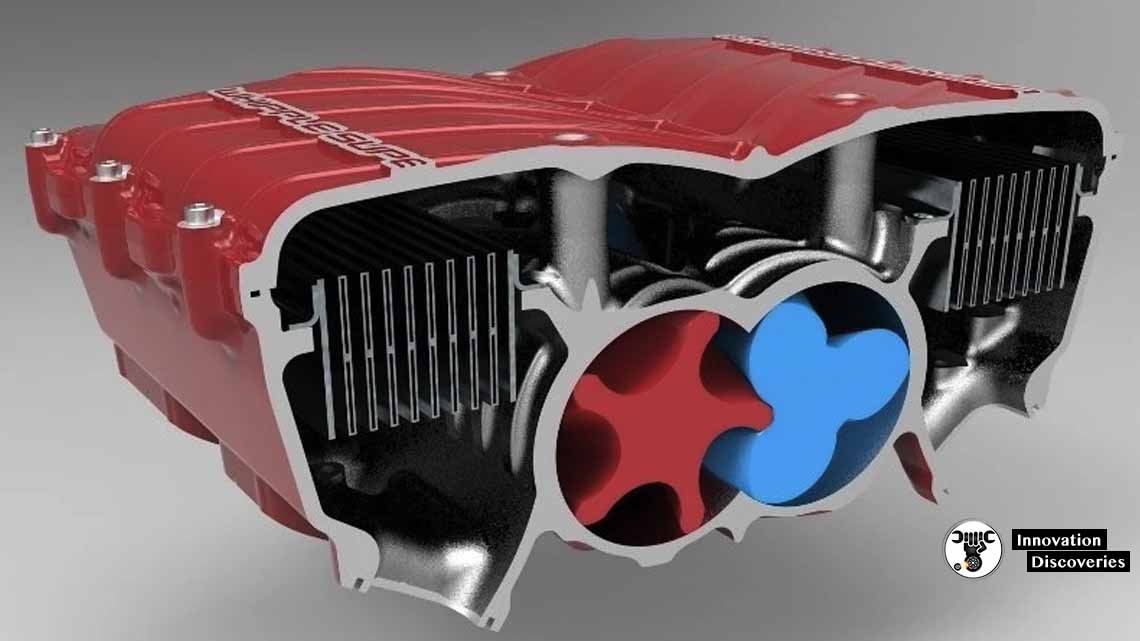

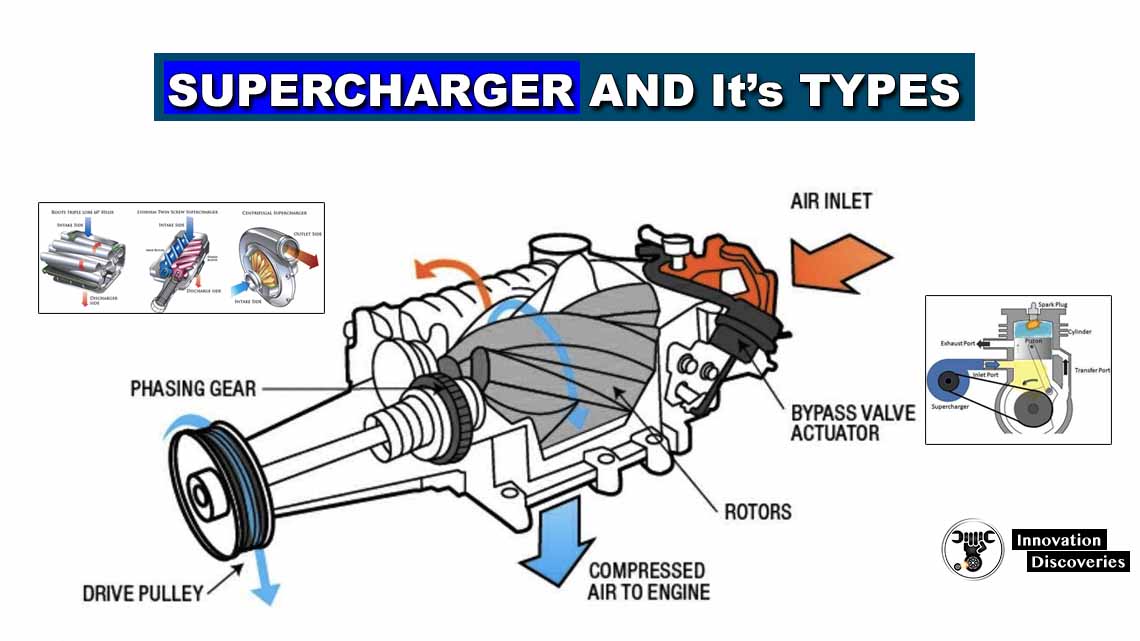

Twin-screw superchargers resemble a pair of rotors that resemble screws. It resembles a pair of worm gears whose lobes are meshed to each other. One of the rotors is run by the engine crankshaft via a belt drive or gear drive.

The air is pulled in from the top and as the rotors rotate,

The air will be squeezed in the pockets or small gaps created between the rotor lobes. The design looks familiar to the Roots supercharger,

But the difference is that in twin-screw superchargers,

The air is compressed within the compressor housing.

In a Roots supercharger, the air is not compressed in the compressor housing.

Advantages of Twin Screw Supercharger:

- Higher thermal efficiency compared to Roots supercharger since the air is compressed within the compressor housing.

- It provides very good boost pressure at low engine rpm.

- Low leakage levels and low parasitic losses

Parasitic loss is referred to as the energy of the engine applied to miscellaneous devices to enhance the engine’s ability to produce more power.

In a supercharger, the power that the supercharger consumes from the engine to provide more boost pressure is referred to as parasitic loss.

Parasitic loss is measured in terms of horsepower (HP).

The reason why turbochargers are used commonly over superchargers is the low parasitic loss of turbochargers.

Disadvantages:

- Expensive in production since the screw-type rotors require more precision in the manufacturing process.

- A lot of noise is generated.

- Boost pressure is not high enough at higher engine rpm.

- Intercooler is required to cool down the compressed air.

Related Topics:

One Comment