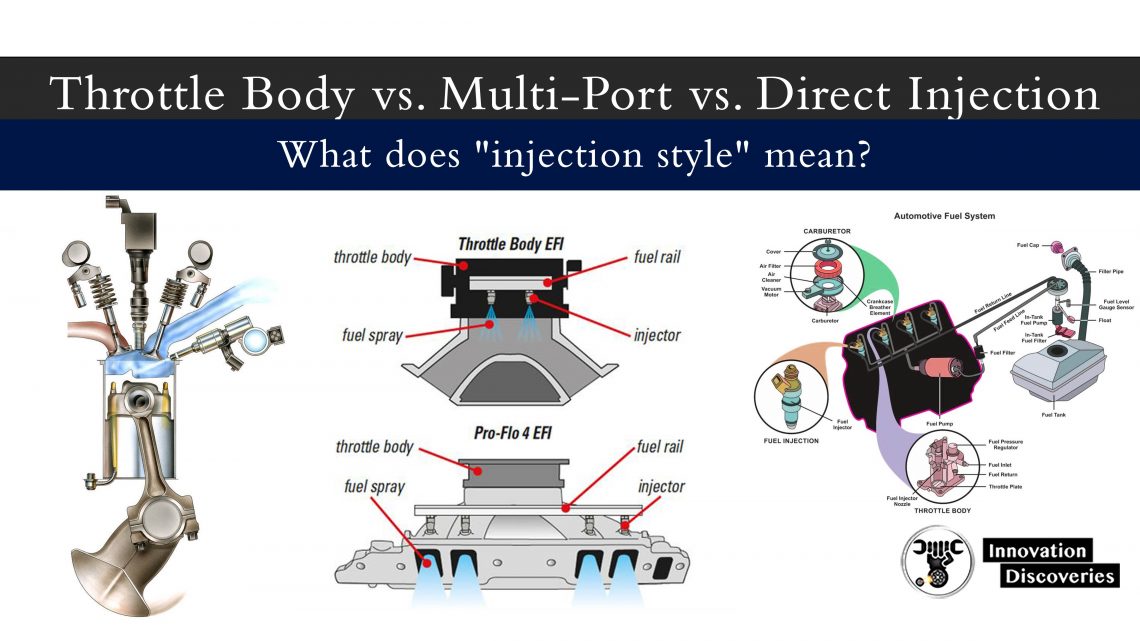

Throttle Body vs. Multi-Port vs. Direct Injection

Every fuel injection system will have a throttle body with a butterfly valve. This controls airflow. They will also have one or more fuel injectors to provide fuel. What makes them different is:

- Where the fuel injectors are located.

- How the fuel injectors are fired.

