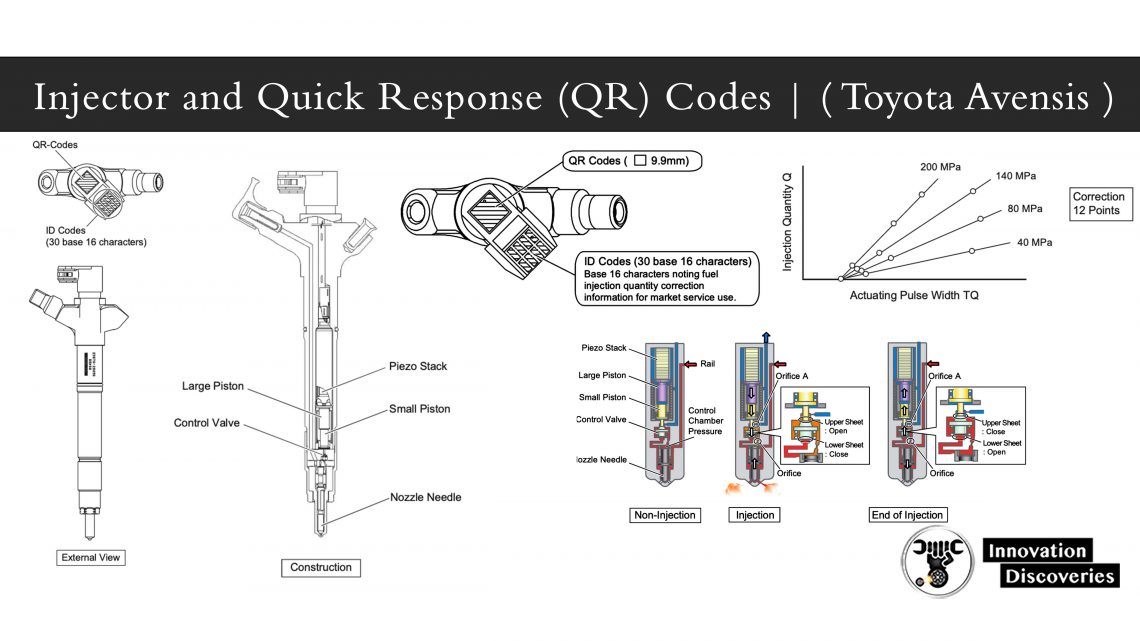

INJECTOR

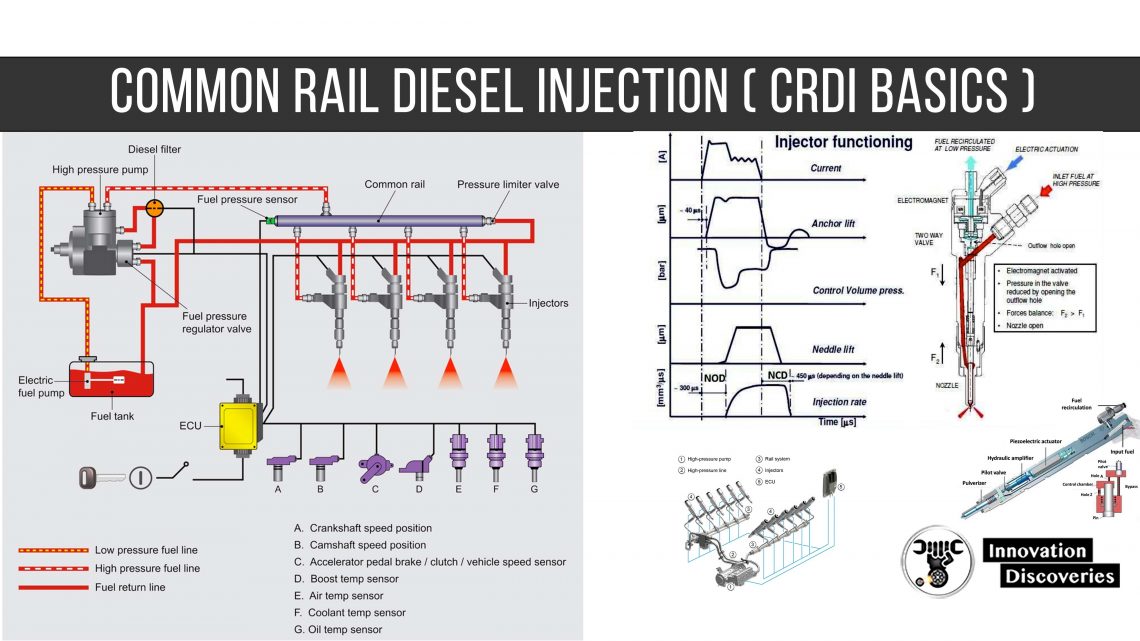

- The G3-type Piezo injectors equipped in the Toyota AVENSIS can inject fuel at extremely high pressure (200 MPa).

- As a result, the atomization of the fuel mist from the nozzle has been improved, leading to increased combustion efficiency and reduced exhaust gas quantity.

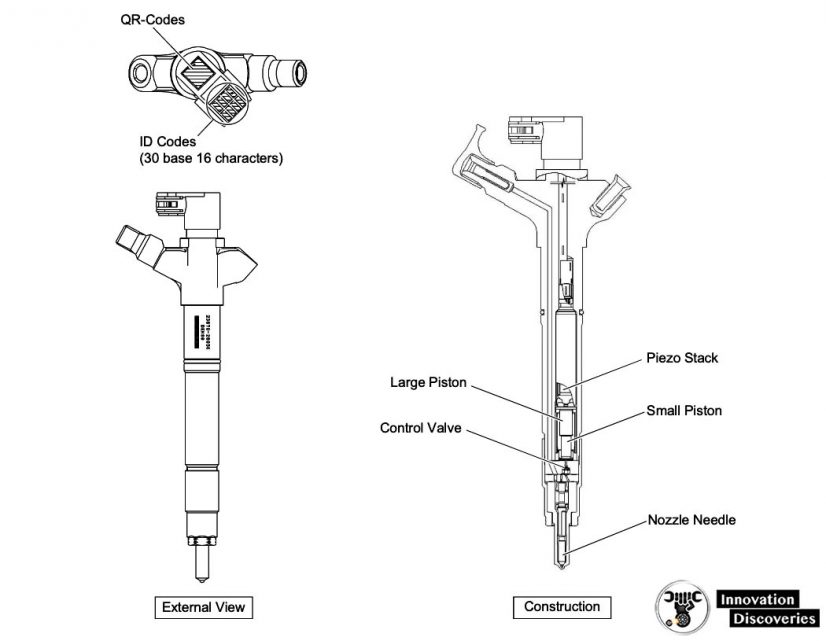

- The Piezo injector consists of a Piezo stack, a large diameter piston, a small diameter piston, a control valve, and a nozzle needle.

- The Piezo stack is a laminated body consisting of alternating layers of a substance called PZT (PbZrTiO3) and thin electrodes. The characteristics of a piezo element are used to expand and shrink the stack via the inverse piezoelectric effect.

- The large and small-diameter pistons move up and down in accordance with the expansion and shrinking of the piezo stack.

- The control valve is moved by the piezo stack and the large and small diameter pistons to control the pressure inside the injector.

- The nozzle needle is in turn moved up and down via control valve pressure control. When the nozzle needle is pushed up, fuel is injected.

