Introduction

Bulletproof tires, also known as run-flat or self-supporting tires, are designed to maintain functionality even after being punctured. These tires are crucial for military vehicles, armored cars, and other high-security applications. The manufacturing process of bulletproof tires involves several advanced materials and technologies. Here’s a detailed look at how they are made:

1. Design and Material Selection

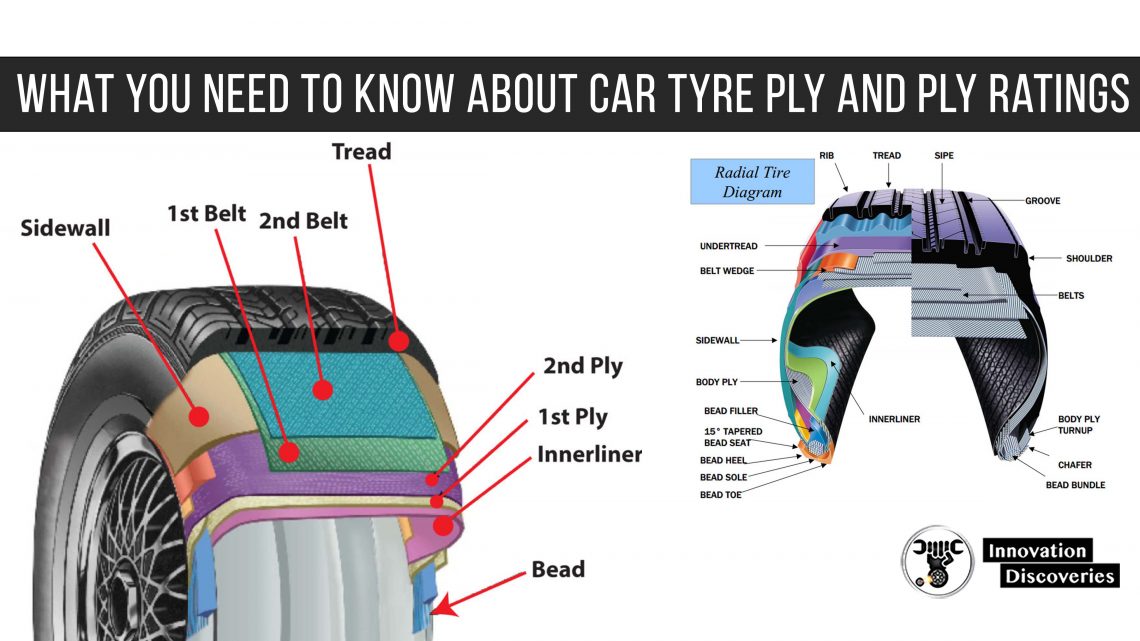

a. Tire Composition:

- Rubber: High-quality rubber compounds are essential for the tire’s durability and performance.

- Kevlar: This synthetic fiber, known for its strength and resistance to heat, is often embedded in the tire’s layers to provide additional protection against punctures.

- Steel Belts: Steel belts are incorporated to enhance the tire’s strength and stability.

- Polyester and Nylon: These materials are used in the tire’s plies to offer flexibility and support.

b. Design Considerations:

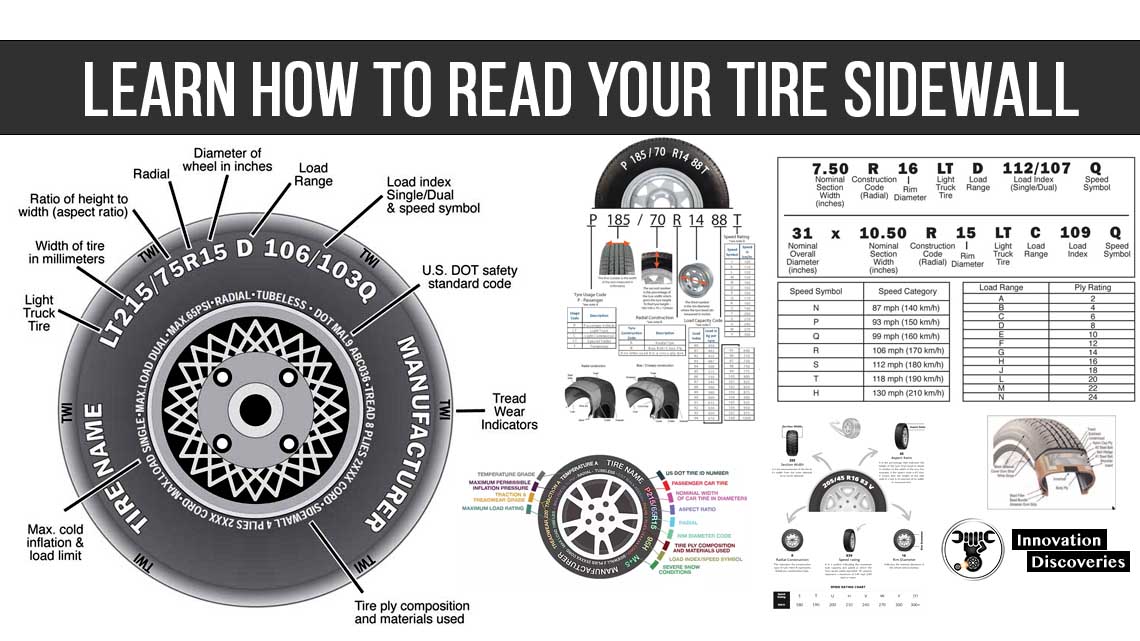

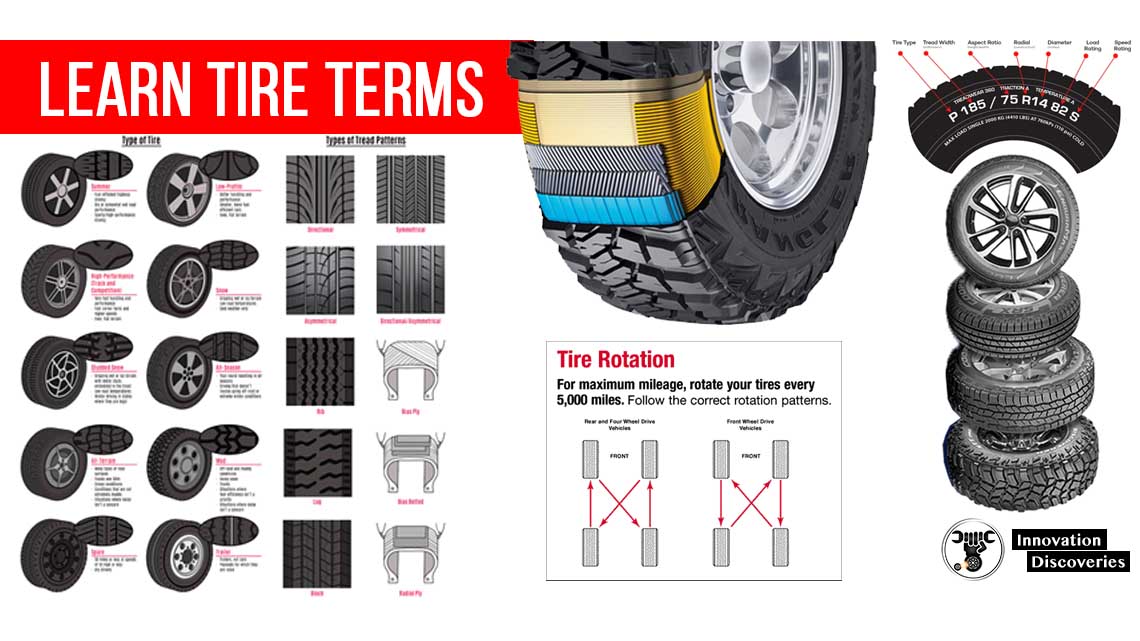

- Tread Pattern: The tread design is optimized for traction and stability, ensuring the tire can perform under various conditions.

- Sidewall Reinforcement: Extra layers of strong material are added to the sidewalls to prevent damage and maintain the tire’s shape after a puncture.

2. Manufacturing Process

**a. Mixing and Compounding:

- Rubber Mixing: The raw rubber is mixed with various additives, including sulfur, carbon black, and other chemicals, to enhance its properties.

- Compound Formation: The mixture is processed into different compounds for different parts of the tire, such as the tread and sidewalls.

