The Electric Park Brake functions as a conventional hydraulic brake for standard service brake applications and as an electric brake for parking and emergency braking.

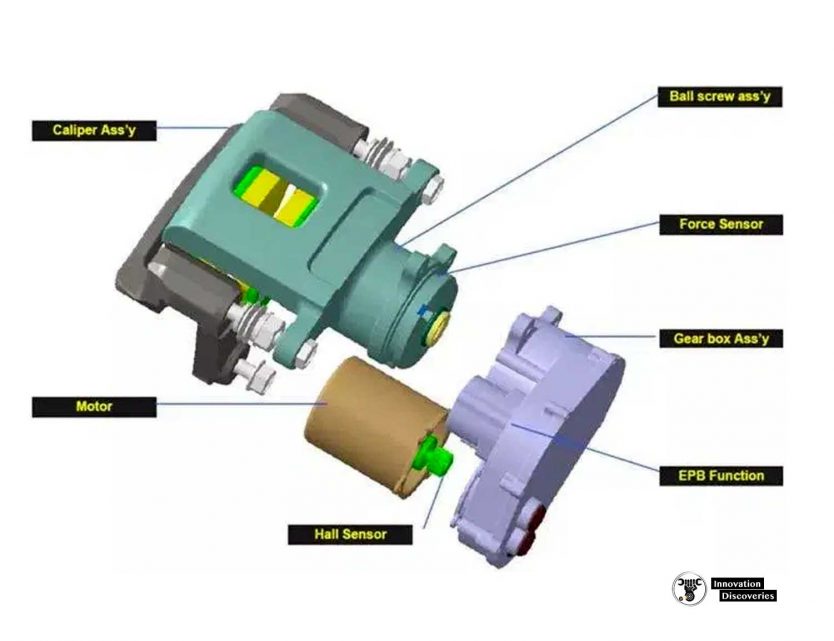

Electric Park Brake (EPB) is a caliper with an additional motor (motor on the caliper) that operates the parking brake.

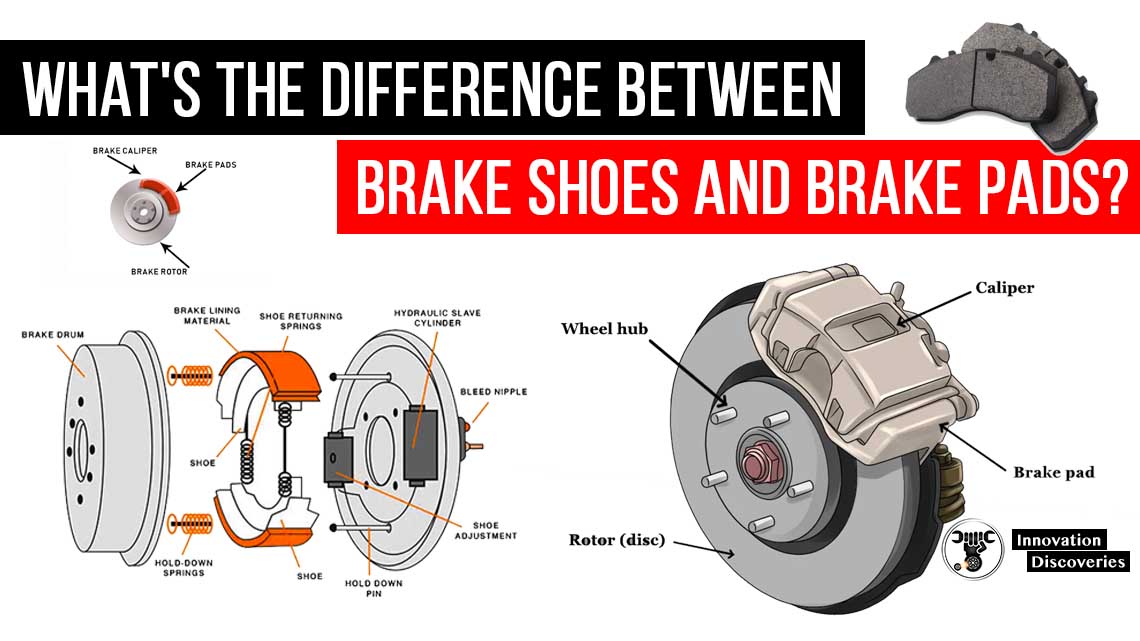

Read: WHAT’S THE DIFFERENCE BETWEEN BRAKE SHOES AND BRAKE PADS?

