We will learn about helicopter construction, working and affecting factors. It is a very useful air transportation vehicle.

First practical helicopter VS-300 was designed by Igor Sikorsky and was by the Vought Sikorsky aircraft division of the United aircraft corporation.

It took flight at Stratford Connecticut on September 14 1939. Firstly it was Incorporated a single main rotor and tail rotor design. The mechanism of the helicopter is the same as the mechanism of the aircraft.

It works on the principle of generating lift. Lift is an upward pushing force that overcomes the weight and sweeps into the air. It is generated by the pressure difference between the upper section of the airfoil and lower section of the airfoil. We have discussed lift and drag in the previous article.

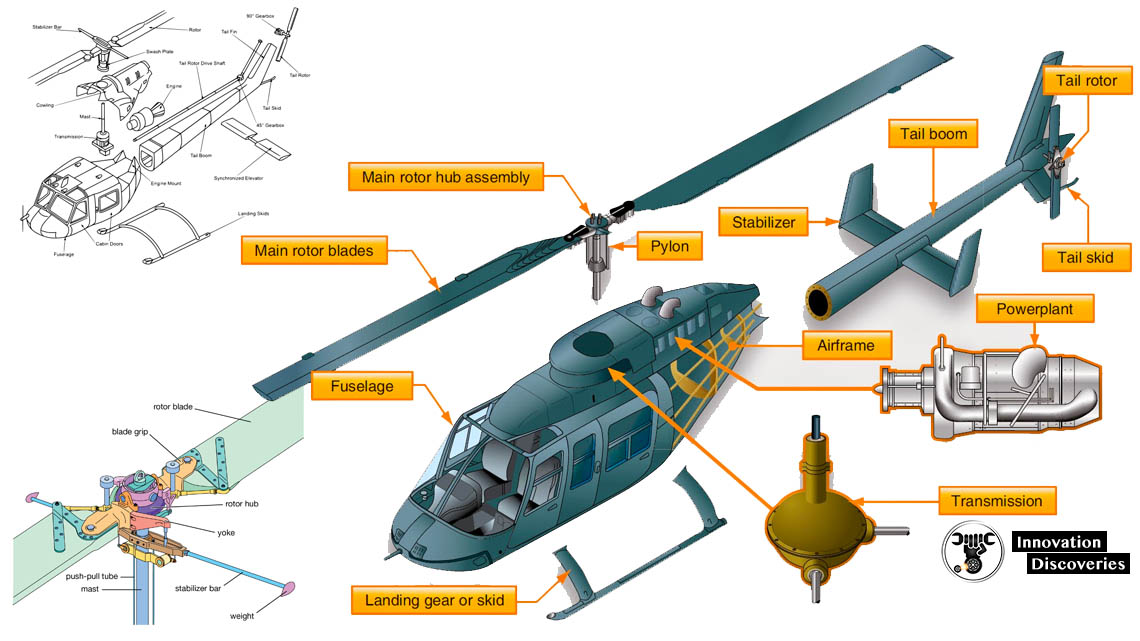

Now we will discussed about construction of a helicopter.

Main components of helicopter:

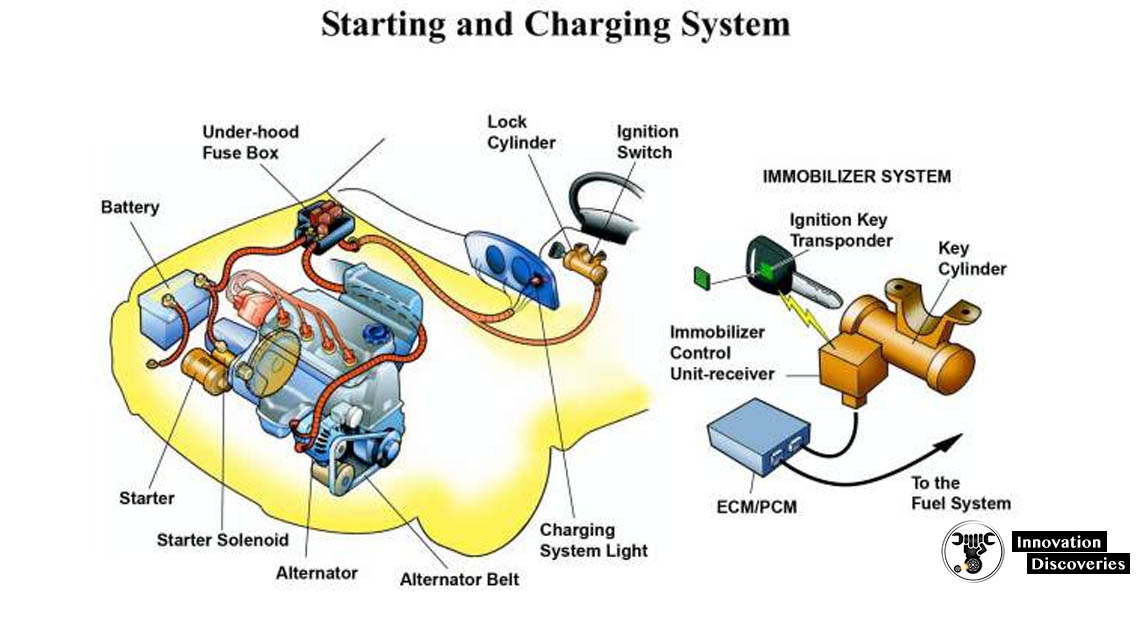

Engine

In the helicopter mostly two types of engines are used. The First one is reciprocating engine and the second one is turbine engine.

