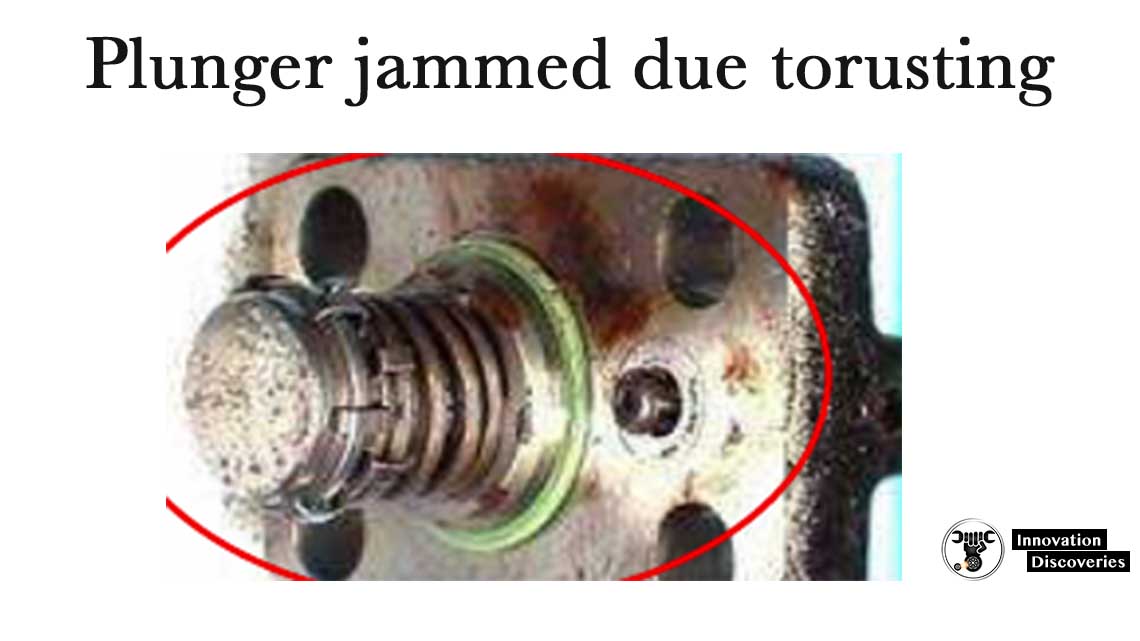

High-pressure pump related issues

P-code Error: 1192 / 1193 / 1250 / 1251

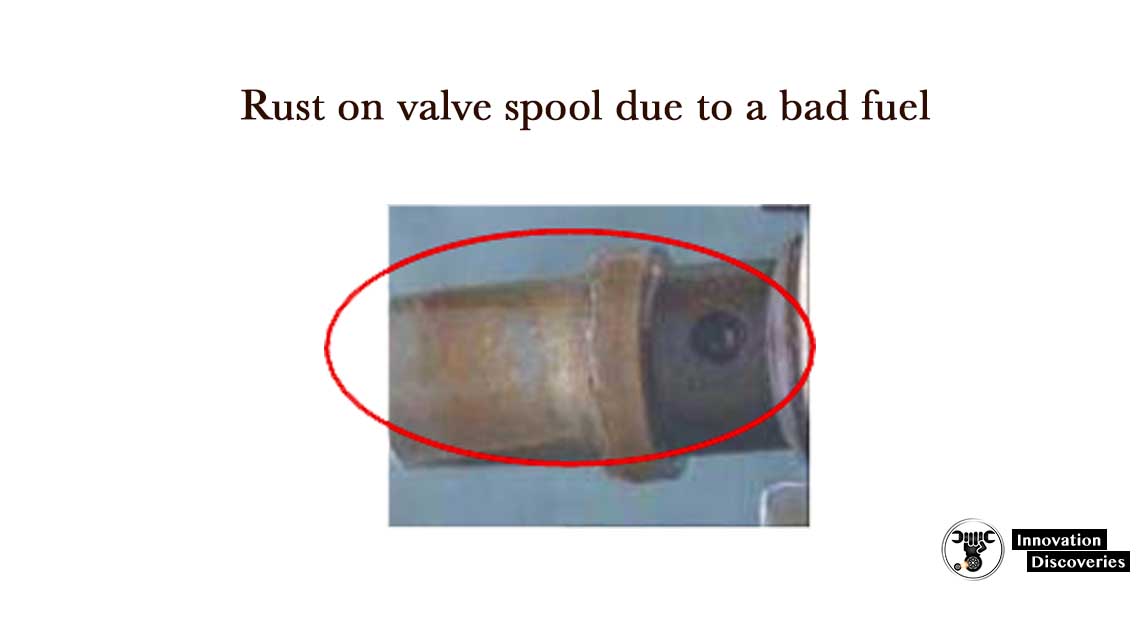

➢Not starting due to rust formation (bad fuel quality/water entry)

Read: Common Problems of the Fuel Delivery System

Filter to be drained periodically during service

➢Transit damage

Use correct pump packing box

– Education and-customer on water draining frequency & fuel filter change interval –