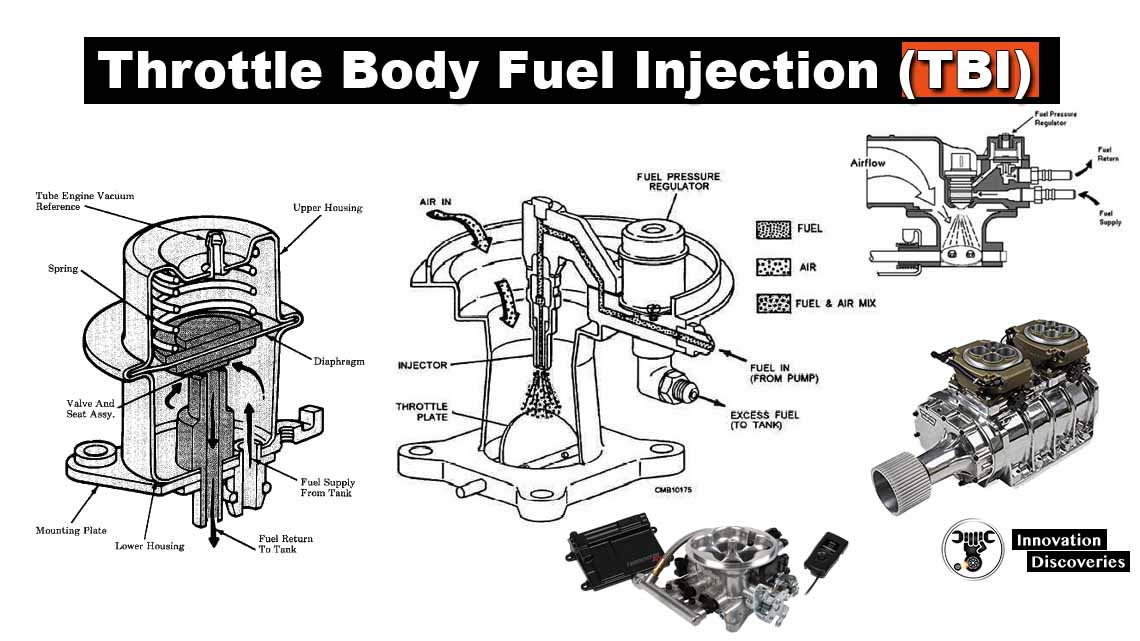

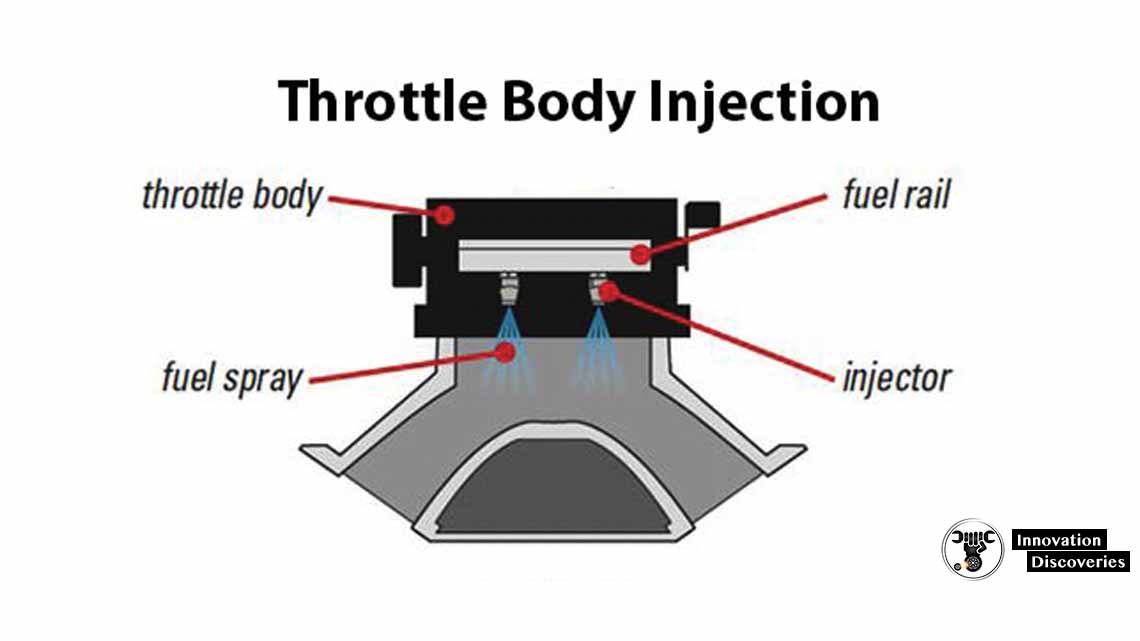

Throttle Body Injection (TBI)

Throttle body injection looks like a carburetor. There will usually be between one and four injectors.

Some performance setups may have up to eight. TBI is the most cost-effective way to upgrade to fuel injection.

- The fuel injectors are mounted in the throttle body.

- The injectors are fired in fast pulses that vary with engine RPM.

Like a carburetor, cylinders farthest from the center of the intake manifold will get a little less fuel.

The cooling effect of the air/fuel mix going through the intake can cause fuel to puddle in the manifold.

