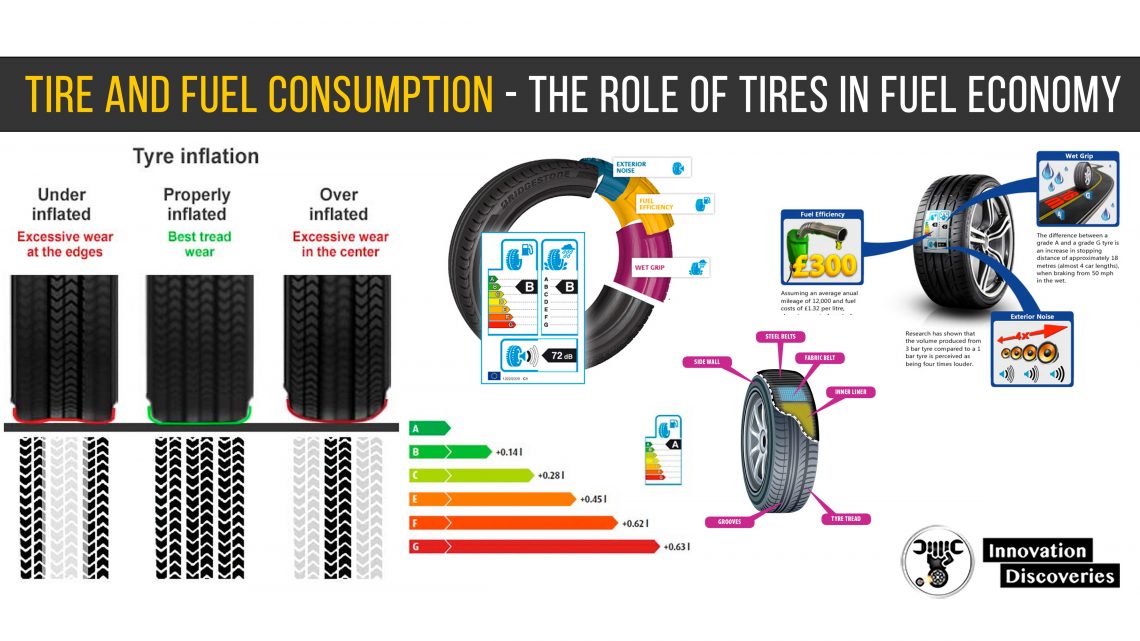

Five principal features of tires which affect fuel consumption:

- Tire structure

- Tire size

- Tire wear (technical condition)

- Tire pressure

- Conditions of tire use

Apart from rolling resistance, every car is subject to the following resisting forces while traveling:

- aerodynamic forces;

- internal friction;

- gravitational forces;

- inertial forces.

To overcome each of these forces, energy is required, and this is provided by the fuel.

A tire’s motion involves hysteresis (loss of energy in the form of accumulated heat due to compression of the tire).

Rolling resistance is an effect of this phenomenon.

A very high level of hysteresis means an excellent grip, while low hysteresis means low rolling resistance.

It is determined by the viscosity and elasticity of the materials from which the tires are made.

Hence rolling resistance affects fuel consumption. The tires also contribute to the vehicle’s aerodynamic resistance.

Overcoming resisting forces accounts for as much as 35% of fuel usage.

Depending on various factors, rolling resistance makes up between 10% and 70% of these forces.

