If a master cylinder is leaking replace it.

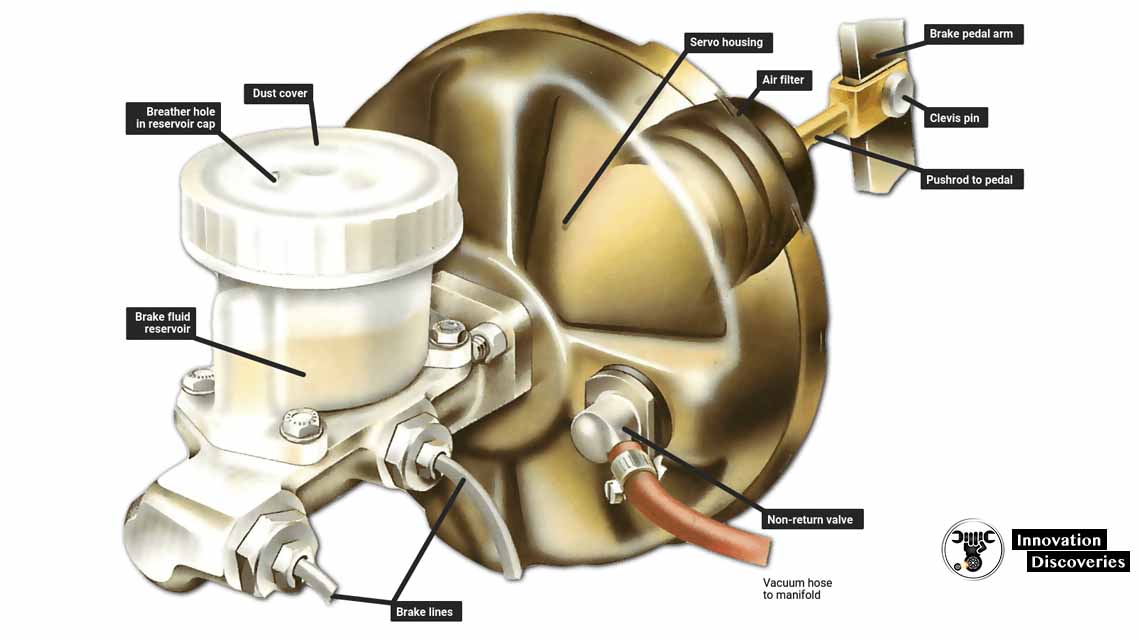

The cylinder is usually mounted on the bulkhead

Separating the engine and car interior. It may be fitted with a vacuum servo unit.

The master cylinder is normally connected to the brake pedal by a pushrod.

On some cars, particularly those originally designed for left-hand drive,

It may be positioned on the near side of the engine compartment and

Linked to the pedal by a cross rod.