Reciprocating engine

Piston engine or reciprocating engine are basically used in a small helicopter which has less capacity to carry the load.

A reciprocating engine is mostly used in the training helicopter because of its simplicity and easy to operate.

Turbine Engine

Turbine Engine is used in the commercial helicopter. It is more powerful and is used in a variety of the helicopter.

The operation of the turbine engine is completely different from the turbine engine used in the aircraft. Turbine Engine produces a huge amount of power for their size at the same time it’s very expensive to operate.

It is found that 75 per cent of the incoming airflow is used to cool the engine.

The turbine engine mounted on the helicopter basically consists of

- Compressor

- Combustion chamber

- Turbine and Gearbox

1.Compressor

It is used to draw the filtered air into a chamber called a plenum chamber where the air is compressed. Compressed air is then directed to the combustion chamber where the atomized fuel is injected into it.

The air-fuel mixture is being ignited and allowed to expand; it produces a tremendous amount of energy. The combustion gas is passed through the series of turbine wheel causing them to rotate.

These wheels give the power to both the engine and gearbox as well. Depend on the model and vary from 20,000 to 51,600 rpm.

2. Combustion Chamber

Combustion process is a continuous process in the turbine engine unlike to piston engine. Combustion chamber is a chamber where the air fuel mixture gets ignited, it continues to burn until the fuel is present.

If the engine is on and there is an interruption in the air-fuel mixture and any of these then it termed as flameout and the engine is being restarted. Especially in the helicopter, it has a special system to tackle it called auto to relight which automatically activates the ignite to start the combustion if the engine flameout case appears.

3. Turbine

In the helicopter, two stage turbines is used to run the engine. The first stage of the turbine is considered to be a gas producer and the second stage is known as power turbine. It is denoted by N1 and N2 respectively.

Both stage of the turbine is connected to the common shaft and are mechanically coupled to each other.

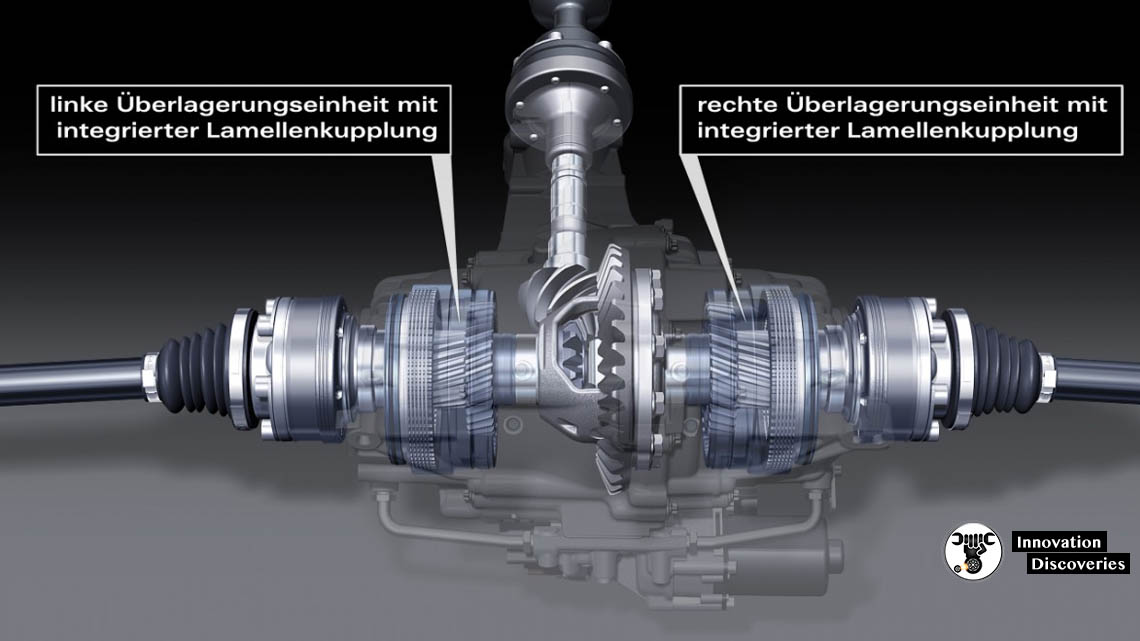

4. Accessory gearbox

The gearbox of the engine encompasses all the necessary gear to drive components of the helicopter.

Independent shaft connected to N1 and N2 Wheel turbine which provides the power to the accessory gearbox. The first stage of the turbine is used to drive the components necessary to complete the turbine cycle.

Second is dedicated to driving the main rotor and tail rotor system and it is also used to run the air conditioning.

How to laren for this page