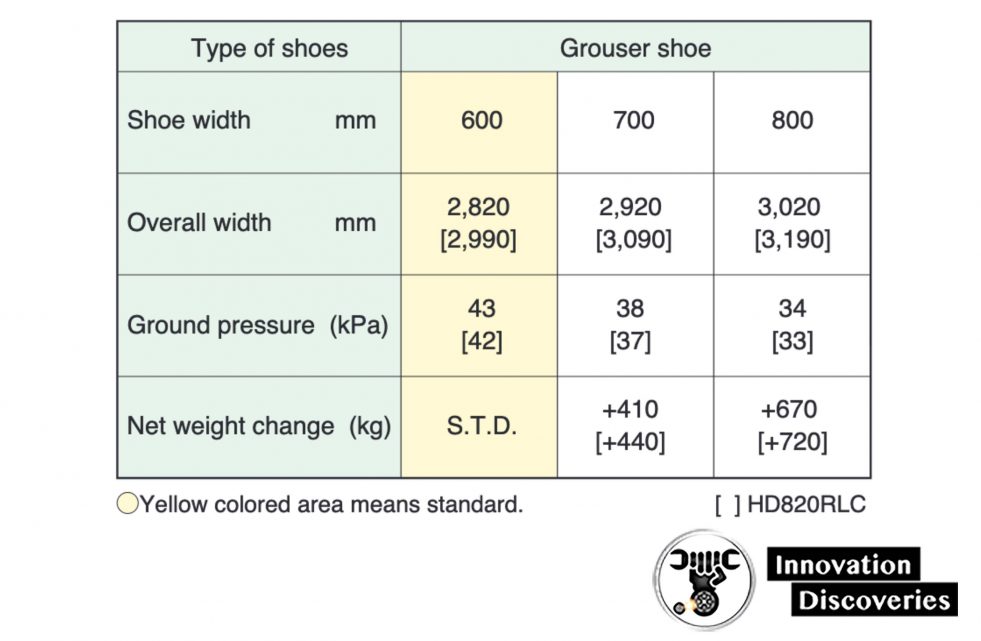

Track Shoes

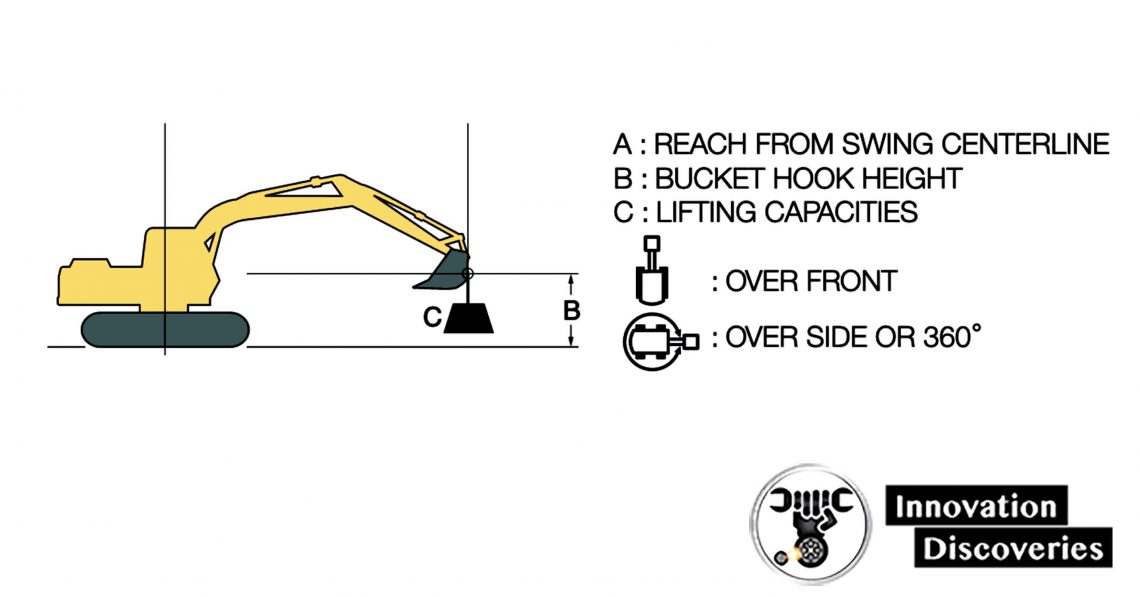

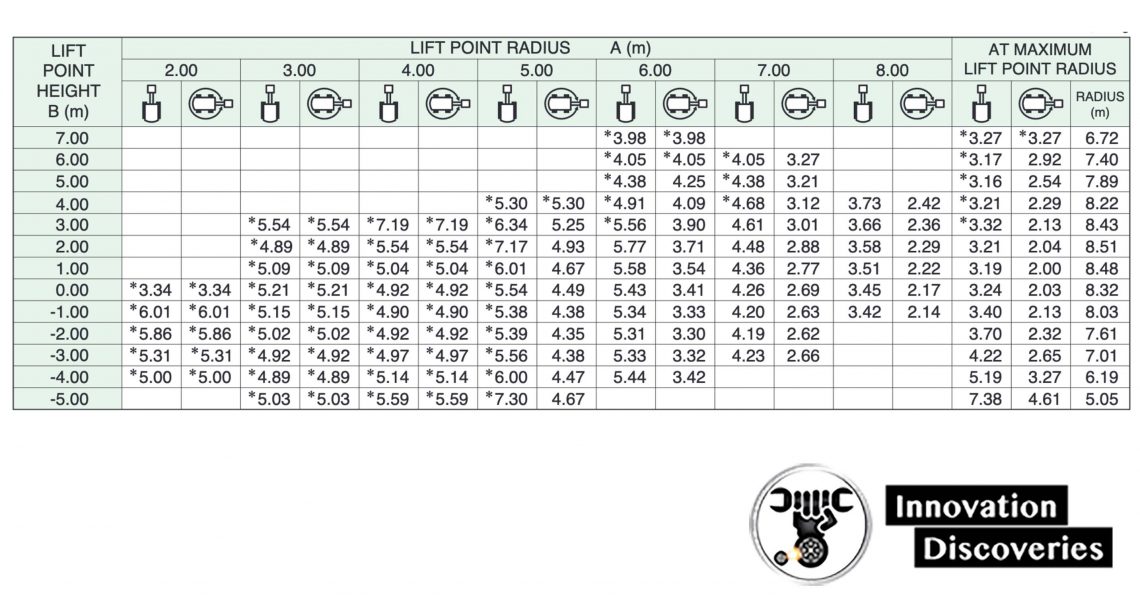

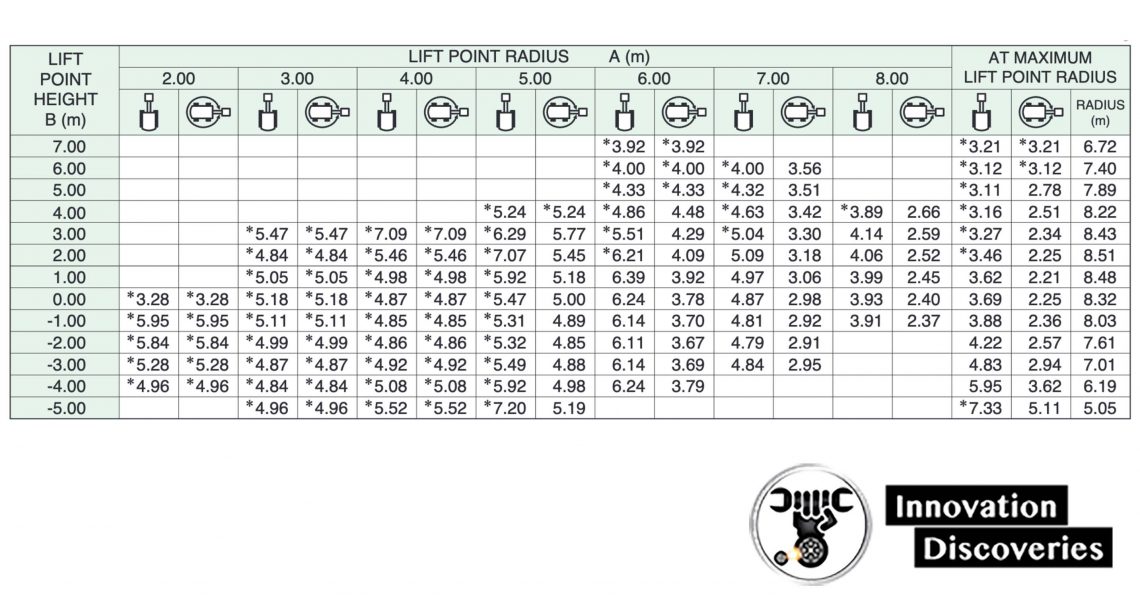

Lifting Capacities

HD820R

BOOM: 5.63m, ARM: 2.93m, BUCKET: 0.8m3 (640kg), SHOE WIDTH: 600mm, COUNTERWEIGHT: 4,200kg, Unit: 1,000kg

HD820RLC

BOOM: 5.63m, ARM: 2.93m, BUCKET: 0.9m3 (710kg), SHOE WIDTH: 600mm, COUNTERWEIGHT: 4,200kg, Unit: 1,000kg

NOTE:

- Lifting capacities are based on ISO 10567

- Lifting capacities shown do not exceed 87% of machine hydraulic capacity or 75% of minimum tipping load.

