Introduction

The introduction of the internal combustion engine in 1884 by

Edward Butler was the boom in the world of machines

As the engine is the machine that gives rise to the invention of many

Machines like automobile vehicles, aeroplanes, marine vehicles, etc.

That we are still using today. The most beautiful thing about the engine that makes it a

Perfect machine is the conversion of chemical energy into mechanical energy.

When we hear the word engine the first thing that comes in our mind is the automobile

Vehicle because the IC engine is being widely used in an automobile for over a century now.

But let’s just think like an engineer since an engine is a perfect source that provides

Mechanical work then why its application is just restricted to the rotational motion only?

This question increases the curiosity and gives rise to the Free Piston Engine.

Let’s just study it in detail.

A free-piston engine is the internal combustion engine in

Which the crankshaft from a normal I C engine used in vehicles is removed and the

Mechanical work is obtained just by the reciprocating movement of the

Piston or by some other mean.

Generation of power is the main purpose of these kinds of pistons that can be obtained by

Any means either by the exhaust gas pressure that can be used to drive a turbine or

Through the linear motion of the piston that can be used as an air compressor for

Pneumatic power or by coupling the linear alternator with the

Moving a piston to generate electricity.

The need of Free Piston Engine

As we all know that energy can neither be created nor be destroyed,

But can be transformed from one state to another and also can be

Transferred from one object to another,

With this knowledge human have invented various machines to decrease human effort,

One of the best inventions of the human is the engine which is being modified from decades,

One of the modifications is a free-piston engine which is invented due to the following reasons.

- Required machines like turbines, compressors, etc. It was required to find the source of the energy that can run these machines, the available sources (Most common of all is the burning of the fuel like wood, coal, etc.) Required large setup and also were inefficient due to the lack of symmetry. This problem was solved with the invention of the free-piston engine in which there is an asymmetrical and efficient way of the Conversion of chemical energy into mechanical work.

- The burning of fuels like wood, coal, etc. was causing lots of pollution due to the impurities present in them, this problem of the pollution was later solved with the introduction of the F P engine that uses pure fractionally distilled fuel which in turn decreases pollution-causing emissions.

- F P engine provides application flexibility which means it provides lots of different ways to use the mechanical work produced by the combustion of fuel. This, in turn, makes it an easy source of energy.

Due to these reasons the new concept of an engine that can be used for

Different purposes were developed and named as a free-piston engine.

Also, read:

Main Components

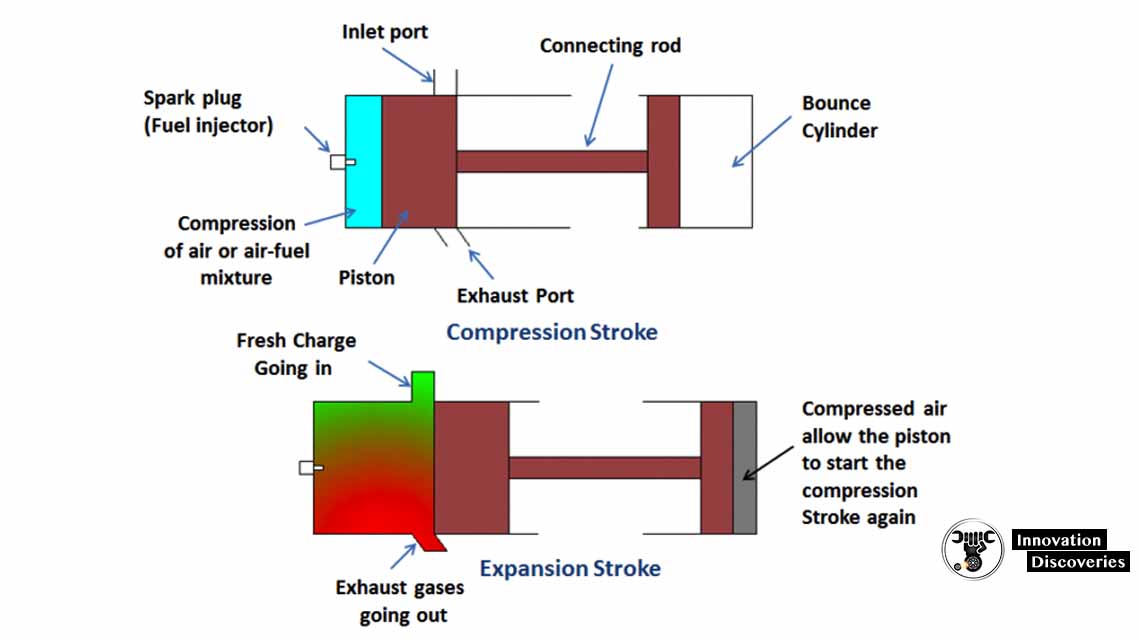

Free piston engine works on the same principle on

Which IC engine of an automobile works i.e. the combustion of the air-fuel inside a closed

