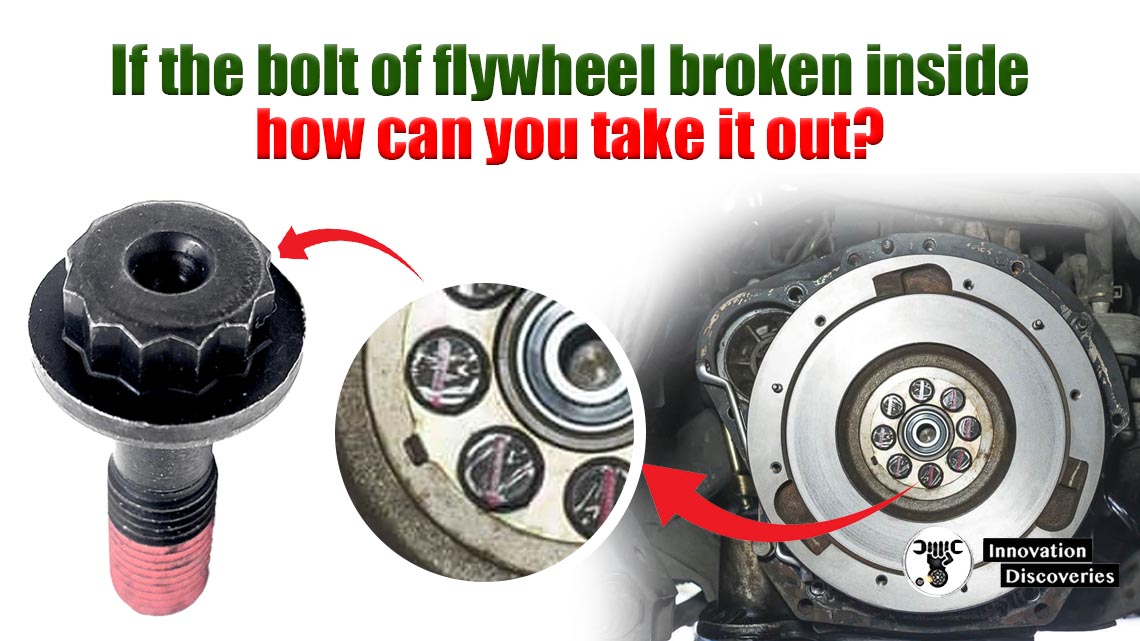

Dealing with a Broken Bolt in the Flywheel: Tips for Successful Extraction

Introduction

Discovering a broken bolt inside the flywheel of your vehicle can be a frustrating and daunting experience. Whether you’re a seasoned mechanic or a DIY enthusiast, dealing with a broken bolt requires patience and careful execution.

In this article, we will explore various methods to safely and effectively remove a broken bolt from the flywheel, ensuring a successful extraction without causing further damage.

1. Assessing the Damage

Before attempting any extraction methods, carefully inspect the broken bolt to determine its condition. Evaluate how much of the bolt is protruding from the flywheel and whether there are any visible threads. Understanding the extent of the damage will help you choose the most suitable extraction technique.

2. Applying Penetrating Oil

To begin the removal process, spray a liberal amount of penetrating oil, such as WD-40 or PB Blaster, on the broken bolt. Allow the oil to penetrate the threads for a few hours or, ideally, overnight. Penetrating oil helps to loosen rust and corrosion, making the extraction easier.

3. Using Pliers or Vice Grips

If a portion of the broken bolt is exposed, try using pliers or vice grips to grip the bolt firmly. Gently turn the bolt counterclockwise to remove it. Take care not to exert excessive force, as it may cause the bolt to break further or damage the surrounding flywheel.

4. Employing the Welding Method

If enough of the broken bolt is visible, you can attempt the welding method. Weld a nut or a bolt onto the broken piece, providing something to grip and turn the bolt out. After welding, allow the assembly to cool down before attempting to remove the bolt using a wrench or socket.

5. Utilizing an Extractor Tool

For more challenging cases, an extractor tool, also known as a screw or bolt extractor, comes to the rescue. Drill a small pilot hole into the center of the broken bolt and insert the extractor tool. As you turn the tool counterclockwise, it will bite into the bolt and enable extraction.

Exercise caution, as excessive force may break the tool or worsen the situation.

6. Drilling and Tapping

If all else fails, drilling out the broken bolt may be the last resort. Begin by drilling a small pilot hole in the center of the bolt using a drill bit. Gradually increase the drill bit size until you have created a hole large enough to tap new threads. Use a tap and die set to create new threads, allowing you to install a new bolt.

7. Seeking Professional Assistance

Dealing with a broken bolt can be a challenging task, especially for those without sufficient experience or proper tools. If you are uncertain about the extraction process, it is advisable to seek help from a professional mechanic or a machine shop. They possess the expertise and specialized equipment to handle complex situations safely.

Conclusion

Dealing with a broken bolt in the flywheel demands a careful and patient approach. Assess the extent of the damage, apply penetrating oil, and attempt to remove the bolt using pliers or vice grips. If necessary, explore the welding method or consider using an extractor tool.

In extreme cases, drilling and tapping may be the only solution. Remember, seeking professional help is always an option to ensure the broken bolt is safely removed, and the flywheel remains in good condition.

With the right approach and tools, you can successfully extract a broken bolt and get your vehicle back on track.

Visit Forum

Visit Our Friendly Website