The starting system in vehicles is a crucial component responsible for initiating the engine’s operation. Understanding how it works can help you troubleshoot problems, perform maintenance, and appreciate the engineering that goes into making a vehicle start reliably.

This article will explore the various components of the starting system and explain how they work together to start your vehicle.

Key Components of the Starting System

Before delving into how the system works, let’s identify the main components:

- Battery: The power source that supplies electrical energy to the starter motor and other vehicle systems.

- Ignition Switch: The driver-operated switch that activates the starting process.

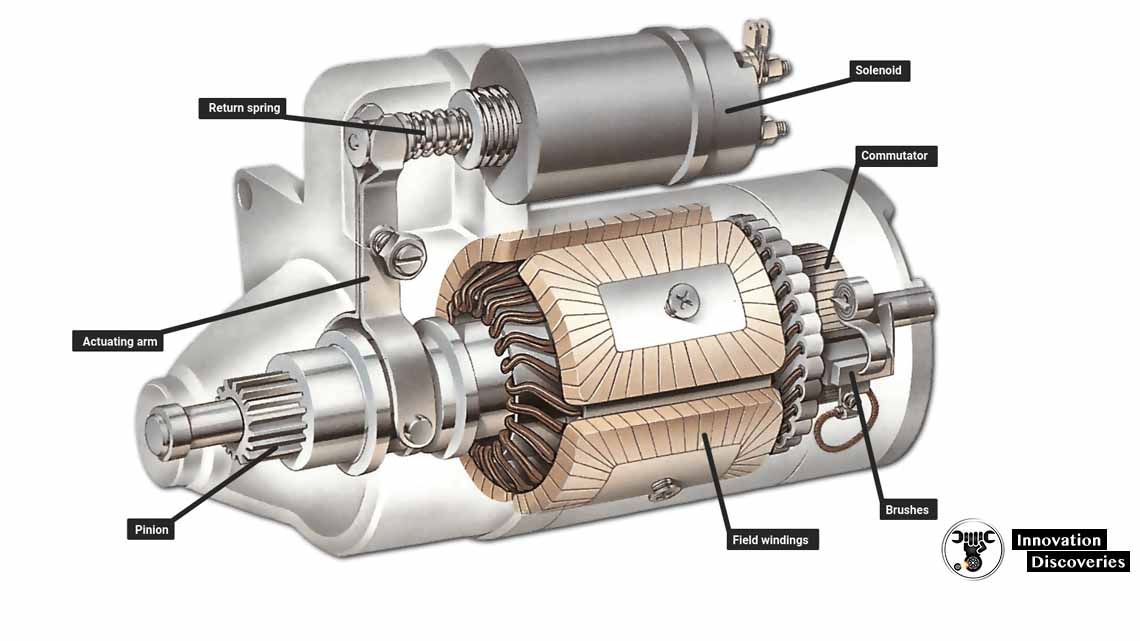

- Starter Motor: The electric motor responsible for turning the engine’s crankshaft to initiate the combustion process.

- Solenoid/Starter Relay: The component that connects the battery to the starter motor when the ignition switch is engaged.

- Flywheel/Flexplate: A large gear attached to the engine’s crankshaft that engages with the starter motor’s gear to turn the engine.

- Neutral Safety Switch: A safety feature that prevents the starter motor from engaging unless the vehicle is in “Park” or “Neutral.”

- Wiring and Connectors: The electrical pathways that connect all these components.

pre-engaged starter

How the Starting System Works

Step 1: Turning the Ignition Switch

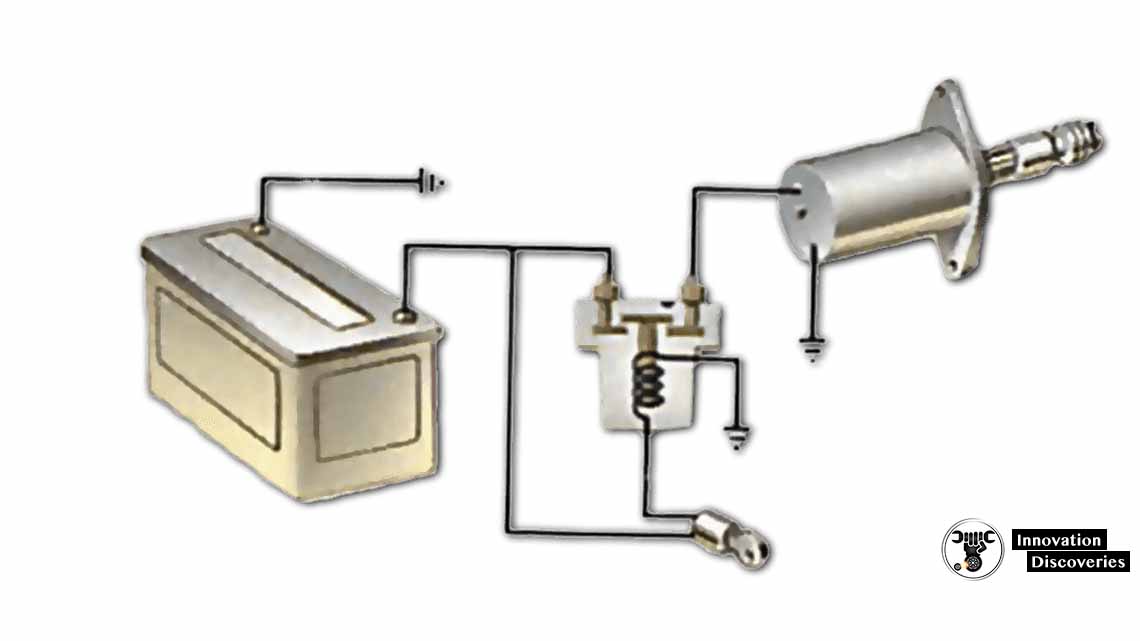

When you turn the key in the ignition switch (or press the start button in modern vehicles), you are completing an electrical circuit. This action sends a signal to the solenoid/starter relay, indicating that the starting process should begin.