Cylinder produces reciprocating motion in

The piston is then obtained mechanical work. So the components of both the engines are also almost the same. It is basically a two-stroke engine.

The main components of the F P engine are –

- Combustion chamber or cylinder- Same as the IC engine a combustion cylinder is the rigid cylindrical chamber inside which the combustion of air-fuel takes place, and also it is the housing inside which piston moves.

- Piston- It is the rigid cylindrical part of the FP engine that produces reciprocating motion inside the combustion chamber due to the combustion of the air-fuel mixture just like the IC engine.

- Engine head- It is the head of the engine the spark plug or fuel injector is attached, engine head is mounted over the combustion chamber just like the IC engine.

- Spark plug or fuel injector- The spark plug is used to ignite the air-fuel mixture and fuel injector injects the diesel fuel during the compression of air which results in the combustion.

- Bounce cylinder: It is a cylinder with a piston which is interconnected with the main piston. The main function of the bounce cylinder is to store the energy during the expansion of the F P engine and apply it to starts the compression stroke again for the working.

- Loading devices- These are the devices that are used in the free-piston engine as the replacement of crankshaft of the IC engine, The selection of the load device which is to be used depends upon the required application of the FP engine

Also, read

For example

- A linear alternator is coupled with the piston of the F P engine for the generation of the electricity.

Note :

For some applications of F P engine like the air compressor,

Turbine rotation etc. No loading device is used to obtain mechanical work.

7. Fuel – Of course just like an I C engine the most important part of an F P engine is the fuel that can be petrol or diesel depending upon the type of F P engine used i.e. Spark ignition F P engine or Compression ignition F P engine.

- The fuel (air-fuel) is the chemical energy that is burned inside the combustion chamber to produce mechanical work i.e. reciprocating motion of the piston.

Working of Free Piston Engine

The application of the free-piston engine is

So, wide so for the better understanding of the working of FP engine;

We have to discuss its few applications that are,

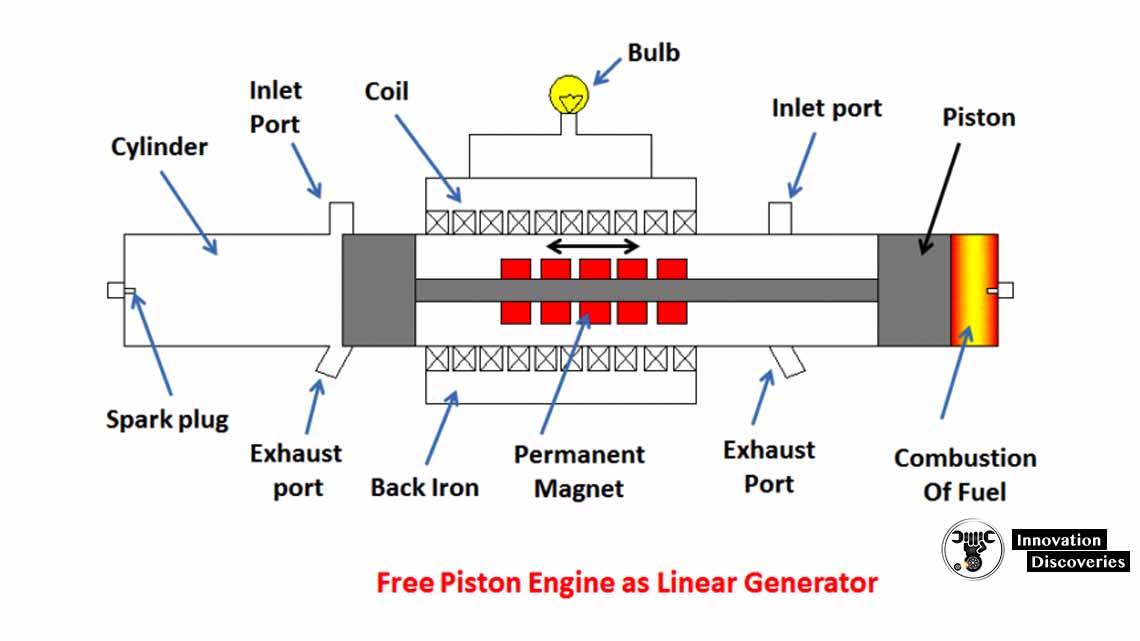

1. Electricity Generator

The electricity generator is the device that is used to

Generate electricity with the help of the F P engine as an external source of energy,