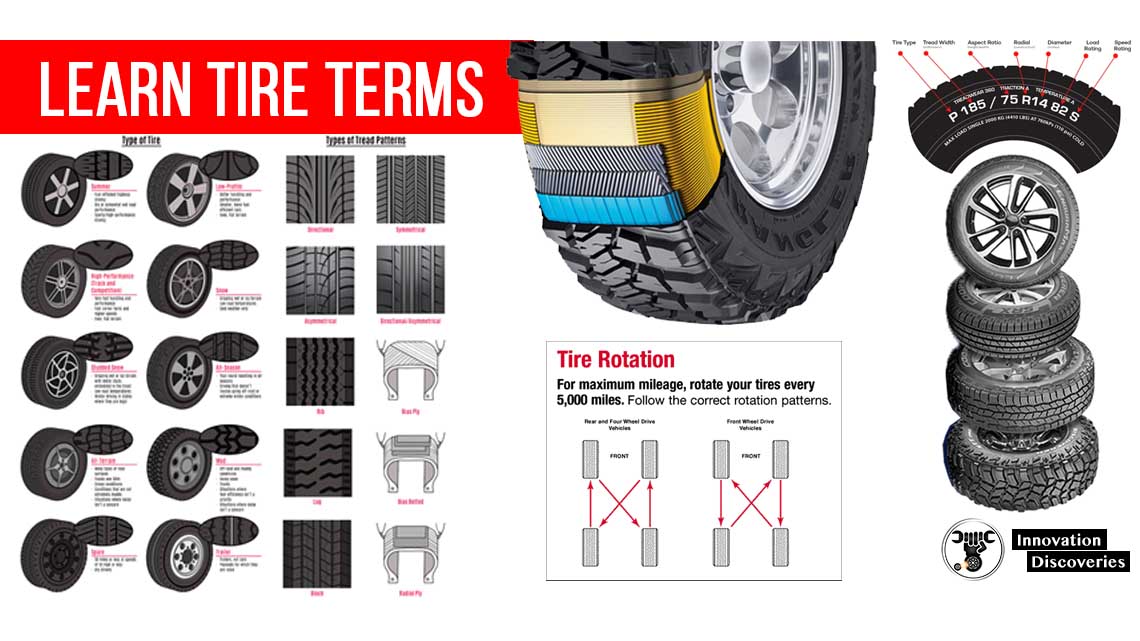

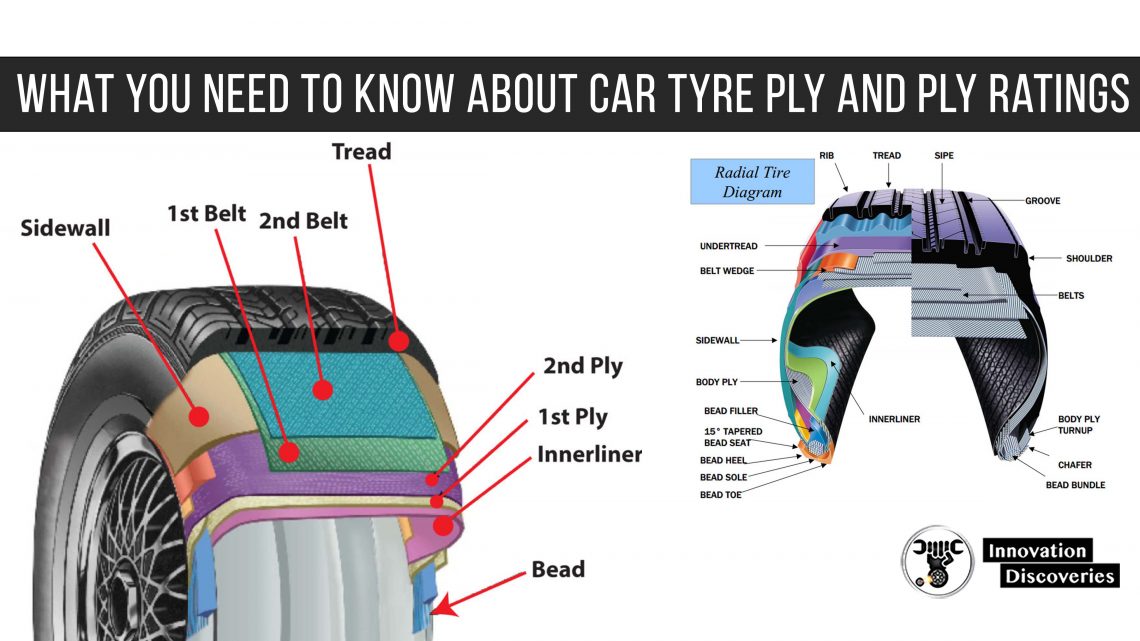

1. Tyre structure

- radial tires have at least 20% lower rolling resistance than diagonal tires;

