A piston is a cylindrical engine component that slides back and forth in the cylinder bore by Forces produced during the combustion process.

The piston acts as a movable end of the combustion chamber.

The stationary end of the combustion chamber is the cylinder head.

Pistons are commonly made of a cast aluminium alloy for excellent and lightweight thermal conductivity.

Thermal conductivity is the ability of a material to conduct and transfer heat.

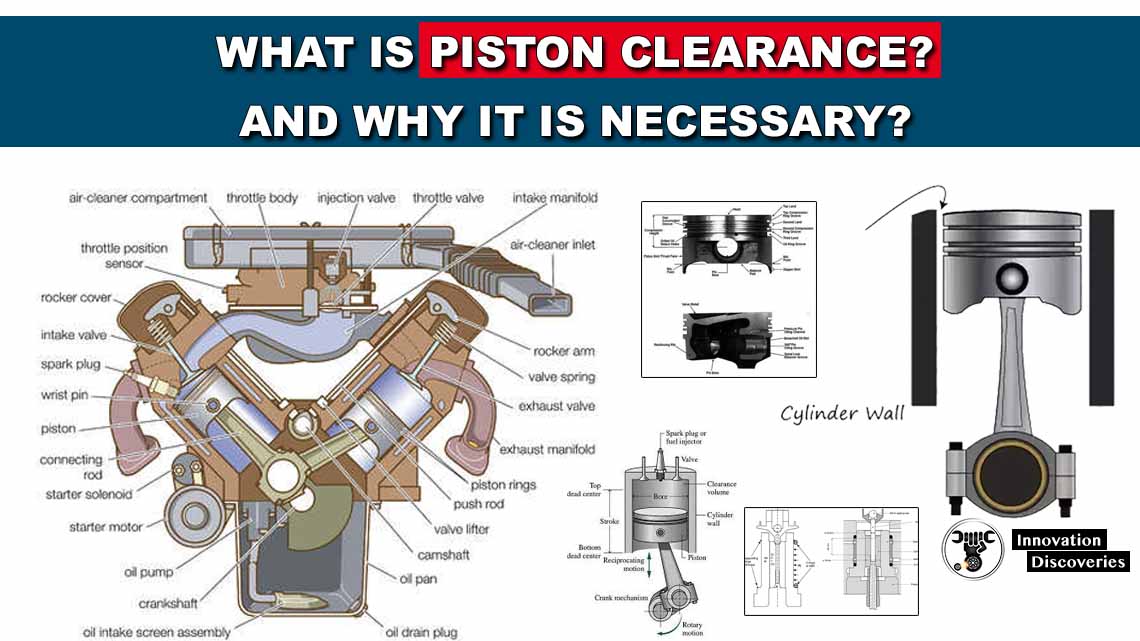

Aluminium expands when heated and proper clearance must be provided to maintain free piston movement in the cylinder bore.

Insufficient clearance can cause the piston to seize in the cylinder.

Excessive clearance can cause a loss of compression and an increase in piston noise.