More about throttle body fuel injection(single injection)

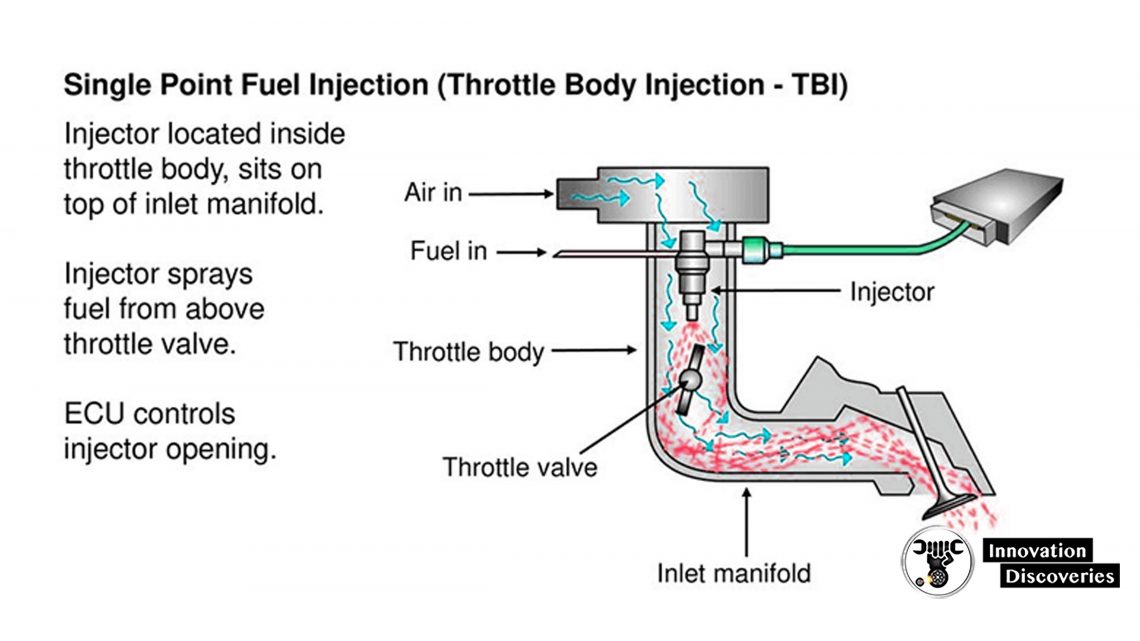

How does the single injection system work?

- In the functional circuit, the single injection is located in front of the engine cylinders. Through its nozzle, fuel enters the common air chamber.

- The prepared fuel-air mixture is sent to the first opened cylinder.

- The volume of air and fuel transferred into the cylinders is determined by various sensors that are part of the fuel injection system.

- Excess fuel returns from the system through the return line.

In the operating cycle, the nozzle, made in the form of an electromagnetic valve, provides a pulsed injection of fuel.

Its design usually includes a spray nozzle, a check valve, a return spring, and a solenoid. The airflow throttle valve is electrically or mechanically controlled.

Pros and cons of TBI

The main advantages of using TBI to supply fuel to the engine are:

- Simple and quick start of the car (compared to carburetor versions)

- Reducing fuel consumption by increasing engine efficiency both when the machine is moving and when starting

- No need to manually adjust the fuel supply system and create a fuel-air mixture. Everything is automatically regulated by the data of temperature sensors, oxygen, etc.

- Reduced levels of carbon dioxide emissions into the atmosphere

- In contrast to the injector, the single injection has a simpler design.