- a smaller quantity and thickness of tire elements, and a thinner tread and sides, lead to lower rolling resistance;

- the smaller the mass of the tire, the lower the rolling resistance (a lighter tire can be produced using materials of smaller thickness, by reducing the quantity of material, and by raising the profile and reducing the width of the tire);

- tire design:

– proper selection of materials;

– mutual positioning of materials;

– quantity of materials used;

– angles of reinforcements and belts.

- the shape of the tire’s contact patch, the tread pattern, and the materials used in its manufacture (the tread structure makes a contribution of 60% to the rolling resistance);

- the positioning of blocks and other elements of the tread – optimum design of this part of the tire reduces its compression and deformation (a more rigid tire has lower rolling resistance);

- the rubber compound used to produce the tire:

– polymers (including butadiene rubbers, natural rubbers, and styrene-butadiene rubbers);

– fillers (soot and silica);

– vulcanizing agent (sulfur).

The greater the number of butadiene parts and the larger the particles of filler (best is silica with a binder in the form of silanes), the lower the rolling resistance.

- the process of production of the compound – its temperature and duration.

Not only rolling resistance is important. When making a purchase, choose a product that will offer good values for a range of performance parameters.

2. Tyre size

- the lower the tire height, the more rigid it will be, and this means lower rolling resistance;

- tire width – a tire that is narrower by 1 cm has approximately 1.5% lower aerodynamic resistance;

- rim width – changing this may also influence the tire’s rigidity, and consequently affect its deformation and rolling resistance.

3. Tire wear (technical condition)

- the more worn a tire is, the lower the rolling resistance;

- in the case of a worn tire, its mass decreases and it undergoes a lesser degree of compression during travel (increased rigidity).

4. Tire pressure

- low tire pressure causes greater compression of the tire and less squeezing of the tread blocks when in contact with the road surface;

- a reduction in pressure by 0.3 bar means a 6% rise in rolling resistance;

- a reduction in pressure by 1 bar means a 30% rise in rolling resistance, increasing fuel consumption by several percent.

5. Conditions of tire use

- A higher ambient temperature causes a reduction in rolling resistance – the reason for this is the increase in pressure and the attainment of the tire’s optimum working temperature (especially in summer).

The impact that tires have on fuel consumption is a fact and results from the influence of many factors.

Importance attaches to the tire’s design and method of production, the size of the tire, and the conditions of use.

We must remember, however, that it is not only the tires that affect a vehicle’s fuel consumption.