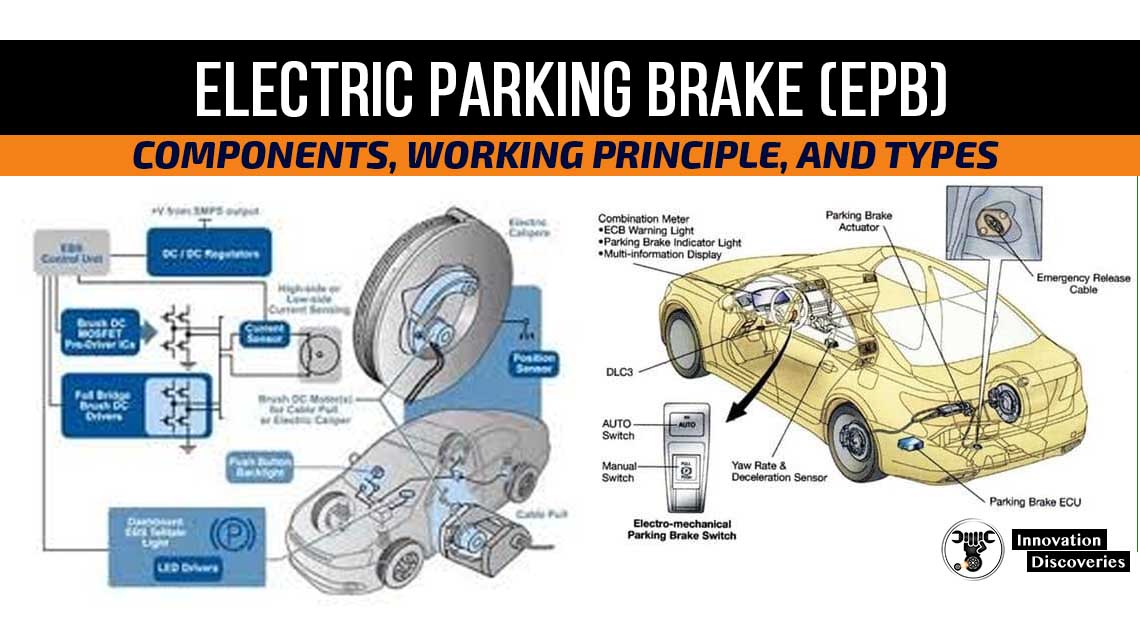

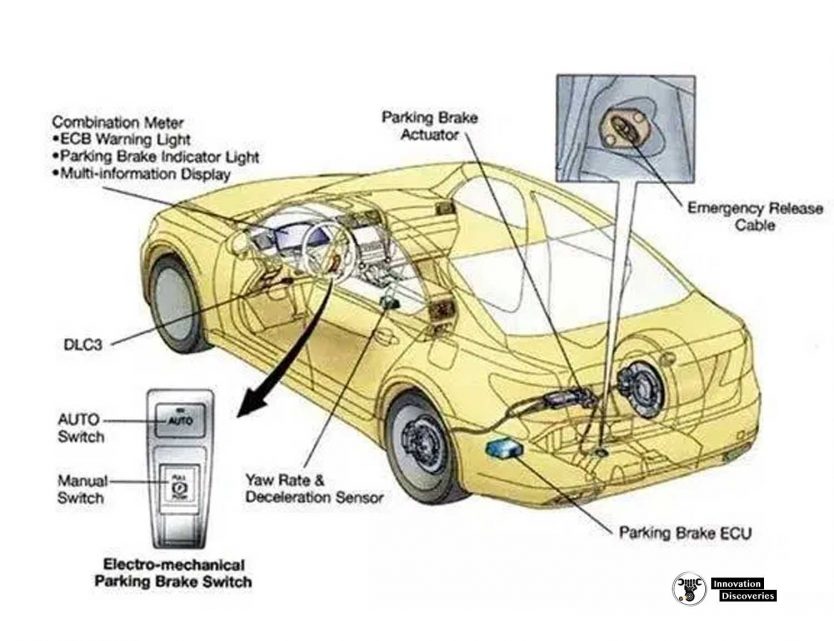

The EPB system is electronically controlled and consists of the EPB switch, the EPB caliper, and the electronic control unit (ECU).

