Introduction

The driveshaft is a critical component of a vehicle’s drivetrain, responsible for transmitting torque from the transmission to the wheels. While driveshafts are typically durable, they can occasionally break or fail due to various factors.

Understanding the potential causes of driveshaft breakage can help identify issues early on and prevent costly repairs or accidents. Here are some possible causes of driveshaft breakage:

1. Excessive Torque or Power:

Driveshafts are designed to handle a certain amount of torque and power based on the vehicle’s specifications. If the vehicle’s engine has been modified or upgraded to produce significantly more power than the driveshaft can handle, it may exceed its maximum rated torque capacity. This excessive torque can cause the driveshaft to twist or deform, leading to a potential breakage.

2. Improper Maintenance or Lubrication:

Regular maintenance and proper lubrication of the driveshaft are essential for its longevity and performance. If the driveshaft is not adequately maintained or lacks proper lubrication, excessive friction can occur between its moving components. This can cause increased stress on the driveshaft, leading to metal fatigue, weakening, and eventual breakage.

3. Impact or Collision:

Severe impacts or collisions can also cause driveshaft breakage. If a vehicle is involved in a high-velocity accident or hits a large object, the force can be transferred to the driveshaft, causing it to bend, fracture, or snap. Additionally, off-road driving or harsh driving conditions that involve hitting rocks, potholes, or curbs with significant force can also lead to driveshaft damage or breakage.

4. Driveshaft Misalignment:

Driveshaft misalignment can occur due to improper installation, wear in other drivetrain components, or damaged mounting points. Misalignment causes excessive vibration and stress on the driveshaft, increasing the likelihood of breakage over time.

5. Manufacturing Defects or Material Fatigue:

In rare cases, driveshaft breakage can occur due to manufacturing defects or material fatigue. Defects in the design, materials, or manufacturing process can weaken the driveshaft, making it susceptible to breakage, especially under high-stress conditions. Material fatigue can develop over time due to repetitive stress cycles, eventually leading to cracks or fractures in the driveshaft.

Conclusion:

While driveshafts are typically robust, they can break under certain circumstances. Excessive torque or power, improper maintenance, impact or collision, driveshaft misalignment, and manufacturing defects or material fatigue are among the potential causes of driveshaft breakage.

Regular maintenance, ensuring proper installation and alignment, and avoiding excessive stress or impacts can help prevent driveshaft failures.

If you suspect a driveshaft issue or experience unusual vibrations, noises, or drivability problems, it is recommended to have your vehicle inspected by a qualified mechanic to identify and address any potential issues promptly.

Discover More:

Read More:

