The suspension system affects both the driver’s control of the car and the comfort of the occupants.

The springs allow the wheels to move up to absorb bumps in the road and reduce jolting,

While the dampers prevent bouncing up and down.

Various mechanical links keep the wheels in line.

Types of spring

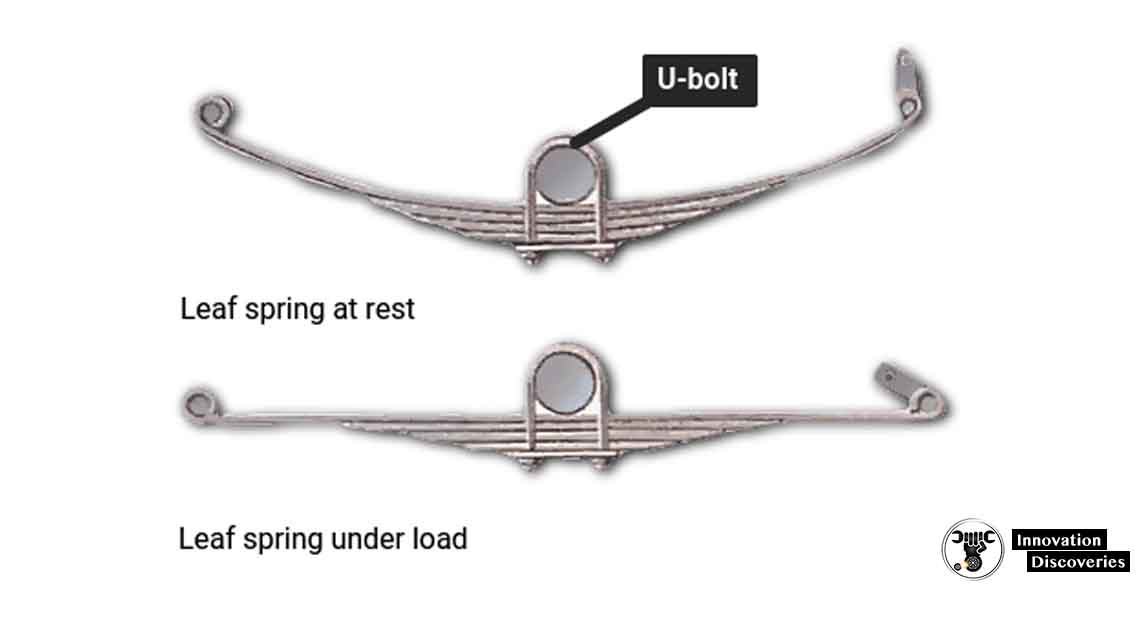

Leaf spring

Stack of steel strips. As the spring deflects, its leaves flatten,

Make greater contact with one another and stiffen the spring. As the leave flattens, it lengthens so one end has a pivoted shackle.

Most cars have steel springs, and the oldest type is the leaf spring.

The topmost and longest strip, the master leaf,

It is curled at each end into an eye by which it is connected to the frame.

The leaves below are progressively shorter and less curved.

Leaf springs in action

As the spring deflects, it flattens, causing the second leaf to touch the master leaf,

Then the third to touch the second. The spring thus becomes progressively stiffer. Such a spring gives a smoother ride than a stiff, plain single leaf could.

In some cars, the multi-leaf spring has been replaced by,

Special single leaf that is tapered in section and has

Progressive stiffness as it is deflected.