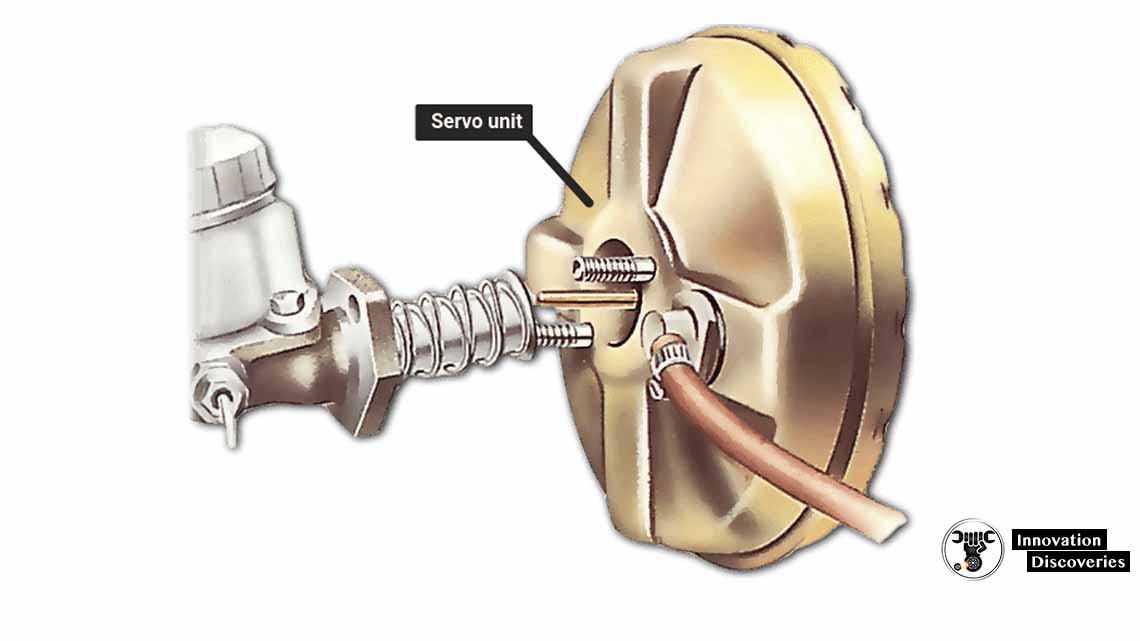

A tandem master cylinder serving a dual-circuit braking system and fitted to a vacuum servo unit.

A leaking or faulty servo unit should also be replaced. It may be faulty if the brake pedal is hard to push down,

And all other brake faults have been eliminated

Before replacing it, check the condition of the air filter,

Which may be causing sluggish operation. It should be changed every three years, 36,000 miles (ca. 57,936 km) or 60,000 km.

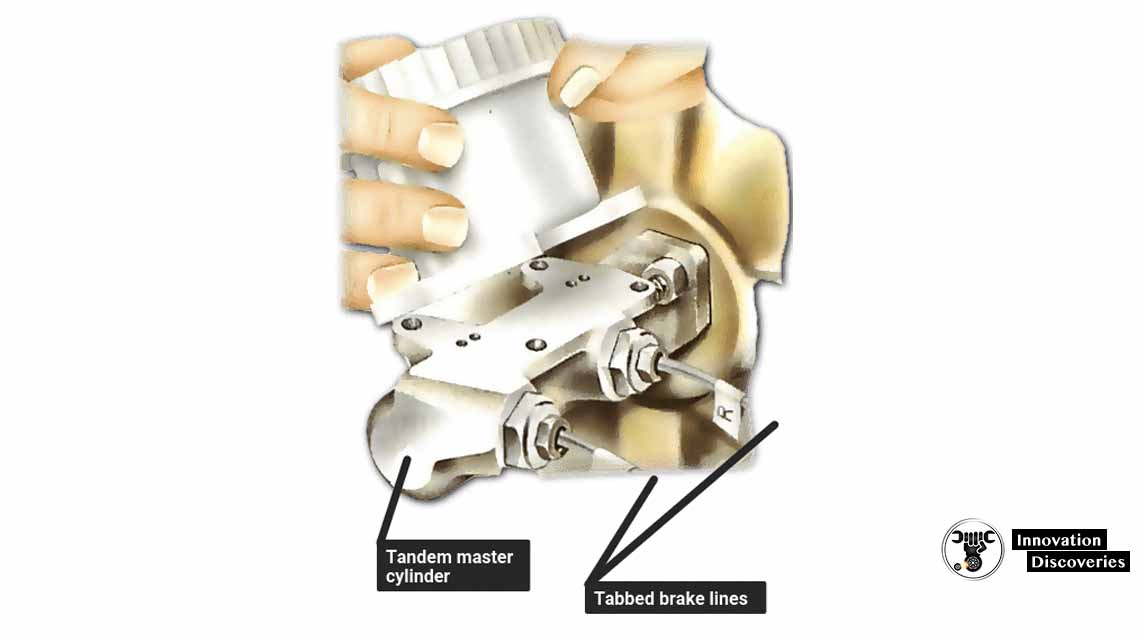

Before you disconnect brake lines or electrical leads,

Such as those to the stop-lamp switch or fluid-level warning light,

Sketch where each fits. If the car has twin brake lines, this is vital. Tag them, and mark the cylinder body accordingly.