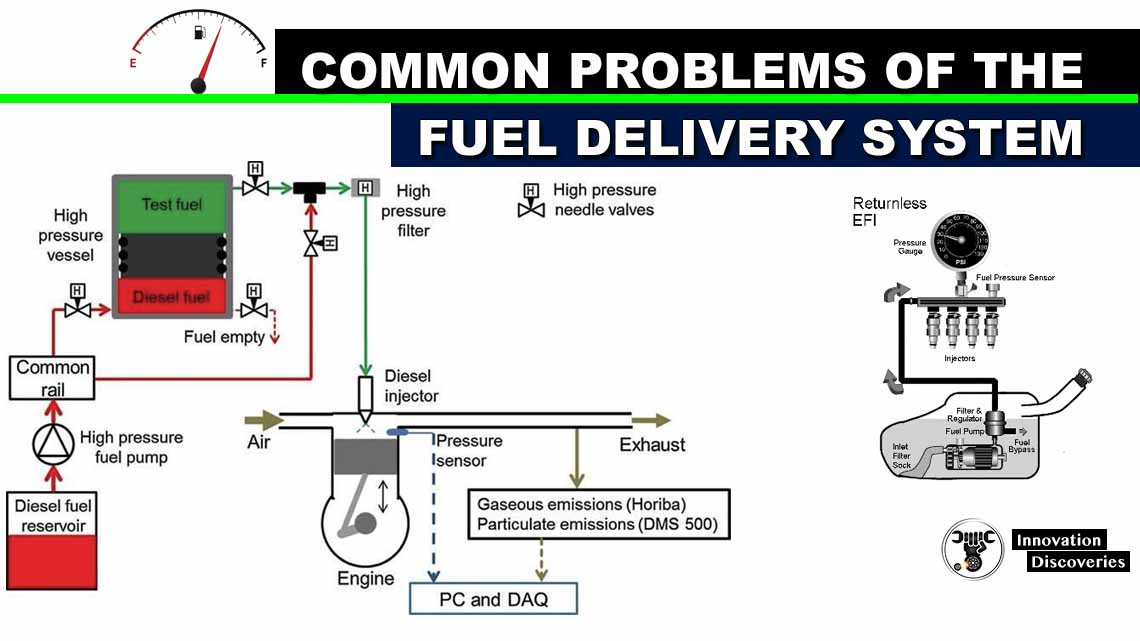

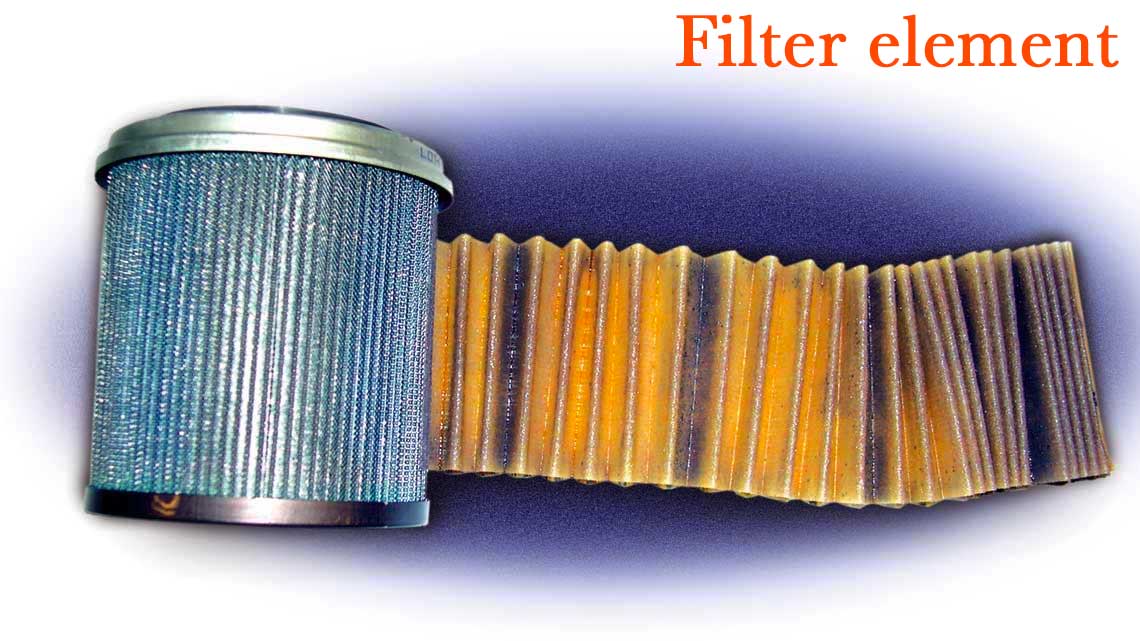

Pump / Fuel Filter Related Issues

P-code Error: 1192 / 1193

➢Wrong removal of the pump for starting problem issues

- Due to airlock in LPC

- Due to fuel filter check

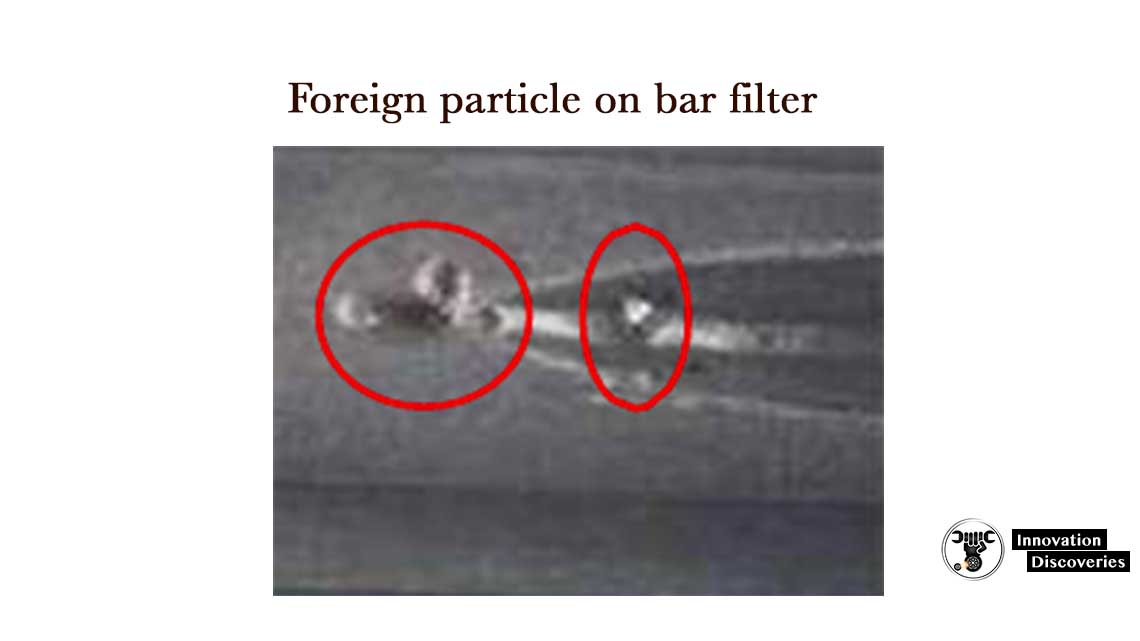

- Particle in filter flap

– Cleanliness level in the tank to be maintained –

