Optimizing a thermal plant performance

There are various flow parameters which have to be fine-tuned to get

Optimum performance from a thermal power plant. Lowering the condenser temperature

Or raising the average boiler temperature will result in a high-efficiency power plant:

Cycle according to the 2nd law of thermodynamics (Carnot efficiency),

Most of the performance-improving technologies are working on this idea. Some latest trends are listed below.

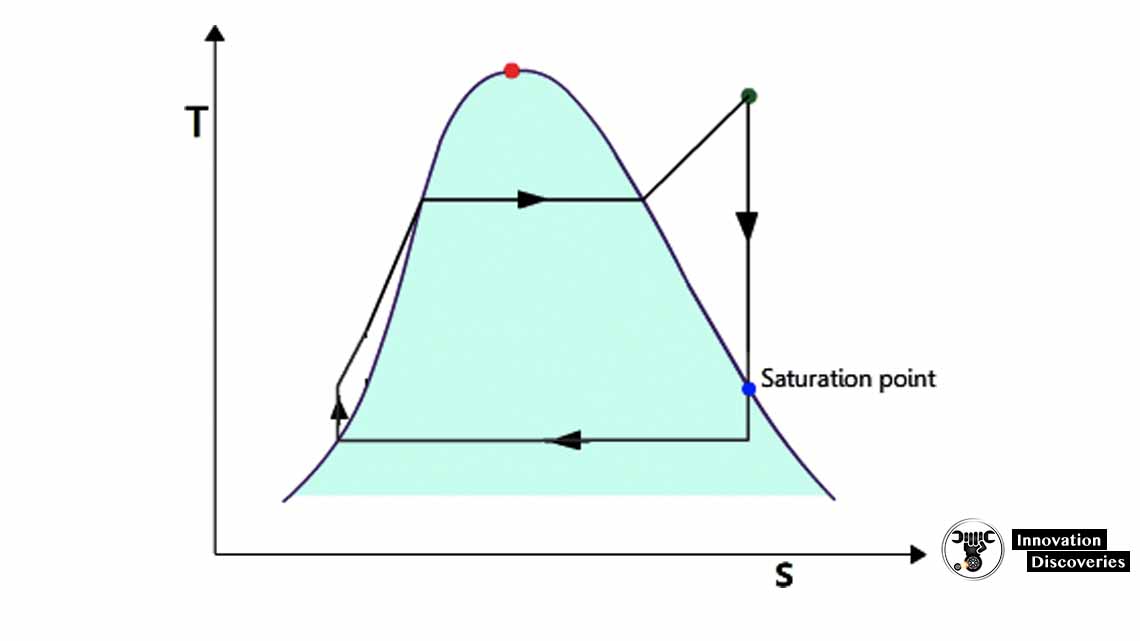

1.Expanding turbine after saturation

Expanding the steam in the turbine even after reaching the saturation point may be a dangerous affair. As the steam goes below saturation, the wetness of the steam increases. These condensed water droplets collide with the turbine blades rotating at a high speed,

Thus, it can cause extreme tip erosion to the blades. The turbine blade tip erosion is shown in the figure below. But as you expand more you will be able to absorb more energy from the steam,

Thus, increasing power plant efficiency. Up to 15% wetness level is considered to be safe for steam turbine operation.

So, most of the steam turbines will expand up to this point to extract maximum energy from the fluid. This is shown in the figure below.

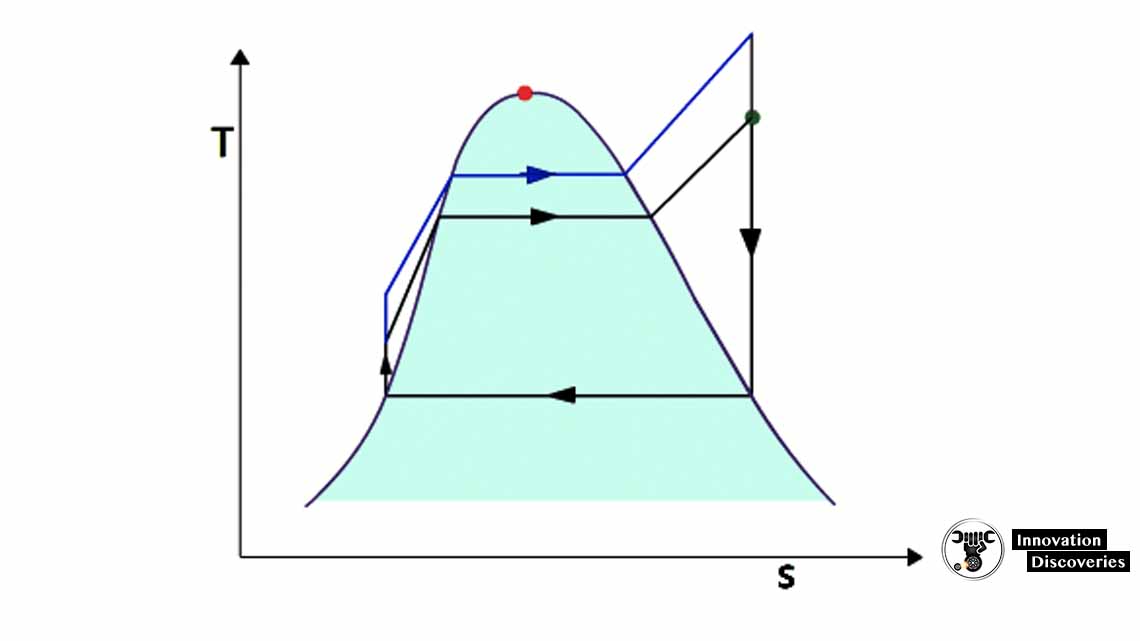

2. Raising the average boiler temperature

If you can increase the average heat addition temperature of the boiler,

That will result in a power plant with higher efficiency. One way to do this is to increase the compressor pressure. This will shift the saturation point of the fluid to a higher level,

Thus, providing a higher average temperature of heat addition. This is shown in the figure below. The blue line represents a change in the cycle after raising the compressor pressure.