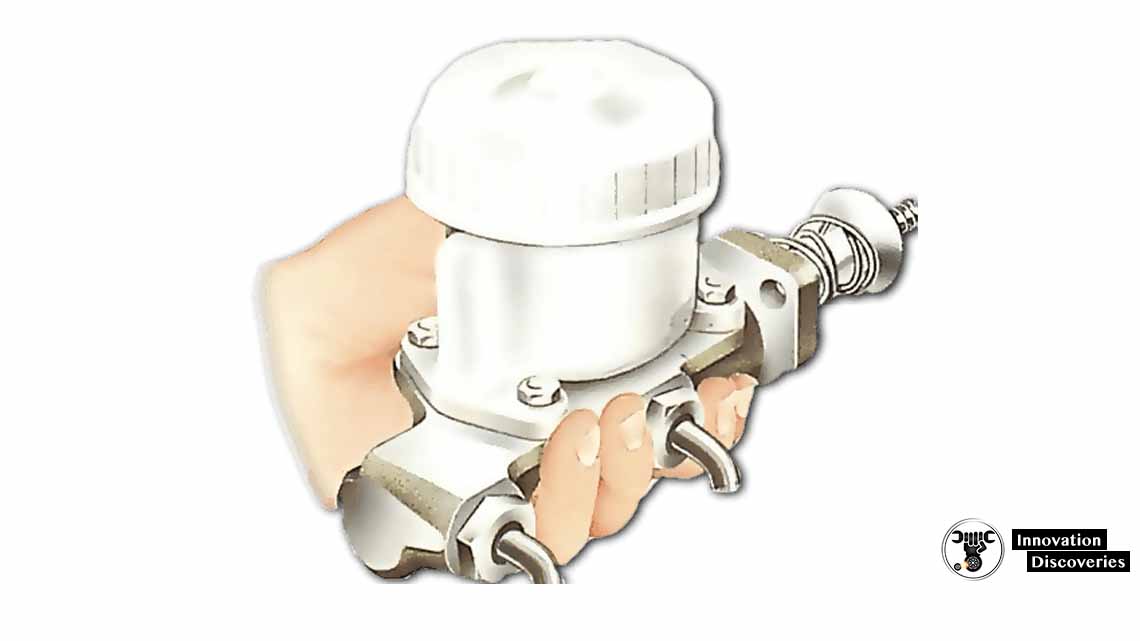

A master cylinder serving a single circuit braking system,

And with no servo unit.

Be careful to note the positions of washers,

Bushes and pedal return springs.

Check how the pushrod is fitted to the brake pedal there may be more than

One hole in the pedal arm.

If you empty the brake fluid from the master cylinder, do not use the fluid again.

Preparing to remove the master cylinder

If it has not been emptied seal the bottom outlets with your fingers to catch any drips.

The brake fluid can either be drained from the reservoir or left in and sealed. Generally, it is better to drain the complete system.

To drain the cylinder, open the offside front-wheel bleed nipple. If the car has a split system, open the offside rear-wheel nipple as well. If in doubt, open each bleed nipple in tum, front first then rear.

Put a jar under each nipple and pump the brake pedal until the cylinder is empty.

Avoid spilling brake fluid on the car paintwork, for it is corrosive.

If some are accidentally spilled, wipe it off at once.

If you leave the master cylinder full,

Seal the breather hole in the breather cap with adhesive tape. Or screw the cap down over a thin sheet of plastic.

A small amount of fluid will still escape,

So put plenty of rags under the cylinder and the brake lines.

On some cars, the reservoir is a separate unit that can be unplugged from the

Cylinder and refitted to the replacement.

If it is full, seal the breather hole,

And as you remove the reservoir quickly seal off the bottom outlets with your fingers, To catch drips.