The electric parking brake or the EPB is an advanced version of the conventional parking brake or handbrake.

Sometimes, people also refer to this system as ‘Electronic Parking Brake.’ Technically this system is a sub-part of ‘Brake by Wire’ system.

Download: BRAKES, BRAKE CONTROL AND DRIVER ASSISTANCE SYSTEMS: FUNCTION, REGULATION AND COMPONENTS

The main function of parking brakes is to avoid the motion of the vehicle when parked.

In addition, these brakes also play an important role in avoiding the backward motion of the vehicle, which resumes moving on a slope.

Generally, parking brakes operate only on the rear wheels of a vehicle.

EPB functionality relies on four elements:

- Control switches,

- A wheel-speed sensor,

- A force sensor, and

- Electric motors.

Together, these monitor a variety of input signals and determine when to apply or release the brakes.

COMPONENTS

However, in Electric Parking Brake, no such cable connection exists.

Instead, it works with the help of the following main components:

- Electronic Brake Module

- Actuator or electric motor

- Electric Switch in cabin

Read: JAKE BRAKE VS. EXHAUST BRAKE: WHICH IS BETTER?

WORKING PRINCIPLE

Conventional parking brakes employ a cable that connects the handbrake lever and brake shoes.

When the driver operates the lever, tension in the cable increases, forcing the brake shoe (or pads) on the brake drum (or disc).

Thus, wheels cannot move further.

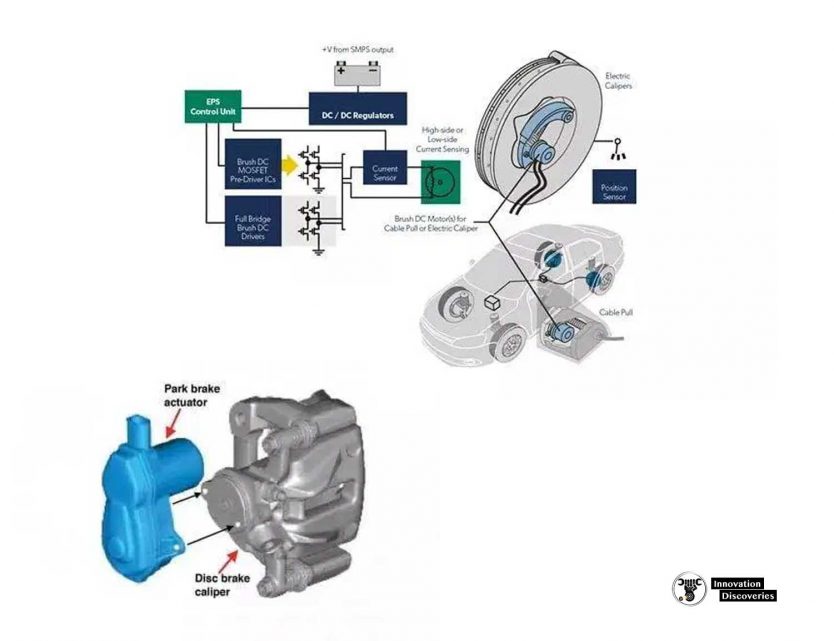

When the driver operates the switch, it sends a command to the Module, which senses that parking brakes are required to be operated.

Later, this Module commands the actuators or electric motors installed in the brake calipers to operate.

Thus, brake pads are forced on the disc, thereby restricting the movement of wheels.

Due to the use of electronic components, the operation of this system is almost instantaneous and efficient.

Also, it improves the reliability of braking because of the absence of a mechanical connection.

This brake deactivates automatically when the driver presses the accelerator pedal.

Some vehicle manufacturers also integrate the Assist function with this system.