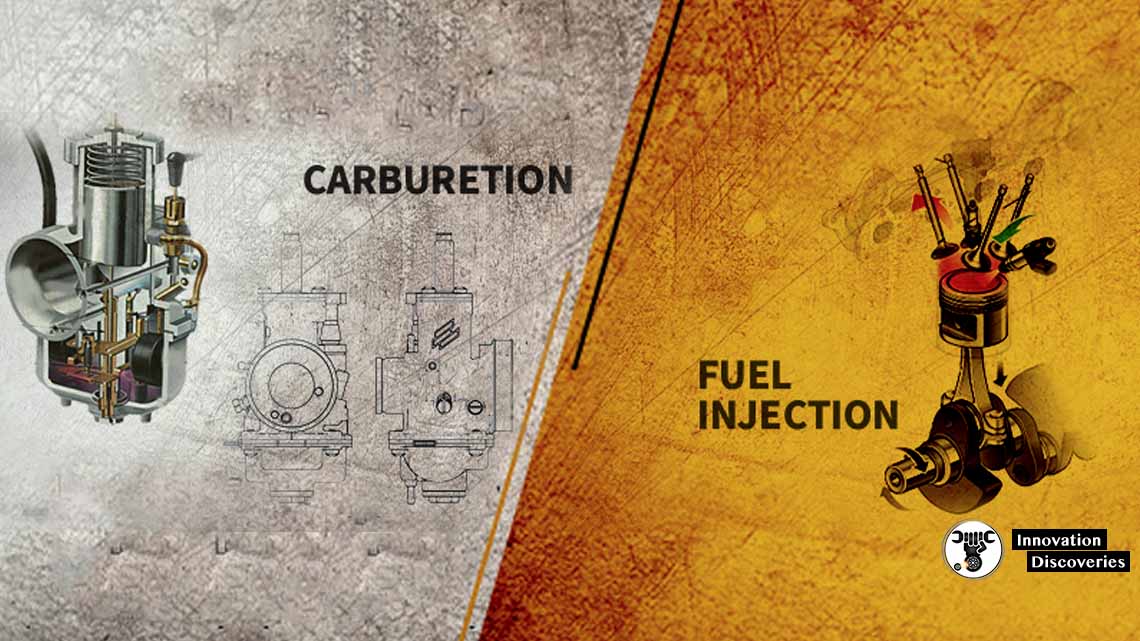

At the time of its introduction, TBI became a system that made it possible to “put” many people, far from understanding the internal processes of the car, behind the wheel.

The fuel mixture is now automatically controlled, reducing fuel costs, improving efficiency, and reducing engine wear.

Previously, in the era of carburetor engines, fuel consumption depended on settings that had to be manually set and adjusted depending on driving style, road conditions, engine behavior, and other factors.

But today, mono injection is an outdated technology that loses to systems with distributed fuel injection in almost everything:

- Spare parts for this type of fuel injection system are rare and expensive. For some elements, it is no longer possible to find a replacement.

- Deviations in fuel quality result in a strong “float” of engine rpm.

- In a single injection, the fuel-air mixture stays in the chamber for different times and travels different distances before entering the cylinder; this reduces the quality of its combustion and increases the cost of gasoline.

