Seat belts are also known as safety belts which are designed to safeguard a passenger

From getting seriously injured in the event of a collision. The basic idea is to prevent the

Occupant from being thrown towards the windshield or dashboard.

Law of motion:

Newton’s first law of motion states that

”Every object in a state of uniform motion tends to remain in that state of

Motion unless an external force is applied to it.”

This means that when we (as passengers) are traveling in a car at a particular speed,

Then we will continue to move forward at that same speed;

Even after brakes are applied due to the momentum our body gains. The momentum is higher if there is a collision and hence our body is thrown in front,

And we get seriously injured.

If a car is traveling at 60 mph, then everything in the car is in inertia.

If the car hits a pole on the road,

Then the car abruptly stops,

But the occupants in the car will be hurdled in front due to the inertia that they carry. Seat belts act against this inertia to slow us down.

Three-Point Retractable Lap and Shoulder Seat Belts:

This is the most commonly used seat belt system for passenger cars worldwide.

Seat Belts Working (Retractor mechanism):

This is the most commonly used mechanism in seat belts. The retractor mechanism uses a spool as its central element. The spool is attached to one end of the webbing. A spring is available inside the retractor that provides a rotational force.

When we pull the webbing (fabric belt) out,

The spool rotates in the anti-clockwise direction. The rotation of the spool also rotates the attached spring in the same direction. The spring will resist the twisting motion and will want to return to the original shape. As soon as we release the webbing, the spring untwists itself in clockwise direction and therefore the spool

Also, it rotates in a clockwise direction until there is no more slack in the webbing.

The Retractor Locking Mechanism:

In the event of a collision, the retractor has a locking mechanism that stops the spool from rotating. The basic idea of a locking system is to lock the spool from rotating in

Order to prevent the occupant from being thrown towards the dashboard.

The locking mechanism nowadays uses two sensors to lock the spool. The first is the vehicle deceleration sensor that detects,

Any sudden deceleration in the vehicle and the second is the webbing sensor to

Detect any violent pull-outs of the webbing.

A centrifugal clutch system is used to lock the spool. When the spool rotates slowly, the centrifugal lever doesn’t pivot at all. When there is a violent rotation of the spool,

The lever’s centrifugal force overcomes the spring force and the clutches get

Locked with the teeth of the spool. The video will clearly show you how this works.

Pretensioners:

A conventional seat belt locking mechanism

Will only lock the rotation of the spool.

A pretensioner will pull the belt in once the car comes to an abrupt stop. Therefore, it helps move the occupants in the opposite direction of the

Momentum tends to carry them forward.

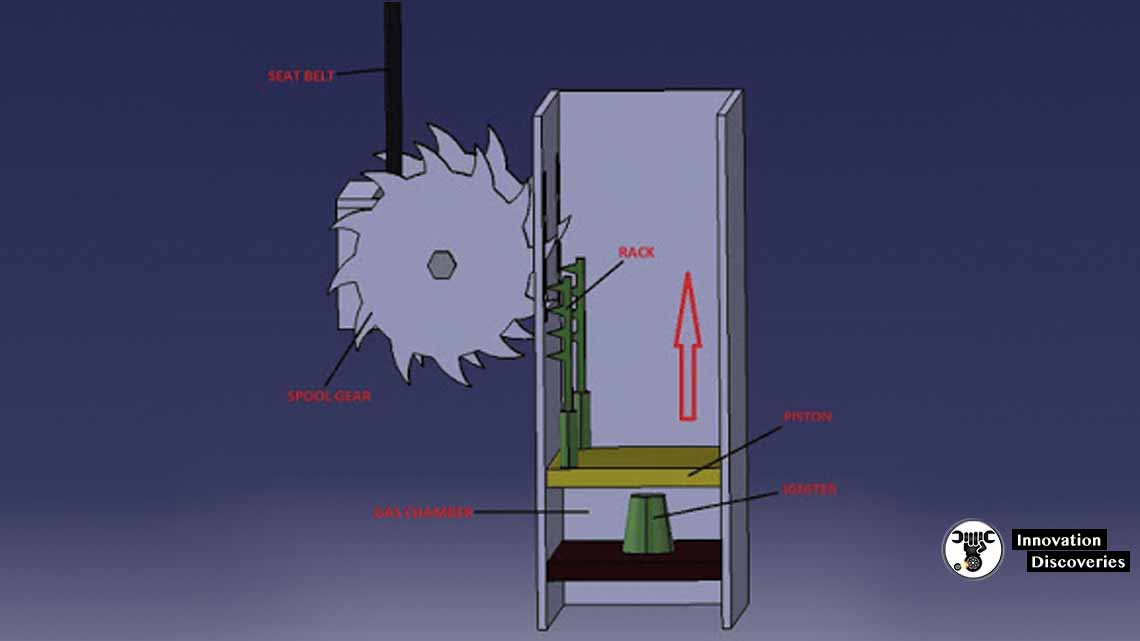

Modern-day pretensioners use pyrotechnics to pull in the belt. It consists of a separate gas chamber with an igniter material. When the sensor detects a collision,

The igniter material is ignited by passing electric current through it. The collision is detected by a central processor which then sends the electric current to the igniter. The ignition releases gases at a huge pressure which pushes the piston upwards.

A rack gear is provided at the top of the piston,

Which moves up and engages with the spool gear and

Rotates the spool forcefully to pull the belt inside.

Read More:

- The History of the Nissan GT-R

- Is Your Car Safe? What A 5-Star Rating Actually Means

- This Bonkers 900-HP Electric Ford Mustang With a Six-Speed Manual Was Built for SEMA

- What is the vehicle identification number (VIN)?

- When To Put Your Vehicle In 4-Wheel Drive?

Load Limiter:

In very violent crashes, seat belts can incur serious damages on the occupants,

Especially the old people who cannot take much load on their rib cages.

The harder the impact of collision,

The harder it will be the force of the seat belt to stop the occupant.

The basic idea of introducing a load limiter is to limit the force of the pretensioner on the occupants. The load limiter allows the belt or webbing to extend a bit more when a great deal of impact is applied to it. The best way to achieve this is by integrating a torsion

Bar with the retractor mechanism. The torsion bar is attached to the locking mechanism on one end and the spool on the other end.

Also, read:

2 Comments