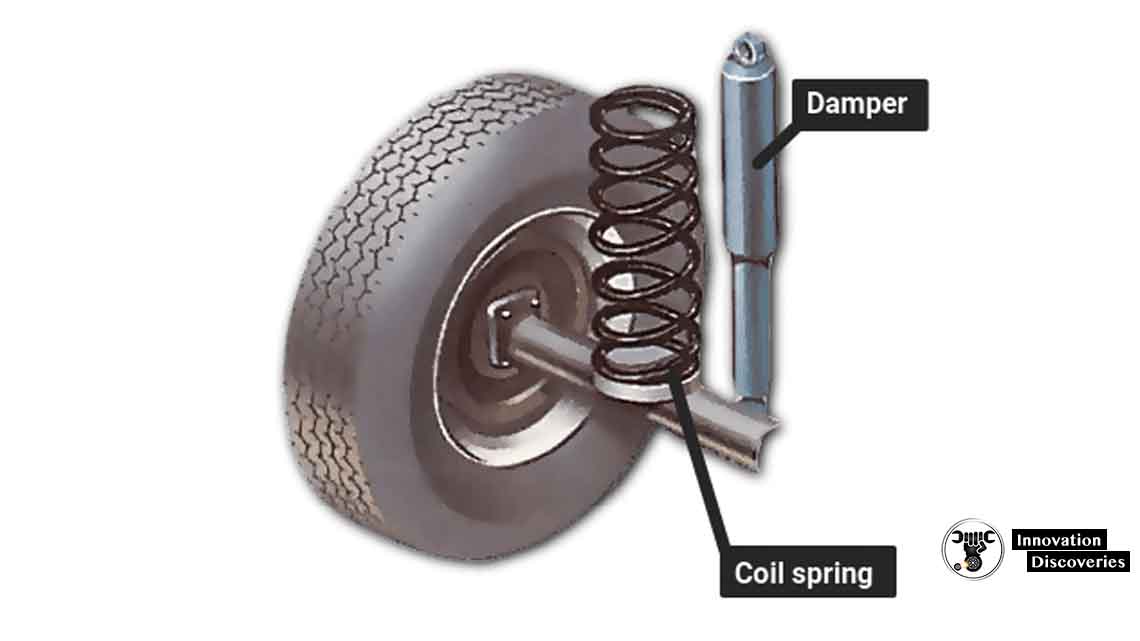

Coil spring

A coil spring is simply a spiral of resilient steel rod.

It is stretched or compressed by the vertical movement of the wheels.

It extends as the wheel moves down and compresses as the wheel moves up,

So the car body remains reasonably level.

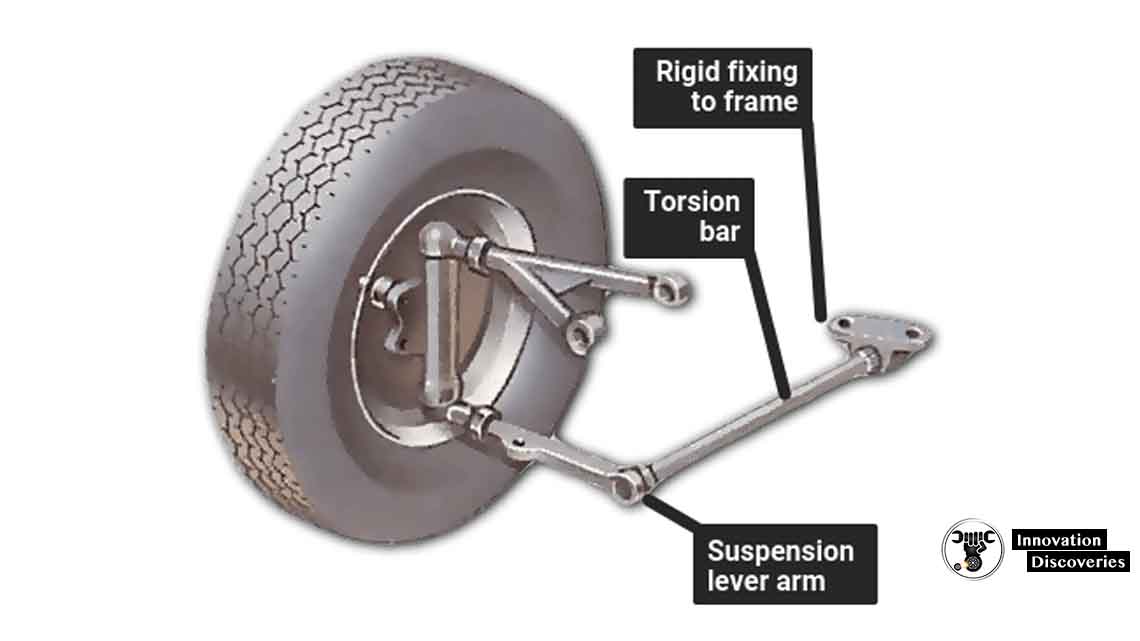

The torsion bar is a length of spring steel with splined or square ends.

One splined end is fixed to a lever arm that forms part of the suspension.

The bar rotates as the lever arm moves up and down.

Torsion bar

The bar twists as the other end rotates with movements of the

Suspension lower arm.

The other splined end is fixed to the frame. The splines stop the bar turning in its fixings. Instead, the bar has to twist as the suspension deflects.

In all forms of steel spring,

The forces set up by road shocks are stored by the spring deflection,

Rather than passed on to the passengers.

The forces are then released gradually to restore the car to a level ride.

Rubber springs can perform the same function,

But they do not store as much energy and are therefore used on light vehicles only.

A form of hydraulic suspension can be combined with rubber springs to refine the system.