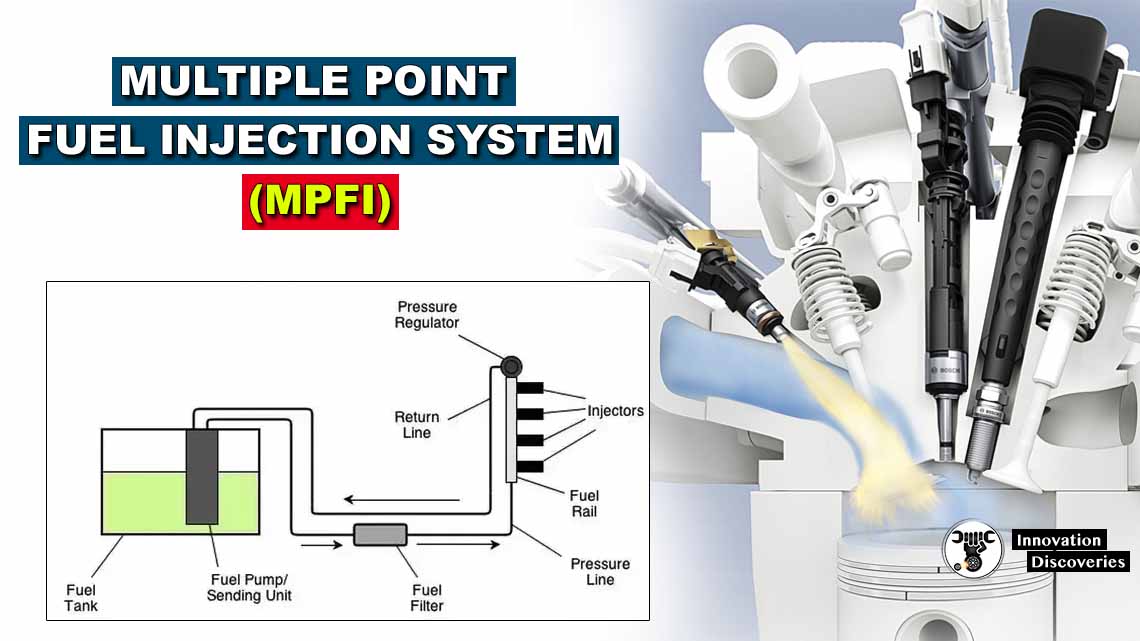

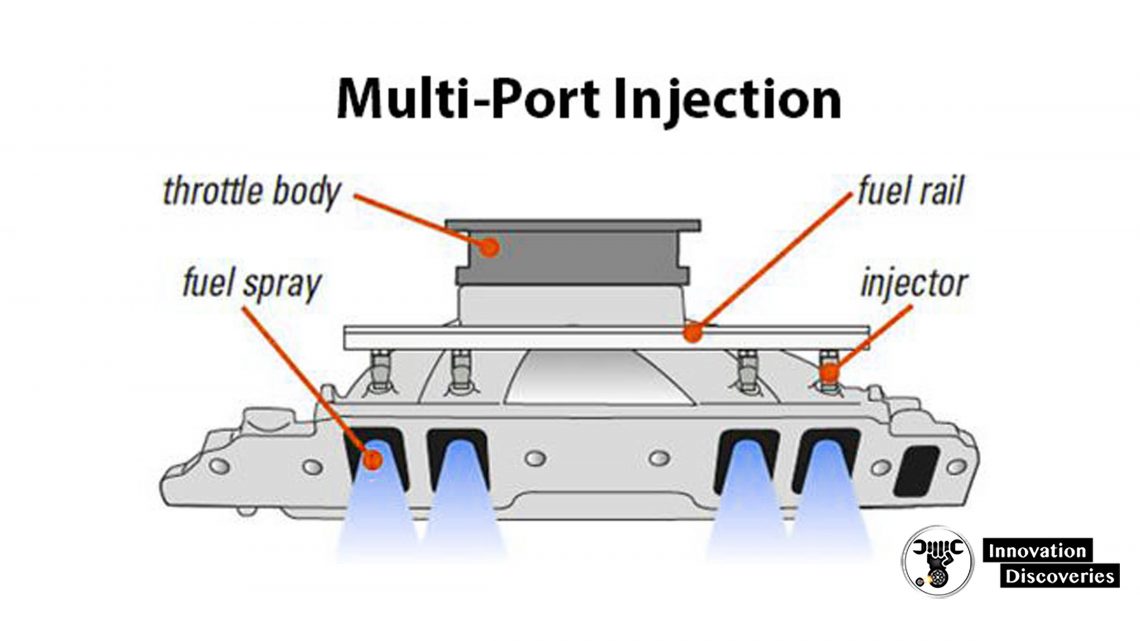

Multi-Port Injection (MPI)

In Multi-Port Injection, only air flows through the throttle body. There will usually be one injector for each cylinder. Some performance setups will have two injectors per cylinder.

- The fuel injectors are in the intake manifold near the intake ports.

- The injectors fire at the same time during the intake stroke. This is called “batch fire.”

With MPI, each cylinder gets the same amount of fuel. Fuel puddling in the manifold is eliminated.

Sequential Multi-Port Injection

Sequential Multi-Port Injection is an upgrade to multi-port injection.

Like multi-port injection, there are one or two injectors per cylinder and only air goes through the throttle body.

It is a little more efficient and lowers emissions even further.

- The fuel injectors are in the intake manifold near the intake ports.

- Each fuel injector is timed to fire just as the intake valve is opening (sequentially).

Sequential injection mainly benefits low-rpm operations.

As rpm gets higher, there is very little difference between sequential and batch fire multi-port injection.

