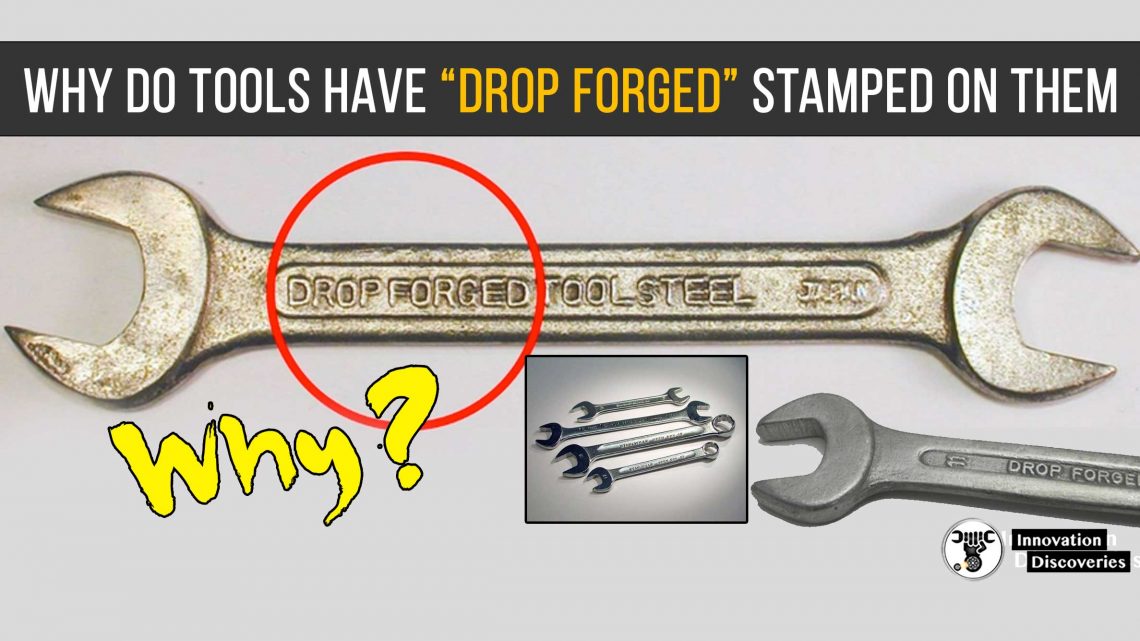

When it comes to manufacturing high-quality tools that are both durable and reliable, drop forging stands out as a superior technique. Drop forging involves shaping metal through a process of controlled deformation using hammers or presses.

This article will delve into the intricacies of drop forging and shed light on the two main techniques used: open die drop forging and closed die drop forging. Additionally, we will discuss the compelling reasons why you should consider purchasing drop forged tools for your various needs.

Drop forging, on the other hand, is the specific technique employed within the drop forged manufacturing process.

What Is Drop Forged?

Drop forging is a metalworking process that involves the shaping of heated metal through the application of force. It is a highly efficient and precise technique that results in tools with exceptional strength and durability. The process begins with heating the metal to make it malleable and then deforming it using a hammer or press to achieve the desired shape.

Drop Forged Techniques

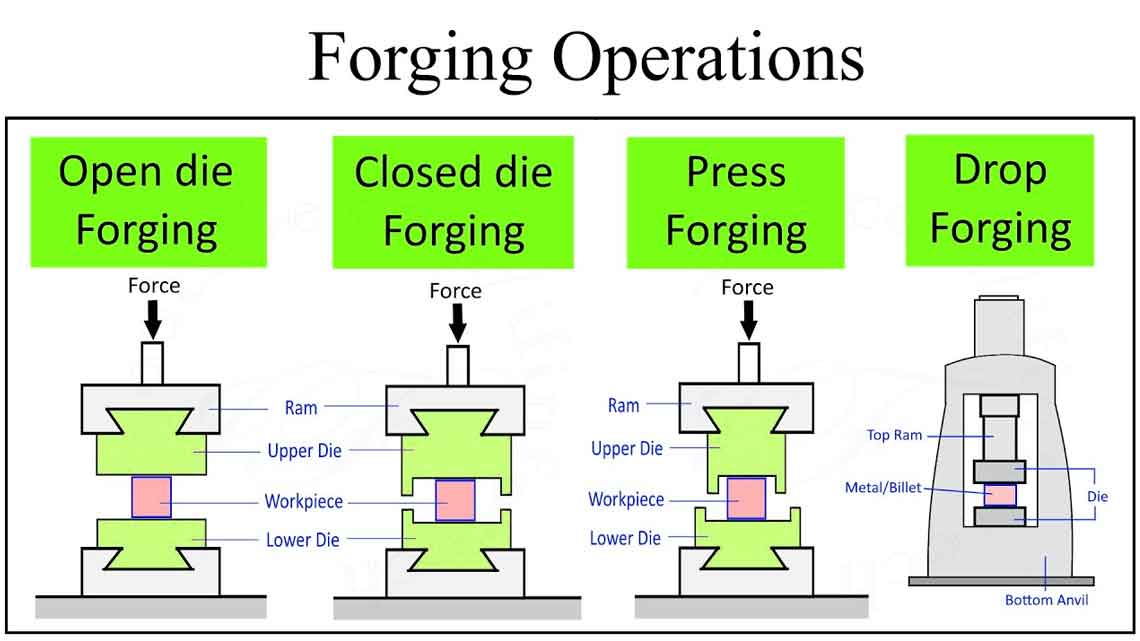

Open Die Drop Forging:

In open die drop forging, the metal is placed between two flat or slightly curved dies. The dies do not fully enclose the metal, allowing it to flow and take the shape of the desired tool. As the hammer strikes the metal, it is gradually deformed and shaped. Open die drop forging is typically used for larger and more complex tools or components, such as crankshafts, connecting rods, and large wrenches.