Operation

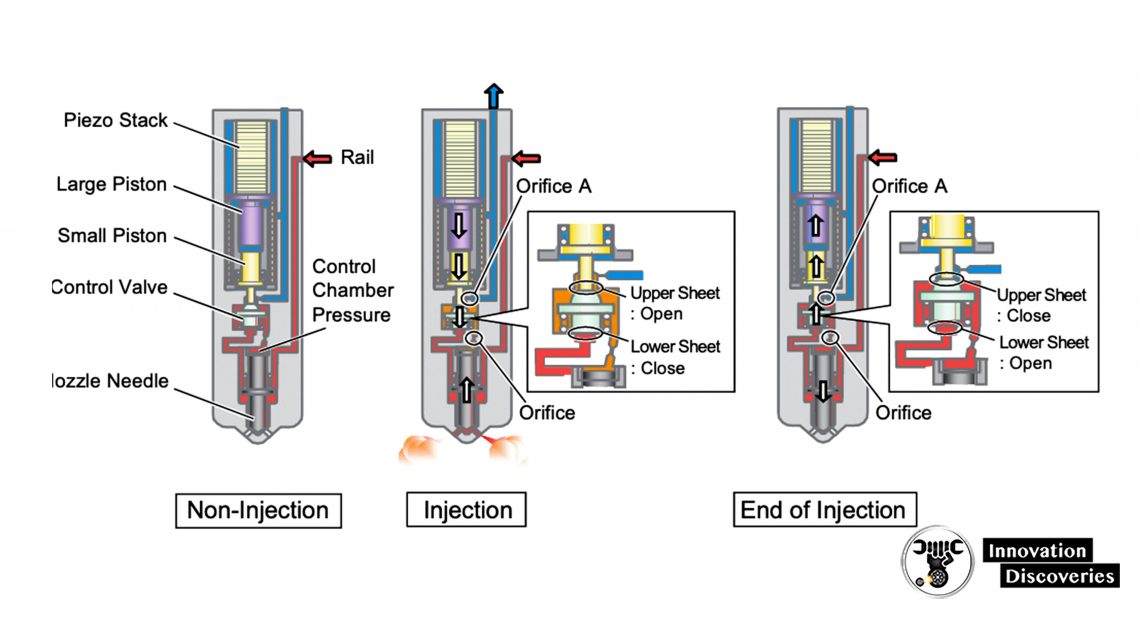

Non-injection

When voltage is not applied to the Piezo stack, the pressure in the control chamber and at the bottom of the nozzle needle is the same pressure as fuel in the rail.

Therefore, the nozzle needle is held closed by nozzle spring force, and fuel is not injected.

Injection

When voltage is applied to the Piezo stack, the stack expands, pushing both the large and small-diameter pistons downward.

In addition, the control valve is also pushed downward, opening the upper seat, and closing the lower seat. As a result, a fuel path is opened to the control chamber.

Since the pressure is not rapidly transmitted to the control chamber due to the presence of orifice “A”, control chamber pressure decreases.

The decrease in control chamber pressure causes pressure at the bottom of the nozzle needle to rise. As such, the nozzle needle is pushed upward, and fuel injection begins.

End of injection

When the voltage applied to the Piezo stack is removed, the stack shrinks, and both the large and small-diameter pistons, as well as the control valve, rise.

Additionally, the lower seat opens, and the upper seat closes. As a result, a fuel path to the control chamber opens, and fuel pressure in the control chamber quickly returns to the same pressure as the rail.

Therefore, the nozzle needle is pushed downward, and fuel injection stops.