The up-and-down movement of the wheel pumps fluid from one chamber to another through a damper valve.

Each chamber has a flexible diaphragm with compressed gas on the other side of it.

The gas is compressed further as fluid comes into the chamber through the valve.

In effect, the gas is acting as a pneumatic spring.

There is usually a link tube through which some of the fluid pumped out of a

Front-wheel chamber travels to the rear wheel on the same side to

Equalize the suspension.

Citroen hydraulic suspension can be pumped up and down to

Raise or lower the car to the desired height.

Dampers

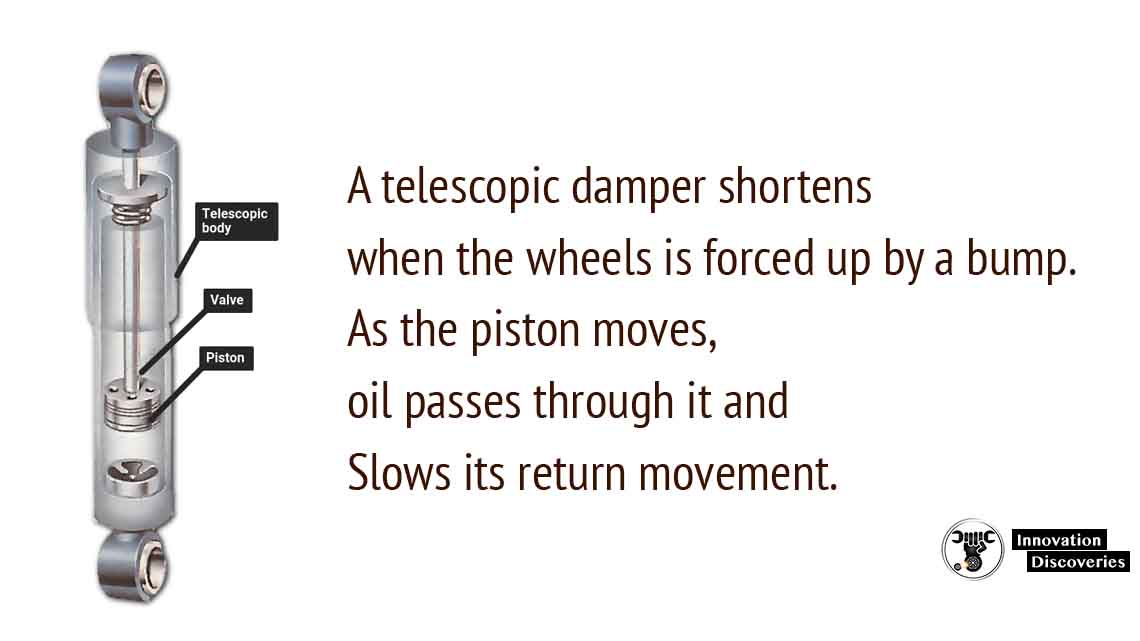

Springs deflect as the car goes over a bump, then bounce back.

The car would continue to bounce up and down,

If the energy stored in the springs were not dissipated in some way.

Dampers – commonly called shock absorbers – perform this function.