Closed Die Drop Forging:

Closed die drop forging, also known as impression die forging, involves the use of specially designed dies that fully enclose the metal. These dies have the desired shape and cavities, allowing the metal to be shaped precisely into the required tool. As the metal is struck, it fills the cavities of the dies, resulting in a highly accurate and detailed tool. Closed die drop forging is commonly used for smaller tools with intricate designs, including sockets, wrenches, and hammers.

Why You Should Buy Drop Forged Tools:

a) Exceptional Strength and Durability:

Drop forged tools are renowned for their superior strength and durability. The controlled deformation process aligns the grain structure of the metal, resulting in a tool with increased tensile strength and resistance to wear and fatigue. This makes drop forged tools ideal for heavy-duty applications that demand reliability and longevity.

b) Enhanced Performance:

The structural integrity of drop forged tools ensures consistent performance under demanding conditions. The tightly aligned grain structure provides optimal force transmission, reducing the risk of breakage or deformation during use. With drop forged tools, you can expect enhanced precision, stability, and efficiency in your work.

c) Cost-Effectiveness:

Despite their exceptional quality, drop forged tools offer a cost-effective solution in the long run. Their extended lifespan and reduced need for frequent replacements make them a wise investment. Moreover, their reliability and performance contribute to increased productivity, ultimately saving both time and money.

d) Versatility:

Drop forging allows for the production of a wide range of tools, from small intricate components to large-scale industrial equipment. This versatility ensures that you can find drop forged tools to suit your specific needs across various industries and applications.

Conclusion:

Drop forging is a time-tested manufacturing technique that produces tools of exceptional strength, durability, and performance. The open die and closed die drop forging techniques enable the creation of a wide range of tools to suit diverse applications.

By choosing drop forged tools, you are investing in superior quality, cost-effectiveness, and versatility. Whether you require tools for industrial or personal use, drop forged tools will undoubtedly exceed your expectations, ensuring reliability and longevity in your work.

DISCOVER MORE:

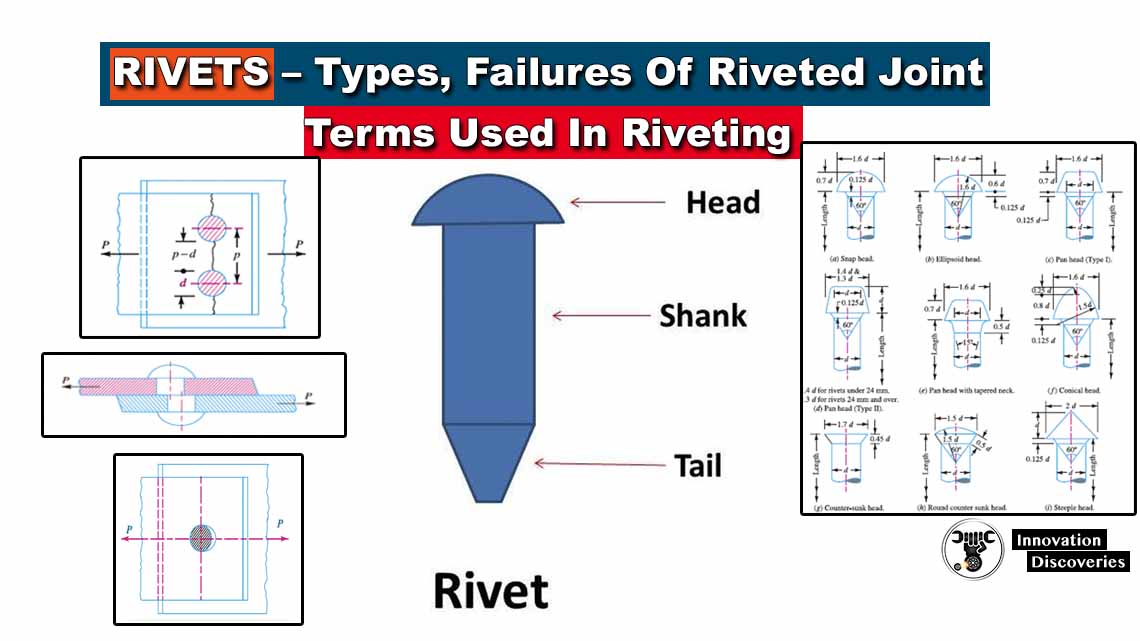

Rivets – Types, Failures Of Riveted Joint, Terms Used In Riveting

Visit Forum

Visit Our Friendly Website