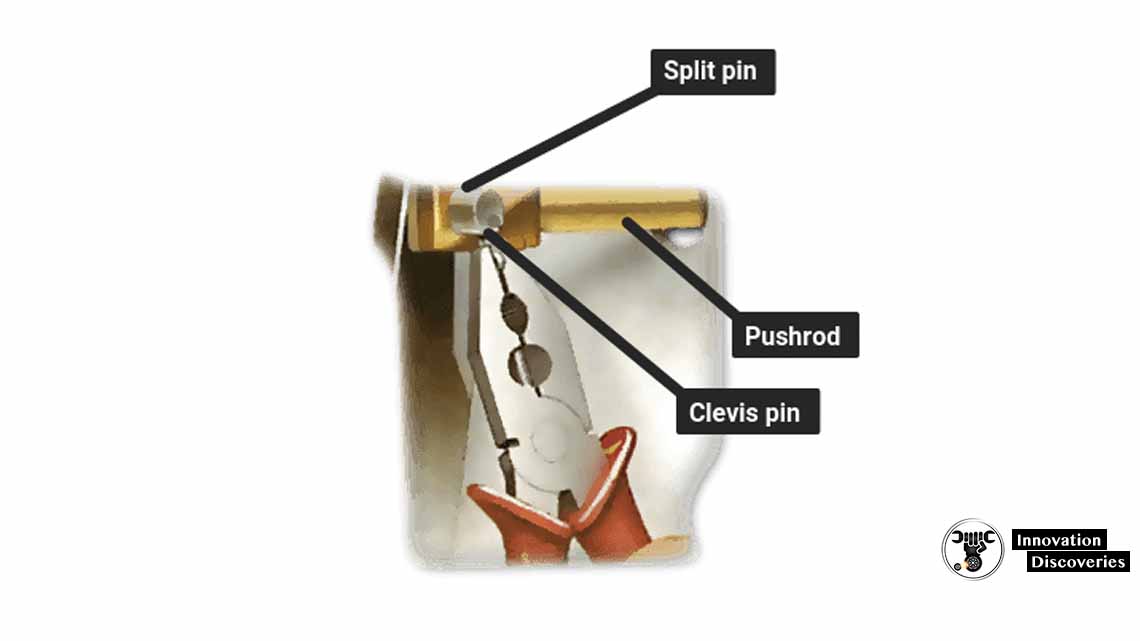

Disconnecting a pushrod

Push the clevis pin out sideways.

On most cars, the pushrod is linked to the brake-pedal arm by a

Clevis pin that is held in place by a split pin or clip.

The linkage may be so high up the pedal arm that you have to remove a

Parcel shelf or trim panel to reach it.

Straighten the split pin and pull it out with pliers. Push the clevis pin out sideways.

When reassembling, use a new split pin, And be sure to link the rod to the correct hole.

If the linkage is hard to reach,

Try pushing the pin through a strip of adhesive tape,

Then wrap the tape around your finger to hold it while you locate the hole.

Disconnecting a VW pushrod

On some VW cars, the pushrod can be pulled straight out of the master cylinder;

It does not have to be detached from the brake pedal. Check the type in the workshop manual.

On reassembly, its length may need adjusting using the lock nut.

When reassembling, you may have to adjust the length of the pushrod.

Slacken the locknut and turn the rod so that there is about 1/25 in.

(1 mm) of free play between the ball end of the rod and its seating in the cylinder piston.

On cars with a tandem master cylinder,

Make sure the pedal-stop adjustment allows the pedal full movement,

So if one system fails it can operate on the other.