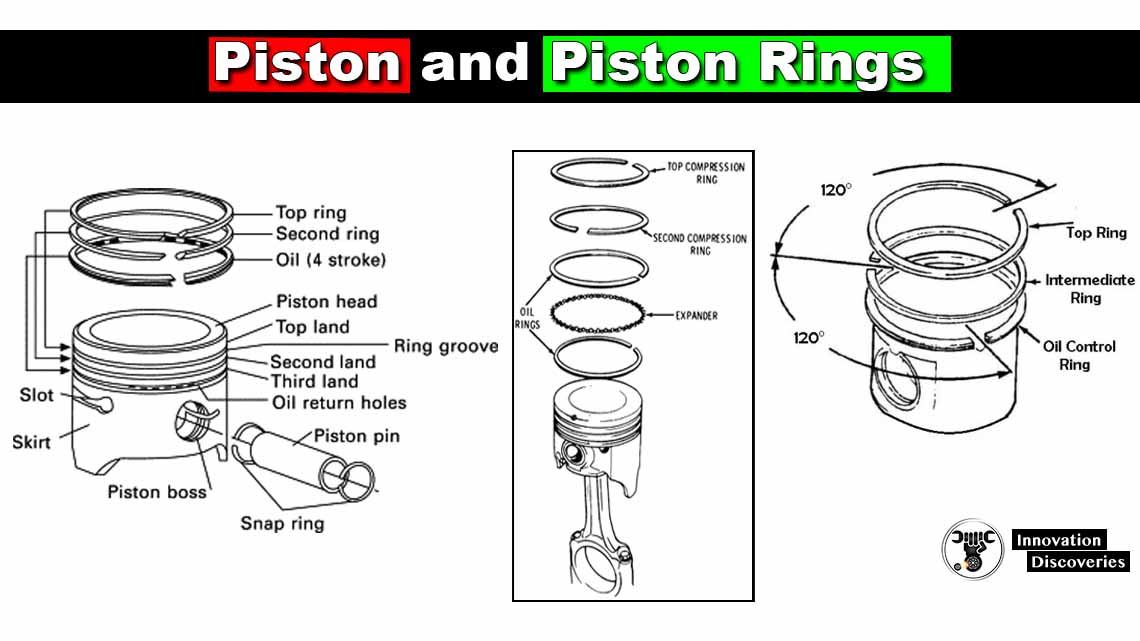

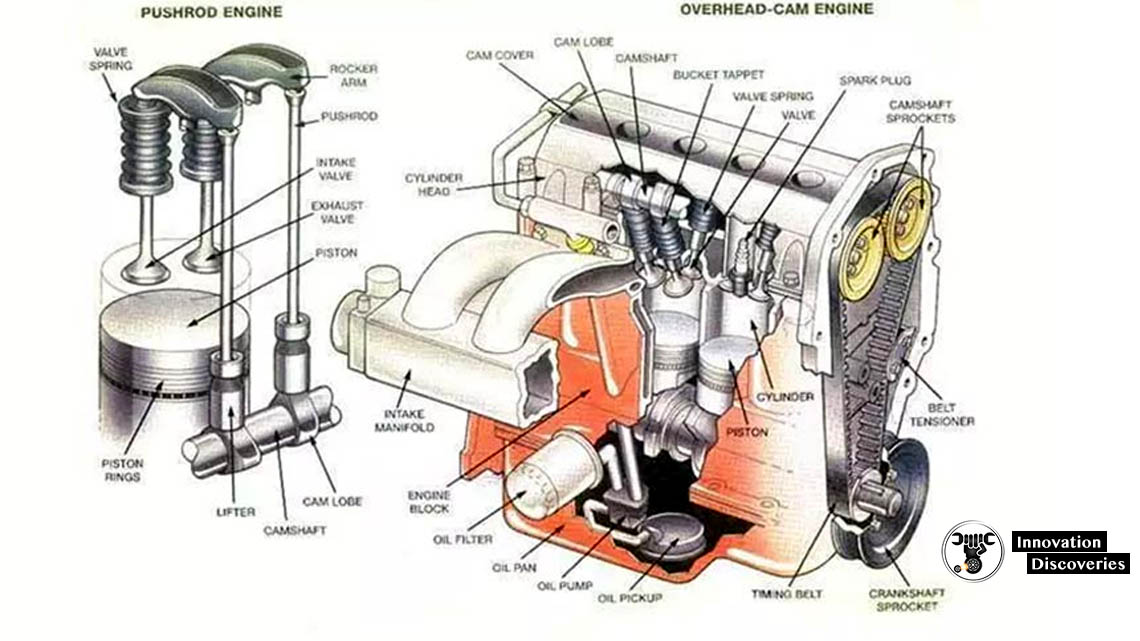

Piston features include the piston head, piston pin bore, Piston pin, skirt, ring grooves, ring lands, and piston rings.

