In simplest terms, a water hand pump is a mechanical simplest

Which uses manual human power to lift water from a well. These are the most basic types of pumps in use since time immemorial and are in use to date. It’s still a very common sight in rural India.

Hand Pumps are really a boon to mankind. They provide a cost-efficient water pumping solution to remote areas. There are many kinds of water hand pump in use and

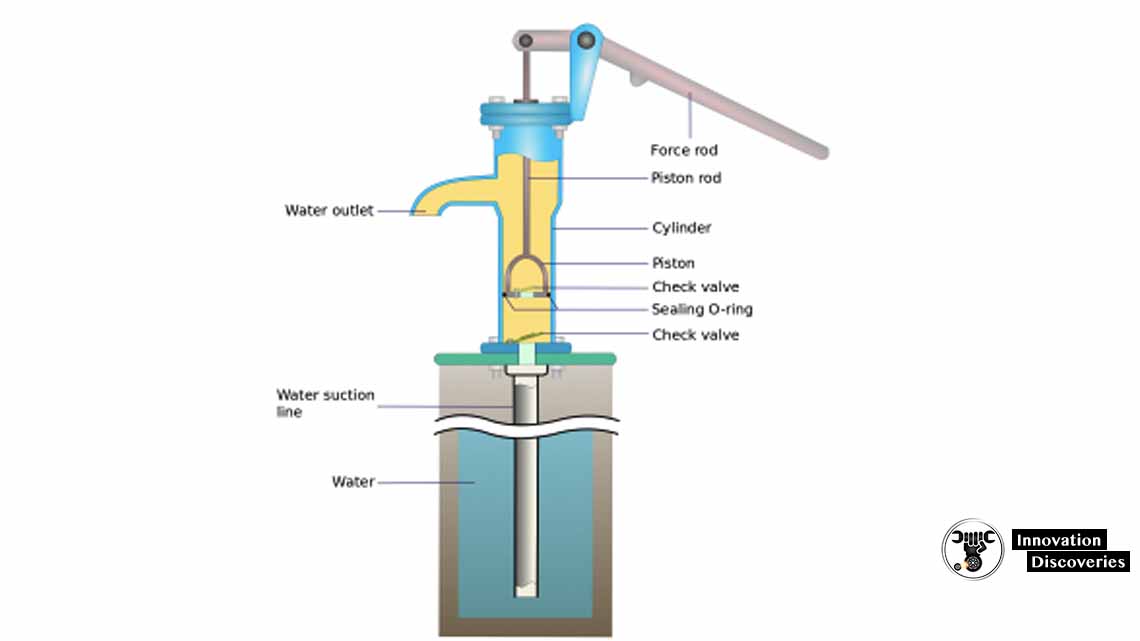

Most of them have a similarity in design and principal. The essential component of hand pumps is Handle, The pump rod, Piston, Piston Valve, Raising main, suction lift and the water outlet.

There are many configurations to the hand pump and,

It generally varies with depth at which the water is available to be pumped to the surface.

The most common type of pump in use is the positive displacement hand pumps. Positive displacement pumps are armed with reciprocating plungers or pistons. The pistons are fitted with non-return values and sliders inside a cylindrical tube. This piston is connected to the pump handle which when used results in the up and down motion of the piston. When the piston comes up it creates a vacuum resulting in the water being

Sucked into the cylinder and is drained through the outlet pipe.

Some of the common types of hand pumps in use are as follows

Direct Pumps:

These types of pump have an operating rod and

Work on the principle of positive displacement,

They are easy to install and maintain

But has a limitation that it can only lift to 15 meters.