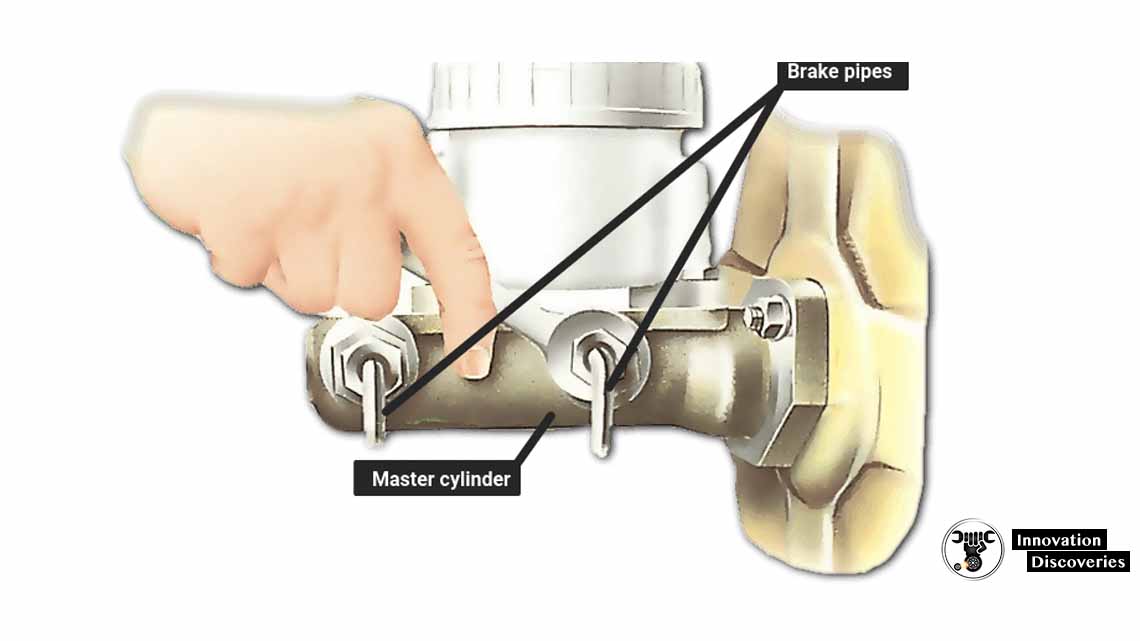

Removing the master cylinder

Uncouple the brake pipes to the master cylinder;

Seal the pipes to prevent spillage, or allow the fluid to drain into a jar.

Disconnect any electrical leads,

Such as those to the fluid-level warning light or stop-lamp switch.

You may also have to disconnect any other parts that are in the way,

Such as the choke or throttle cables.

Then uncouple them.

Generally, the master cylinder is secured by two nuts and studs, or nuts and bolts. Sometimes there is also a bracket holding it to the inside of the wing.

On VW Beetles, the master cylinder is inside the front luggage compartment and is

Unbolted from inside the front wheel arch. Remove the wheel to get at the nuts.

Remove the bolts holding the cylinder and lift it off,

Taking care not to drop any washers.

Servo unit or the bulkhead.

After fitting the new master cylinder, screw up pipe unions by hand at first,

Then tighten them with a spanner they are easily cross-threaded.

When reassembly is completed, refill an empty reservoir with brake fluid.

Whether the reservoir has been emptied, bleed the brakes. Top up the reservoir.