The piston head is the top surface (Closest to the cylinder head) of the piston which is subjected to tremendous forces and heat during normal engine operation.

A piston pin bore is a thorough hole in the side of the piston perpendicular to Piston travel that receives the piston pin.

A piston pin is a hollow shaft that connects the small end of the connecting rod to the piston.

The skirt of a piston is the portion of the piston closest to the Crankshaft that helps align the piston as it moves in the cylinder bore.

Some skirts have profiles cut into them to reduce piston mass and to provide clearance for the rotating crankshaft counterweights.

A ring groove is a recessed area located around the perimeter of the piston, that is used to retain a piston ring.

Ring lands are the two parallel surfaces of the ring groove which function as the sealing surface for the piston ring.

A piston ring is an expandable split ring used to provide a seal between the piston a cylinder wall.

Piston rings are commonly made from cast iron.

Cast iron retains the integrity of its original shape under heat, load and other dynamic forces.

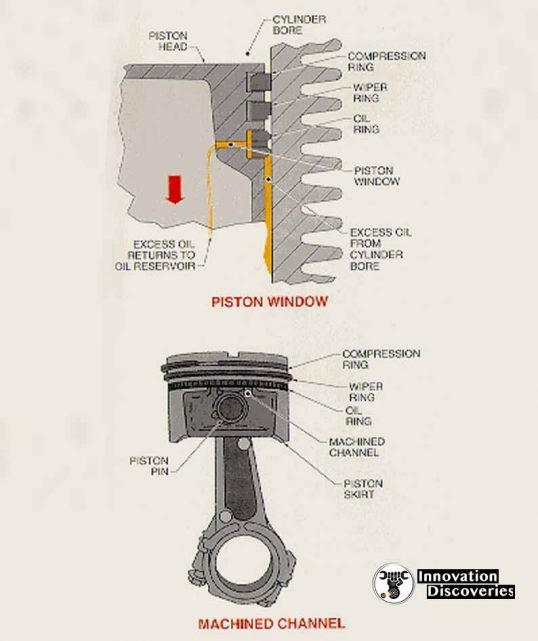

Piston rings seal the combustion chamber, conduct heat from the piston to the cylinder wall, and return oil to the crankcase.

The Piston ring size and configuration vary depending on engine design and cylinder material.

Piston rings commonly used on small engines include the compression ring, Wiper ring, and oil ring.

Click to read: PISTON DAMAGE FROM OVERHEATING

A compression ring is the piston ring located in the ring groove closest to the piston head.

The compression ring seals the combustion chamber from any leakage during the combustion process.

When the air-fuel mixture is ignited pressure from combustion gases is applied to the piston head, Forcing the piston toward the crankshaft.

The pressurized gases travel through the gap between the cylinder wall and the piston and into the piston ring groove.

Combustion gas pressure forces the piston ring against the cylinder wall to form a seal.

Pressure applied to the piston ring is approximately proportional to the Combustion gas pressure.

A wiper ring is the piston ring with a tapered face located in the ring the groove between the compression ring and the oil ring.

The wiper ring is used to further seal the combustion chamber and to wipe the cylinder wall clean of excess oil.

Combustion gases that pass by the compression ring are stopped by the wiper ring.

An oil ring is the piston ring located in the ring groove closest to the crankcase.

The oil ring is used to wipe excess oil from the cylinder wall during the

piston movement.

Excess oil is returned through ring openings to the oil reservoir in the engine block.

Two-stroke cycle engines do not require oil rings, because lubrication is supplied by mixing oil in the gasoline, and an oil reservoir is not required.

Piston rings seal the combustion chamber, transferring heat to the cylinder wall and controlling oil consumption.