Spec for Pressure drop –0.4 bar max

➢Few filters pressure drop found more than 1bar

➢Particle found in the flap area

– Education and-customer on water draining frequency & fuel filter change interval –

Injector related issues

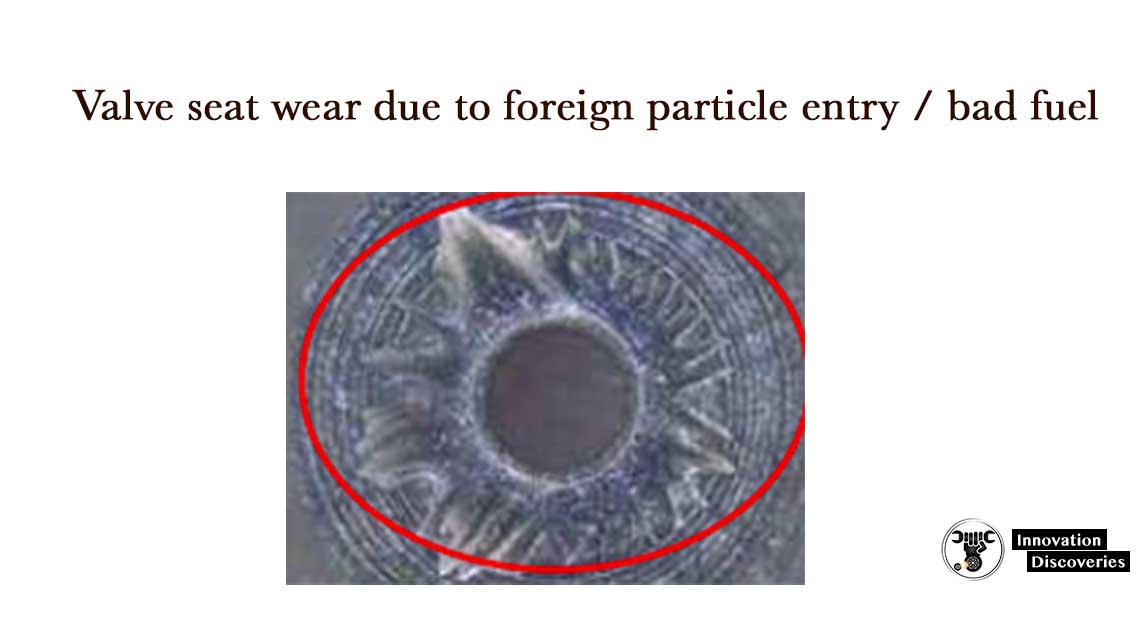

➢Not starting, late-starting &abnormal noise due to valve seat wear.

P-code error:

