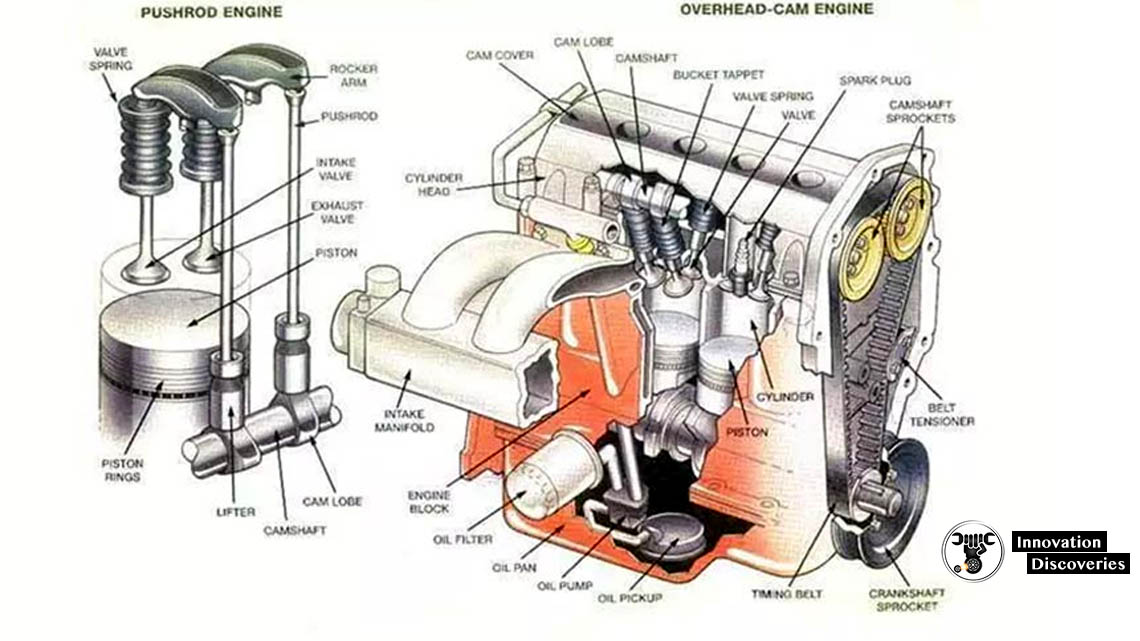

Over several decades now the reciprocating; Internal combustion engine has become a ubiquitous rotational power source.

It came with its own set of complexities,

However, which made it very unsatisfactory for a certain gentleman;

Who considered it wasted to use reciprocal motion to produce rotational motion.

His frustration contributed to the Wankel engine developing.

A Wankel engine is a type of internal combustion engine;

That uses rotary motion to generate crank power instead of reciprocating motion.

The engine is named in honor of its inventor,

Felix Wankel, who had come up with this concept when he was just 17.

The concept was intended to be a simple and more compact unit with less moving parts and

Greater performance, though rotating in one direction as well.

It was somewhat different from modern reciprocating engines,

Which had many moving parts and meant the almost instantaneous reversal of these parts’ motion.

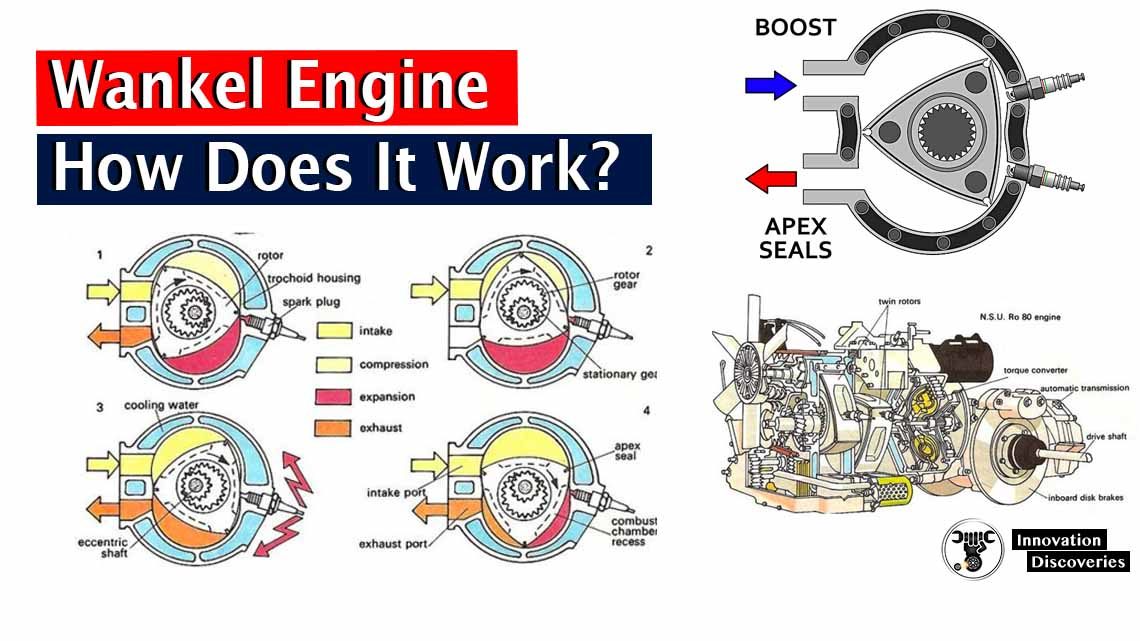

Construction of a Wankel Engine

Any rotational motion occurring at a point other than the center of the body,

Being rotated is known as eccentric motion.

A Wankel engine is regarded as an eccentric motion engine, as the rotational forces produced at the crankshaft are due to the moving parts’ excentric motion.

It is simple in its design, in that as compared to an internal combustion engine it uses less moving parts.

1. Rotor

A Wankel engine’s most important component is a rotor. It is a loosely formed three-dimensional structure around the Releaux triangle which is an equilateral triangle with slightly rounded ends.

The rotor is composed of chambers built into the sides for combustion.

It also has sealing surfaces at the vertices and faces to prevent losses resulting from the energy leakage produced by combustion.

2. Housing

The housing where the rotor travels is built in an oval shape which is approximately elongated, also known as an epitrochoid.

The advantage of such a design is that all vertices of the rotor remain in constant contact with the casing.

It’s also important to remember that there is often a slight gap between the rotor’s face and the housing’s inner surface.

The housing also has holes for the inlet and exhaust ports for the induction and discharge of gases.

very good explanation with understandable as we see. thanks aot