For the generation of electricity,

A linear alternator is coupled as a loading device with the F P engine.

The working of this electricity generator is as follows,

- The fuel enters in the combustion chamber of the engine in the expansion stroke and gets ignited at the end of the compression stroke either by the spark plug (gasoline engine) or by compression (diesel engine).

- This combustion of the fuel inside the combustion chamber produces high-stress pulses over the surface of the piston which in turn produces the reciprocating motion of the piston.

- This reciprocating motion of the piston is then transferred to the linear alternator which is used as the loading device and is coupled with the piston.

- Due to the reciprocating movement of the permanent magnet attached to the connecting rod of the piston, there is a fluctuation of the magnetic field takes which induces current and voltage in the coil and electricity is produced that is further stored in the accumulator (battery) used in electricity generator for the further use.

Also, read:

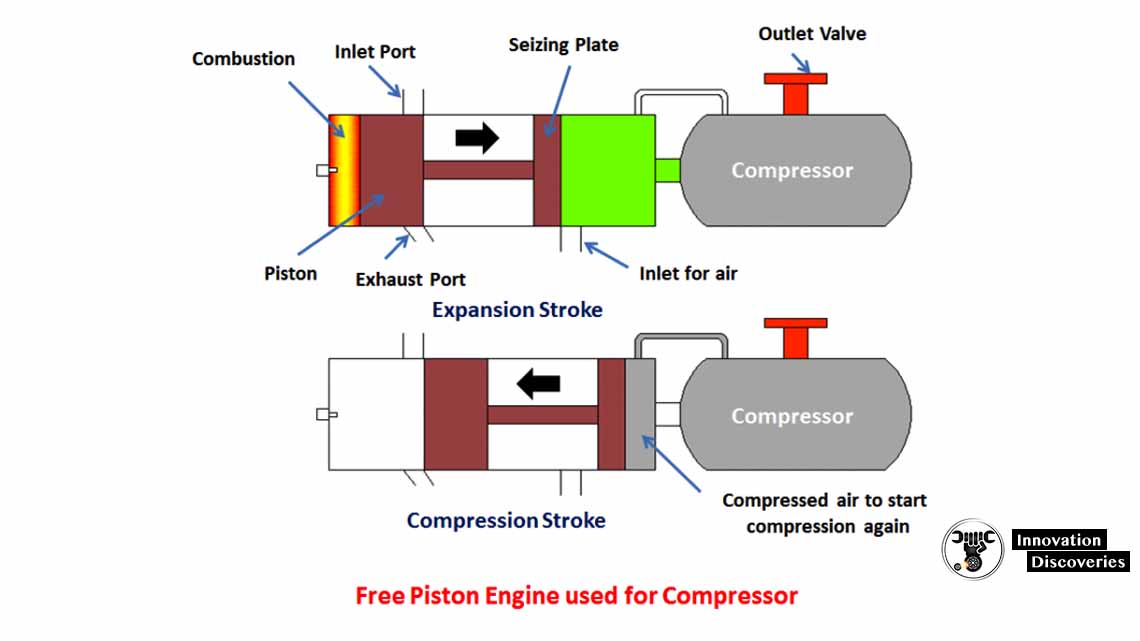

2. Air Compressor

It is the device which is used to compress or increases the pressure of the

Air for the various purposes like pneumatic machines with the help of

Free piston engine as the external source of energy.

For using F P engine as an air compressor no loading device is used

But there is the coupling of air compressor cylinder with the plates which are

Mounted at the tail end of the piston.

The working of FP air compressor is as follows,

- Same as the electricity generator fuel enters at the end of the expansion stroke and gets ignited at compression stroke of the F P engine respectively but there is the entry of the fresh air inside the air compressor cylinder during the expansion stroke through the inlet valve of the compressor cylinder.