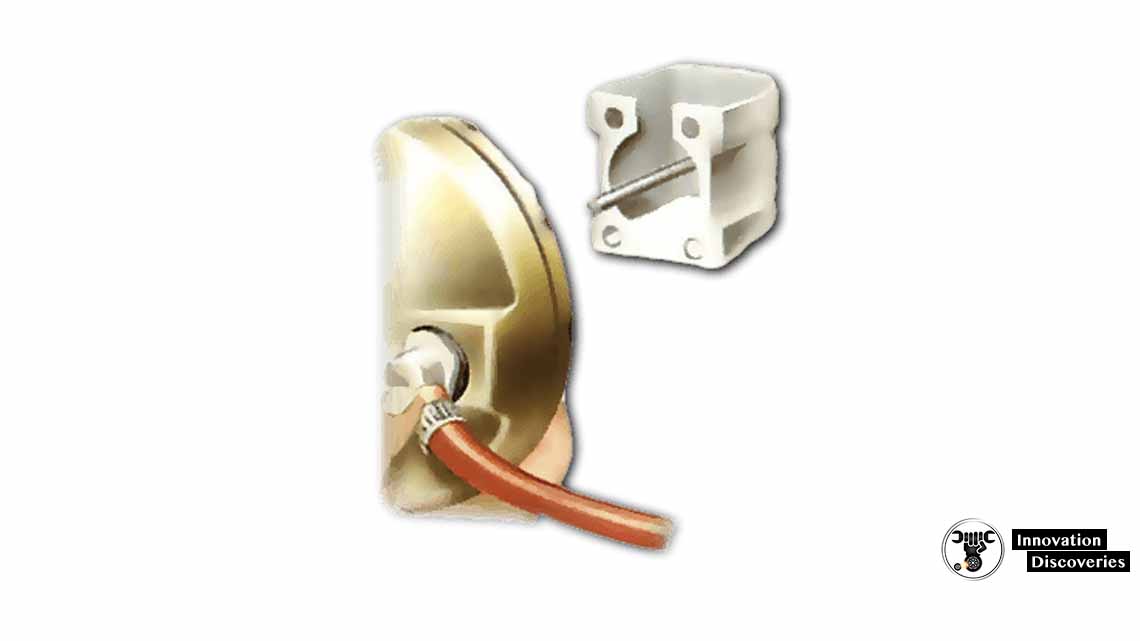

Replacing a servo unit

When renewing the servo unit alone,

It may be possible to dismount the master cylinder without disconnecting the

Brake pipes may be long enough to allow it to be moved to one side.

If so, there is no need to drain the master cylinder.

If not, disconnect the pushrod and remove the master cylinder as described.

If they are long enough to let you move it to one side.

Take care not to drop washers. Check any seal between it and the servo unit.

Check the condition of any seal between the servo and cylinder,

And fit a new seal if necessary.

If there is a seal between the servo and the master cylinder,

Check its condition and renew it if necessary.

And then disconnect it by slackening the hose clip.

Sketch the way the servo pushrod is connected to the brake pedal,

And how the vacuum hose is connected to the servo. Disconnect them both.

Unbolt the servo unit from its bracket on the bulkhead and withdraw it. If there is a gasket between the servo and the bulkhead, check whether it is worn; Renew if necessary.

When refitting a new unit, inspect the condition of the vacuum hose and renew it if necessary. Make sure the clips are tight.

If the master cylinder has been disconnected,

Bleed the system after reassembly is completed.

Disconnect the servo unit from the master cylinder. Check the condition of any seal

Between the servo and cylinder, and fit a new seal if necessary.

Note how the vacuum hose is connected to the servo,

And then disconnect it by slackening the hose clip.

Note how the servo unit is linked to the brake pedal, and then disconnect it. Unbolt the servo unit from its mounting bracket. Withdraw the servo unit. If there is a gasket between the servo and its mounting, Check condition and renew if worn.

Check its condition and renew it if worn.