- 1192

- 1193

- 1201/0201

- 1202/0202

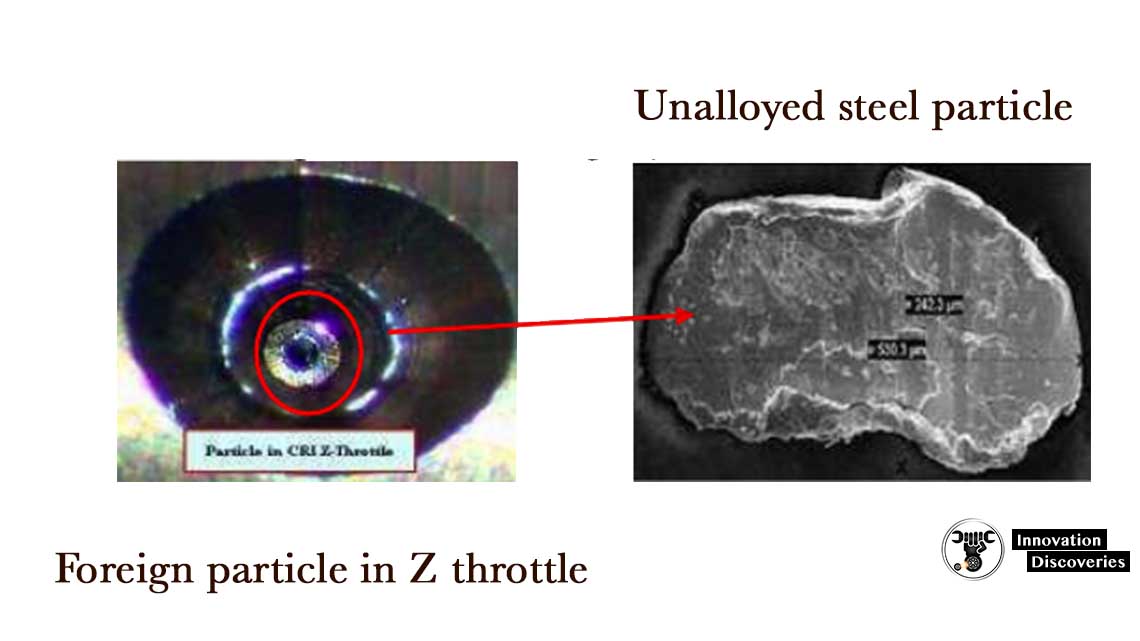

➢Knocking due to foreign particle in A / Zthrottle

– Cleanliness to be taken care of while servicing & Use good fuel –

Injector Related Issues

Conforming to specification:

➢Wrong removal of injectors

- for high smoke-related issues

- for knocking related issues

Check the following steps before removing injectors:

1.Error code using a diagnostic tool

2.Check whether IQA/ IMA code on Injector & ECU is matching

3.Back leak quantity check at idle-speed

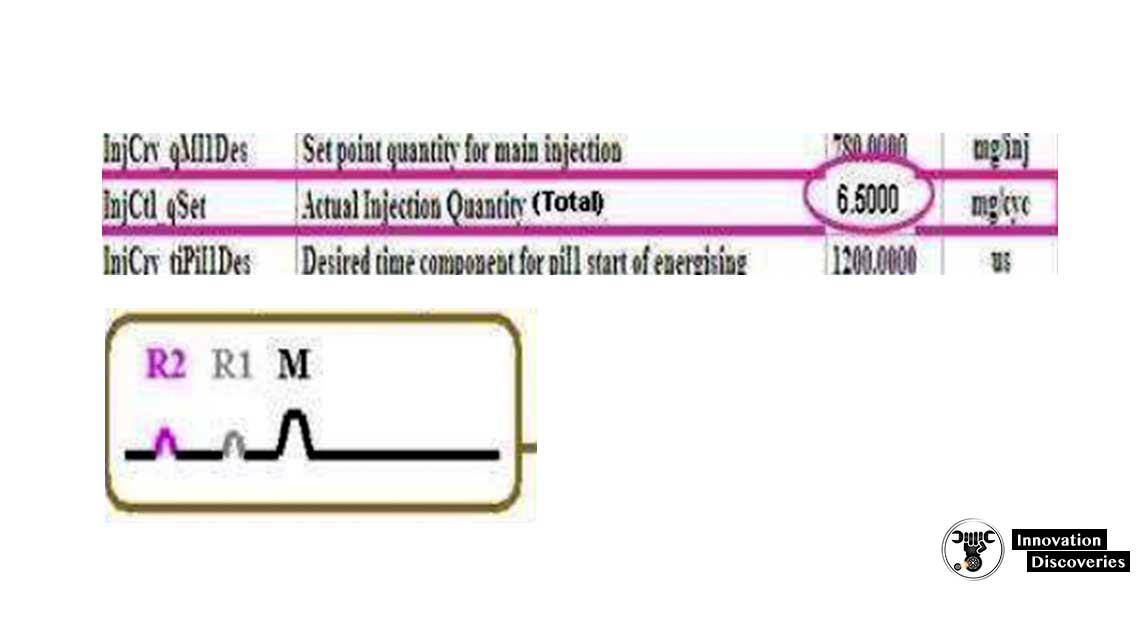

4.Total injected quantity check at idle-speed

5.Check for the presence of all injections (Pil1, Pil2 & Maininjection)

6.FBC check at idle-speed

Note: FBC check is an approximate check. The FBC variation may be due to one of the following other than the injectors

- Higher friction between block/piston or engine

- Piston ring wear or Piston/block wear

– Following checks to be done before removal of injectors –

Conforming to specification:

➢Wrong removal of rail due to Low-pressure circuit-related issue

Eg: P1192, P1193 error (rail pr. deviation) is fuel related issues like leakage, air entry, fuel starvation, no fuel supply

Non-Bosch responsibility:

➢Not starting due entry of foreign liquid residue into RDS (Rail pr. Sensor).