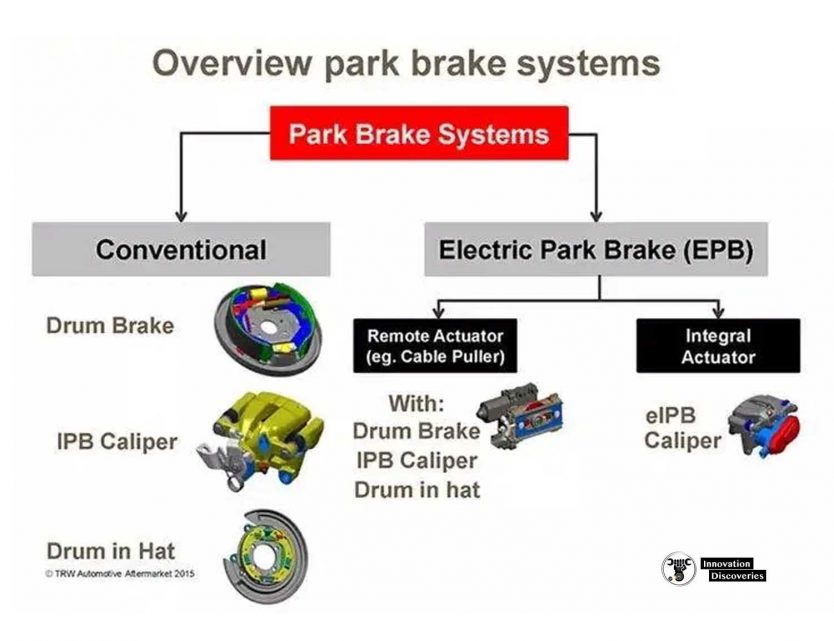

TYPES OF EPB

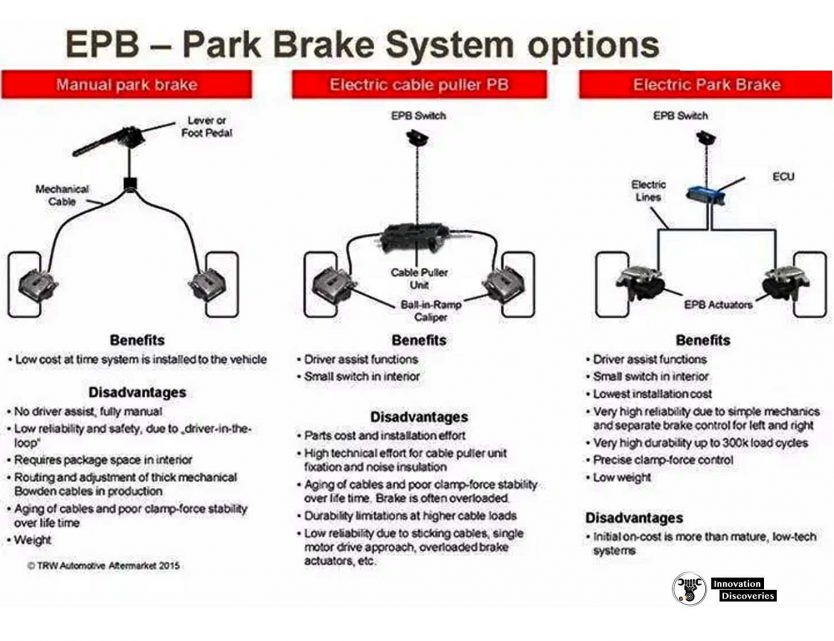

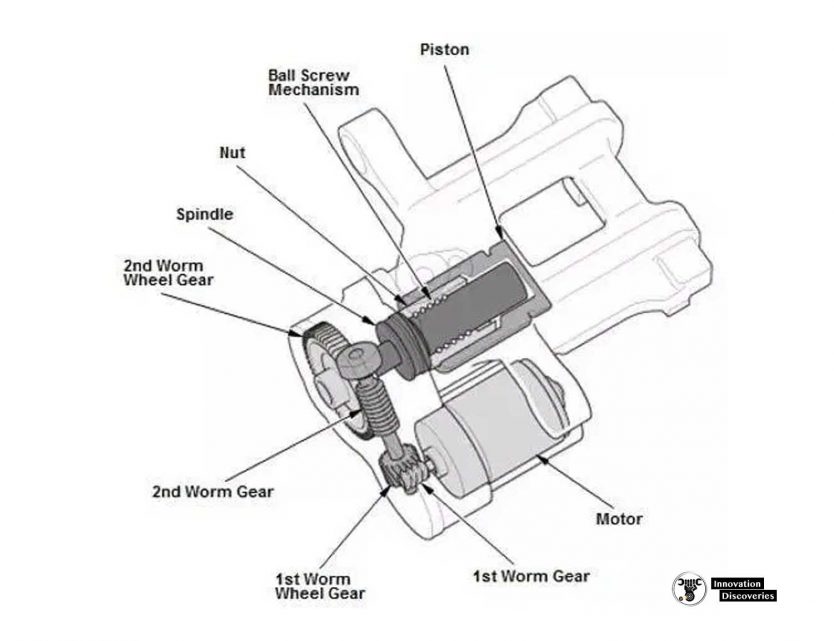

1. Cable-pull systems

The cable pull system is simply a development of the traditional lever and cable method.