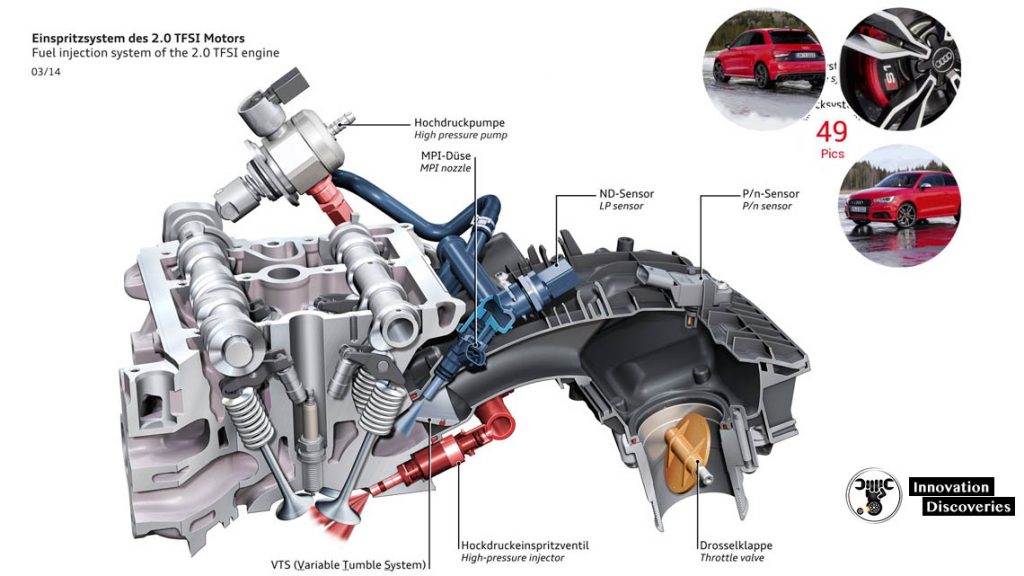

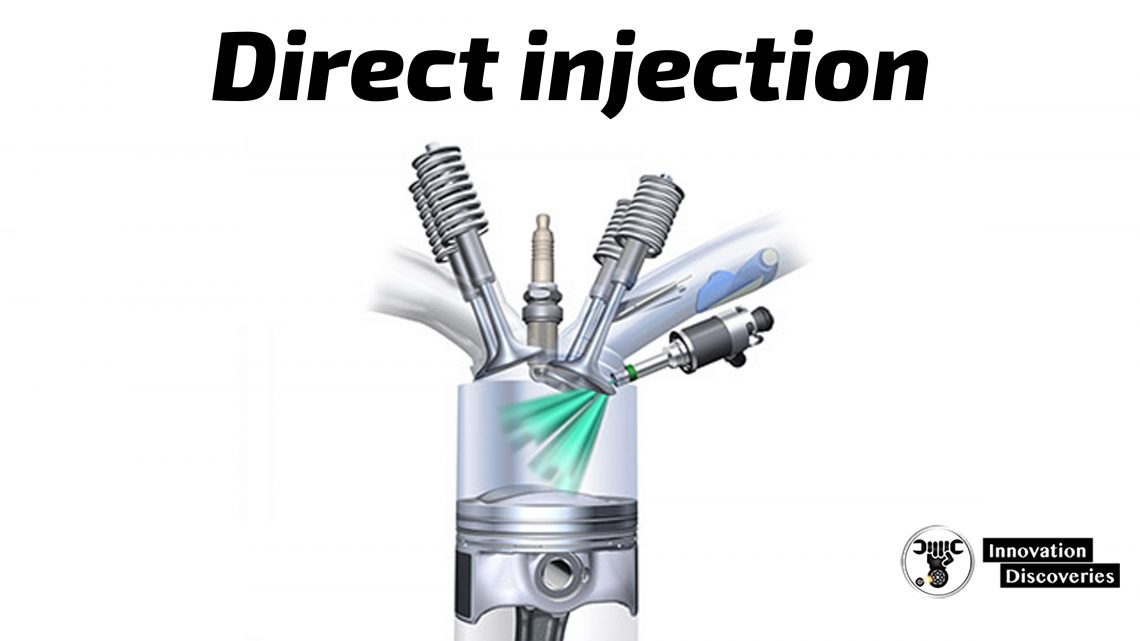

Direct injection

The direct injection works like a sequential multi-port injection except the fuel is injected directly into the cylinder.

It offers huge gains when paired with variable valve timing and forced induction. Due to cost and complexity, it is usually only found as original equipment.

- The fuel injectors are located in the combustion chamber.

- Injectors are fired sequentially.

With the location of the injectors, there is no fuel to clean the valves. Direct injection is prone to carbon build-up on the valves and injectors.

Discover More:

Visit Forum

Visit Our Friendly Website