P-code Error: 0192 / 0193

– Cleanliness to be taken care of while servicing –

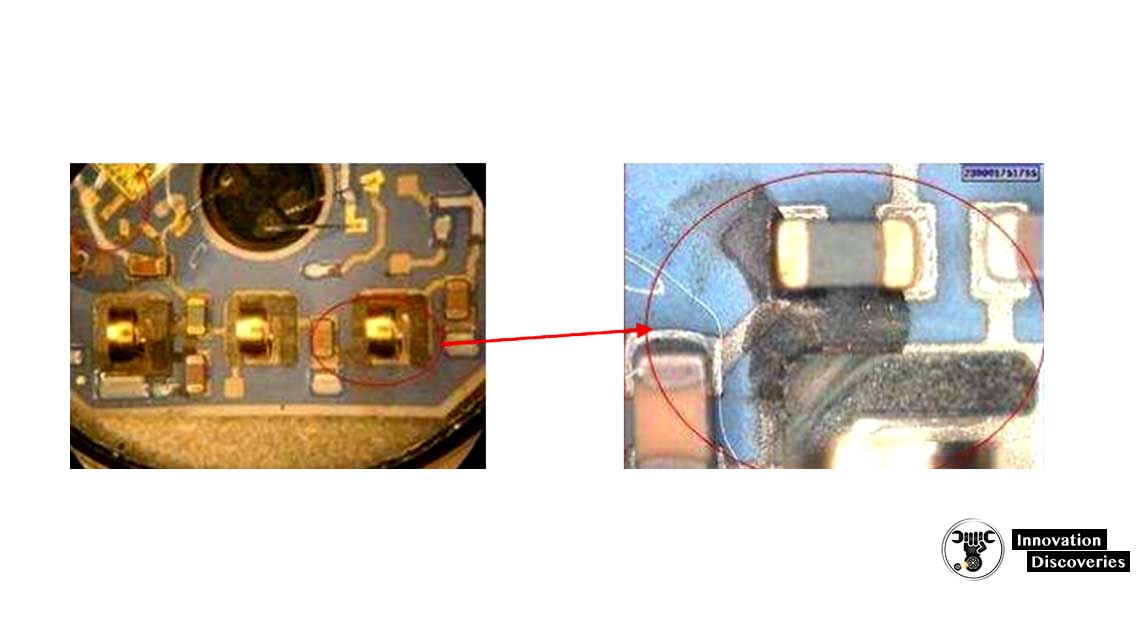

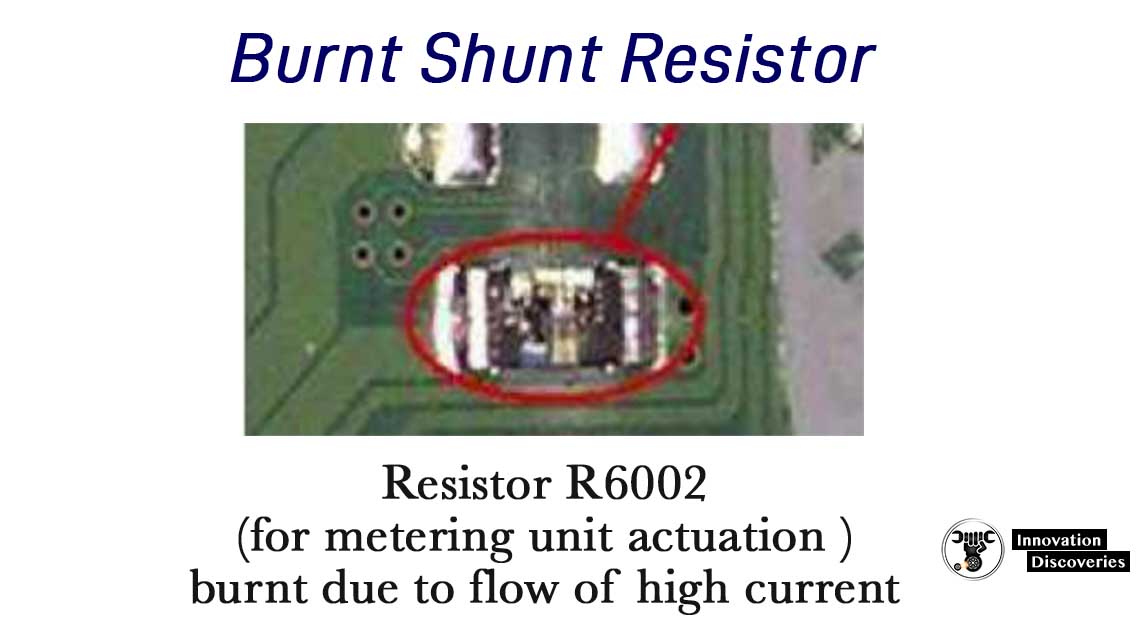

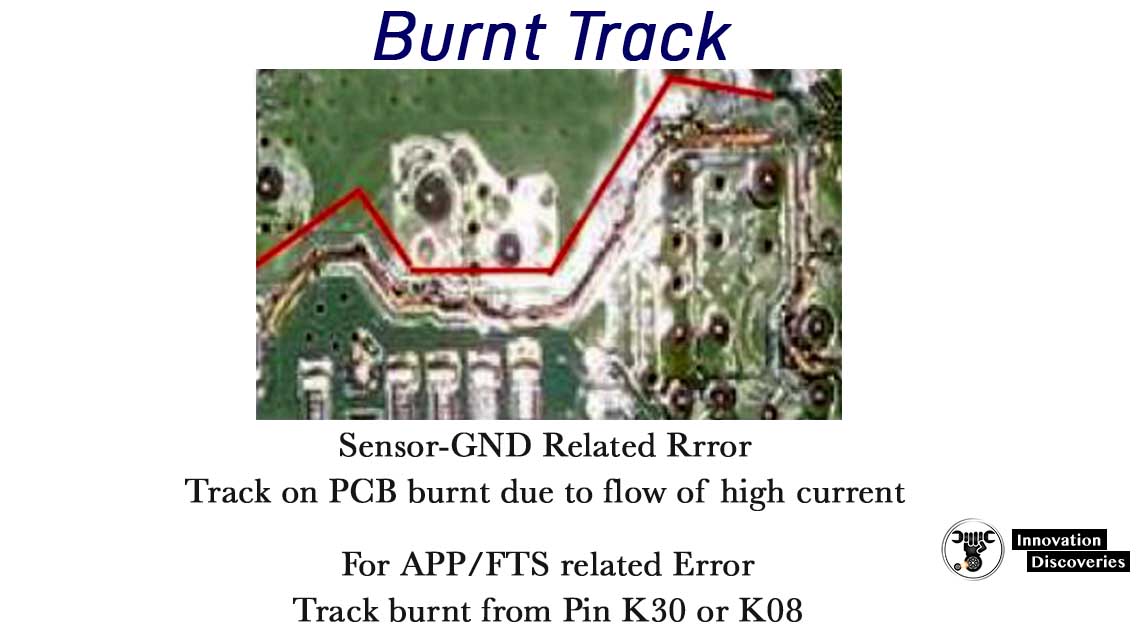

ECU Related Issues

➢Not starting, engine goes to limp-home mode

P-code Error:1250 / 1252

P-code Error: 0123

– Care has to be taken while servicing. Avoid jump-starting, ensure proper grounding, avoid using open-ended wires (causing short circuit) –