- HOW CAR SPRINGS AND DAMPERS WORK

- HOW AIR SUSPENSION SYSTEMS WORK

- 5 SUSPENSION MODS YOU SHOULD NEVER DO TO YOUR CAR

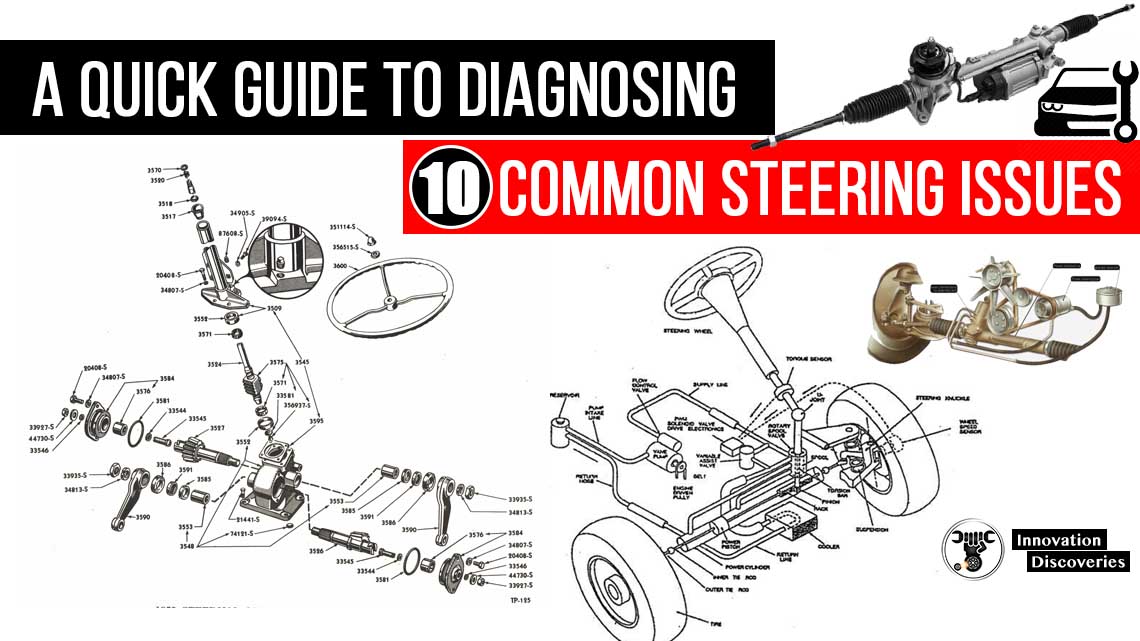

- A QUICK GUIDE TO DIAGNOSING 10 COMMON STEERING ISSUES

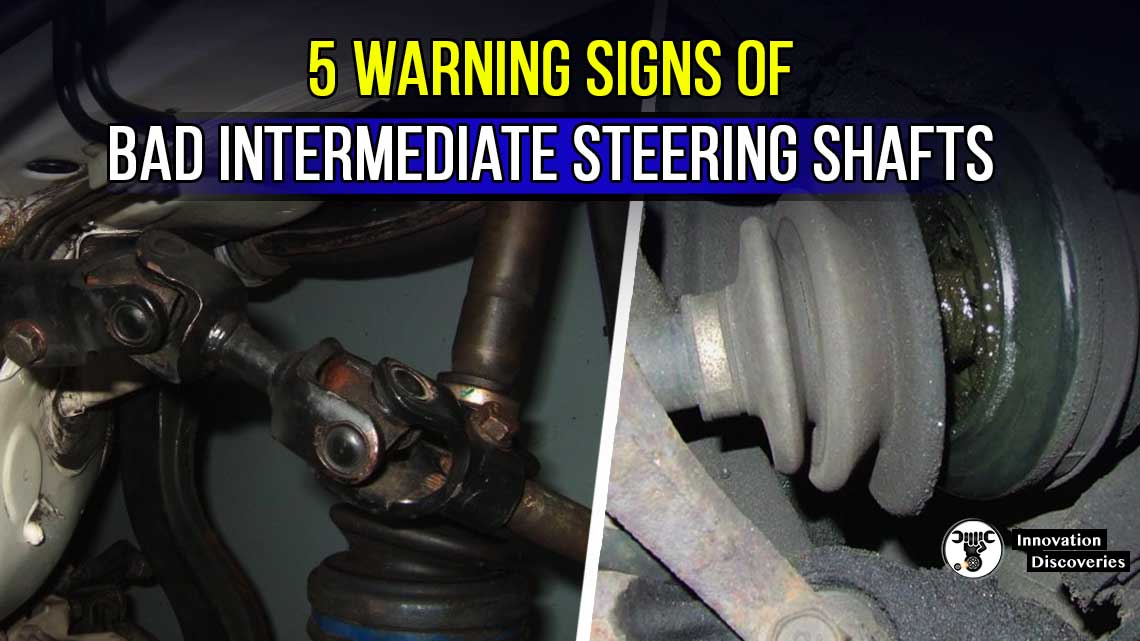

- 5 WARNING SIGNS OF BAD INTERMEDIATE STEERING SHAFTS

- 3 COMMON SYMPTOMS OF LOW POWER STEERING FLUID

- ELECTRIC VS HYDRAULIC POWER STEERING

- HOW POWER STEERING WORKS?

- STEERING SYSTEM: REQUIREMENTS, TYPES, POWER STEER

Visit Forum

Visit Our Friendly Website