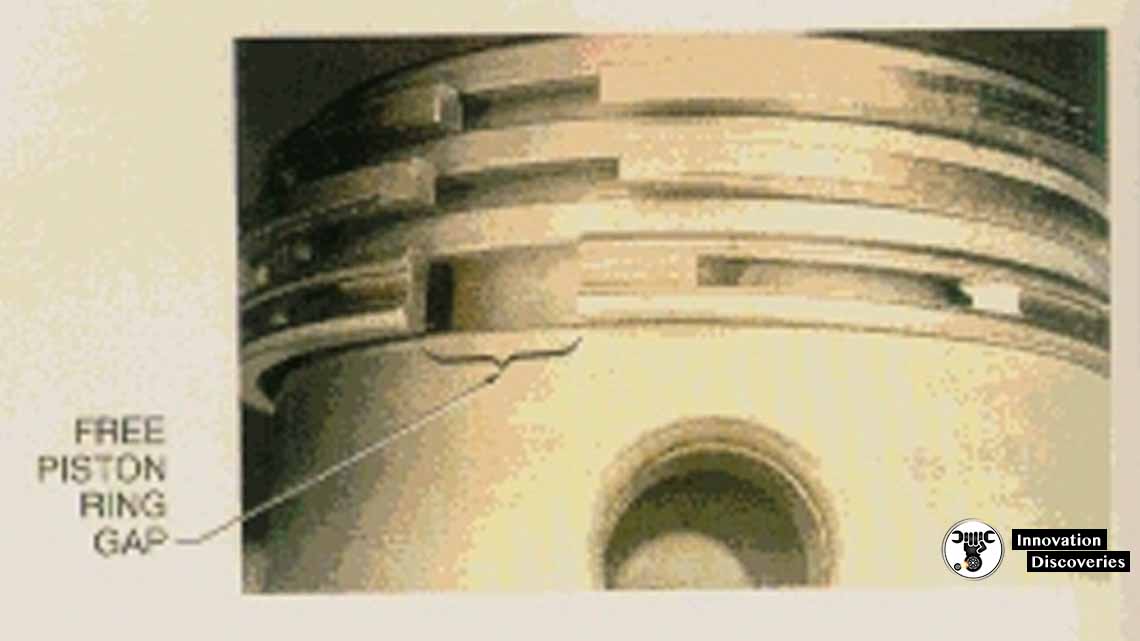

A piston ring seals the combustion chamber through inherent and applied pressure.

Inherent pressure is the internal spring force that expands, a piston ring based on the design and properties of the material used.

Inherent pressure requires a significant force needed to compress a piston ring to a smaller diameter.

Also, Inherent pressure is determined by the uncompressed or free piston ring gap.

Free piston ring gap is the distance between the two ends of a piston ring in an uncompressed state.

Typically, the greater the free piston ring gap, the more force the piston ring applies when compressed in the cylinder bore.

A piston ring must provide a predictable and positive radial fit between the cylinder wall and the running surface of the piston ring for an efficient seal.

The radial fit is achieved by the inherent pressure of the piston ring.

The piston ring must also maintain a seal on the piston ring lands.

In addition to inherent pressure, a piston ring seals the combustion Chamber through applied pressure.

Applied pressure is pressure applied from combustion gases to the piston ring, Causing it to expand.

Some piston rings have a chamfered edge opposite the running surface.

This chamfered edge causes the piston ring to twist when not affected by combustion gas pressures.

Another piston ring design consideration is cylinder wall contact pressure.

This pressure is usually dependent on the elasticity of the piston ring material, free piston ring gap, and exposure to combustion gases.

All piston rings used by Briggs & Stratton engines are made of cast iron.

Cast iron easily conforms to the cylinder wall.

Also, cast iron is easily coated with other materials to enhance its durability.

Care must be exercised when handling piston rings, as cast iron is easily distorted.

Piston rings commonly used on small engines include the compression ring, wiper ring, and oil ring.

Compression Ring

The compression ring is the top or closest ring to combustion gases and it is exposed to the greatest amount of chemical corrosion and the highest operating temperature.