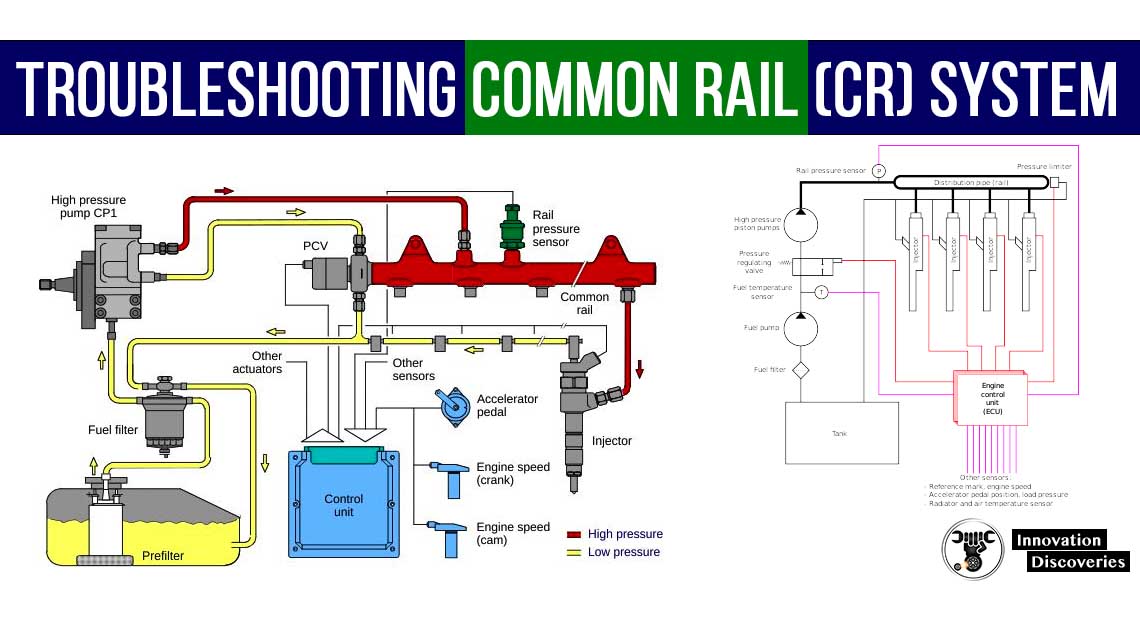

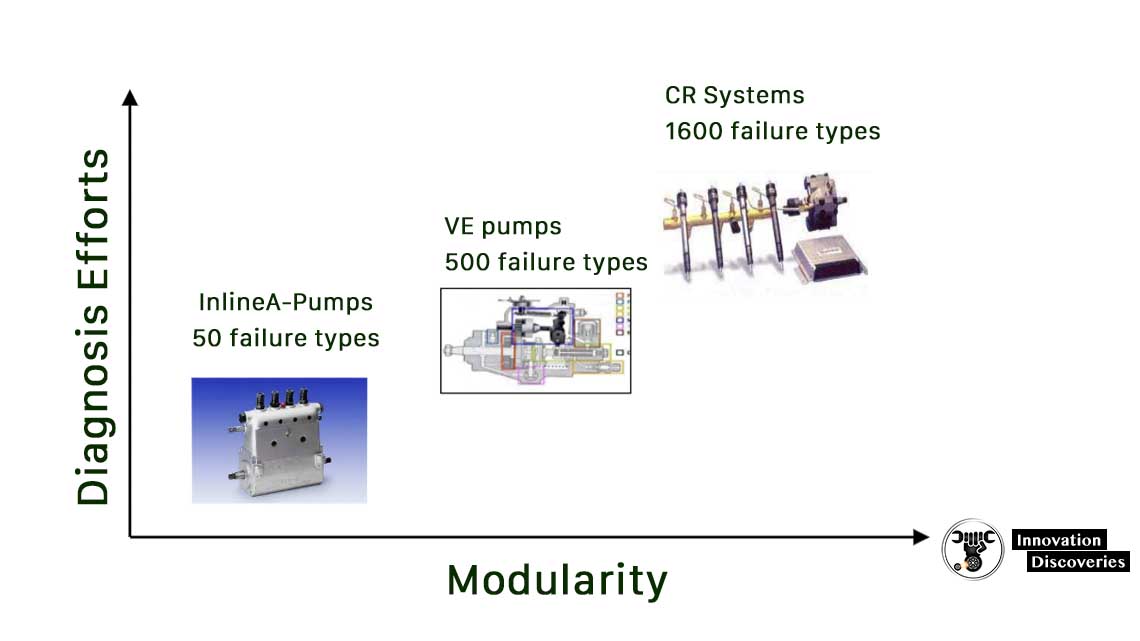

The complexity of diagnosis on CR diesel engines

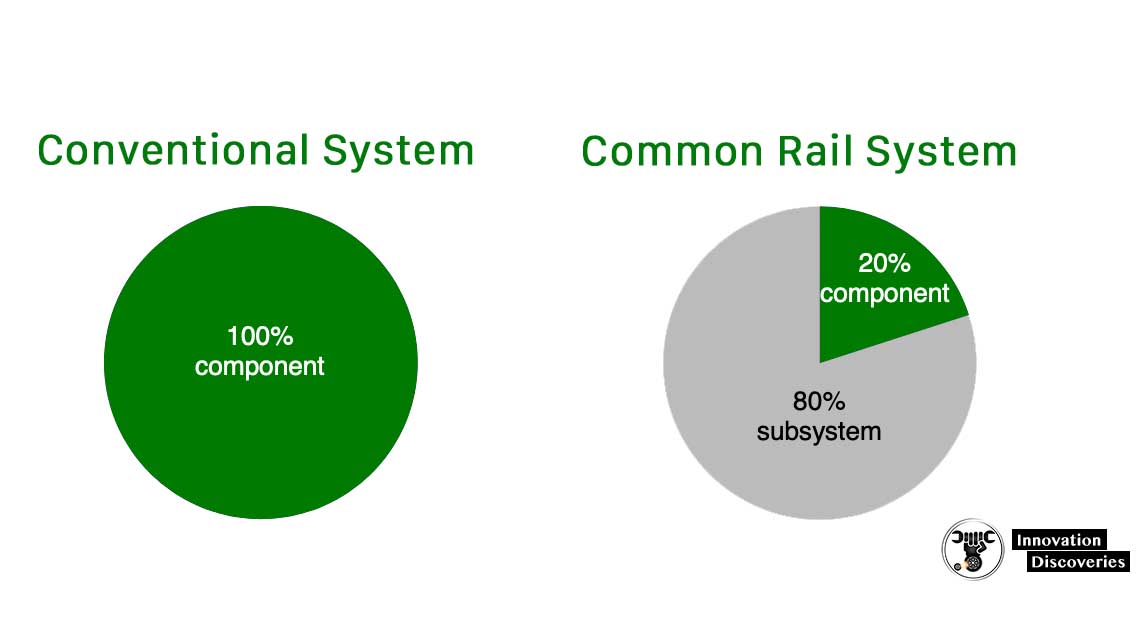

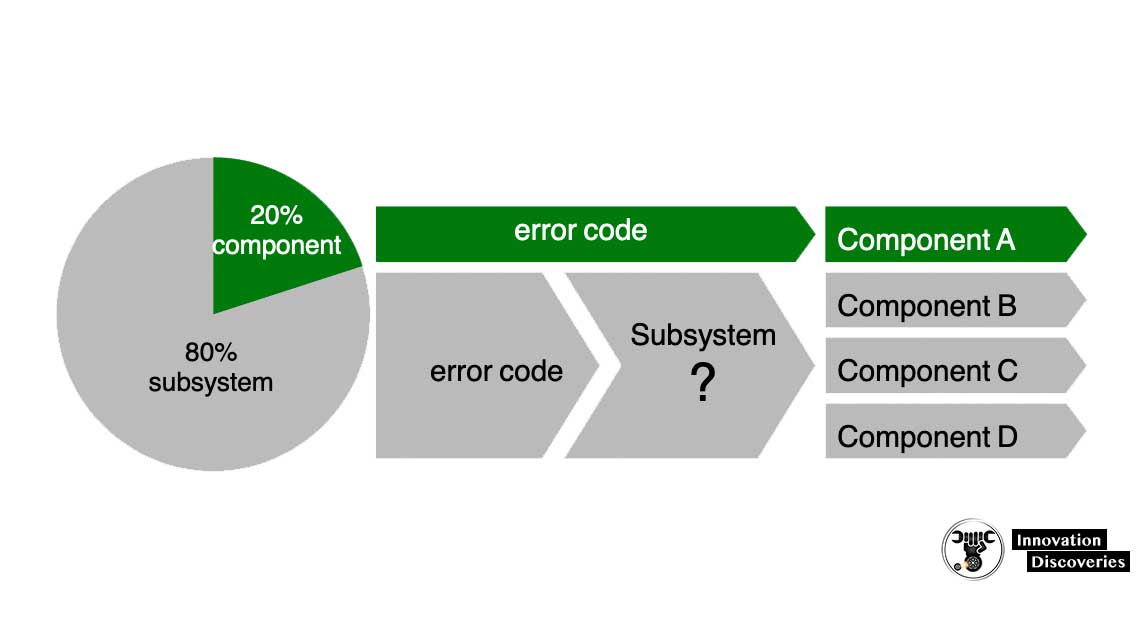

Failure Allocation: Consequences

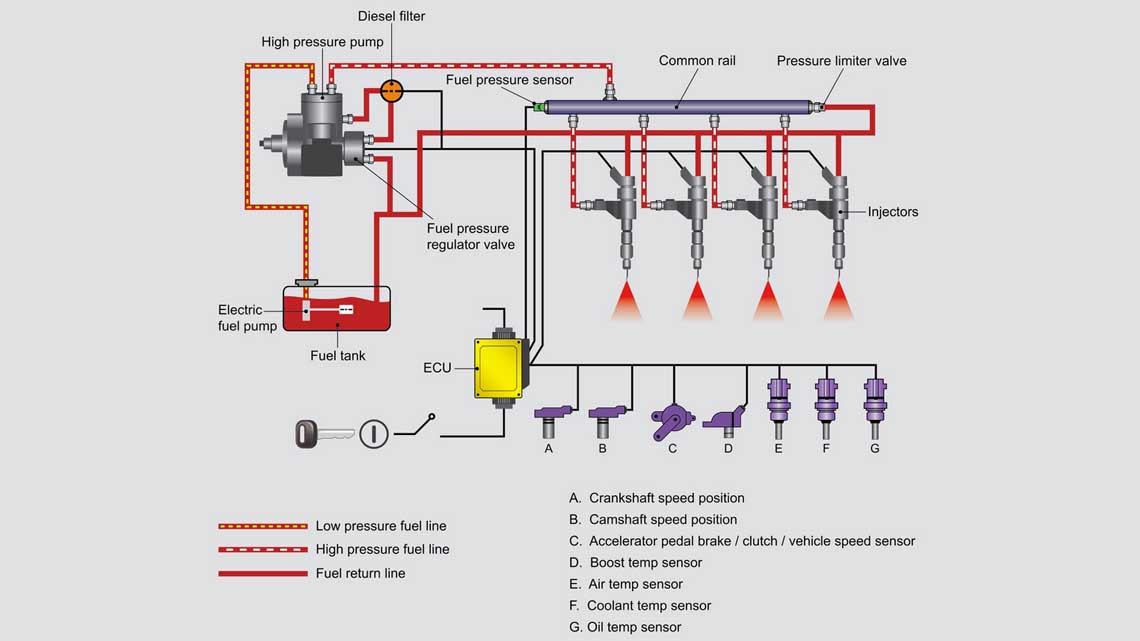

Common Rail System

A systematic approach to problem-solving

1. Engine not starting

Probable Related Error Code: P 1192 / 1193 / 1250 / 0192 /0193

| 1st Level Reason | 2nd Level Reason | 3rd Level Reason | Action |

|---|---|---|---|

| no power supply to ECU | battery level low | replace battery | |

| power supply disturbed | |||

| no fuel supply to HP pump | insufficient fuel flow from tank | low fuel level | refill fuel |

| strainer in fuel tank chocked | check fuel tank | ||

| air lock in system | clear air lock | ||

| air entry in system | fuel pipe clamp losen | tighten low pressure circuit | |