- Capacities marked with an asterisk(*)are limited by hydraulic capacities.

- Lifting capacities are based on machine standing on firm, uniform supporting surface. User must make allowances for job conditions such as soft or uneven ground.

- Lifting capacities shown should not be exceeded. Weight of all lifting accessories must be deducted from the above lifting capacities.

- Capacities apply only to the machine as originally manufactured and equipped by KATO WORKS CO., LTD.

- The operator should be fully acquainted with the Operation Manual before operating the machine.

Optional Equipment

- TRANSPARENT ROOF HATCH WITH SUN VISOR

- OPTIONAL WORKING LIGHT (BOOM-R)

- OPTIONAL WORKING LIGHT (CAB-R)

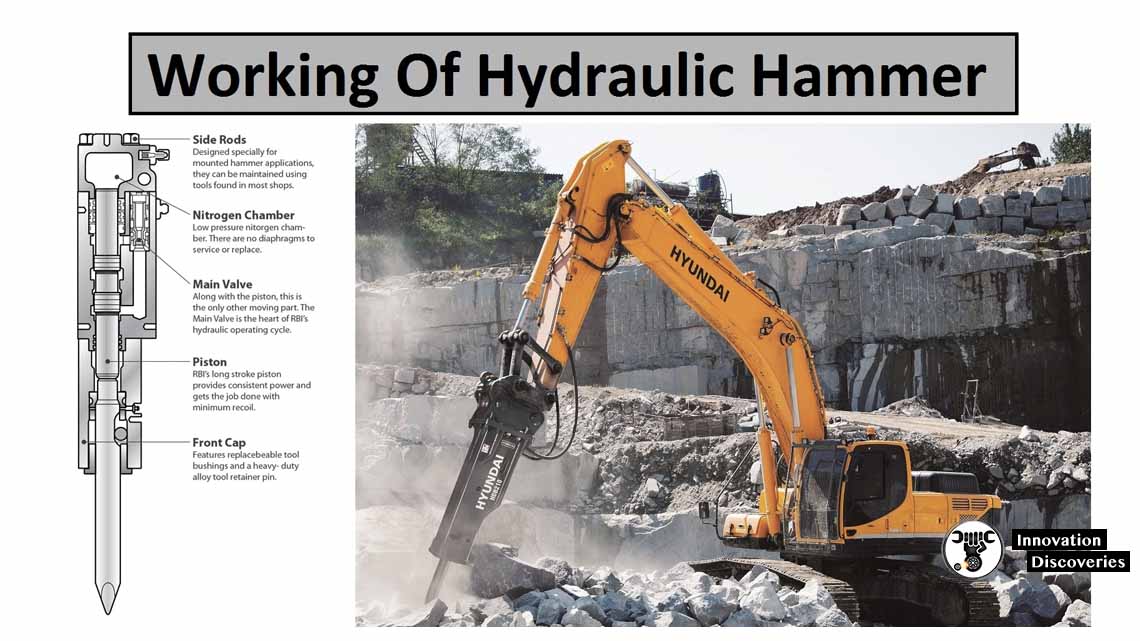

- 2 WAY OPTION PIPING (FOR CRUSHER & BREAKER)

- OPTION PIPING (FOR BREAKER)

- WINDSHIELD HALF SIZE GUARD

- WINDSHIELD FULL SIZE GUARD

- CABIN HEAD GUARD

- ROOM FAN

- ELECTRIC REFUELING PUMP

- HIGH PERFORMANCE FUEL FILTER

Standard Equipment

- COLOR MONITOR DISPLAY (APC150)

- SEAT-BELT

- AUTOMATIC AIR CONDITIONER (PRESSURIZED)

- HOT & COOL BOX

- INTERMITTED WINDSHIELD WIPER

- EMERGENCY EXIT REAR WINDOW

- AM/FM RADIO (2 SPEAKERS)

- 13 CM DUAL CORN SPEAKER X2

- CABIN LIGHT

- 3 STD WORKING LIGHTS (SLEWING TABLE-R, BOOM-L, CAB-L)

- REAR VIEW MIRROR-R

- WORKING MODE SELECTOR (APC150)

- AUTO-SLOW, ONE TOUCH SLOW

- BOOM/ARM ANTI-DRIFT VALVE

- SLEWING ANTI-COUNTER ACTION

- AUTOMATIC PARKING BRAKE (SLEWING TABLE)

- AUTOMATIC PARKING BRAKE (TRAVELING)

- SERVICE PORT (1 SPOOL)

- TRACK GUARD (1 PD EACH SIDE)

- AIR CLEANER DOUBLE ELEMENT

- PRE-CLEANER

- COVER ON THE BOTTOM FACE OF TRAVELING FRAME

Source – kato-works.co.jp

READ MORE:

Visit Forum

Visit Our Friendly Website