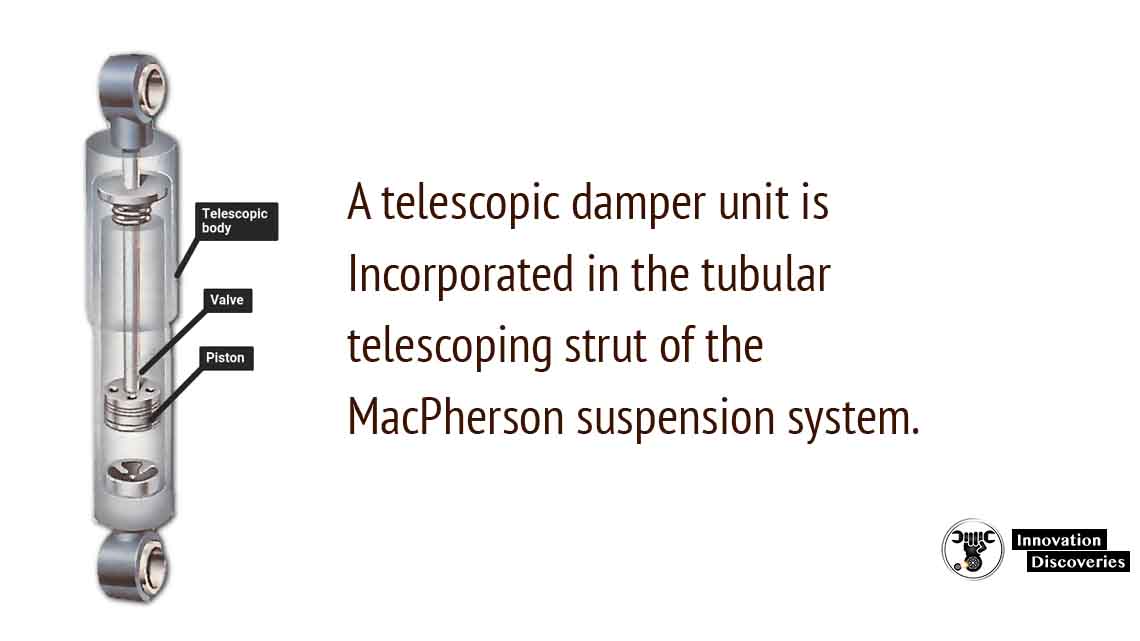

A damper has a piston which moves inside a sealed,

Oil-filled cylinder with the up-and-down movement of the wheel.

There are narrow control passages and one-way valves in the piston,

Which allows the oil to flow through it from one chamber to another but only very slowly.

This action slows down the spring oscillations and returns the car to a level ride.

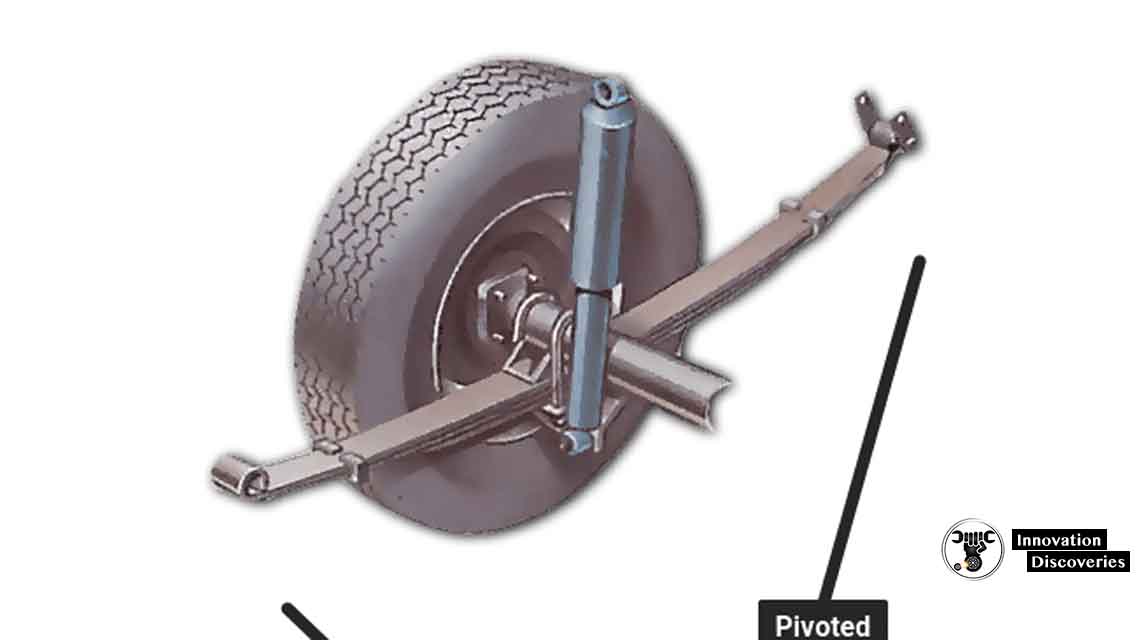

There are three types of damper. Telescopic dampers look like telescopes and shorten in the same way. One end is bolted to the axle, the other to the body.

Strut inserts are similar, but are designed to fit inside a MacPherson strut

Lever-arm dampers resemble hydraulic door closers.

The damper, which contains one or two pistons,

It is fixed to the car body or frame, and a pivoted lever extends from it to the axle.