| fuel filter chocked | change filter | ||

| fuel filter flap blocked open | change/repair | ||

| Irreversible error recorded | Clear the error memory | ||

| Check for system error | Rectify in case of error | ||

| starter not OK |

2. Power loss

Probable Related Error Code : P 1192 /1193

| 1st Level Reason | 2nd Level Reason | 3rd Level Reason | Action |

|---|---|---|---|

| air system error | air filter clogged | replace air filter | |

| MAF sensor signal nok | MAF sensor dirty | clean & check for cause of dirt | |

| MAF sensor defect | replace MAF sensor | ||

| air leakage in intake system | leakage on pipes | replace pipes | |

| leakage on manifold | replace manifold | ||

| leakage on intercooler | replace intercooler | ||

| EGR error | EGR valve stucked | no vacuum to EGR | check modulator |

| EGR lever broken | check EGR | ||

| turbo charger malfunction | VTG stucked | VTG not actuated | check modulator and pipes |

| rotor stucked | replace turbocharger | ||

| rail pressure deviation | fuel supply to rail nok | fuel filter choked | change fuel filter |

| HP pump nok | check HP pump | ||

| system internal leakage | injector nok | check injector | |

| Rail DRV nok | check DRV | ||

| Check for system error | Rectify in case of error |

3. Vibration /jerky

Probable Related Error Code: P1192

| 1st Level Reason | 2nd Level Reason | 3rd Level Reason | Action |

|---|---|---|---|

| combustion nok | Injector IQA not matching | Check and reflash IQA | |

| Injector not firing | wiring harness nok | check harness | |

| connection nok | check connector | ||

| engine friction | power loss in cylinder | check compression | |

| air lock in system | check for air lock and clear it | ||

| Check for system error | Rectify in case of error |

Download: REPAIR GUIDE FOR DENSO COMMON RAIL INJECTOR REPAIR

2 Comments