TYPES OF TURBOCHARGER

1. Single-Turbo

Single turbochargers alone have limitless variability.

Differing the compressor wheel size and turbine will lead to completely different torque characteristics.

Large turbos will bring on high top-end power, but smaller turbos will provide better low-end grunt as they spool faster.

There are also ball bearing and journal bearing single turbos. Ball bearings provide less friction for the compressor and turbine to spin on, thus are faster to spool (while adding cost).

Advantages

- A cost-effective way of increasing an engine’s power and efficiency.

- Simple, generally the easiest of the turbocharging options to install.

- Allows for using smaller engines to produce the same power as larger naturally-aspirated engines, which can often remove weight.

Disadvantages

- Single turbos tend to have a fairly narrow effective RPM range.

- This makes sizing an issue, as you’ll have to choose between good low-end torque or better high-end power.

- Turbo response may not be as quick as alternative turbo setups.

2. Twin-Turbo

Just like single turbochargers, there are plenty of options when using two turbochargers.

You could have a single turbocharger for each cylinder bank (V6, V8, etc).

Alternatively, a single turbocharger could be used for low RPM and bypass to a larger turbocharger for high RPM (I4, I6, etc).

You could even have two similarly sized turbos where one is used at low RPM and both are used at higher RPM.

On the BMW X5 M and X6 M, twin-scroll turbos are used, one on each side of the V8.

Advantages

- For parallel twin turbos on ‘V’ shaped engines, the benefits (and drawbacks) are very similar to single turbo setups.

- For sequential turbos or using one turbo at low RPM and both at high RPM, this allows for a much wider, flatter torque curve. Better low-end torque, but the power won’t taper at high RPM like with a small single turbo.

Disadvantages

- Cost and complexity, as you’ve nearly doubled the turbo components.

- There are lighter, more efficient ways of achieving similar results (as discussed below).

3. Twin-Scroll Turbo

A turbo is powered by exhaust gases that are redirected to spin turbine blades and force air into the engine.

Now, an engine’s cylinders fire in sequence, meaning that exhaust gases enter the turbo in pulses.

As you can probably imagine, these pulses can easily overlap and interfere with one another when powering the turbo, and a twin-scroll turbocharger solves this issue by using a divided-inlet turbine housing and a specific exhaust manifold that pairs the right cylinders to each scroll.

In a four-cylinder vehicle, you can then have the first and fourth cylinders powering one scroll, and two and three powering another.

This means that there are less pulse overlap and less lag.

Advantages

- More energy is sent to the exhaust turbine, meaning more power.

- A wider RPM range of effective boost is possible based on the different scroll designs.

- More valve overlap is possible without hampering exhaust scavenging, meaning more tuning flexibility.

Disadvantages

- Requires a specific engine layout and exhaust design (eg: I4 and V8 where 2 cylinders can be fed to each scroll of the turbo, at even intervals).

- Cost and complexity versus traditional single turbos.