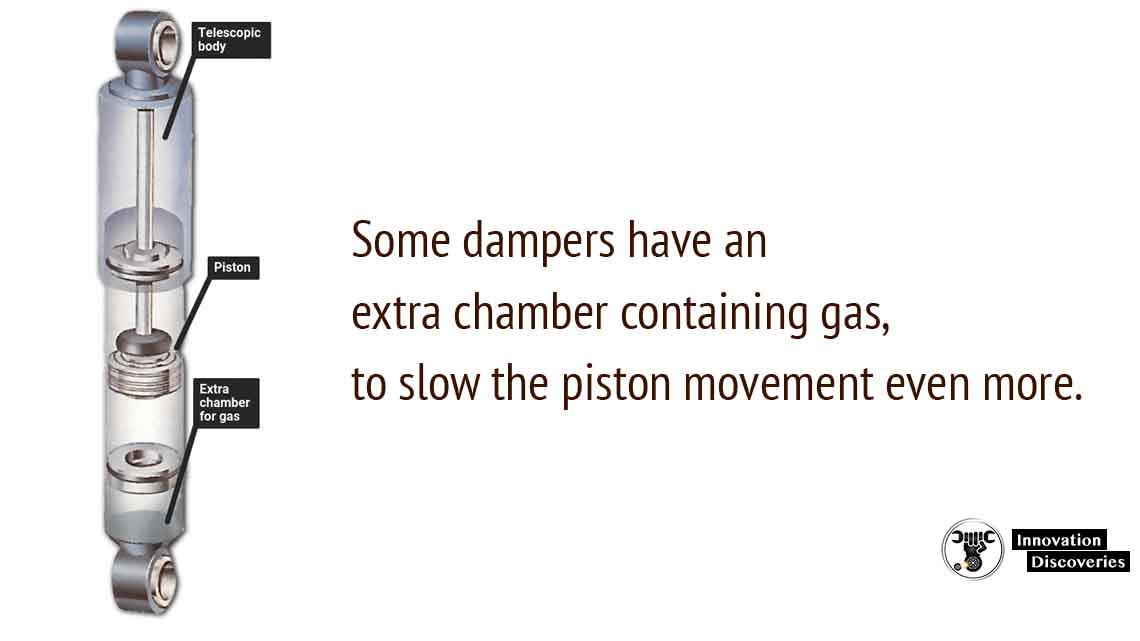

Some cars have dampers that contain both oil and gas.

These act more efficiently than oil-filled dampers.

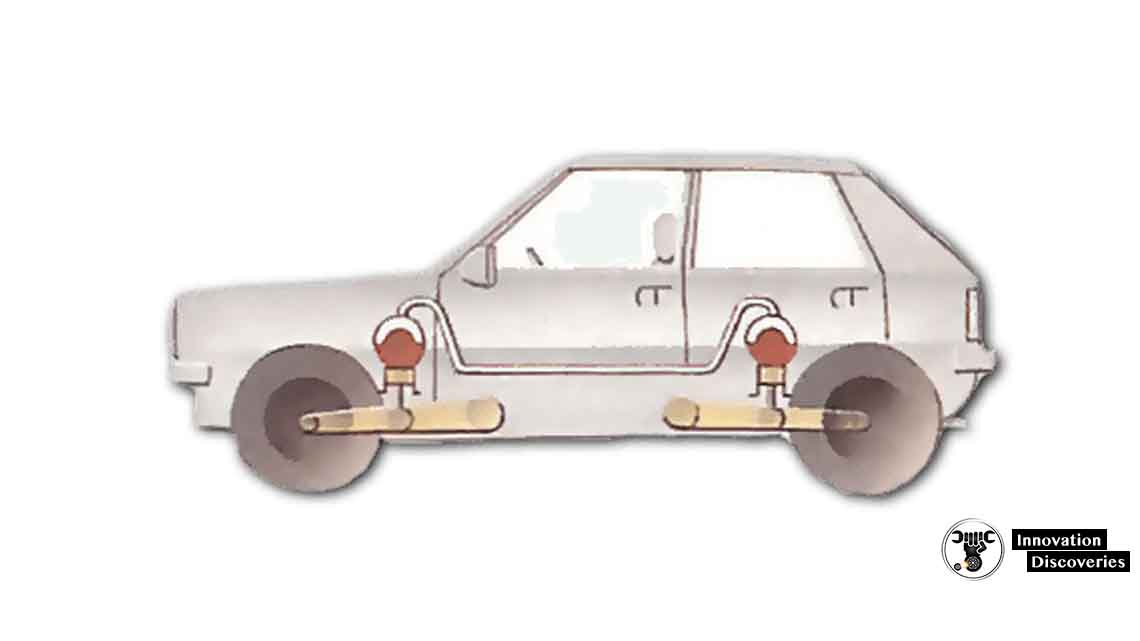

Hydraulic suspension

Hydraulic suspension combines rubber springs with a damper system

Linking the front and rear wheel on the same side of the car.

As the front wheel rises over a bump,

Some fluid from its suspension unit flows to the rear-wheel unit and raises it,

So tending to keep the car level.

In each of the displacer units,

The fluid passes through a two-way valve, which provides the damping effect.

3 Comments