Step 2: Activating the Solenoid/Starter Relay

The solenoid, often attached to the starter motor, serves as a high-current switch. When it receives the signal from the ignition switch, it closes the circuit between the battery and the starter motor. This allows a large amount of electrical current to flow from the battery to the starter motor.

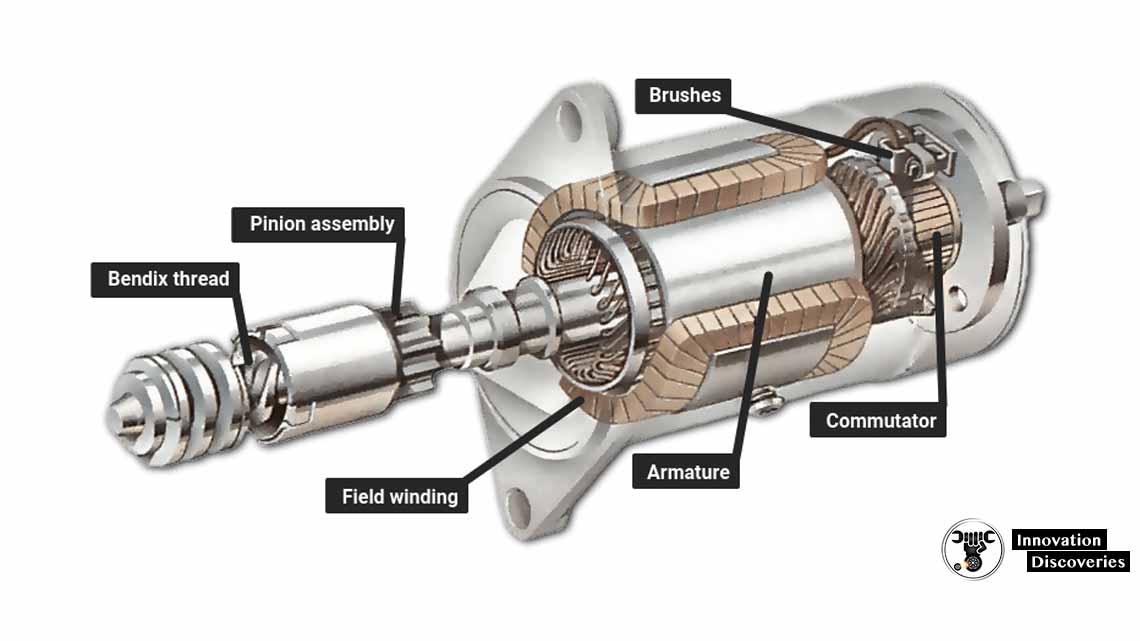

Step 3: Engaging the Starter Motor

The current flowing through the starter motor causes it to spin rapidly. The motor has a small gear, called the pinion, which is designed to engage with the teeth of the flywheel or flexplate. When the solenoid is activated, it pushes the pinion into engagement with the flywheel, allowing the spinning starter motor to turn the engine’s crankshaft.

Step 4: Turning the Engine

As the starter motor spins the flywheel, the engine’s crankshaft begins to turn. This motion initiates the process of drawing air and fuel into the engine’s cylinders and compressing it, leading to combustion. Once the engine starts running, it generates its own power to keep the process going.

Step 5: Disengaging the Starter Motor

When you release the ignition switch (or the start button), the signal to the solenoid is cut off, causing the solenoid to disengage the starter motor from the flywheel. The starter motor stops spinning, and the engine continues running on its own power. At this point, the starting process is complete.

The starter circuit

Inertia system

Safety and Efficiency Considerations

The starting system has several safety and efficiency features:

- Neutral Safety Switch: This switch ensures that the vehicle can’t start unless it’s in “Park” or “Neutral.” This prevents accidental vehicle movement during the starting process.

- Starter Motor Protection: Some systems have mechanisms to prevent the starter motor from overheating or staying engaged too long, which could damage the motor or the flywheel.

- Battery Management: The system relies on a healthy battery with adequate charge. If the battery is weak or depleted, the starting process may fail.

Common Problems and Troubleshooting

Here are some common issues you might encounter with the starting system:

- No Start: If the engine doesn’t start, it could be due to a dead battery, a faulty starter motor, a broken solenoid, or a problem with the ignition switch.

- Clicking Sound: A clicking noise when turning the key often indicates a weak battery or a faulty solenoid.

- Grinding Noise: This can happen if the starter motor’s pinion gear is worn or if it doesn’t engage correctly with the flywheel.

- Starter Motor Stays Engaged: If the starter motor continues to run after the engine starts, it could be a solenoid issue or a stuck ignition switch.

To address these issues, you may need to test the battery, check the connections, inspect the starter motor, or replace faulty components.

Conclusion

The starting system is a complex yet vital part of your vehicle’s operation. By understanding how it works, you can better appreciate the role of each component and be more prepared to address common issues when they arise.

Proper maintenance and prompt attention to problems will help ensure that your vehicle starts reliably every time you turn the key.

7 Comments