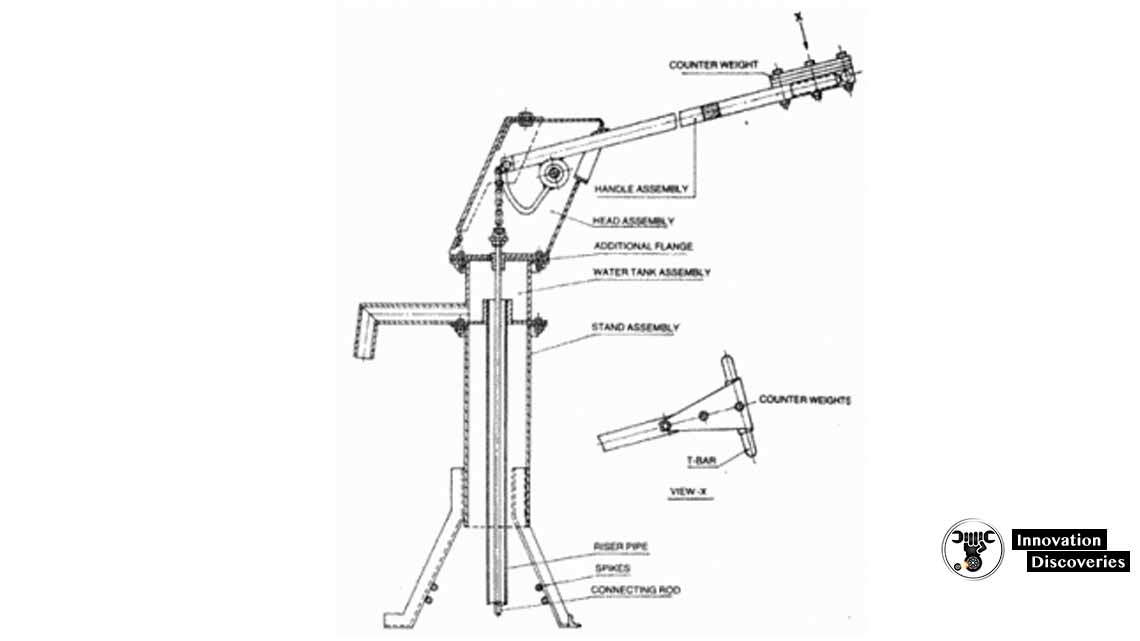

Deep Well Hand Pumps:

These pumps are used when the water has to be lifted from a deep source

Typically over 15 meters of depth.

In case of deep good hand pumps the weight of the water

To be lifted is too high and to aid a human in operating this pump

Some mechanical additions like a lever or flywheel is used.

The installation and maintenance of deep good hand pumps are

More complicated and expensive than other hand pumps. These kinds of pumps also have to be stronger and

Sturdier owing to the nature of the work involved. Theoretically a deep well hand pump

Has no limited when it comes to the depth at which it can operate,

But in reality, it is limited by human strength. Deep well hand pumps have an operational depth of 80 meters in general.

Diaphragm Pump:

This is also a type of positive displacement pump. They are significantly lighter in weight as they do not have any pulling rods. The use of rubber and plastic tubing also makes it almost corrosion-free.

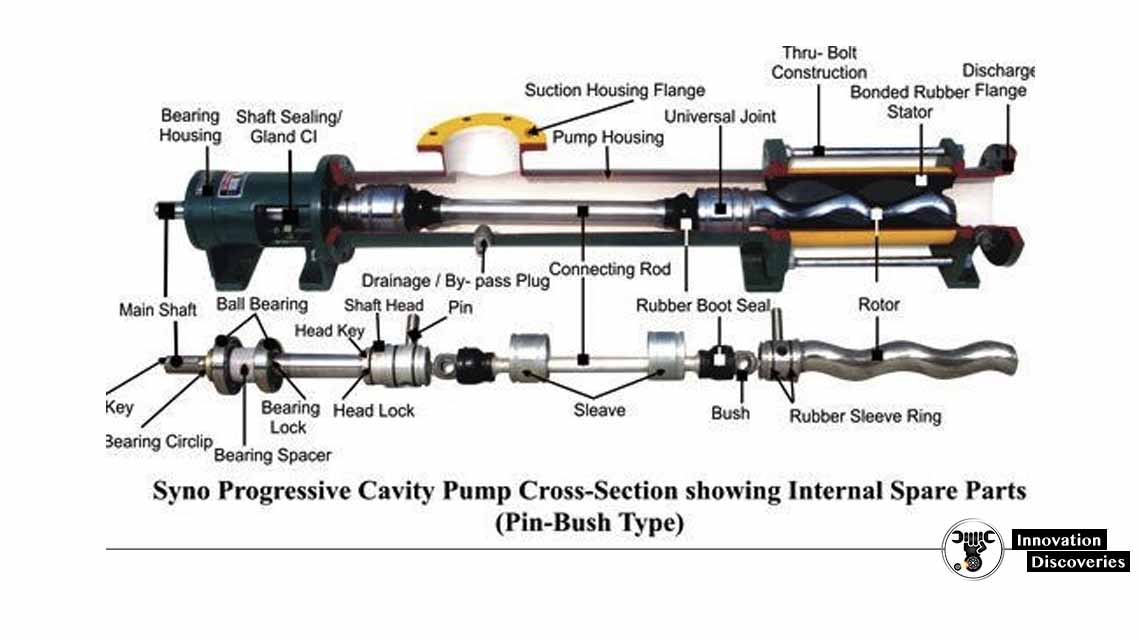

Progressive Cavity Pump:

Again a type of positive displacement pump,

This one is more efficient owing to its compact design.

It consists of a helical rotor inserted into a double helical stator.

As the rotor moves the cavity is filled with water and is eventually pumped out.

Although the design is compact its complex gear mechanism makes,

It difficult for local repairs men to repair and maintain. This is what also makes it slightly expensive operationally. A rope and washer pump is an example of a progressive cavity pump.

2 Comments