**b. Tire Building:

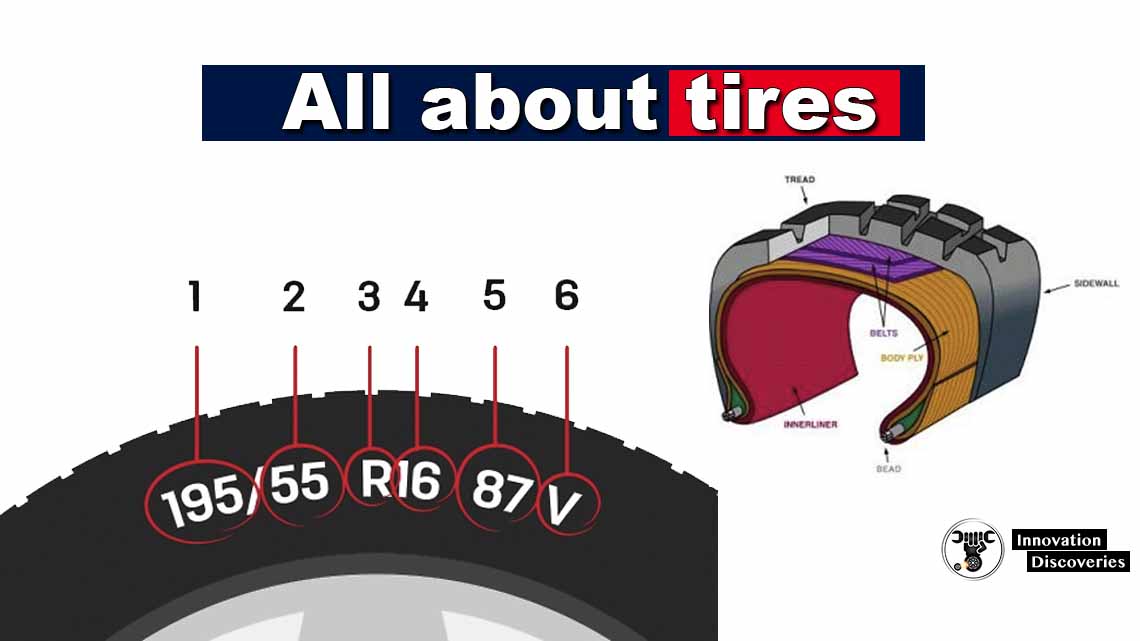

- Component Preparation: The tire components, including the inner liner, body plies, belts, bead, sidewalls, and tread, are prepared separately.

- Tire Assembly: These components are assembled on a tire-building machine. The inner liner is laid down first, followed by the body plies, belts, bead, sidewalls, and tread.

- Kevlar and Steel Belts: Kevlar fibers and steel belts are strategically placed to provide puncture resistance and structural integrity.

**c. Curing and Vulcanization:

- Curing Process: The assembled tire is placed into a mold and heated at high temperatures. This process, called vulcanization, causes the rubber to harden and become more durable.

- Mold Design: The mold contains the desired tread pattern and sidewall markings, which are imprinted onto the tire during curing.

**d. Inspection and Testing:

- Quality Control: Each tire undergoes rigorous inspection to ensure there are no defects. This includes visual inspections, X-rays, and other non-destructive testing methods.

- Performance Testing: The tires are tested for their ability to withstand punctures and maintain performance. This includes shooting the tires with various calibers of bullets and driving tests under different conditions.

3. Additional Technologies

**a. Self-Sealing Technology:

- Inner Layer: Some bulletproof tires include an inner layer of sealant that can automatically seal small punctures.

- Sealant Composition: This sealant is usually made from a special gel or polymer that can flow into punctures and harden upon exposure to air.