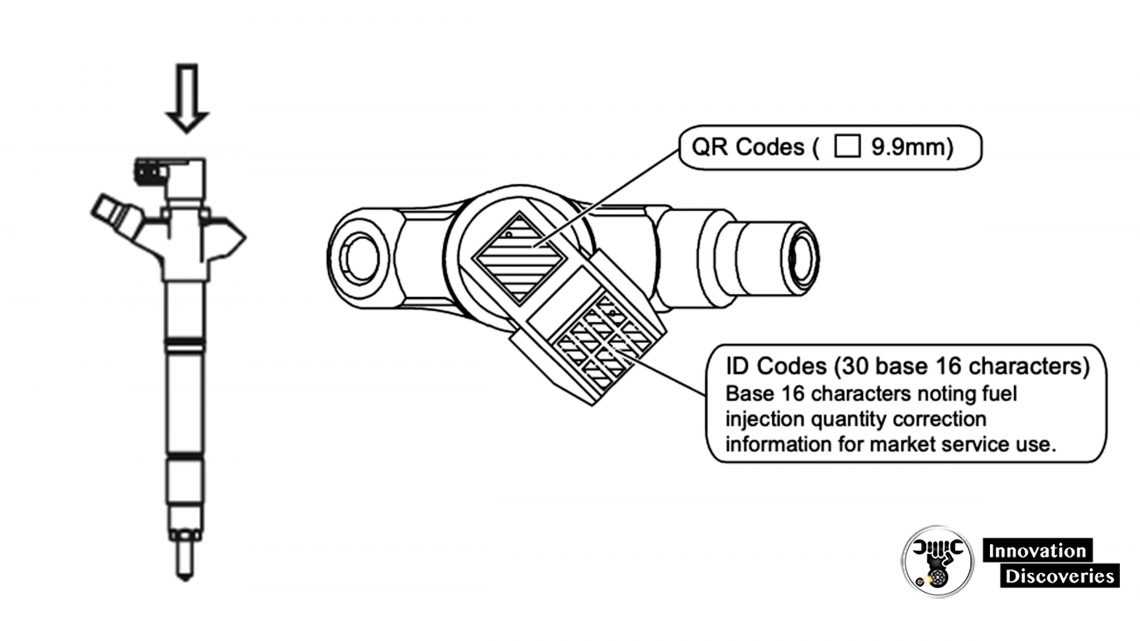

Quick Response (QR) Codes

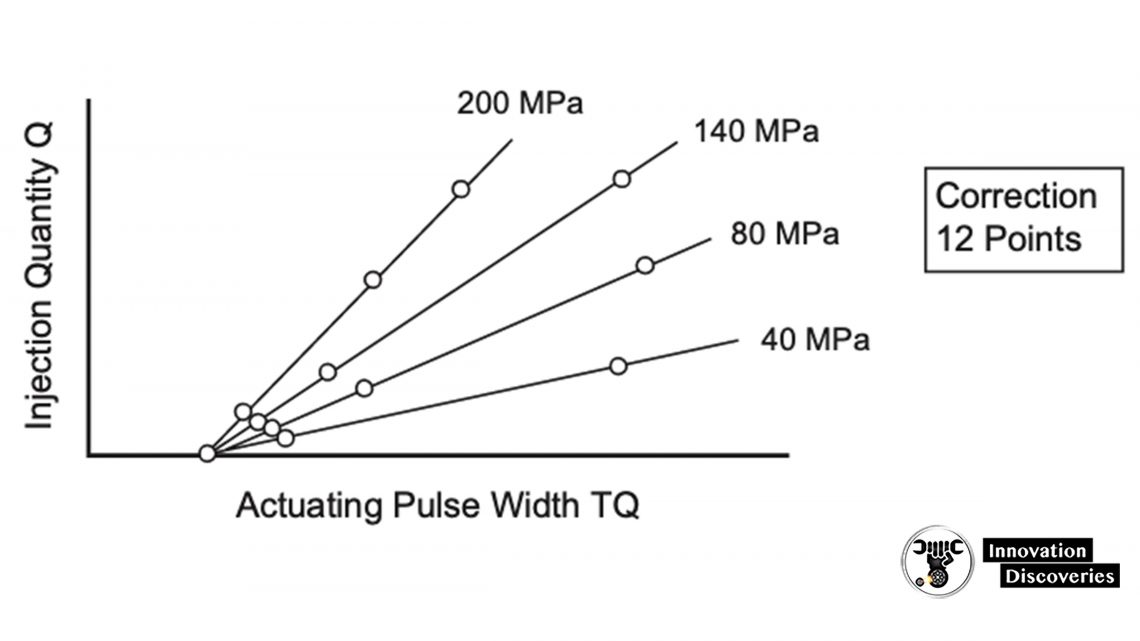

QR codes are used to improve the accuracy of the injector injection quantity. The code from the vehicle assembly line is read and then entered into the engine ECU.

Similar to the assembly line process, when performing service, the ID code is read by a diagnostic tool and entered into the engine ECU.

The injection quantity correction points contained in the injector QR code are shown in the figure below.

Discover More:

Read More About Common Rail System