As the switch is operated, a motor, or motors, pull the cable by either rolling it on a drum or using an internally threaded gear on a spiral attached to the cable.

The electronic parking brake module shown in figure 1, also known as the EPB actuator, is fitted to some Range Rover and Landrover models.

Can release the parking brake manually on most vehicles.

After removing a plastic cover or similar, pulling a wire cable loop will let off the brake.

2. Electric-hydraulic caliper systems

These types are usually employed as part of a larger control system, such as an electronic stability program (ESP).

When the driver presses the switch to activate the parking brake, the ESP unit automatically generates pressure in the braking system and pushes the brake pads against the disc.

The calipers are then locked in position by an electrically controlled solenoid valve.

The caliper remains locked without any need for hydraulic pressure.

To release the brake, the ESP briefly generates pressure again, slightly more than was needed to lock the caliper, and the valve is released.

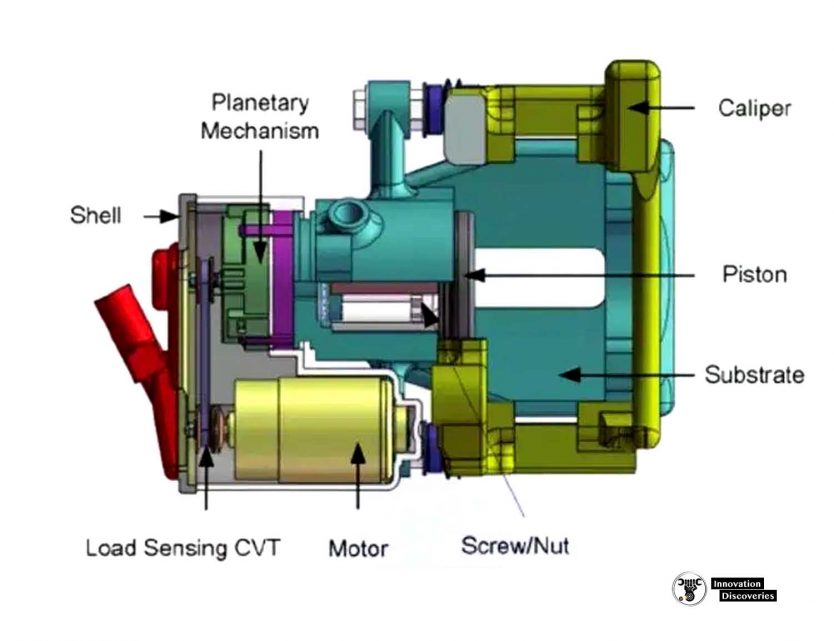

3. Full electric drive-by-wire systems

Continental developed the drive-by-wire system shown in figure 3.

It uses an electric motor (3) and gearbox to apply pressure on the pads and therefore on to the disc.

A key component is the parking brake latch.

This is like a ratchet, and it prevents the pressure in the piston from rotating the motor – and it, therefore, keeps the brakes applied.

ADVANTAGES AND DISADVANTAGE

Advantages

- Modular architecture, scalable clamp load, and durability with reduced hysteresis

- Significant weight savings compared to mechanical park brake systems to support enhanced fuel economy and reduced emissions

- Vehicle coverage from small car to light truck segments

- Electronic control allows for integration with other safety technologies

- Pioneered EPB technology in 2000 and now in the fifth generation with more than 90 million EPB calipers on world roadways

- The response time of this system is very short.

- The operation is highly reliable.

- Improves control of the vehicle while starting from standstill condition on a slope.

Disadvantages

- This system is costly.

- It needs a skilled professional for troubleshooting.

Read:

- TROUBLESHOOTING A HARD BRAKE PEDAL

- THE IMPORTANCE OF MEASURING BRAKE PAD THICKNESS

- CONVERT DRUM BRAKES TO DISC BRAKES IN 3 STEPS!

- WHAT TO DO WHEN YOUR BRAKES LOCK UP?

- JAKE BRAKE VS. EXHAUST BRAKE: WHICH IS BETTER?

Visit Forum

Visit Our Friendly Website

3 Comments