- Due to that combustion, the reciprocating motion of the piston is produced which in turn compresses the air inside the compressor with the help of the seizing plate mounted at the tail end of the piston.

- This compressed air is then taken out through the exhaust valve of the compressor for further work.

Note :

At the end of the expansion stroke, the air from the compressor is entered into the cylinder at the tail end and forces the piston to begin the compression stroke again.

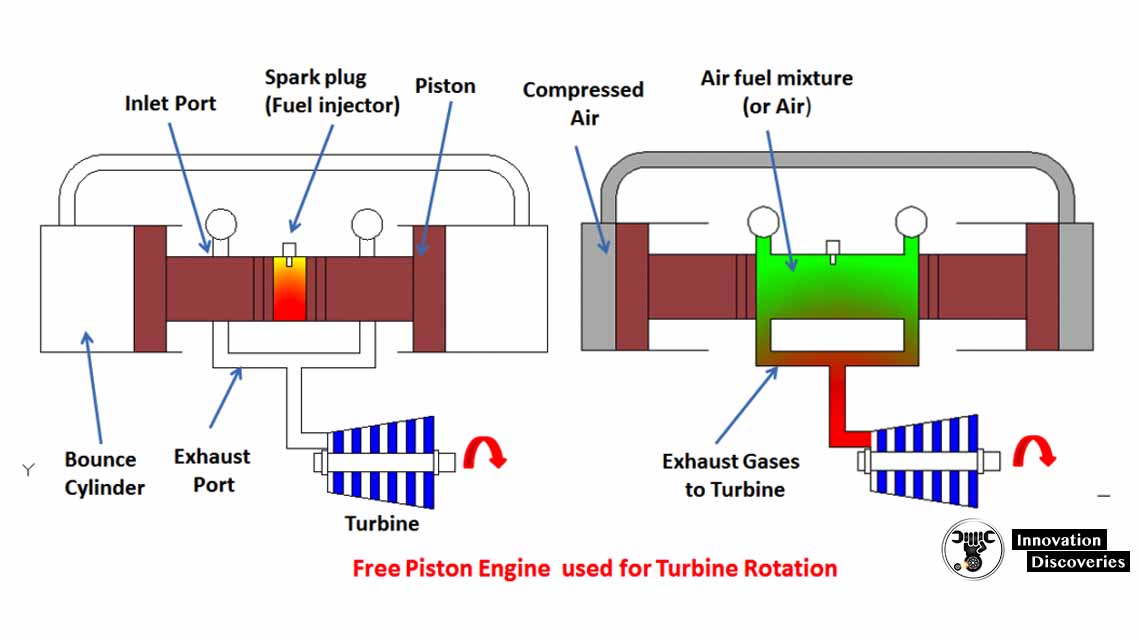

3. Turbine Rotation

The free-piston engine is also used to rotate the turbine of the turbine

Electricity generator for the production of the electricity.

In this application of the F P engine instead of the reciprocating motion of the piston,

Exhaust pressure of the engine is used to apply force over the blades of

The turbine which in turn causes rotation of the turbine.

The working of the turbine electricity generator that uses

FP engine as the source of energy is as follows,

- The entry of fuel through the inlet port of the engine takes place at the end of the expansion stroke of the engine.

- After the entry of the fuel inlet port closes and the compression of the fuel due to the compression stroke occurs which in turn increases the pressure of the fuel inside the combustion chamber.

- After this compression fuel gets ignited either by a spark plug (gasoline engine) or by compression (diesel engine) depending upon the type of the F P engine used.

- Due to this combustion of the fuel high-pressure impulse is generated which in turn pushes the piston and the expansion of the gases produced during the combustion occurs.

- The gases expanded during the expansion stroke are then exhausted with the high pressure through the exhaust port of the engine during the expansion stroke.

- These exhaust gases having high pressure are blown over the blades of the electric generator turbine which in turn causes rotation of the turbine and the generation of the electricity takes place.

Apart from these above-mentioned applications free-piston engine with

Different loading and rebounding devices are widely used in various

Machines like hydraulic machines,

Marine devices, aerospace devices, etc. But the basic working principle of all these devices is same i.e. reciprocating motion of the piston caused by the burning of the fuel is

The mechanical output obtained due to the combustion of the chemical substance(fuel).

3 Comments