**b. Run-Flat Technology:

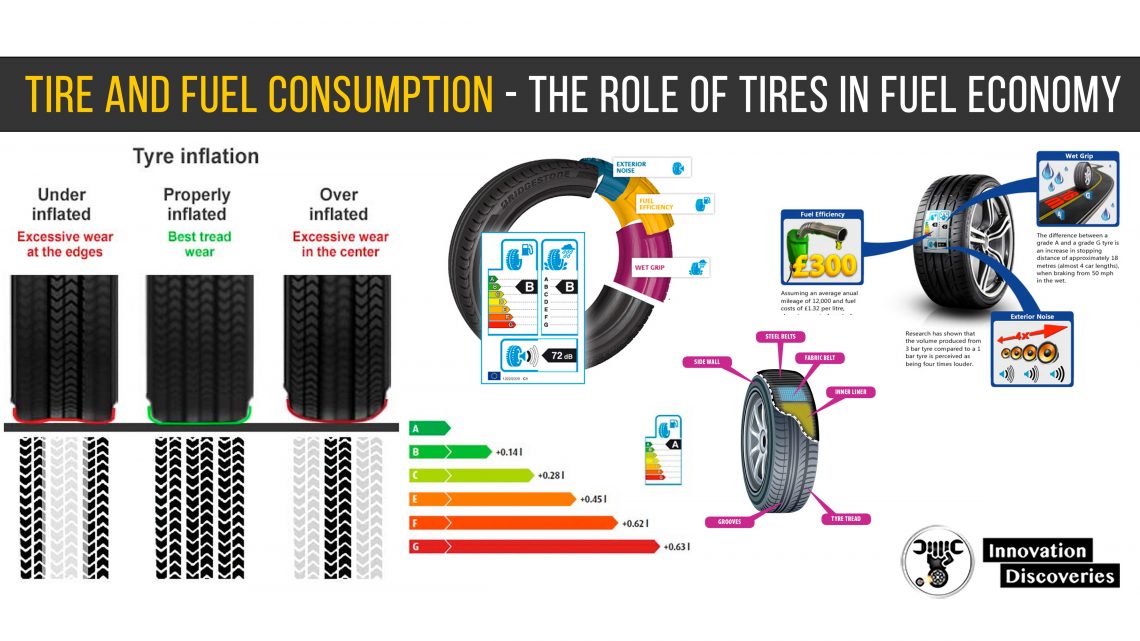

- Reinforced Sidewalls: The sidewalls are heavily reinforced to support the vehicle’s weight even when the tire has lost air pressure.

- Special Inserts: Some designs include a supportive ring or insert inside the tire that allows it to continue functioning even without air.

4. Applications and Advancements

**a. Military and Security Vehicles:

- Armored Vehicles: These tires are essential for armored vehicles used by military and security forces, providing protection and reliability in combat zones.

- VIP Protection: High-profile individuals and VIPs often use vehicles equipped with bulletproof tires for enhanced safety.

**b. Future Developments:

- Advanced Materials: Research is ongoing into using even stronger and lighter materials for bulletproof tires, such as advanced composites and nanomaterials.

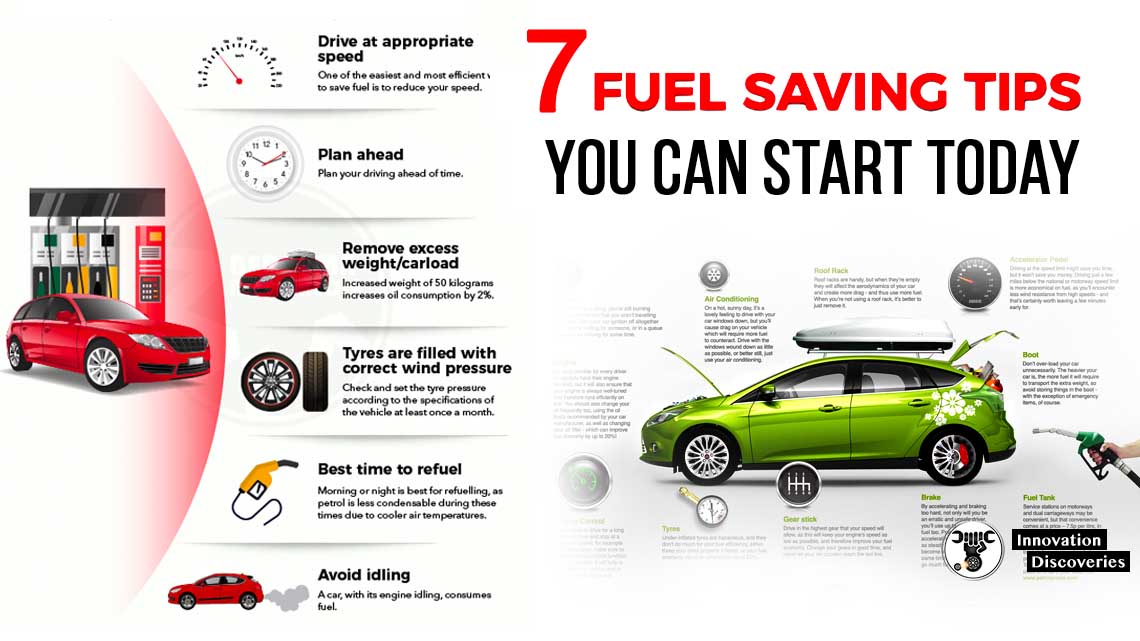

- Smart Tires: Integration of sensors and smart technology to monitor tire pressure, temperature, and damage in real-time, providing feedback to the driver and enhancing safety.

Conclusion

Bulletproof tires are a result of advanced engineering and material science. They are meticulously designed and manufactured to provide maximum protection and performance in critical situations.

From the careful selection of materials to the intricate manufacturing processes, every step ensures that these tires can withstand the harshest conditions while keeping the vehicle operational.

As technology progresses, bulletproof tires continue to evolve, offering even greater levels of safety and durability for a wide range of applications.

Discover More:

Visit Forum

Visit Our Friendly Website