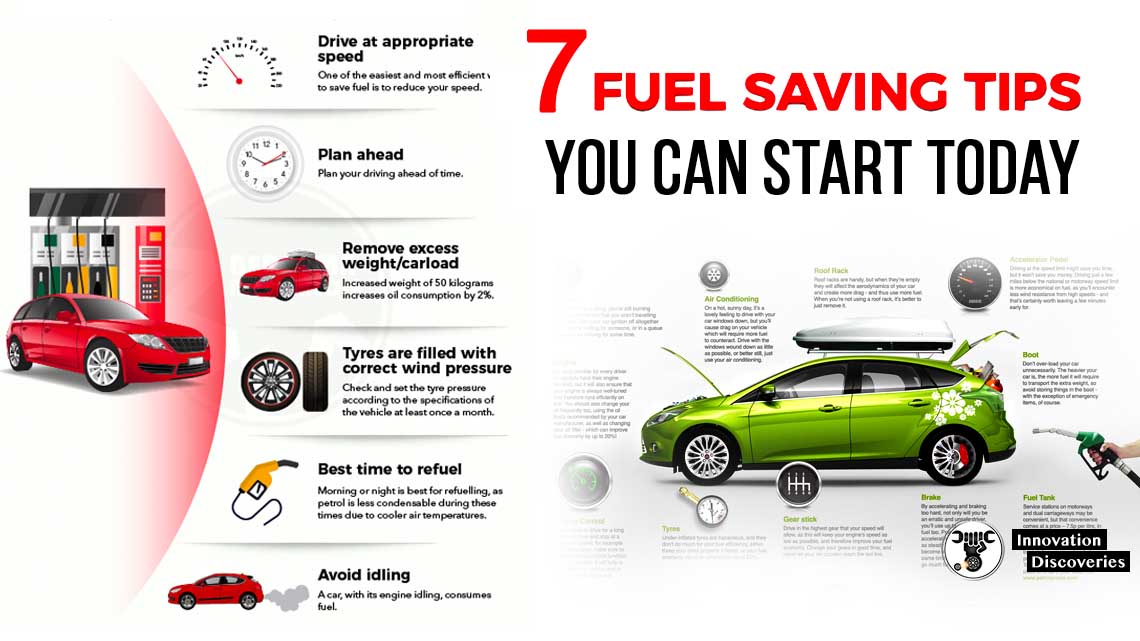

Naturally, it is worth buying tires with low rolling resistance, but it is also necessary to drive economically.

Eco-driving experts recommend not warming up the engine while stationary, accelerating rapidly and dynamically (changing to a higher gear as soon as possible), and using the engine to brake.

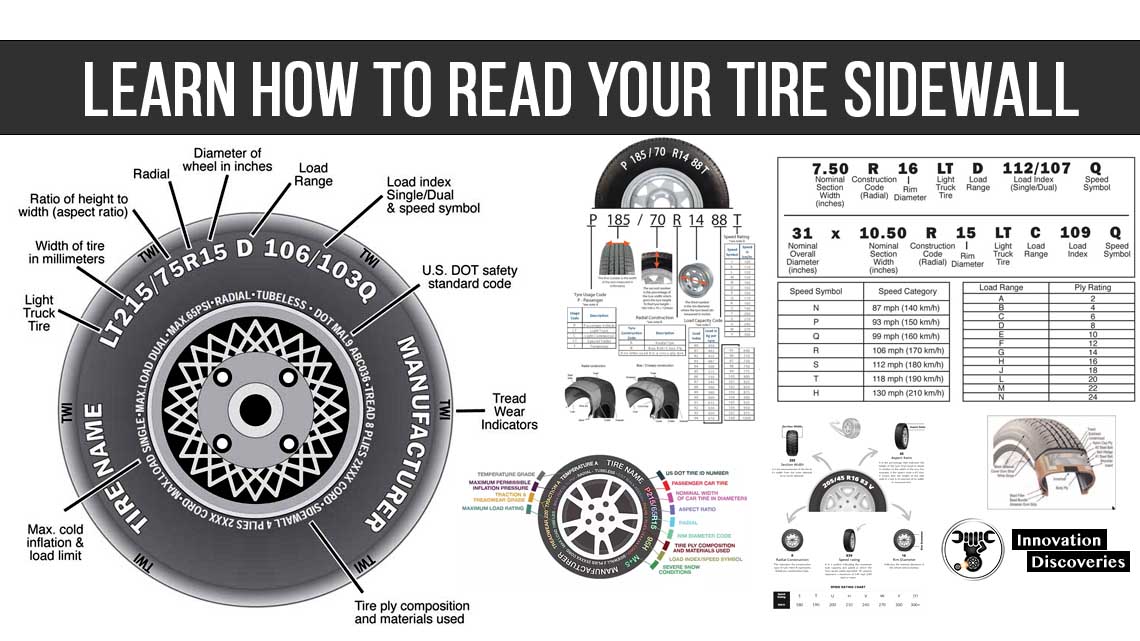

READ: Learn How to Read Your Tire Sidewall

Visit Forum

Visit Our Friendly Website