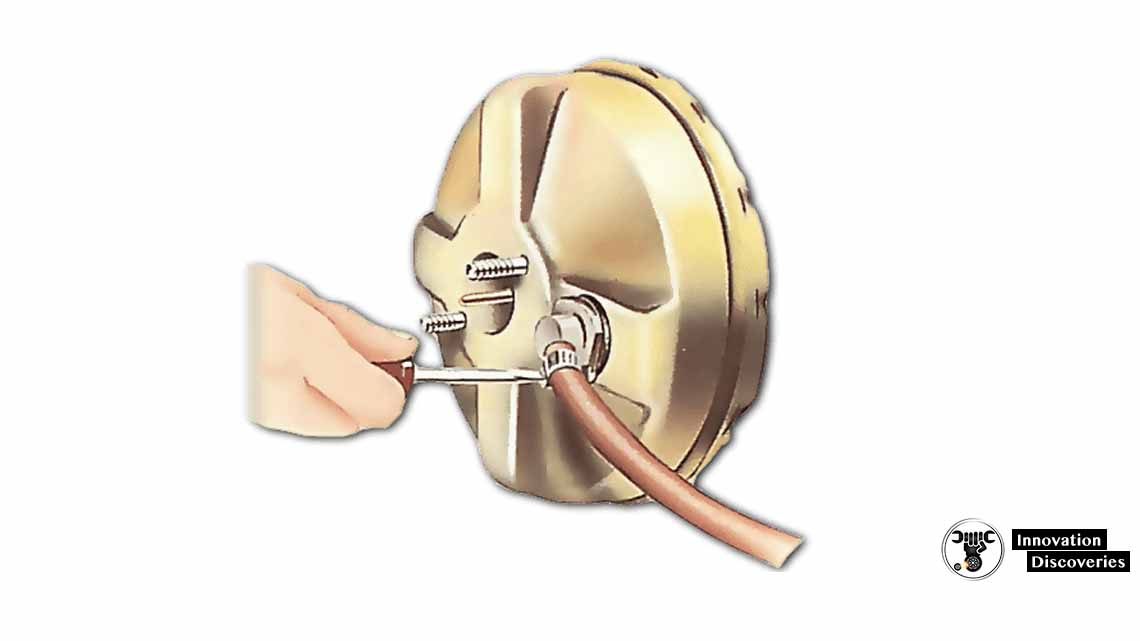

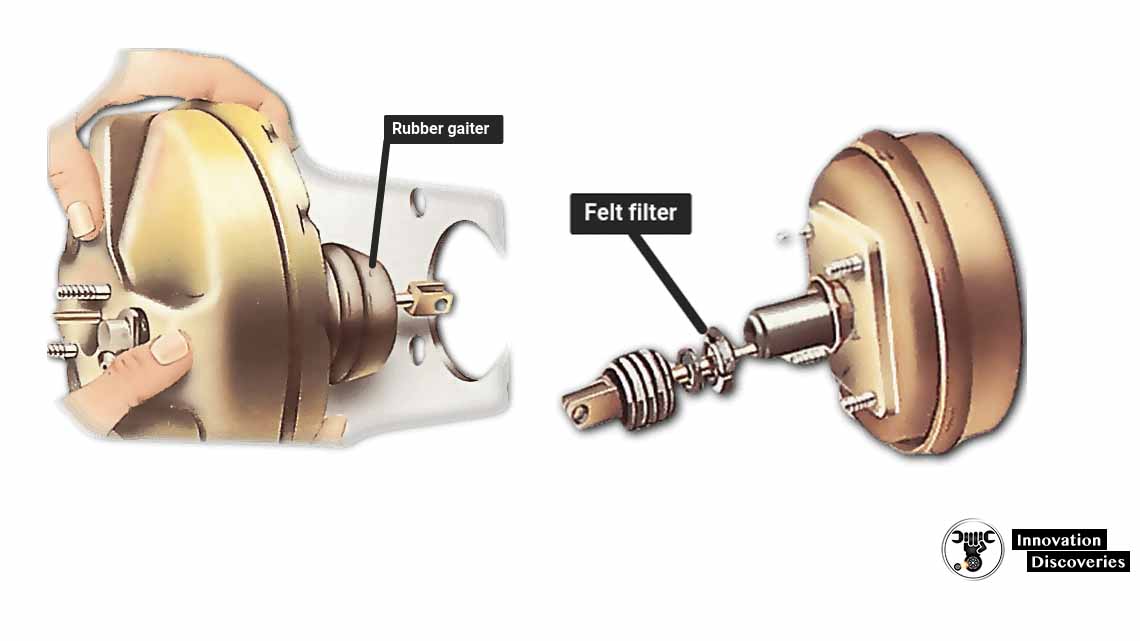

Renewing a servo air filter

On most later cars, there is a felt air filter fitted on the rear of the servo unit,

Encircling the pushrod.

It is not usually necessary to take off the servo to renew the filter.

You should be able to reach it either between the rear of the unit and the bulkhead,

Or from inside the car.

Use a sharp knife to cut a new felt filter across its radius,

Making a sloping cut at an angle of about 45 degrees,

To fit it to the pushrod. The filter is covered by a rubber gaiter.

Slide the gaiter along the pushrod to expose the filter, and prise the filter off.

Use a sharp knife to slit the new filter across its radius,

Cutting at an angle of approximately 45 degrees.

Slip the filter over the pushrod, position it in its housing,

And press the two ends of the filter together. Replace the rubber gaiter over the filter.

Remove a servo unit to get at the air filter.

Reach it from inside the car or between the rear of the unit and the bulkhead.

Making a sloping cut at an angle of about 45 degrees,

In order to fit it to the pushrod.

Also, read – DISC BRAKES: CONSTRUCTION, WORKING PRINCIPLE, TYPES, AND ROTOR MATERIALS

5 Comments