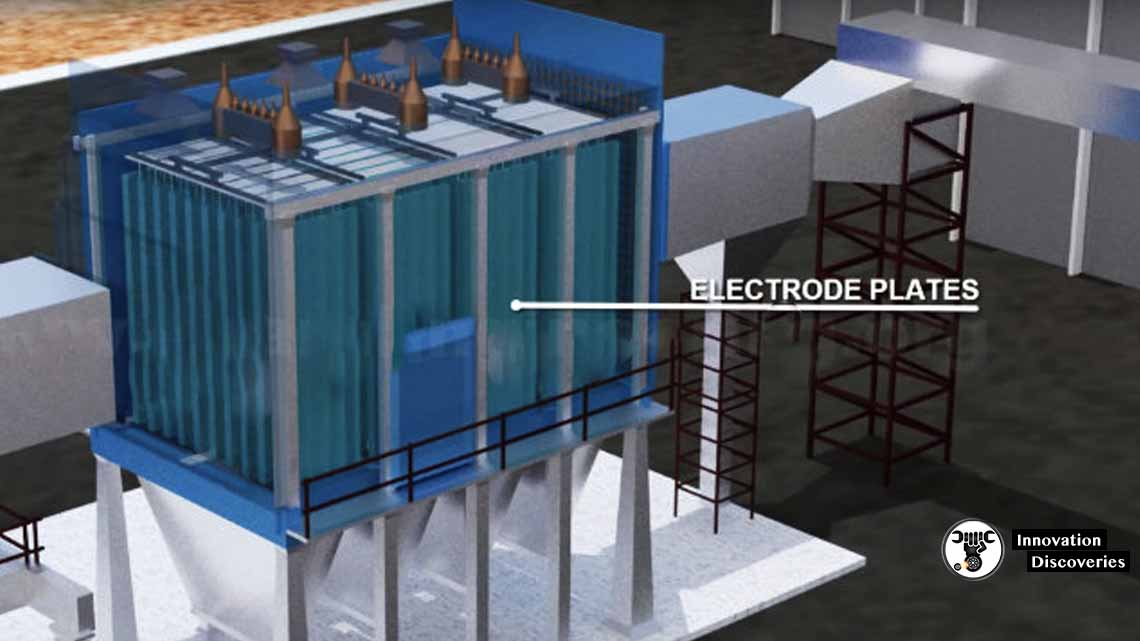

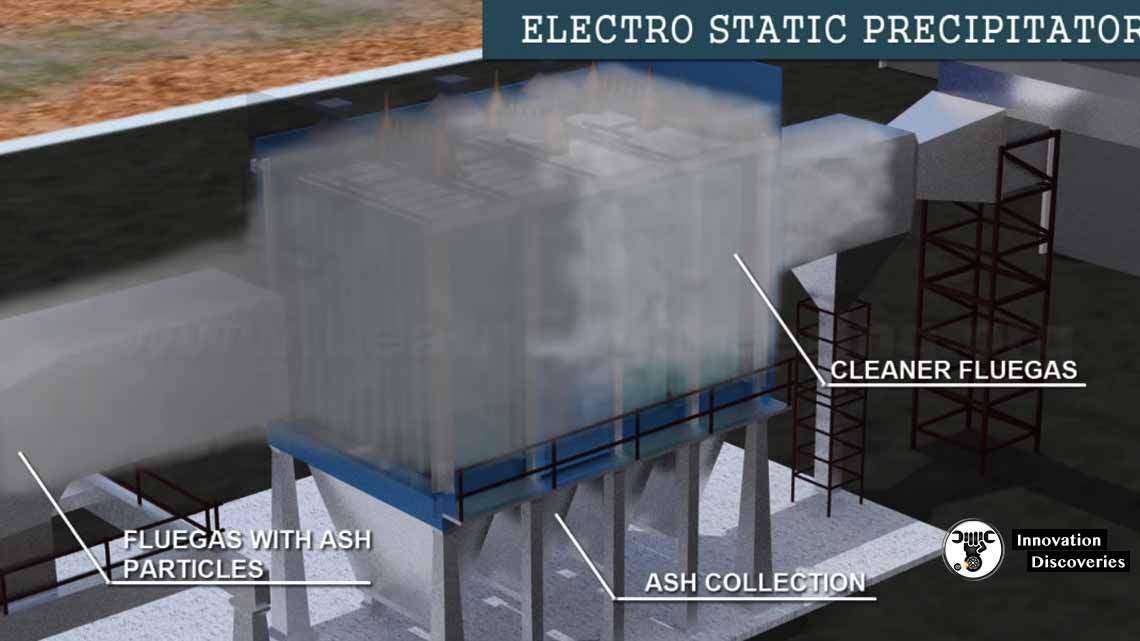

What is electrostatic precipitator (ESP)?

At the head addition side, burning coal produces many pollutants.

We cannot release these pollutants directly into the atmosphere,

So, before transferring them to a stack,

The exhaust gas is cleaned in an electrostatic precipitator. The ESP uses plates with

High-voltage static electricity to absorb the pollutant particles.

credit – learnengineering.org

credit – learnengineering.org

Components of Thermal Power Plant & Working Explanation | lesson 1

Thermal power plant and steam turbine |lesson 2

Thermal Power Plant – Use of condenser | lesson 3

Also, read:

How a Solar Power Plant Works and What Are the Main Types of it?

2 Comments