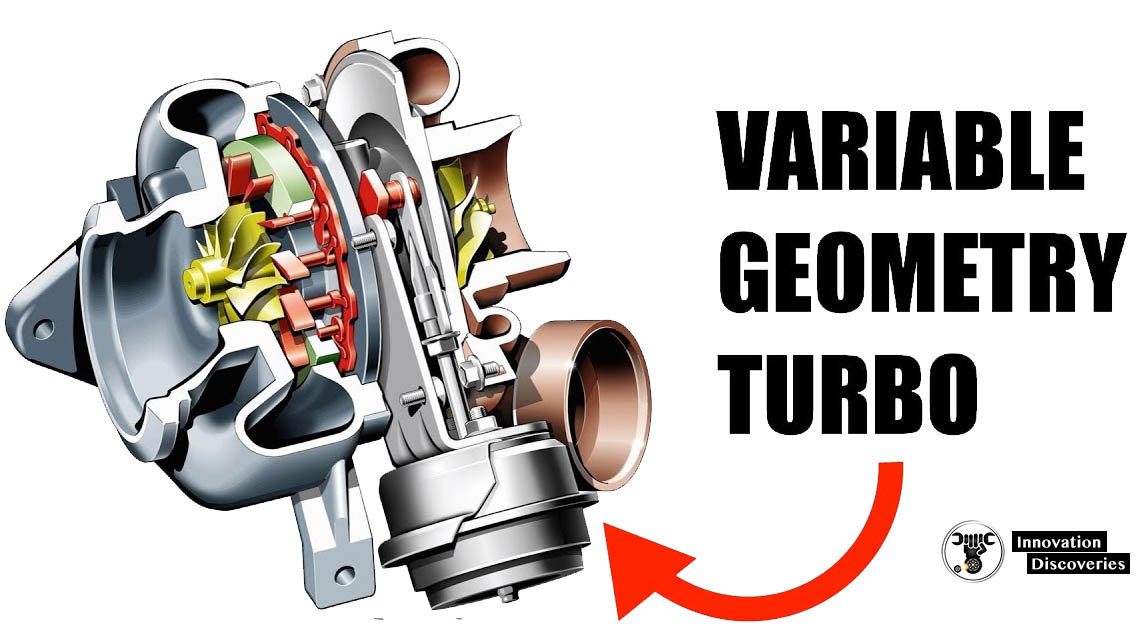

4. Variable Geometry Turbocharger (VGT)

A variable geometry turbo (VGT) is an expensive and complex power solution that’s especially prevalent in diesel engines.

A VGT has a ring of aerodynamically-shaped vanes in the turbine housing that can alter their area-to-radius ratio to match the revolutions of the engine.

At low revs, area-to-radius ratio creates more pressure and velocity to spool up the turbo more effectively.

At higher revolutions, the ratio increases to let in more air. The result is a wider boost range and less lag.

Advantages

- Wide, flat torque curve. Effective turbocharging at a very wide RPM range.

- Requires just a single turbo, simplifying a sequential turbo setup into something more compact.

Disadvantages

- Typically only used in diesel applications where exhaust gases are lower so the vanes will not be damaged by heat.

- For gasoline applications, the cost typically keeps them out as exotic metals have to be used in order to maintain reliability.

- The tech has been used on the Porsche 997, though very few VGT gasoline engines exist as a result of the cost associated.

5. Variable Twin-Scroll Turbocharger

A variable twin-scroll turbo combines a VGT with a twin-scroll setup, so at low revolutions, one of the scrolls is closed completely, forcing all the air into the other.

This results in good turbo response and low-end power.

As you speed up, a valve opens to allow air into the other scroll (this is a completely variable process, meaning the valve opens in small increments), you get good high-end performance.

You get the sort of performance from a single turbo that you’d normally only be able to get from a twin-turbo set-up.

Advantages

- Significantly cheaper (in theory) than VGTs, thus making an acceptable case for gasoline turbocharging.

- Allows for a wide, flat torque curve.

- More robust in design versus a VGT, depending on the material selection.

Disadvantages

- Cost and complexity versus using a single turbo or traditional twin-scroll.

- The technology has been played with before (eg: quick spool valve) but doesn’t seem to catch on in the production world. There are likely additional challenges with technology.

6. Electric Turbochargers

A very recent development is the introduction of turbos with electric compressors.

An example is BorgWarner’s booster, which is an electrically powered compressor.

The compressor provides an instant boost to the engine until the turbocharger has spooled up enough.

A similar version of this can be found in Audi’s SQ7. With the instant boost, lag becomes a thing of the past, but again, the system is expensive and complex.

A compressor needs a motor, which in turn needs to be powered, so this is not a simple system to implement.

Advantages

- By directly connecting an electric motor to the compressor wheel, turbo lag and insufficient exhaust gases can be virtually eliminated by spinning the compressor with electric power when needed.

- By connecting an electric motor to the exhaust turbine, wasted energy can be recovered (as is done in Formula 1).

- A very wide effective RPM range with even torque throughout.

Disadvantages

- Cost and complexity, as you now must account for the electric motor and ensure it remains cool to prevent reliability issues. That goes for the added controllers as well.

- Packaging and weight become an issue, especially with the addition of a battery onboard, which will be necessary to supply sufficient power to the turbo when needed.

- VGTs or twin-scrolls can offer very similar benefits (though not at quite the same level) for a significantly lower cost.

Read More:

- THE VARIABLE GEOMETRY TURBOCHARGER

- 5 REASONS YOU SHOULDN’T BUY A TURBOCHARGED CAR

- WHY YOU SHOULD NEVER STOP TURBOCHARGED ENGINES AFTER DRIVING?

- HOW AUDI’S ELECTRIC SUPERCHARGER ELIMINATES TURBO LAG

- TURBO LAG VS BOOST THRESHOLD – WHAT’S THE DIFFERENCE?

- KNOW THE DIFFERENCE IN BITURBO VS. TWIN TURBO HERE

- YOU WANT TO TURBOCHARGE YOUR NORMALLY ASPIRATED CAR?

Visit Forum

Visit Our Friendly Website

9 Comments