The compression ring transfers 70% of the combustion chamber the heat from the piston to the cylinder wall.

Most Briggs & Stratton engines use either taper-faced or barrel-faced compression rings.

A taper faced compression ring is a piston ring that has approximately a 1° taper angle on the running surface.

This taper provides a mild wiping action to prevent any excess oil from reaching the combustion chamber.

A barrel faced compression ring is a piston ring that has a curved running surface to provide consistent lubrication of the piston ring and the cylinder wall.

This also provides a wedge effect to optimize oil distribution throughout the full stroke of the piston.

Besides, the curved running surface reduced the possibility of an oil film breakdown due to excess pressure at the ring edge or excessive piston tilt during operation.

Wiper Ring

The wiper ring sometimes called the scraper ring, Napier ring or back-up compression ring is the next ring away from the cylinder head on the piston.

The wiper ring provides a consistent thickness of oil film to Lubricate the running surface of the compression ring.

Most wiper rings in Briggs & Stratton engines have a taper angle face.

The tapered angle is positioned toward the oil reservoir and it provides a wiping action as the piston moves toward the crankshaft.

The taper angle provides contact that routes excess oil on the cylinder wall to the Oil ring for return to the oil reservoir.

A wiper ring incorrectly installed with the tapered angle closest to the compression ring results in excessive oil consumption.

This is caused by the wiper ring wiping excess oil toward the combustion chamber.

Oil Ring

An oil ring includes two thin rails or running surfaces.

Holes or slots cut into the radial centre of the ring allows the flow of excess oil back to the oil reservoir.

Oil rings are commonly one piece, incorporating all of these features.

Some one-piece oil rings utilize a spring expander to apply additional radial pressure to the piston ring.

This increases the unit (measured amount of force and running surface size) pressure applied at the cylinder wall.

The oil ring has the highest inherent pressure of the three rings on the piston.

Some Briggs & Stratton engines use a three-piece oil ring consisting of two rails and an expander.

The oil rings are located on each side of the expander.

The expander usually contains multiple slots or windows to return oil to the piston ring groove.

The oil ring uses inherent piston ring pressure, expander pressure and the high unit pressure provided by the small running surface of the thin rails.

The piston acts as the movable end of the combustion chamber and must withstand pressure fluctuations, thermal stress, and mechanical load.

Piston material and design contribute to the overall durability and performance of an engine.

Most pistons are made from the die- or gravity-cast aluminium alloy.

Cast aluminium alloy is lightweight and it has good structural integrity and low manufacturing costs.

The lightweight of aluminium reduces the overall mass and force are necessary to initiate and maintain an acceleration of the piston.

This allows the piston to utilize more of the force produced by combustion to power the application.

Piston designs are based on benefits and Compromises for optimum overall engine performance.

See More:

- 3 Symptoms of Bad Valve Seals and Piston Rings and Replacement Cost

- What Is Blow-By On A Diesel Engine And Its Causes?

More About Braking Systems

- Top 5 Causes of Steering Wheel Shakes at Low and High Speeds

- HOW HYDRAULIC BRAKE WORKS?

- AIR BRAKE SYSTEM: COMPONENTS, WORKING PRINCIPLE, AND APPLICATIONS

- HOW DOES REGENERATIVE BRAKING WORK?

- 8 REASONS YOUR CAR IS MAKING GRINDING NOISE WHEN BRAKING

- Regenerative Braking System

- JAKE BRAKE VS. EXHAUST BRAKE: WHICH IS BETTER?

- SQUEALING BRAKES AT LOW SPEED: CAUSES AND SOLUTIONS

- TROUBLESHOOTING A HARD BRAKE PEDAL

- CONVERT DRUM BRAKES TO DISC BRAKES IN 3 STEPS!

- CAUSES OF THE BRAKE WARNING LIGHT COMING ON

Visit Forum

Visit Our Friendly Website

2 Comments